JIS G 3455 steel pipe is produced by seamless steel pipe manufacturing process, mainly used for carbon steel pipe with working temperature below 350℃ environment, mainly used for mechanical parts.

Navigation Buttons

Size Range

Grade Classification

Manufacturing Processes

Heat Treatment

Pipe End Type

Chemical Components of JIS G 3455

Mechanical Property of JIS G 3455

Hydrostatic Test or Nondestructive Test

JIS G 3455 Steel Pipe Weight Chart and Pipe Schedules

JIS G 3455 Dimensional Tolerances

Appearances

Marking

Applications of JIS G 3455 Steel Pipe

JIS G 3455 Equivalent Standards

Our Related Products

Size Range

Pipe outside diameter: 10.5-660.4mm (6-650A) (1/8-26B)

A=DN; B=NPS.

Grade Classification

JIS G 3455 has three grades according to the minimum tensile strength of the pipe, namely STS370, STS410, and STS480.

Manufacturing Processes

Pipes shall be manufactured seamlessly from killed steel.

Final molding is divided into two types, hot-finished and cold-finished, depending on the outside diameter and wall thickness.

| Symbol of grade | Symbol of the manufacturing process | |

| Pipe manufacturing process | Finishing method | |

| STS370 STS410 STS480 |

Seamless: S | Hot-finished: H Cold-finished: C |

Heat Treatment

| Symbol of grade | Hot-finished seamless steel pipe |

Cold-finished seamless steel pipe |

| STS370 STS410 |

As manufactured. However, low-temperature annealing or normalizing may be applied as necessary. |

Low temperature annealed or normalized |

| STS480 | Low temperature annealed or normalized | |

Heat treatments other than those given in the table may be performed by agreement between the purchaser and the manufacturer.

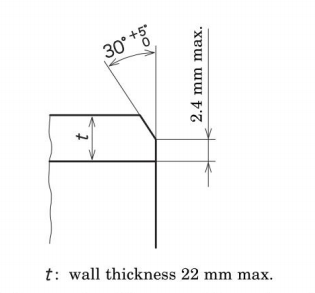

Pipe End Type

Pipes shall be finished with flat ends.

If a beveled end is specified, the tapered end shape of pipes with wall thickness ≤ 22 mm shall conform to 30-35°, and the bevel width of the steel pipe edge is max 2.4mm.

Chemical Components of JIS G 3455

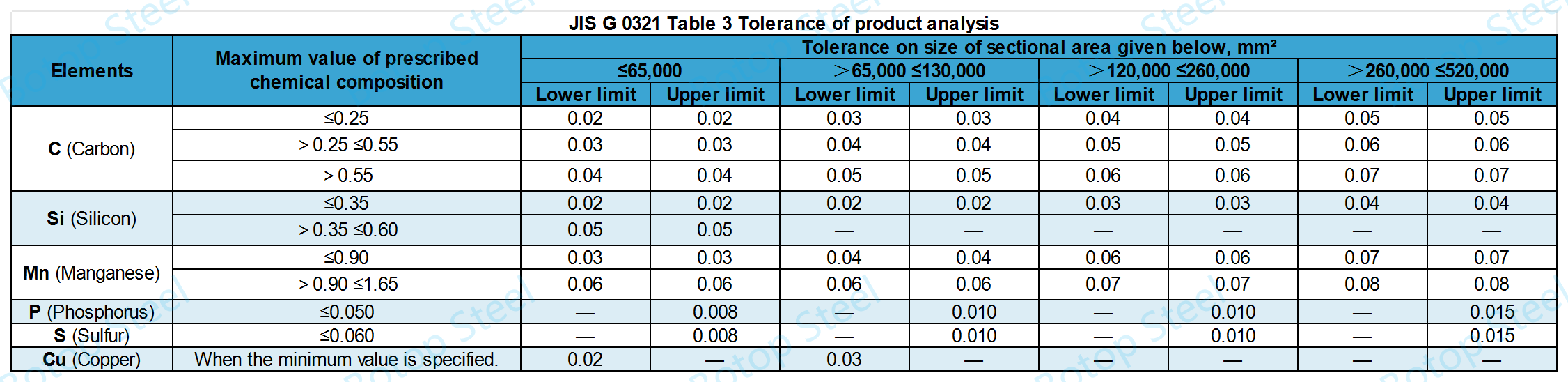

The heat analysis shall be in accordance with JIS G 0320. The product analysis shall be in accordance with JIS G 0321.

