| Outside Diameter | 1/4"-30",13.7mm-762mm |

| Schedule | SCH5,SCH10,SCH20,SCH60,SCH80,SCH100,SCH120,SCH140,SCH160,XXS,STD |

| Specification | 1.Outer Diameter:13.7mm---762mm 2.Wall Thickness:2mm--80mm 3.Length:Max 12m 4.We can also produce according to customersrequirement |

| Material | 10#,20#,45#,16Mn, A106 GrA,BA53 Gr B, ASTM A179,A335 P11,A335 P22,A335 P5 12CrMo 15CrMo 20CrMo 42CrMo 12Cr1Mov 10CrMo |

| Standards | 1.ASTM:ASTM A106 GR.A;ASTM A106 GR.B;ASTM A53 GR.A;ASTM A53 GR.B; ASTM A333;ASTM A335;ASTMA192;ASTM A210,ASTM A179; 2.JIS:G3452;G3457;G3454;G3456;G3461;G3454;G3455; 3.DIN:ST33:ST38ST35;ST42;ST45:ST52.4;ST52; 4.API: API 5L,API 5CT,API LINE PIPE and so on 5. We can also produce according to customer requirement |

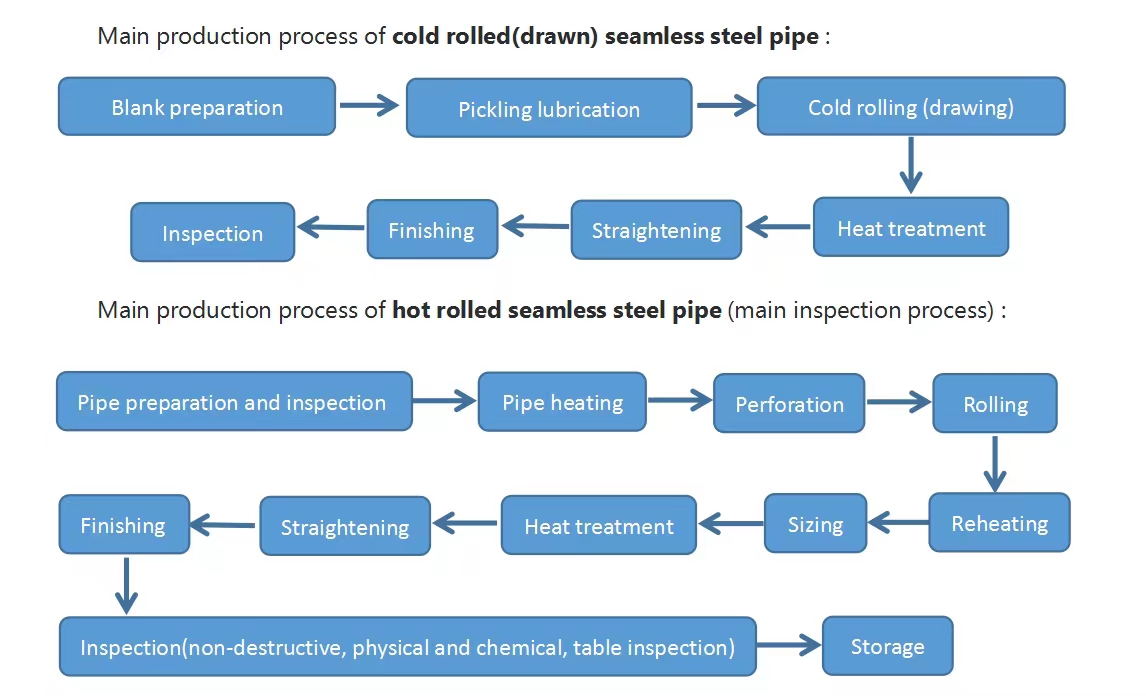

| Process Method | 1.Cold Drawn 2.Cold rolled 3. Hot rolled |

| Face finished | 1. Black paint ,Varnish 2. Corrossion coating: 3LPE,FBE,3PEE 3. Galvanized |

Pipe ordered under this specification shall be suitable for bending, flanging, and similar forming operations, and for welding. When the steel is to be welded, it is presupposed that a welding procedure suitable to the grade of steel and intended use or service will be utilized.

API 5L GR.B Heavy Wall Thickness Seamless Steel Pipe are made either by cold-drawn or hot rolled, as required by the customers.

