BS EN 10219 steel is cold-formed structural hollow steels made from non-alloy and fine-grained steels for structural applications without subsequent heat treatment.

EN 10219 and BS EN 10219 are identical standards but with different organizations.

Navigation Buttons

BS EN 10219 Classification

BS EN 10219 Size Range

Raw Materials and Delivery Conditions

BS EN 10219 Steel Name

Chemical Composition of BS EN 10219

Mechanical Properties of BS EN 10219

Impact Tests

Non-destructive Testing

Appearance and Defect Repair

Dimensional Tolerances

Galvanized

BS EN 10219 Marking

Applications

Our Related Products

BS EN 10219 Classification

By Type of Steel

Unalloyed and alloyed special steels.

Unalloyed steels:

S235JRH, S275J0H, S275J2H, S355J0H, S355J2H, S355K2H, S275NH, S275NLH, S355NH, S355NLH.

Alloyed special steels:

S460NH, S460NLH, S275MH, S275MLH, S355MH, S355MLH, S420MH, S420MLH, S460MH, S460MLH.

An easy way to tell the difference: steel types containing M or 4 are alloys, and the alloying properties of the steel can be quickly recognized.

By Manufacturing Process

The production processes primarily employed for manufacturing steel pipes according to BS EN 10219 include Electric Resistance Welding (ERW) and Submerged Arc Welding (SAW).

SAW can be further categorized into Longitudinal Submerged Arc Welding (LSAW) and Spiral Submerged Arc Welding (SSAW) based on the form of the weld seam.

By Cross-section Shape

CFCHS: Cold Formed circular hollow sections;

CFRHS: Cold Formed square or rectangular hollow sections;

CFEHS: Cold Formed elliptical hollow sections;

This paper focuses on CFCHS (Cold Formed Circular Hollow Section).

BS EN 10219 Size Range

Wall thickness: T ≤ 40mm

Outer diameter (D):

Round (CHS): D ≤ 2500 mm;

Square (RHS): D ≤ 500 mm × 500 mm;

Rectangular (RHS): D ≤ 500 mm × 300 mm;

Oval( EHS): D ≤ 480 mm × 240 mm.

Raw Materials and Delivery Conditions

Non-alloy steels

per Appendix A, Rolled or Standardized/Standardized Rolled (N) for JR, J0, J2, and K2 steels;

Fine grain steels

Per Appendix B, Standardized/Standardized Rolling (N) for N and NL steels;

Per Appendix B. M and ML, steels were thermomechanically rolled (M).

The hollow sections shall be delivered cold-formed without subsequent heat treatment except that the weld seam may be in the as-welded or heat-treated condition.

For SAW hollow sections above 508 mm outside diameter, it may be necessary to perform a warm shaping operation, which does not affect the mechanical properties, in order to meet the out-of-roundness tolerance requirements.

BS EN 10219 Steel Name

The naming convention of BS EN 10219 is the same as BS EN 10210, which uses the EN10027-1 standard.

For non-alloy steel hollow sections, the steel designation consists

Example: Structural steel (S) with a specified minimum yield strength for thickness not greater than 16 mm of 275 MPa, with a minimum impact energy value of 27 J at 0 ℃(J), hollow section (H).

BS EN 10219-S275J0H

Consists of four parts: S, 275, J0, and H.

1. S: indicates that the structural steel.

2. Numerical value (275): thickness ≤ 16mm for the minimum specified yield strength, in MPa.

3. JR: indicates that at room temperature with specific impact properties;

J0: indicates that at 0 ℃ with specific impact properties;

J2 or K2: indicated in -20 ℃ with specific impact properties;

4. H: indicates hollow sections.

For fine grain steel structural hollow sections the steel designation consists

Example: Structural steel (S) with a specified minimum yield strength for thickness not greater than 16 mm of 355 MPa.normalized fine grain steel feedstock (N), with a minimum impact energy value of 27 J at -50 ℃(L), hollow section (H).

EN 10219-S355NLH

Consists of five parts: S, 355, N, L, and H.

