ASTM A500 steel is cold-formed welded and seamless carbon steel structural tubing for welded, riveted, or bolted bridges and building structures and general structural purposes.

Navigation Buttons

Hollow Section Shape

Grade Classification

Size Range

Raw Materials

Manufacturing Methods

Tube End Type

Heat Treatment

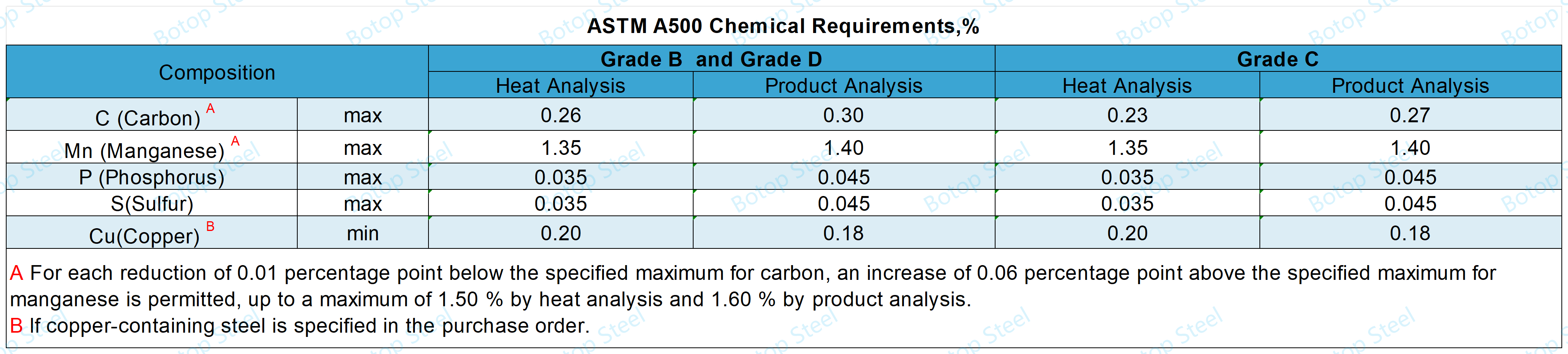

Chemical Composition of ASTM A500

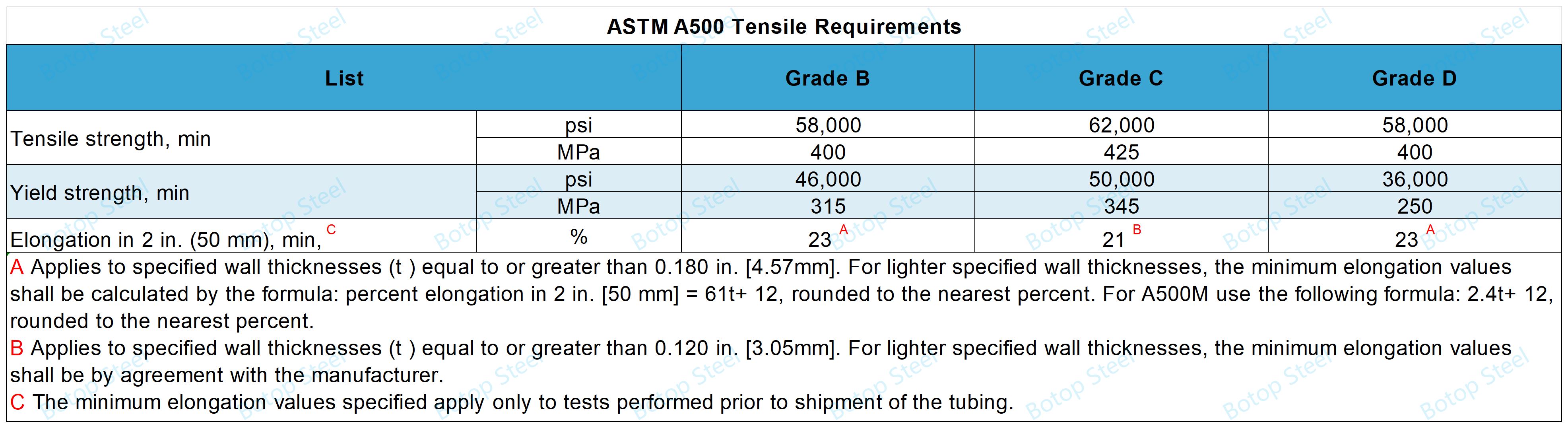

Tensile Requirements of ASTM A500

Flattening Test

Flaring Test

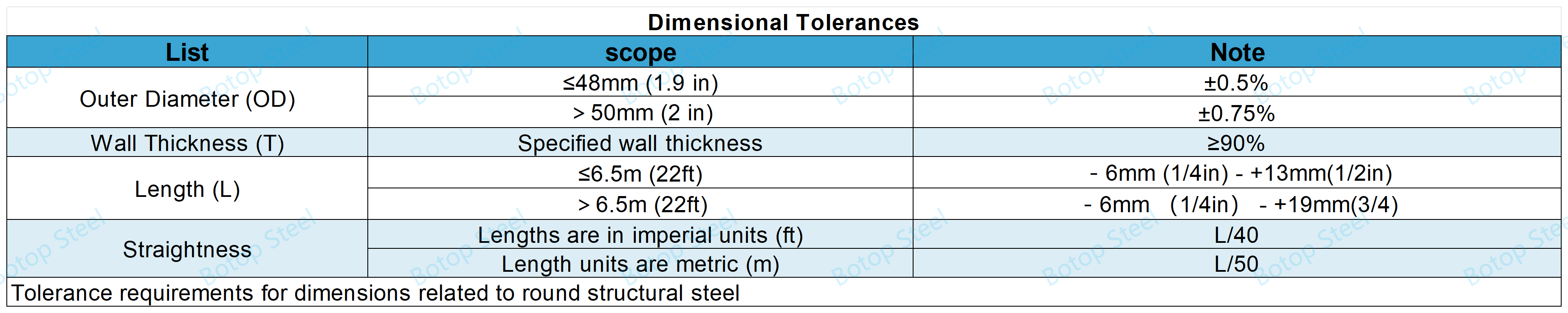

Dimensional Tolerance of ASTM A500

Tube Marking

Applications of ASTM A500

Alternative Materials of ASTM A500

Our Related Products

Hollow Section Shape

It can be round, square, rectangular, or other special structural shapes.

This article focuses on the requirements of ASTM A500 for round structural steel.

Grade Classification

ASTM A500 classifies steel pipe into three grades, grade B, grade C, and grade D.

It is worth noting that earlier versions of ASTM A500 also had Grade A, which was removed in the latest version of 2023.

Size Range

For tubes with outside diameter ≤ 2235mm [88in] and wall thickness ≤ 25.4mm [1in].

Raw Materials

The steel shall be made by one or more of the following processes: basic oxygen or electric furnace.

Basic Oxygen Process: This is a modern rapid method of steel production, which reduces the carbon content by blowing oxygen into the molten pig iron, while removing other unwanted elements such as sulphur and phosphorus. It is suitable for the rapid production of large quantities of steel.

Electric Furnace Process: The Electric Furnace Process uses a high temperature electric arc to melt scrap and directly reduce iron, and is particularly useful for producing specialty grades and controlling alloy compositions, as well as for small batch production.

