SSAW (also known as SAWH) steel pipe refers to spiral welded seam submerged arc welded steel pipe.

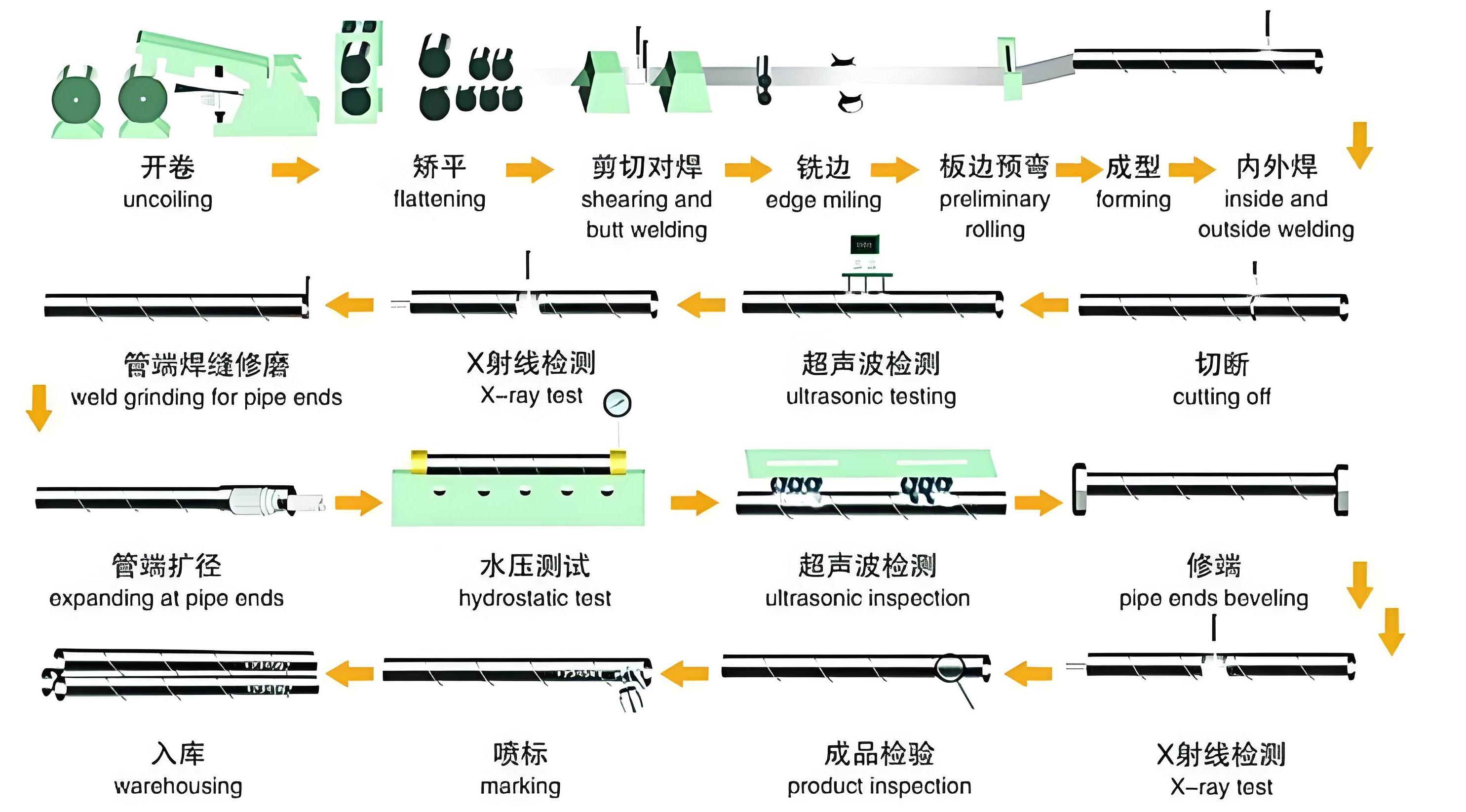

The production process for this type of steel pipe involves continuously crimping steel plates into a spiral shape and welding the edges of the plates together by internal and external submerged arc welding to form a spiral weld seam for the pipe.

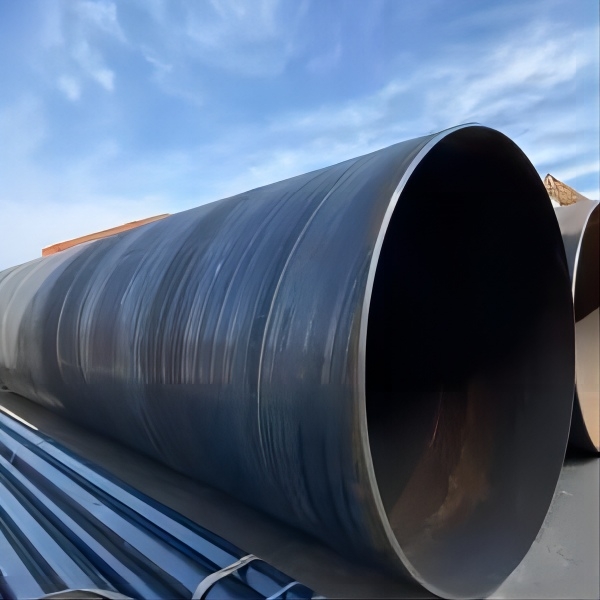

This type of steel pipe is characterized by having a spiral weld seam, and its high production efficiency makes it suitable for manufacturing large-diameter steel pipes.

Botop Steel is a welded steel pipe manufacturer and supplier from China, offering a wide range of standards and sizes of steel pipe that can be customized to meet your project requirements.

The SSAW steel pipe products that we can supply include spiral steel pipe of API 5L, ASTM A252, EN 10217, GB/T 9711, and many other standards. In addition, we offer a number of services including steel pipe processing, flanging, pipe fittings, coating, shot peening, and more.

The unique advantage of SSAW tubes is the ability to produce large-diameter tubes up to 3,500 mm, which is not possible with other types of tubes.

In addition to this, SSAW tubes have the advantages of fast production speeds, the ability to produce tubes in longer individual lengths, and a wide range of applications.

The production of SSAW steel pipe is a highly automated process, which not only greatly improves the efficiency of steel pipe production, but also ensures the high quality standard of the product.

SSAW is sometimes referred to as DSAW because the welding process is done using double-sided submerged arc welding technology.

| Standard | Common Grade |

| API 5L / ISO3183 / GB/T 9711 | Grade B, X42, X46, X52, X56, X60, X65, X70, X80, PSL1 and PSL2 |

| ASTM A252 | Grade 1, Grade 2, and Grade 3 |

| EN 10219 / BS EN 10219 | S235JRH, S275J0H, S275J2H, S355J0H, S355J2H 1.0039, 1.0149, 1.0138, 1.0547, 1.0576, 1.0512 |

| EN 10217 / BS EN 10217 | P195TR1, P195TR2, P235TR1, P235TR2, P265TR1, P265TR2 1.0107, 1.0108, 1.0254, 1.0255, 1.0258, 1.0259 |

| JIS G 3457 | STPY 400 |

| CSA Z245.1 | Grade 241, Grade 290, Grade 359, Grade 386, Grade 414 |

| GOST 20295 | K34, K38, K42, K50, K52, K55 |

| AS 1579 | — |

| GB/T 3091 | Q195, Q215A, Q215B, Q235A, Q235B, Q275A, Q275B, Q345A, Q345B |