1. S: indicates structural steel.

2. Numerical value(355): thickness ≤ 16mm minimum specified yield strength, unit is MPa.

3. N: standardized or standardized rolling.

4. L: specific impact properties at -50 °C.

5. H: denotes hollow section.

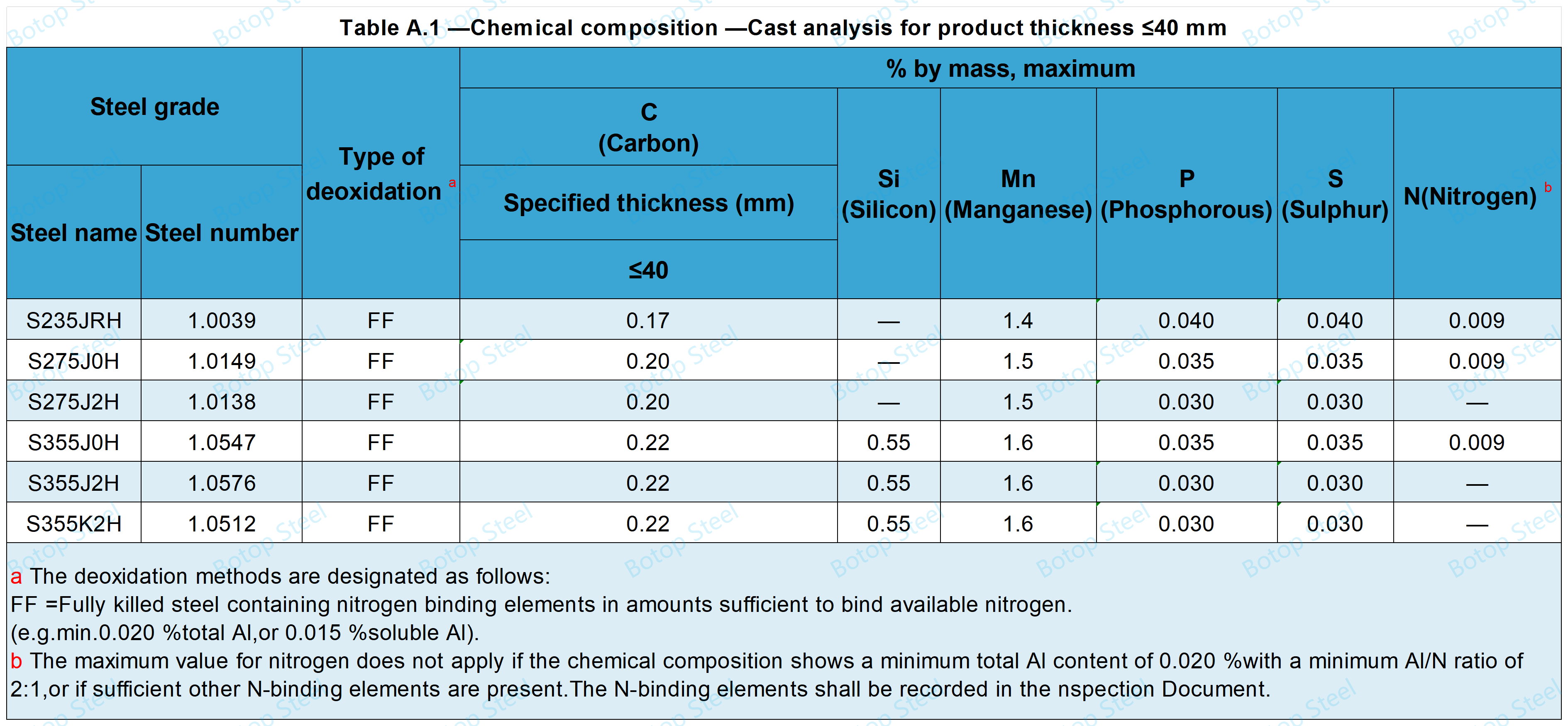

Chemical Composition of BS EN 10219

Non-alloy Steels - Chemical Composition

