| SPECIFICATIONS FOR LSAW STEEL PIPE | |

| 1.Size | 1)OD:355.6mm-1828.8mm |

| 2)Wall Thickness: 8mm-60mm | |

| 3)SCH20,SCH40,STD ,XS,SCH80 | |

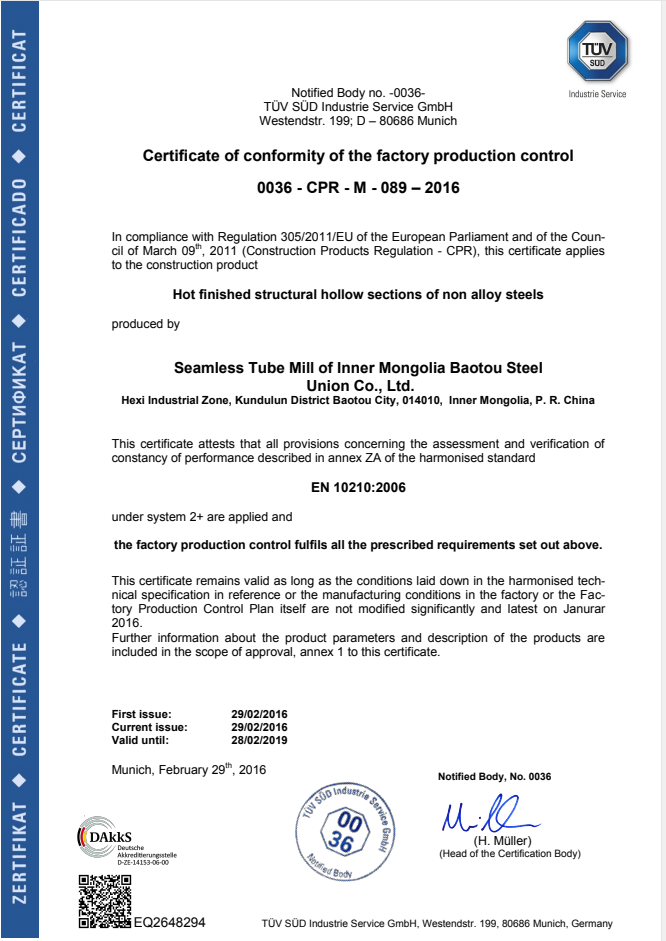

| 2.Standard: | ASTM A53,API 5L,EN10219,EN10210,ASTM A252 ,AS1163 etc |

| 3.Material | ASTM A53 Gr.B,API 5L Gr.B,X42,X52,X60,X70,X80,S235JR,S355J0H ,etc |

| 4.Usage: | 1)low pressure liquid, water, gas, oil, line pipe |

| 2)structure pipe, pipe piling construction | |

| 3)fence, door pipe | |

| 5.Coating | 1) Bared 2) Black Painted (varnish coating) 3) Galvanized 4) Oiled 5) PE,3PE, FBE, comosion resistant coating, Anti corrosion coating |

