ASTM A501 Grade B is a hot-formed welded and seamless carbon steel pipe with a minimum tensile strength of 448 MPa (65,000 psi) for a variety of structural applications.

ASTM A501 is for the fabrication and performance of hot-formed welded and seamless carbon steel tubing for structural applications.

These steel tubes can be black (uncoated) or hot-dipped galvanized, the latter of which has increased corrosion resistance through the galvanizing process, making it suitable for a wide range of environmental conditions.

These steel pipes are widely used in bridges, buildings, and many other general structural applications.

ASTM A500 classifies steel pipe into three grades, grade A, grade B, and grade C.

Grade B is the most widely used of the three grades because it provides well-balanced properties for numerous structural applications.

The steel shall be made by basic-oxygen or electric-arc-furnace steel-making process.

Steel may be cast in ingots or may be strand cast.

When steels of different grades are sequentially stranded cast, the steel producer shall identify the resultant transition material and remove it using an established procedure that positively separates the grades.

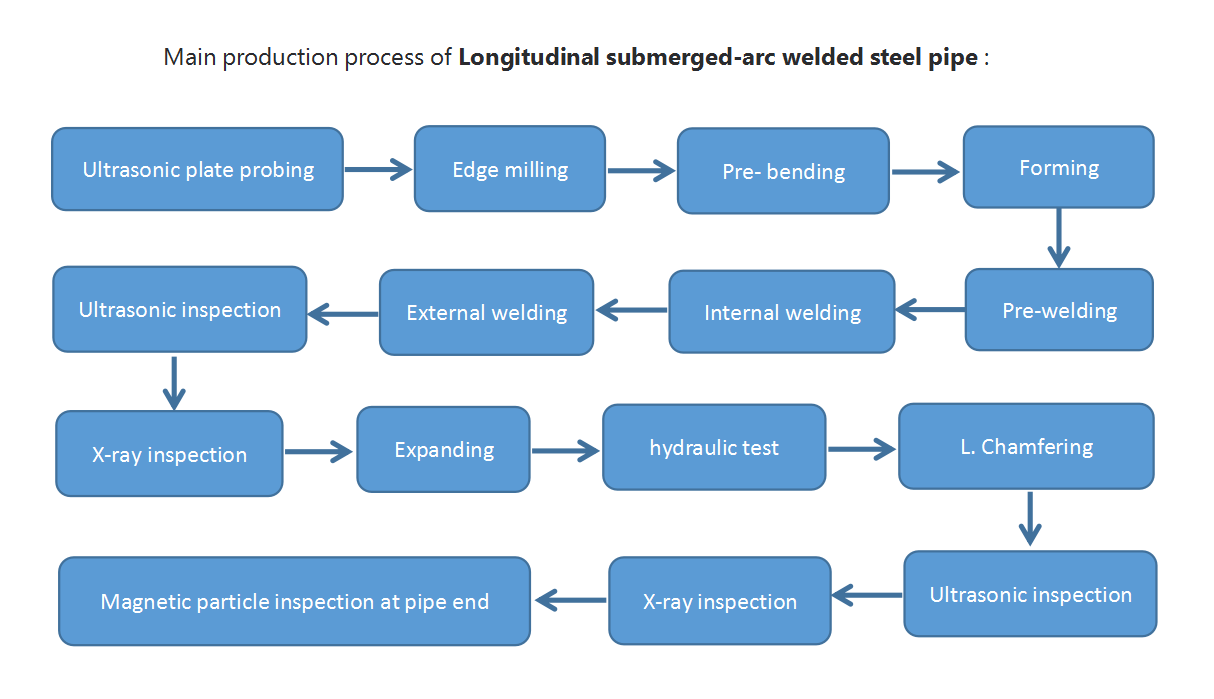

The tubing shall be made by one of the following processes: seamless; furnace-butt-welding (continuous welding); electric resistance welding (ERW) or submerged arc welding (SAW) followed by reheating throughout the cross-section and hot forming by a reducing or shaping process, or both.

The SAW welding process is subdivided into LSAW (SAWL) and SSAW (HSAW).

The final shape formation shall be made by a hot forming process.

It shall be permissible to add a normalizing heat treatment for tubing with a wall thickness greater than 13mm [1/2 in].

| ASTM A501 Grade B Chemical Requirements,% | |||

| Composition | Grade B | ||

| Heat Analysis | Product Analysis | ||

| C (Carbon) B | max | 0.22 | 0.26 |

| Mn (Manganese) B | max | 1.40 | 1.45 |

| P (Phosphorus) | max | 0.030 | 0.040 |

| S(Sulfur) | max | 0.020 | 0.030 |

| Cu(Copper) B (when copper steel is specified) |

min | 0.20 | 0.18 |

| B For each reduction of 0.01 percentage point below the specified maximum for carbon, an increase of 0.06 percentage point above the specified maximum for manganese is permitted, up to a maximum of 1.60 % by heat analysis and 1.65 % by product analysis | |||

Product analyses shall be made using test specimens taken from two lengths of tubing from each lot of 500 lengths, or a fraction thereof, or two pieces of flat-rolled stock from each lot of a corresponding quantity of flat-rolled stock.