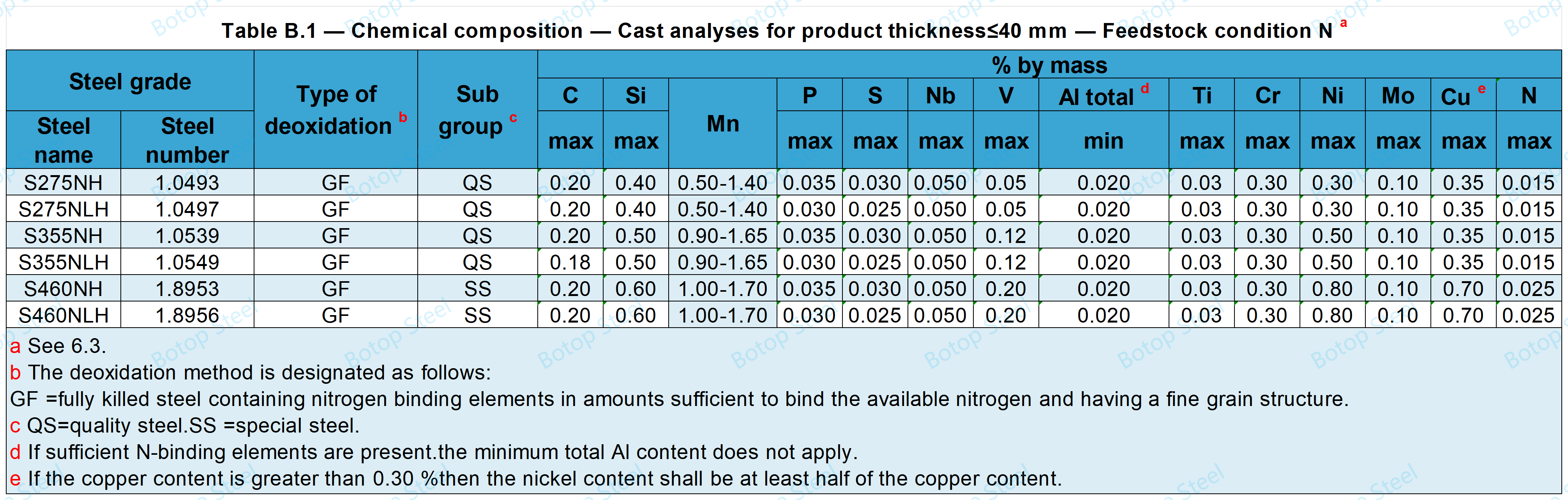

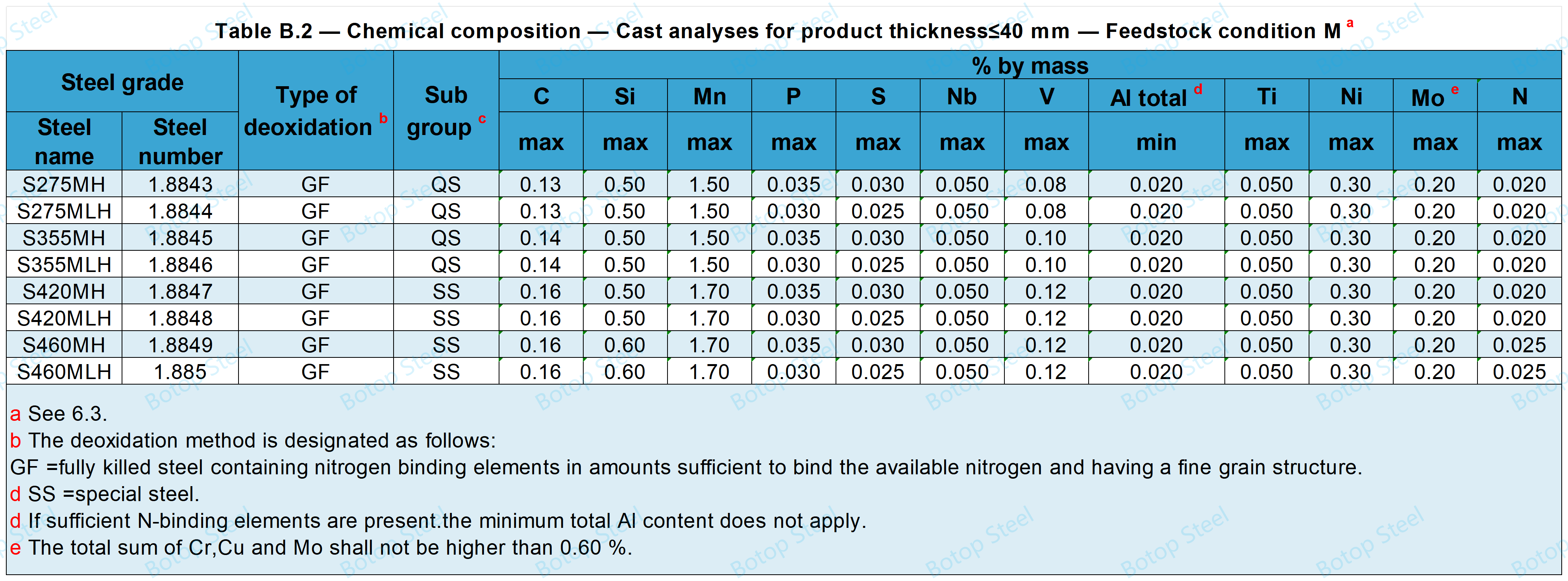

Fine Grain Steels - Chemical composition

When fine-grained steel is used as a raw material, it can be categorized into M and N according to the delivery conditions, and the chemical composition requirements of these two types may differ.

