BS EN 10210 steel tubes are hot-finished hollow sections of unalloyed and fine-grain steels for a wide range of architectural and mechanical structural applications. Contains round, square, rectangular, and oval sections.

EN 10210 and BS EN 10210 are identical standards but with different organizations.

Navigation Buttons

BS EN 10210 Classification

BS EN 10210 Size Range

Raw Materials

BS EN 10210 Steel Name

Delivery Conditions of BS EN 10210

Chemical Composition of BS EN 10210

Mechanical Properties of BS EN 10210

Impact Tests

Weldability

Dimensional Tolerance

Surface Appearance

Galvanized

Repair of Surface Defects

BS EN 10210 Marking

Applications

Our Related Products

BS EN 10210 Classification

By Type of Steel

Unalloyed and alloyed special steels

Unalloyed steels:S235JRH, S275JOH ,S275J2H, S355JOH, S355J2H, S355K2H , S275NH、S275NLH、S355NH、S355NLH.

Alloyed special steels: S420NH、S420NLH、S460NH、S460NLH.

A simple method of identification is: in the name of the steel, if the yield strength of the index begins with the number '4', for alloy steel

By Manufacturing Process

Structural hollow sections should be manufactured by seamless or welded processes.

Seamless includes: hot-finished and cold-finished

Common welds include Electric Resistance Welding (ERW) and submerged Arc Welding (SAW): LSAW, SSAW.

Electrically welded hollow sections usually do not require internal weld trimming.

By Cross-section Shape

CHS: circular hollow sections;

RHS: square or rectangular hollow sections;

EHS: elliptical hollow sections;

This article is organized by the circular cross-section (CHS) of the relevant content.

BS EN 10210 Size Range

Wall thickness: ≤120mm

Outer diameter:

Round (CHS): Outer diameter≤2500 mm;

Square (RHS): Outer diameter≤ 800 mm × 800 mm;

Rectangular (RHS): Outer diameter≤750 mm × 500 mm;

Oval( EHS): Outer diameter≤ 500 mm × 250 mm.

Raw Materials

Unalloyed and fine grain steel.

Unalloyed steel four qualities JR, JO, J2, and K2 are specified.

Fine grain steels: four qualities N and NL are specified.

Fine grain steels are steels with a fine grain structure, with a ferrite grain size ≥ 6.

BS EN 10210 Steel Name

For non-alloy steel hollow sections the steel designation consists

Example: BS EN 10210-S275J0H

consists of four parts: S, 275, J0, and H.

1. S: indicates that the structural steel.

2. Numerical value(275): thickness ≤ 16mm for the minimum specified yield strength, in MPa.

3. JR: indicates that at room temperature with specific impact properties;

J0: indicates that at 0 ℃ with specific impact properties;

J2 or K2: indicated in -20 ℃ with specific impact properties;

4. H: indicates hollow sections.

For fine grain steel structural hollow sections the steel designation consists

Example: EN 10210-S355NLH

Consists of five parts: S, 355, N, L, and H.

1. S: indicates structural steel.

2. Numerical value(355): thickness ≤ 16mm minimum specified yield strength, unit is MPa.

3. N: standardized or standardized rolling.

4. L: specific impact properties at -50 °C.

5. H: denotes hollow section.

Delivery Conditions of BS EN 10210

JR, J0, J2 and K2 - hot finished.

N and NL - normalized. Normalized includes normalized rolled.

JR, J0, J2 and K2 - hot worked

N and NL - Normalizing. Normalizing includes normalizing rolling.

It may be necessary for seamless hollow sections with a wall thickness above 10 mm, or when T/D is greater than 0,1, to apply accelerated cooling after austenitizing to achieve the intended structure, or liquid quenching and tempering to achieve the specified mechanical properties.

For seamless hollow sections with wall thicknesses exceeding 10 mm, or when the T/D is greater than 0.1, accelerated cooling after austenitization may be required to achieve the desired structure, or liquid quenching and tempering to achieve the specified mechanical properties.