Manufacturing Methods

Seamless or welding process.

Welded tubing shall be made from flat-rolled steel by the electric-resistance-welding (ERW) process. The weld seam should be welded through to ensure the strength of the pipe.

Pipes produced by the welding process usually do not have the inner weld removed.

Tube End Type

If not specifically required, structural tubes should be flat-ended and clean of burrs.

Heat Treatment

Grade B and Grade C

Can be annealed or stress-relieved.

Annealing is accomplished by heating the tube to a high temperature and then slowly cooling it. Annealing rearranges the microstructure of the material to improve its toughness and uniformity.

Stress relieving is generally accomplished by heating the material to a lower temperature (usually lower than that of annealing) then holding it for a period of time and then cooling it. This helps prevent distortion or rupture of the material during subsequent operations such as welding or cutting.

Grade D

Heat treatment is required.

It should be performed at a temperature of at least 1100°F (590°C) for 1 hour per 25 mm wall thickness.

Chemical Composition of ASTM A500

Test method: ASTM A751.

Tensile Requirements of ASTM A500

Specimens shall meet the applicable requirements of ASTM A370, Appendix A2.

Flattening Test

Welded Round Structural Tubes

Weld ductility test: Using a specimen at least 4 inches (100 mm) long, flatten the specimen with the weld at 90° to the direction of loading until the distance between the plates is less than 2/3 of the outside diameter of the pipe. the specimen shall not be cracked or broken on the inside or outside surfaces during this process.