When determining the CEV the following formula shall be used: CEV=C+Mn/6+(Cr+Mo+V)/5+(Ni+Cu)/15.

Feedstock condition N

Feedstock condition M

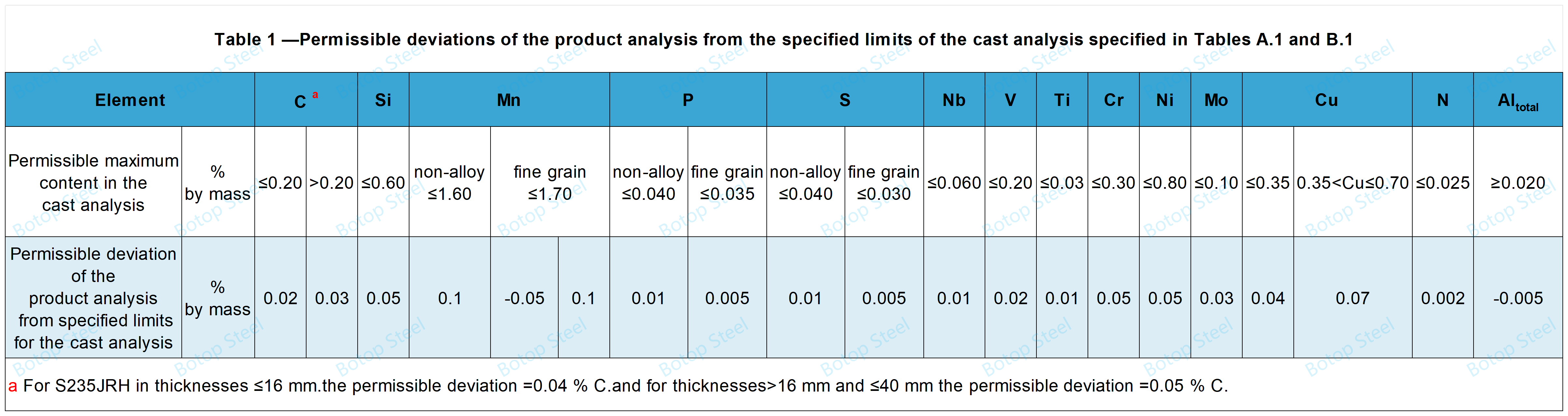

Deviation in Chemical Composition

Mechanical Properties of BS EN 10219

It should be carried out in accordance with EN 1000-2-1. The test shall be carried out in the temperature range from 10°C to 35°C.