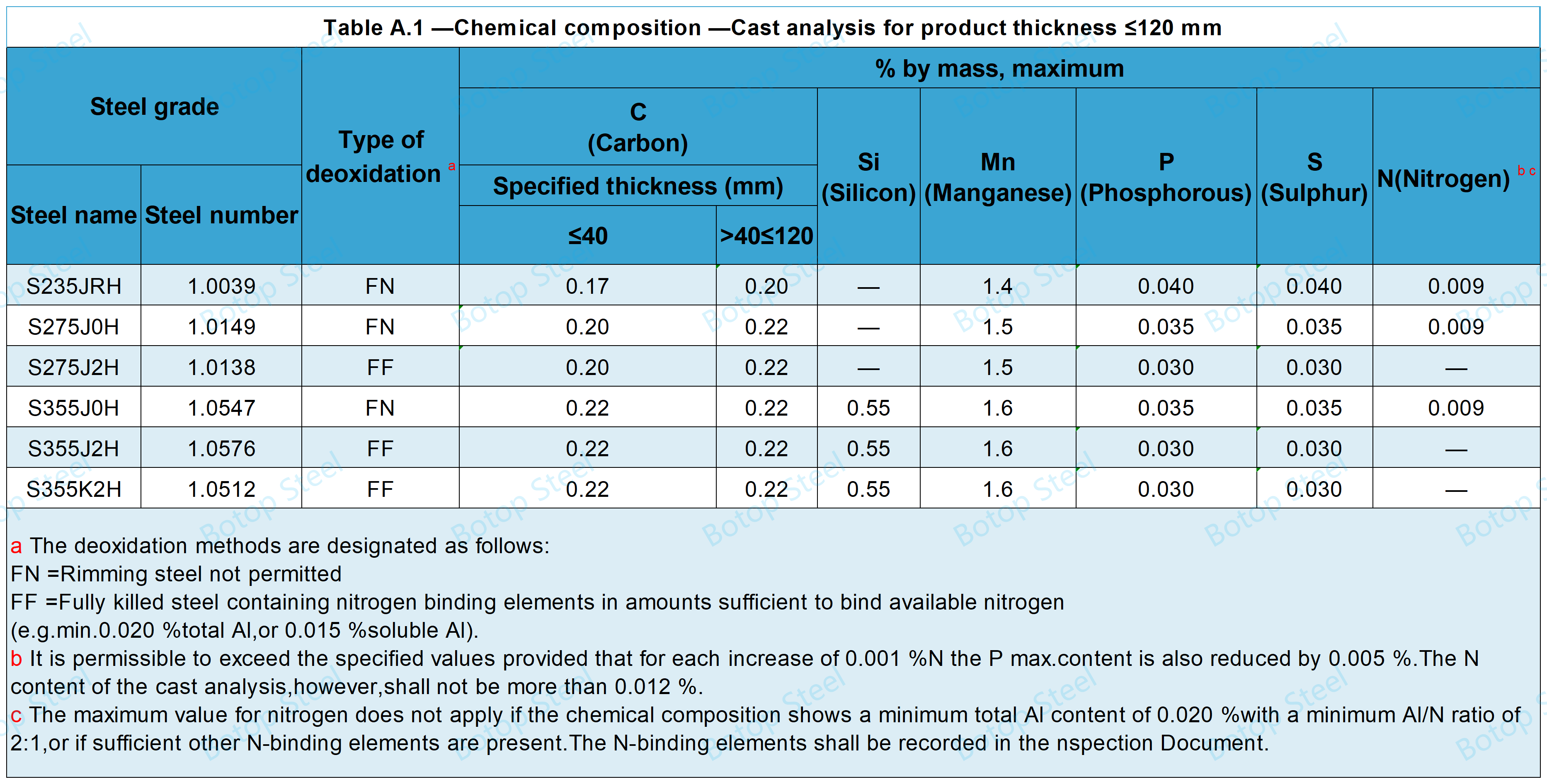

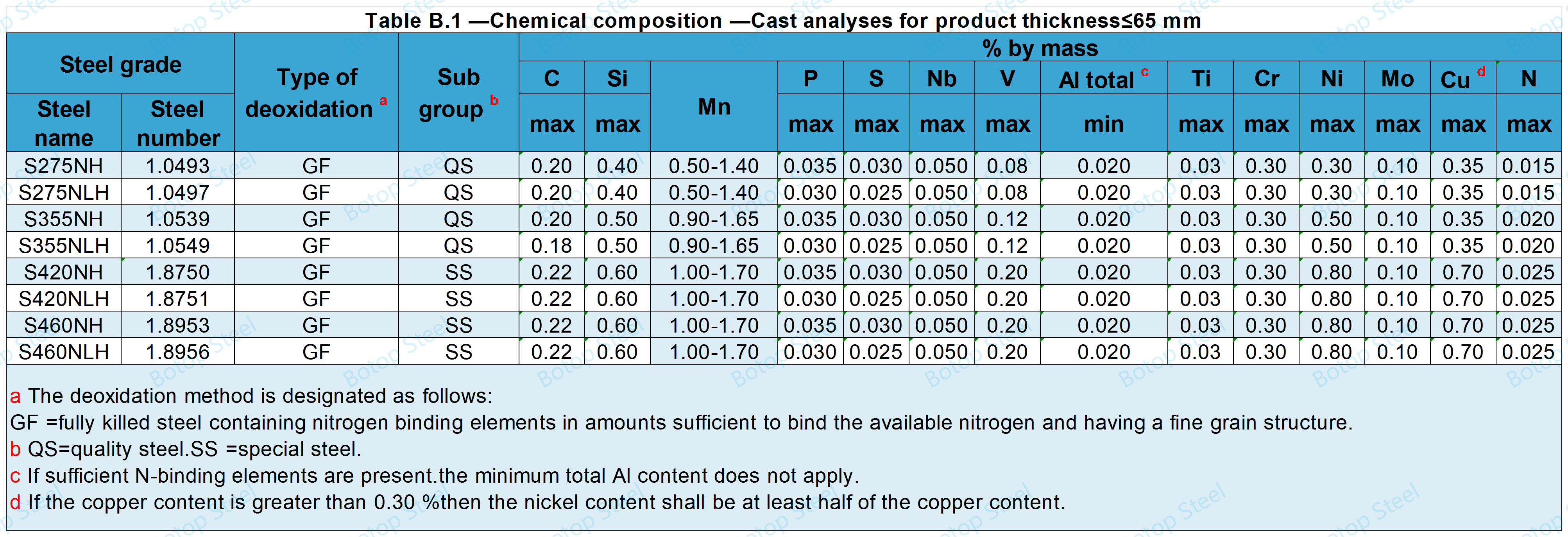

Chemical Composition of BS EN 10210

Non-alloy Steels - Chemical composition

Fine Grain Steels - Chemical composition

When determining the CEV the following formula shall be used:

CEV=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15

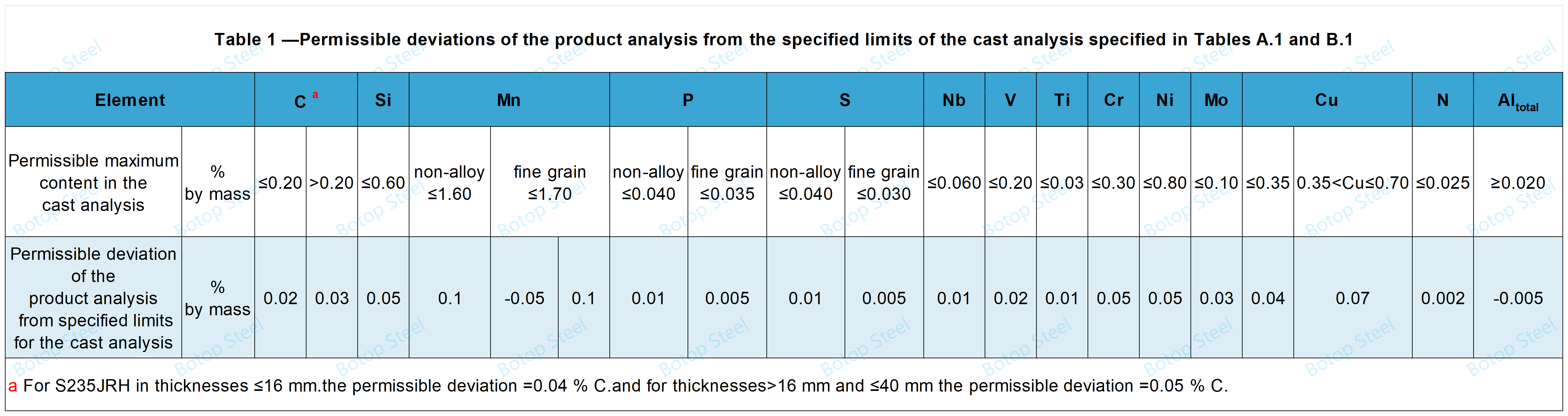

Deviation in Chemical Composition

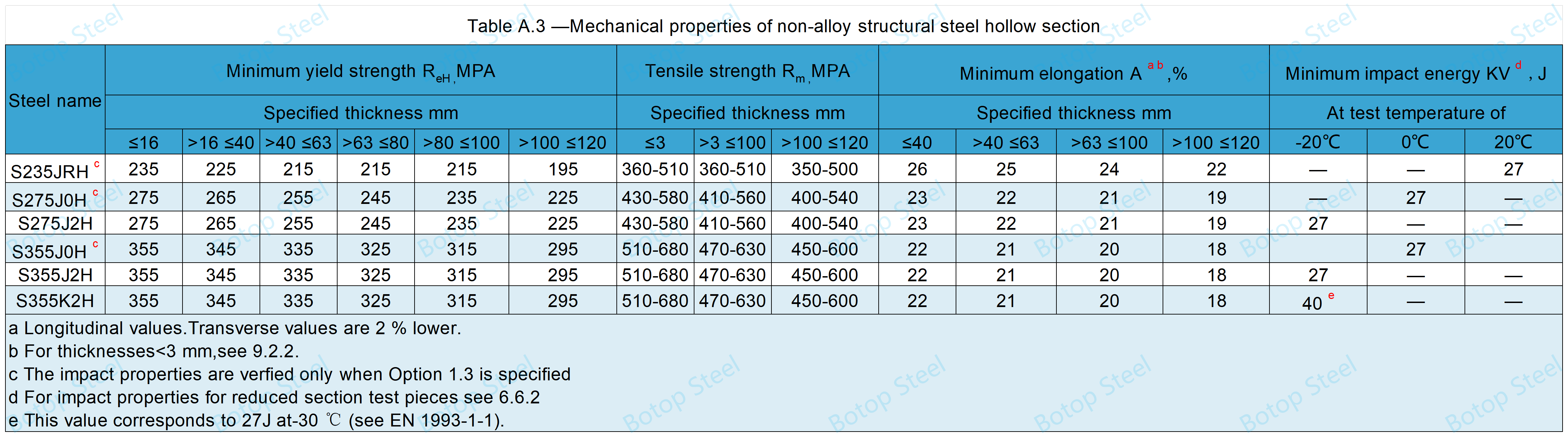

Mechanical Properties of BS EN 10210

Stress relief annealing at more than 580 °C or for over one hour may lead to deterioration of the mechanical properties.