Pipe ductility test: continue to flatten the specimen until the distance between the plates is less than 1/2 of the pipe's outer diameter. at this time, the pipe should not have cracks or fractures on the inner and outer surfaces.

Integrity test: Continue to flatten the specimen until a fracture occurs or until the relative wall thickness requirements are met. If evidence of ply peeling, unstable material, or incomplete welds is found during the flattening test, the specimen will be judged unsatisfactory.

Seamless Round Structural Tubes

Specimen Length: The length of the specimen used for testing shall not be less than 2 1/2 in (65 mm).

Ductility test: Without cracking or fracture, the specimen is flattened between parallel plates until the distance between the plates is less than the "H" value calculated by the following formula:

H=(1+e)t/(e+t/D)

H = distance between flattening plates, in. [mm],

e= deformation per unit length (constant for a given grade of steel, 0.07 for Grade B, and 0.06 for Grade C),

t= specified wall thickness of tubing, in. [mm],

D = specified outside diameter of tubing, in. [mm].

Integrity test: Continue to flatten the specimen until the specimen breaks or the opposite walls of the specimen meet.

Failure criteria: Laminar peeling or weak material found throughout the flattening test will be grounds for rejection.

Flaring Test

A flaring test is available for round tubes ≤ 254 mm (10 in) in diameter, but is not mandatory.

Dimensional Tolerance of ASTM A500

Tube Marking

The following information should be included:

Manufacturer's name: This can be the manufacturer's full name or an abbreviation.

Brand or Trademark: The brand name or trademark used by the manufacturer to distinguish its products.

Specification Designator: ASTM A500, which need not include the year of publication.

Grade Letter: B, C or D grade.

For structural tubes ≤ 100mm (4in) in diameter, labels can be used to mark the identification information clearly.

Applications of ASTM A500

Due to its excellent mechanical properties and weldability, ASTM A500 steel pipe is used in a wide variety of structures where durability and strength are required.

Construction: Used to support building structures such as framing systems, roof structures, arch design elements, and round columns.

Bridge construction: For structural elements of bridges, such as circular load-bearing columns and trusses for bridges.

Industrial infrastructure: In large industrial buildings such as oil and gas facilities, chemical plants, and steel mills, round steel tubes are used to build support structures and transmission piping.

Transportation systems: For traffic sign posts, light poles, and guardrail struts.

Machinery manufacturing: As part of machinery and heavy equipment, such as agricultural machinery, mining equipment, and construction machinery.

Utilities: Used in pipelines for water, gas, petroleum products, etc., and as wire and cable protection pipes.

Sports facilities: In the construction of sports venues, round steel tubes are used to make bleachers, lighting towers, and other support structures.

Furniture and decoration: Round structural steel tubes are used to make metal furniture, such as legs for tables and chairs, as well as decorative elements for modern interior design.

Fence and railing systems: Used as posts for fencing and railing systems, especially where structural strength and durability are required.

Alternative Materials of ASTM A500

ASTM A501: This is a standard for hot-formed carbon steel structural tubing, similar to ASTM A500, but applicable to the hot-forming manufacturing process.

ASTM A252: Standard for steel pipe piles for use in foundation and piling work.

ASTM A106: Seamless carbon steel pipe, typically used in high-temperature environments.

ASTM A53: Another type of carbon steel pipe for pressure and mechanical applications, widely used in fluid transfer systems.

EN 10210: In Europe, the EN 10210 standard specifies technical delivery conditions for hot-formed structural hollow sections, which have similar application areas to ASTM A500.

CSA G40.21: A Canadian standard that provides a wide range of structural quality steels in a variety of strength grades that can be used for similar applications.

JIS G3466: Japanese Industrial Standard for square and rectangular tubes of carbon steel for general structural use.

IS 4923: Indian Standard for cold-formed welded or seamless carbon steel structural hollow sections.

AS/NZS 1163: Australian and New Zealand standards for structural steel tubes and hollow sections.

Our Related Products

Since its establishment in 2014, Botop Steel has become a leading carbon steel pipe supplier in Northern China, known for its excellent service, high-quality products, and comprehensive solutions. The company's extensive product range includes seamless, ERW, LSAW, and SSAW steel pipes, as well as pipe fittings, flanges, and specialty steels.

With a strong commitment to quality, Botop Steel implements stringent controls and tests to ensure the reliability of its products. Its experienced team provides personalized solutions and expert support, with a focus on customer satisfaction.

Tags: astm a500, astm a500 grade b, astm a500 grade c, astm a500 grade d.

Post time: May-04-2024