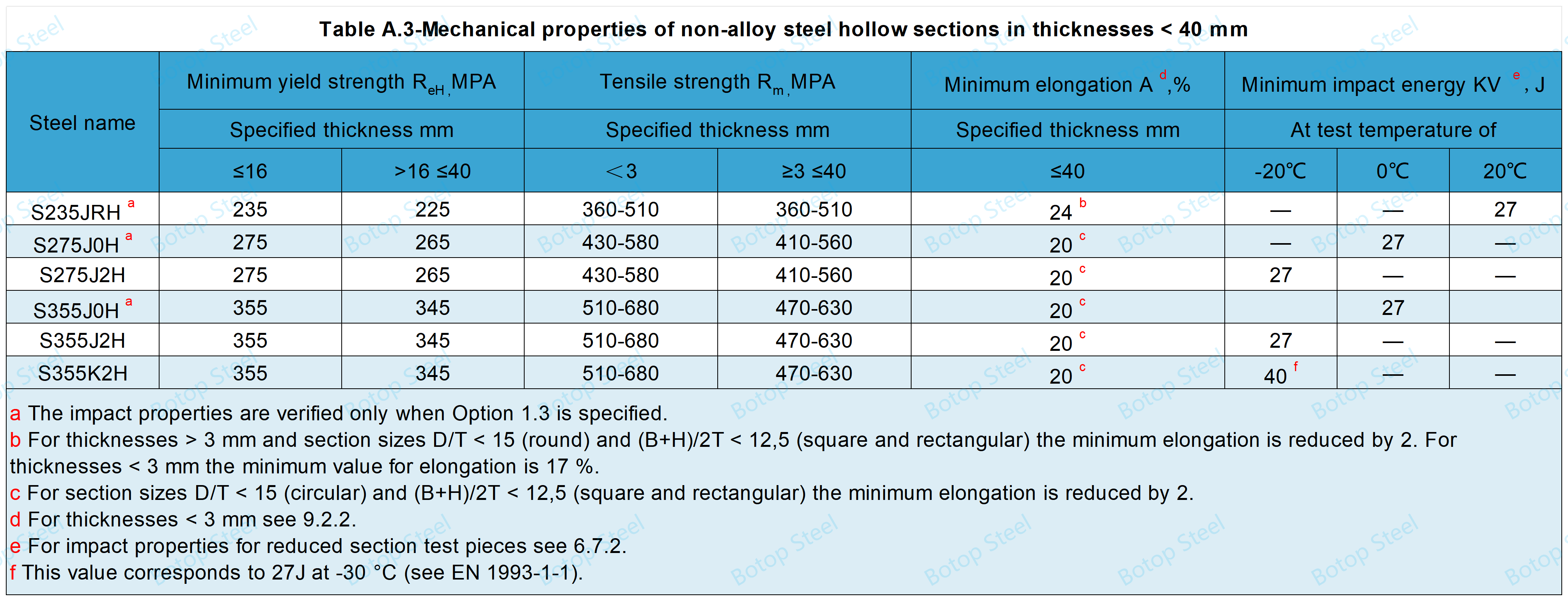

Non-alloy Steels - Mechanical Properties

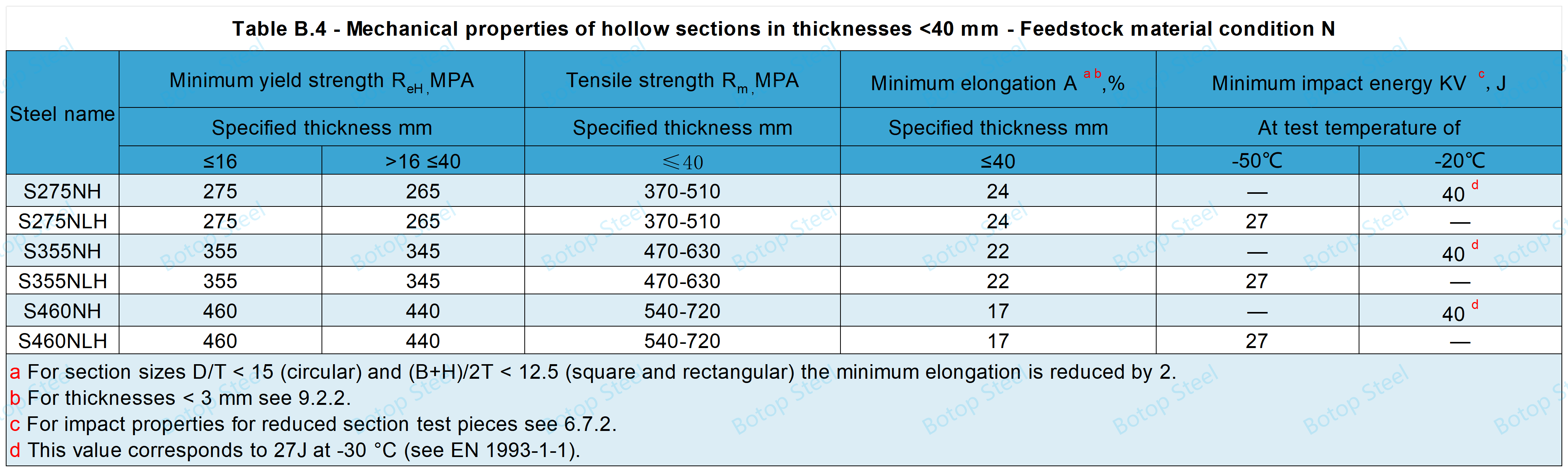

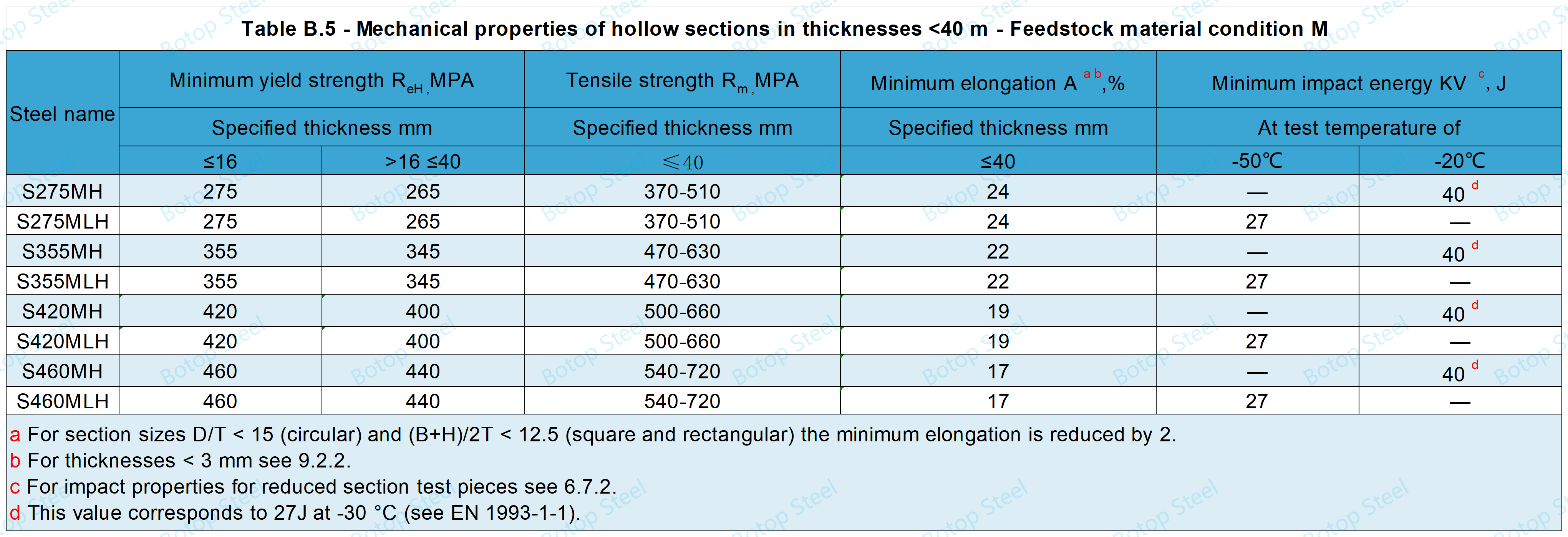

Fine Grain Steels - Mechanical Properties

When fine-grained steel is used as a raw material, it can be categorized into M and N according to the delivery conditions, and the mechanical properties of these two types can be different.