Non-alloy Steels - Mechanical Properties

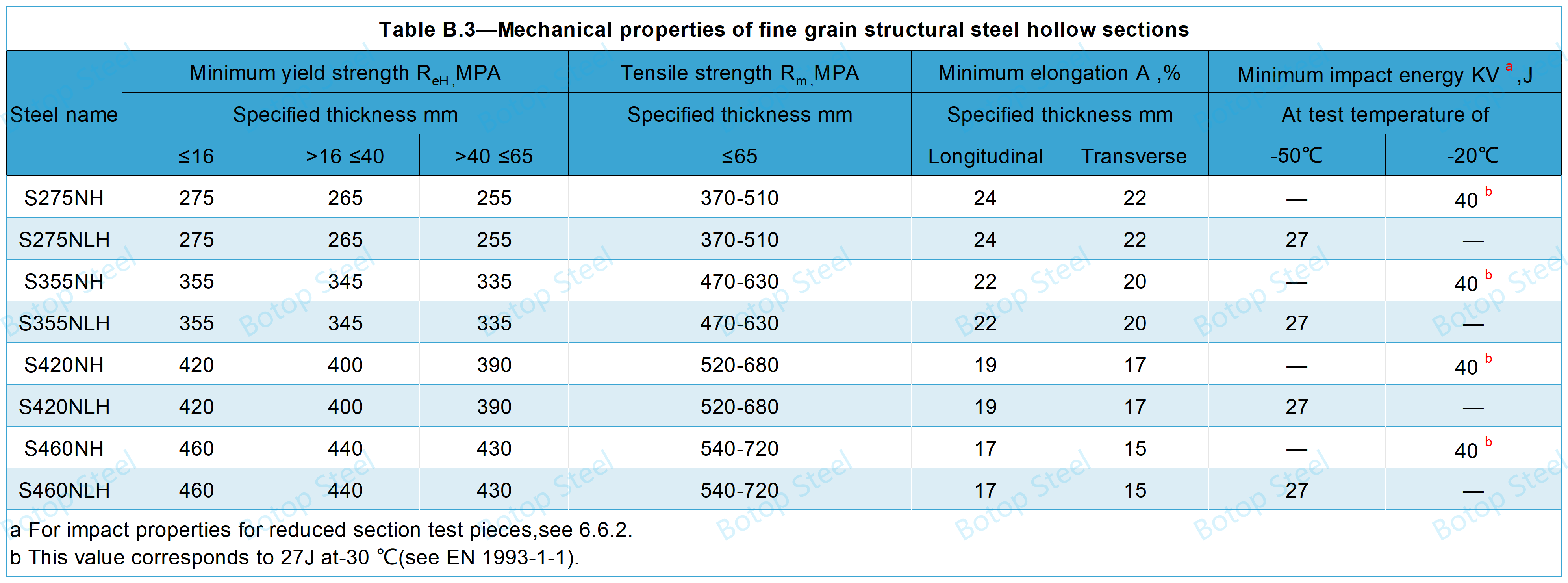

Fine Grain Steels - Mechanical Properties

Impact Tests

Impact testing is not required when the specified thickness < is 6 mm.

Standard V-notched specimens according to EN 10045-1 shall be used.

If the nominal product thickness is insufficient for the preparation of standardized specimens, tests shall be carried out using specimens with a width of less than 10 mm, but not less than 5 mm.

Weldability

The steels in BS EN 10210 are weldable.

EN 1011-1 and EN 1011-2 specify the general requirements for welded products.

Cold cracking in the weld zone is the main risk as product thickness, strength level, and CEV increase.