Grade and Chemical Composition (%) For API 5L PSL2

|

Standard |

Grade |

Chemical composition(%) |

|||

|

C |

Mn |

P |

S |

||

| API 5L |

B |

≤0.24 |

≤1.20 |

≤0.025 |

≤0.015 |

Grade and Chemical Composition (%) For API 5L X42 PSL2

|

Standard |

Grade |

Chemical composition(%) |

|||

|

C |

Mn |

P |

S |

||

|

API 5L |

X42 |

≤0.22 |

≤1.30 |

≤0.025 |

≤0.015 |

Mechanical Properties of API 5L GR.B Heavy Wall Thickness Seamless Steel Pipe (PSL1):

|

Yield Strength(MPa) |

Tensile Strength(MPa) |

Elongation A% |

||

|

psi |

MPa |

psi |

MPa |

Elongation (Min ) |

|

35,000 |

241 |

60,000 |

414 |

21~27 |

Mechanical Properties of API 5L GR.B Heavy Wall Thickness Seamless Steel Pipe (PSL2):

|

Yield Strength(MPa) |

Tensile Strength(MPa) |

Elongation A% |

Impact (J) |

||

|

psi |

MPa |

psi |

MPa |

Elongation (Min ) |

Min |

|

241 |

448 |

414 |

758 |

21~27 |

41(27) |

Bare pipe, black coating ( customized);

6" and below sizes In bundles with two cotton slings, other sizes in loose;

Both ends with end protectors;

Plain end, bevel end;

Marking.

Pipe End Beveling

Plastic Caps

Black Painting with Marking

Wrapper

Bundling and Sling

Package Appearance

|

Size |

Tolerance (with respect to specified outside diameter) |

|

<2 3/8 |

+ 0.016 in., - 0.031 in. (+ 0.41 mm, - 0.79 mm) |

|

> 2 3/8 and ≤4 1/2, continuous welded |

±1.00% |

|

> 2 3/8 and < 20 |

±0.75% |

|

> 20. seamless |

± 1.00% |

|

>20 and <36, welded |

+ 0.75%.-0.25% |

|

> 36、welded |

+ 1/4 in.. - 1/8 in. (+ 6.35 mm, -3.20 mm) |

ln the case of pipe hydro-statically tested to pressures in excess of standard test pressures, other tolerances may be agreed upon between the manufacturer and the purchaser.

|

Size |

Minus Tolerance |

Plus Tolerance |

End-to-End Tolerance |

Out-of-Roundness |

|

|

Diameter,Axis Tolerance (Percent of Specified OD) |

Maximum Differential Between Minimum and Maximum Diameters (Applies Only to Pipe With D/t≤

75) |

||||

|

≤10 3/4 l&V4 |

1/64(0.40mm) |

1/16(1.59mm) mm) |

— |

— |

|

|

>10 3/4 and ≤20 |

1/32 (0.79 mm) |

3/32 (2.38 mm) |

— |

— |

— |

|

> 20 and≤ 42 |

1/32 (0.79 mm) |

3/32(2.38 mm) |

b |

± 1% |

<0.500 in. (12,7 mm) |

|

>42 |

1/32 (0.79 mm) |

3/32 (2.38 mm) |

b |

± 1% |

£ Q625 in. (15.9 mm) |

Out-of-roundness tolerances apply to maximum and minimum diameters as measured with a bar gauge, caliper, or device measuring actual maximum and minimum diameters.

The average diameter (as measured with a diameter tape) of one end of pipe shall not differ by more than 3/32 in. (2.38 mm) from that of the other end.

Out Diameter Inspection

Wall Thickness Inspection

End Inspection

Straightness Inspection

UT Inspection

Appearance Inspection

| Size |

Type of Pipe |

Tblerancr1 (Percent of Specified Wall Thickness} |

|

|

Grade B or Lower |

Grade X42 or Higher |

||

|

<2 7/8 |

All |

+20.- 12.5 |

+ 15.0.-12.5 |

|

>2 7/8and<20 |

All |

+ 15,0,-12.5 |

+ 15-I2.5 |

|

>20 |

Welded |

+ 17.5.-12.5 |

+ 19.5.-8.0 |

|

>20 |

Seamless |

+ 15.0.-12.5 |

+ 17.5.-10,0 |

|

Quantity |

Tolerance (percent) |

| Single lengths, special plain-end pipe or A25 pipeSingle lengths, other pipeCarloads.GradeA25,40,000lb(18 144kg)or moreCarloads, other than Grade A25,40.0001b (18 144 kg) or moreCarloads, all grades less than 40000 lb (18 144 kg)Order items. Grade A25. 40.000 lb (18 144 kg) or moreOrder items, other than Grade A25,40,000 lb (18 144 kg) or more

Order items, all grades, less than 40.000 lb (18 144 kg) |

+ 10.-5.0 + 10,- 35 -2.5 -1.75 -15 -3.5 -1.75 -3.5 |

Notes:

1. Weight tolerances apply to the calculated weights for threaded-and-coupled pipe and to the tabulated or calculated weights for plain-end pipe. Where negative wall thickness tolerances smaller than those listed in above table are specified by the purchaser, the plus weight tolerance for single lengths shall be increased to 22.5 percent less the wail thickness negative tolerance.

2. For carloads composed of pipe from more than one order item, the carload tolerances are to be applied on an individual order item basis.

3. The tolerance for order items apply to the overall quantity of pipe shipped for the order item.