Feedstock condition N

Feedstock material condition M

Impact Tests

The impact test shall be carried out in accordance with EN 10045-1.

The average value of a set of three specimens shall be equal to or greater than the specified value.

An individual value may be less than the specified value, but it is not less than 70% of that value.

Non-destructive Testing

When performing NDT on welds in hollow structural sections, the following requirements are to be met.

Electric Welded Sections

Meet one of the following requirements:

a) EN 10246-3 to acceptance level E4, with the exception that the rotating tube/pancake coil technique shall not be permitted;

b) EN 10246-5 to acceptance level F5;

c) EN 10246-8 to acceptance level U5.

Submerged Arc Welded Sections

The weld seam of submerged arc welded hollow sections shall be tested either in accordance with EN 10246-9 to acceptance level U4 or by radiography in accordance with EN 10246-10 with an image quality class R2.

Appearance and Defect Repair

Surface Appearance

Hollow sections shall have a smooth surface corresponding to the manufacturing method used; bumps, grooves or shallow longitudinal grooves resulting from the manufacturing process are permitted if the residual thickness is within tolerance.

The ends of the hollow section shall be cut nominally square to the axis of the product.

Defect Repair

Surface defects may be removed by grinding provided that the thickness is not less than the minimum permissible thickness specified in BS EN 10219-2 after repair.

For fine grain hollow sections, repair of the body by welding shall not be permitted unless otherwise agreed.

Weld repair procedures shall comply with the requirements of EN ISO 15607, EN ISO 15609-1, and EN ISO 15614-1.

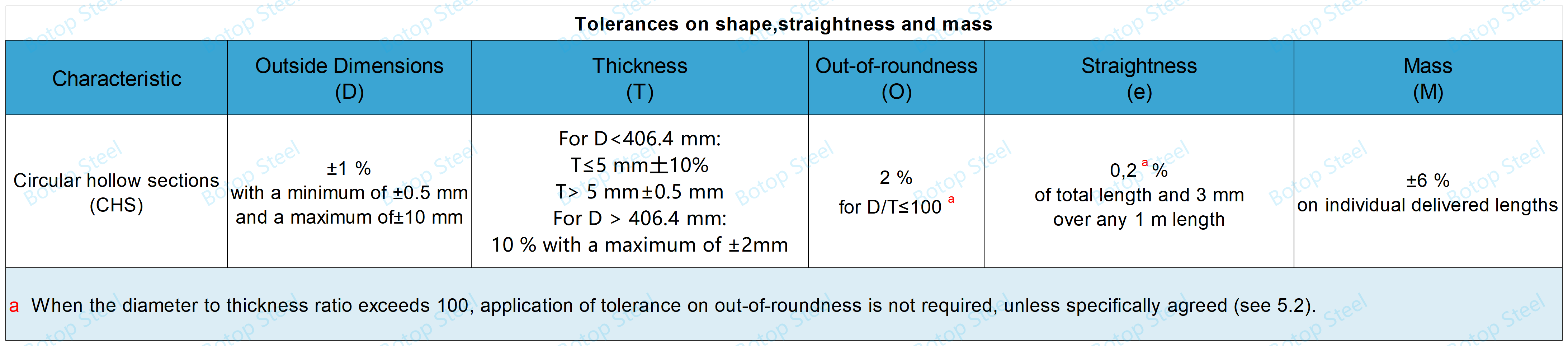

Dimensional Tolerances

Dimensional tolerances shall be in accordance with the corresponding requirements of EN 10219-2 and attention shall be paid to the shape of the cross section.