Tensile specimens shall comply with the applicable requirements of Test Methods and Definitions A370, Appendix A2.

| ASTM A501 Grade B Tensile Requirements | |||

| List | Wall Thickness mm [in] |

Grade B | |

| Tensile strength, min, psi[MPa] | All | 65000 [448] | |

| Yield strength, min, psi[MPa] | ≤25 [1] | 46,000 [315] | |

| >25 [1] and ≤ 50 [2] | 45,000 [310] | ||

| >50 [2] and ≤ 76 [3] | 42,500 [290] | ||

| >76 [3] and ≤ 100 [4] | 40,000 [280] | ||

| Elongation, min, % | — | 24 | |

| Impact Energy | min, average, ft/Ibf [J] | — | 20 [27] |

| min, single, ft/Ibf [J] | — | 14 [19] | |

Tension test specimens shall be full-size longitudinal test specimens or longitudinal strip test specimens.

For welded tubing, any longitudinal strip test specimens shall be taken from a location at least 90° from the weld and shall be prepared without flattening in the gauge length.

Longitudinal strip test specimens shall have all burrs removed.

Tension test specimens shall not contain surface imperfections that would interfere with the proper determination of the tensile properties.

Wall thicknesses ≤ 6.3mm [0.25in] do not require impact testing.

| ASTM A501 Dimensional Tolerances | ||

| List | scope | Note |

| Outer Diameter (OD) | ≤48mm (1.9 in) | ±0.5mm [1/48 in] |

| >50mm (2 in) | ± 1% | |

| Wall Thickness (T) | Specified wall thickness | ≥90% |

| Weight | specified weight | 96.5%-110% |

| Length (L) | ≤7m (22 ft) | -6mm (1/4in) - +13mm (1/2in) |

| 7-14m (22-44 ft) | -6mm (1/4in) - +19mm (3/4) | |

| Straightness | Lengths are in imperial units (ft) | L/40 |

| Length units are metric (m) | L/50 | |

The structural tubing shall be free of defects and shall have a smooth finish resulting from the hot rolling manufacturing process.

When the depth of defects on the surface of the pipe exceeds 10% of the nominal wall thickness, these defects shall be considered non-conforming. Repair by welding shall be permitted only when agreed upon between the purchaser and the manufacturer. Prior to repair by welding, the defects to be repaired must be completely removed by cutting or grinding methods.

For structural pipe to be hot-dip galvanized, this coating shall conform to the relevant requirements of Specification ASTM A53.

Each length of structural tubing should be marked by a suitable method, such as rolling, stamping, stamping, or painting.

The ASTM A501 marking should have the following information as a minimum:

Manufacturer's name

Brand or trademark

Size

Name of the standard (year of publication is not required)

Grade

For structural tubes <50 mm [2 in] OD, it is permissible to mark the steel information on a label attached to each bundle.

ASTM A501 Grade B steel combines strength and ductility with a hot-forming production process, making it suitable for a variety of structural applications.

Building and construction: Typically used in building and construction applications where high strength and durability of robust materials are required. This includes buildings, sports stadiums, bridges, and other structures.

Industrial Facilities: Due to its high strength, it is suitable for use in industrial facilities such as factories and warehouses where structural integrity is critical.

Transportation infrastructure: this grade is used in the manufacture of transportation infrastructure, including train stations, airports, and highway overpasses.

Structural Components: It is also commonly used in the manufacture of structural components such as columns, beams, and trusses, which form the framework of various structures.

Equipment manufacturing: In the production of heavy equipment and machinery, it can be used for parts that require high-strength structural components.

The manufacturer shall furnish the purchaser with a certificate of compliance stating that the product was sampled, tested, and inspected in accordance with this specification and any other requirements specified in the purchase order or contract and that all such requirements were met. The certificate of compliance shall include the specific number and year of issuance.

Botop Steel is a high-quality Welded Carbon Steel Pipe manufacturer and supplier from China, also a seamless steel pipe stockist.

Botop Steel has a strong commitment to quality and implements rigorous controls and testing to ensure product reliability. Its experienced team provides personalized solutions and expert support, with a focus on customer satisfaction. We look forward to working with you.