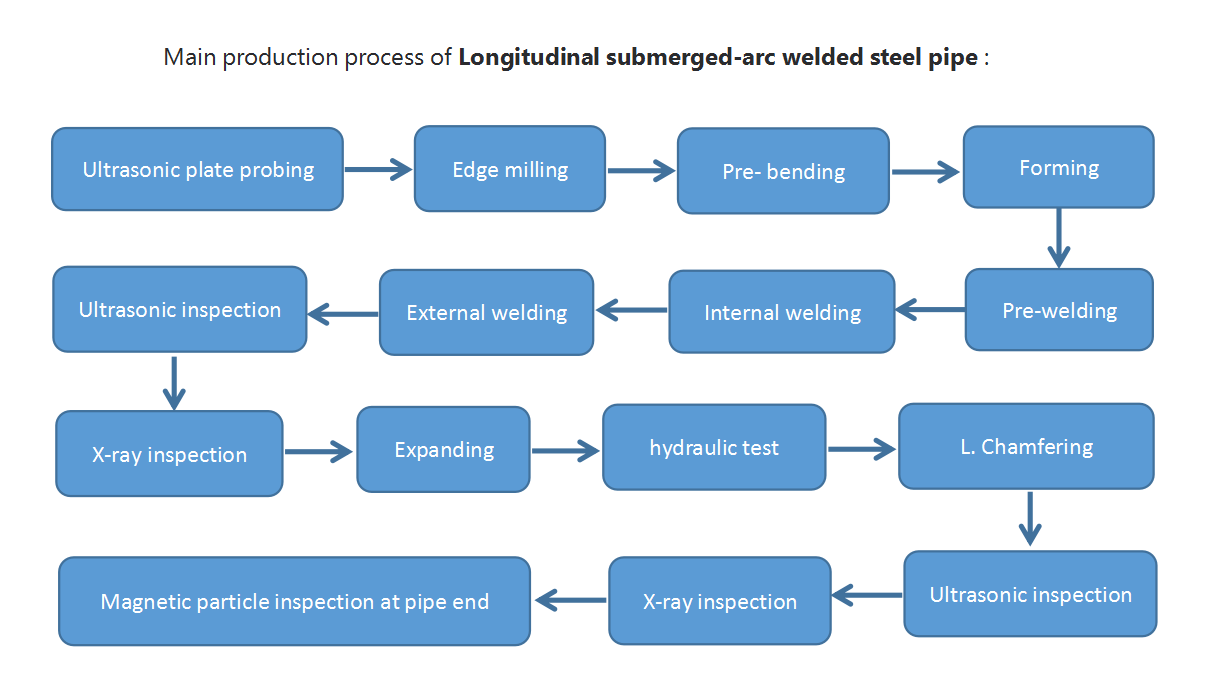

| 6.Technique | longitudinal welded steel pipe |

| 7. Inspection: | With Hyd raulic Testing, Eddy Current, RT, UT or inspection by 3rd party |

| 8.Delivery | Container, Bulk Vessel. |

| 9.About Our Quality: | 1) No damage, no bent 2) no burrs or sharp edges and no scraps 3) Free for oiled&marking 4) All goods can be checked by third party inspection before shipment |

Pipe ordered under this specification is used for structural.

The steel shall contain no more than 0.050 % phosphorous.

Tensile Requirements

|

Tensile Requirements |

|||

|

Grade 1 |

Grade 2 |

Grade 3 |

|

| Tensile strength, min, psi (MPa) |

50 000 (345) |

60 000 (415) |

66 000 (455) |

| Yield point or yield strength, min, psi(MPa) |

30 000 (205) |

35 000 (240) |

45 000 (310) |

| Basic minimum elongation for nominal wall thicknesses %6 in. (7.9 mm) or more:Elongation in 8 in. (203.2 mm), min, % Elongation in 2 in. (50.8 mm), min, % |

18 30 |

14 25 |

... 20 |

| For nominal wall thicknesses less than %6 in. (7.9 mm), the deduction from the basic minimum elongation in 2 in. (50.08 mm) for each Vzi - in. (0.8 mm) decrease in nominal wall thickness below %6 in. (7.9 mm), in percentage points |

1.5A |

1.25A |

1.0A... |

Bending Test— a sufficient length of pipe shall stand being bent cold through 90° around a cylindrical mandrel.

Flattening test-although testing is not required ,pipe shall be capable of meeting the flattening test requirements.

Hydro-static test—except as allowed ,each length of pipe shall be subjected to the hydro-static test without leakage through the pipe wall.

Nondestructive electric test-as an alternative to the hydro-static test ,the full body of each pipe shall be tested with a nondestructive electric test . where nondestructive electric test is performed,the lengths shall be marked with the letters”NDE”

The ultrasonic testing

The eddy current examination

UT Testing

RT Testing

Hydrostatic Testing