Tolerances on Shape,Straightness and Mass

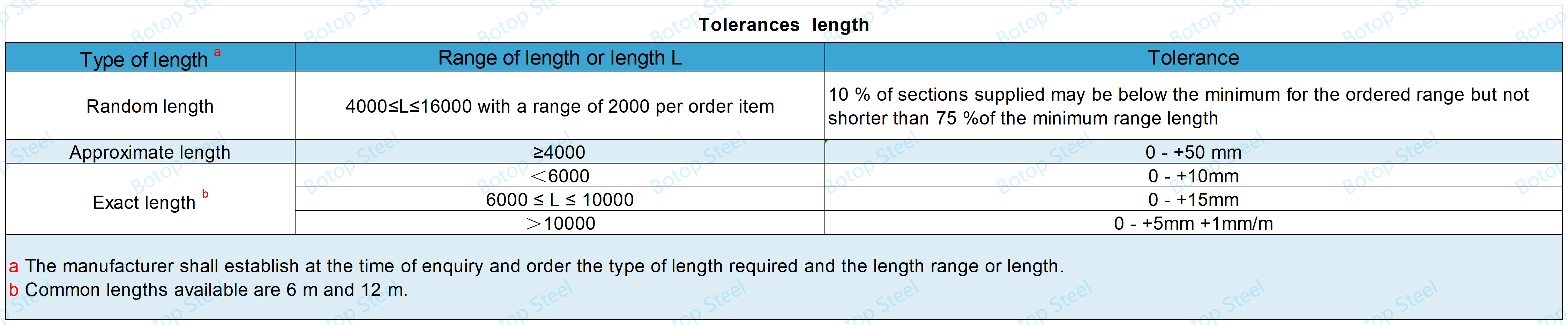

Tolerances of Length

Seam Height of SAW Weld

Tolerance on the height of internal and external weld seam for submerged arc welded hollow sections.

| Thickness, T | Maximum weld bead height, mm |

| ≤14,2 | 3.5 |

| >14,2 | 4.8 |

Galvanized

BS EN 10219 Hollow tubing can be hot-dip galvanized for extended service life.

The hollow tubes are fed into a bath containing at least 98% zinc content to form a galvanized layer.

BS EN 10219 Marking

The contents of the steel pipe marking are to contain:

Name of the steel, e.g. EN 10219-S275J0H.

Name or trademark of the manufacturer.

Identification code, e.g. an order number.

BS EN 10219 steel tubes can be marked by a variety of methods to ensure ease of identification and traceability, either by painting, stamping, adhesive labels, or additional labels, which can be used individually or in combination.

Applications

The application of the BS EN 0219 standard covers all areas of structural steelwork requirements.

Construction: BS EN 10219 specification steel pipes are widely used in construction projects, such as constructing bridges, structural support for buildings, etc.

Infrastructure construction: they are used in water conservancy projects, road construction, pipeline systems, and other infrastructure construction projects, such as drainage pipes, water pipelines, and so on.

Manufacturing: These steel pipes are also used in the manufacture of mechanical equipment, conveyor systems, and other industrial applications.

Municipal engineering: In urban municipal engineering, BS EN 10219 standard steel pipes can be used to manufacture guardrails, railings, road barriers, and so on.

Architectural decoration: The aesthetic design and strength of steel tubes make them a common material used in architectural decoration, such as stair railings, balustrades, decorative brackets, etc.

Since its establishment in 2014, Botop Steel has become a leading carbon steel pipe supplier in Northern China, known for its excellent service, high-quality products, and comprehensive solutions. The company's extensive product range includes seamless, ERW, LSAW, and SSAW steel pipes, as well as pipe fittings, flanges, and specialty steels.

With a strong commitment to quality, Botop Steel implements stringent controls and tests to ensure the reliability of its products. Its experienced team provides personalized solutions and expert support, with a focus on customer satisfaction.

Tags: bs en 10219, en 10219, chs, cfchs, s355j0h, s275j0h.

Post time: Apr-26-2024