Dimensional Tolerance

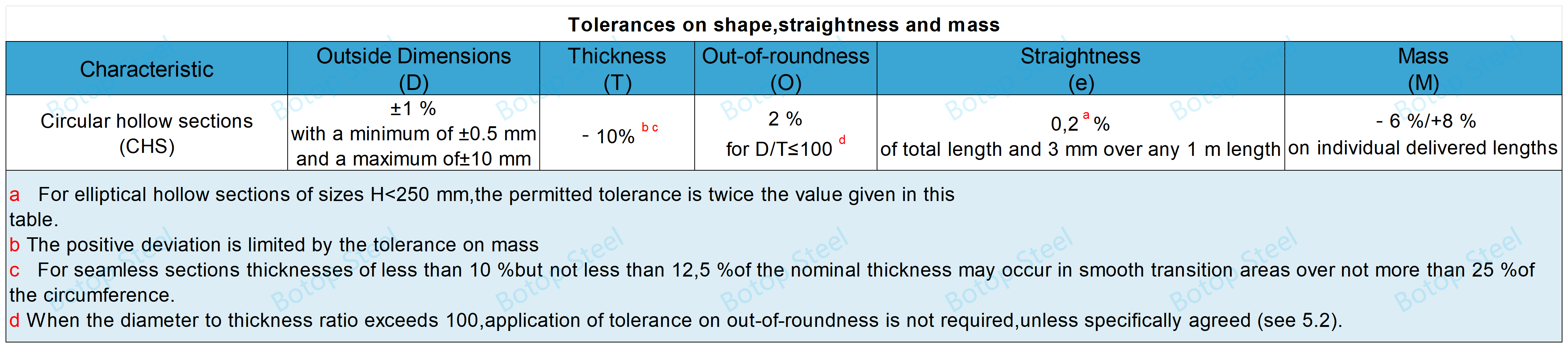

Tolerances on Shape,Straightness and Mass

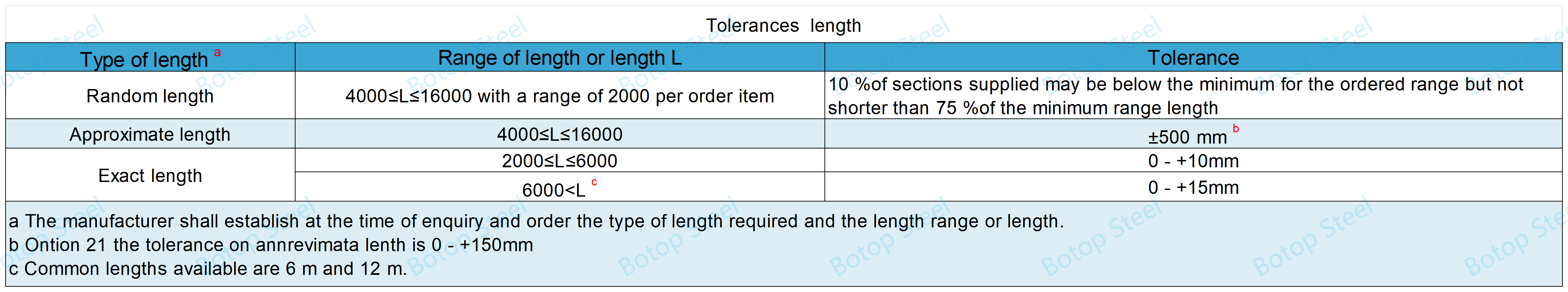

Tolerances of Length

Seam Height of SAW Weld

Tolerance on the height of internal and external weld seam for submerged arc welded hollow sections.

| Thickness, T | Maximum weld bead height, mm |

| ≤14,2 | 3.5 |

| >14,2 | 4.8 |

The BS EN 10210 standard covers both seamless and welded hot-finished hollow section products. The main welding processes are resistance welding (ERW) and submerged arc welding (SAW). The welds in ERW steel pipes are largely invisible, while SAW welds are usually rougher and more visible due to SAW.

Surface Appearance

The surface shall have a smooth finish corresponding to the manufacturing method used;

If the thickness is within tolerance, bumps, grooves, or shallow longitudinal grooves resulting from the manufacturing process are permitted.

Galvanized

Products in BS EN 10210 are suitable for hot dip galvanizing treatment.

EN ISO 1461 should be used to specify coating requirements.

Zinc coatings are applied by immersion in a molten solution containing at least 98% zinc content.

Repair of Surface Defects

Surface defects may be removed by grinding by the manufacturer, provided the repaired thickness is not less than the minimum allowable thickness.

If manufactured by the welding process, repair of welds is not permitted except for submerged arc welding.

Non-alloy steel pipe may be repaired by welding the pipe body. Alloy steel pipe may not be repaired by welding the body.

BS EN 10210 Marking

The contents of the steel pipe marking are to contain:

is the name of the steel, e.g. EN 10210-S275JOH.

is the name or trademark of the manufacturer.

an identification code, e.g. an order number.

BS EN 10210 steel tubes can be marked by a variety of methods to ensure ease of identification and traceability, either by painting, stamping, adhesive labels, or additional labels, which can be used individually or in combination.

Applications

Due to its high strength, good toughness, and weldability, BS EN 10210 is able to withstand a wide range of environments and loading conditions and is widely used in a variety of structural applications.

Building structures: e.g. skeletons for high-rise buildings, roof structures for stadiums, and support elements for bridges.

Mechanical engineering: frames and supports for machinery and heavy equipment.

Civil engineering: such as tunnel supports, bridge columns, and other load-bearing structures.

Transportation infrastructure: including components for roads and railroad bridges.

Energy sector: e.g. wind turbine towers and other structural components for energy facilities.

We are a high-quality welded carbon steel pipe manufacturer and supplier from China, and also a seamless steel pipe stockist, offering you a wide range of steel pipe solutions!

Tags: bs en 10210, en 10210,s275j2h,s275j0h,s355j2h.

Post time: Apr-25-2024