Thermal analysis values shall conform to the following requirements:

| Symbol of grade | C (Carbon) | Si (Silicon) | Mn (Manganese) | P (Phosphorus) | S (Sulfur) |

| max | max | max | |||

| STS370 | 0.25% | 0.10-0.35% | 0.30-1.10% | 0.35% | 0.35% |

| STS410 | 0.30% | 0.10-0.35% | 0.30-1.40% | 0.35% | 0.35% |

| STS480 | 0.33% | 0.10-0.35% | 0.30-1.50% | 0.35% | 0.35% |

The analyzed values of the product should not only meet the values in the table, but the tolerance range of each element should be in accordance with the requirements of Table 3 of JIS G 3021.

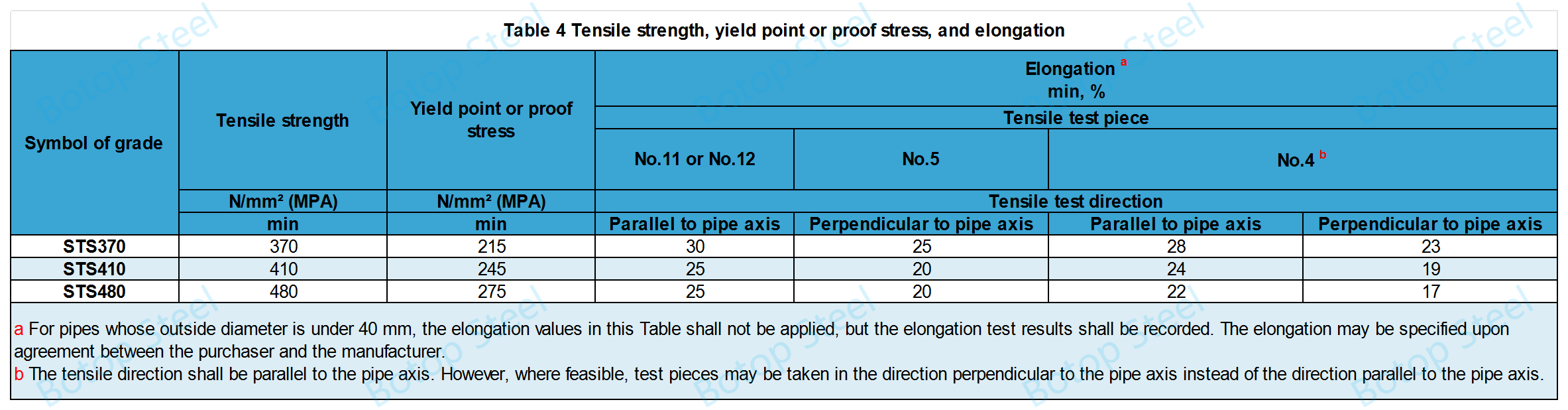

Mechanical Property of JIS G 3455

The general requirements for mechanical tests shall be in accordance with clauses 7 and 9 of JIS G 0404. Sampling methods for mechanical tests shall be in accordance with Class A of JIS G 0404, Clause 7.6.

Tensile Strength, Yield Point or Proof Stress, and Elongation

The test method shall be in accordance with the standards in JIS Z 2241.

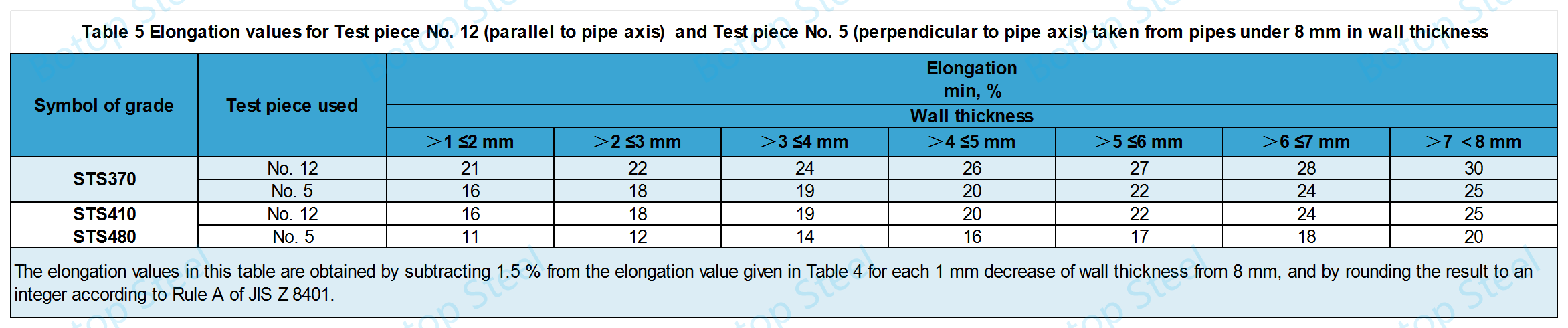

For pipes subjected to tensile testing using specimen No. 12 or No. 5, the elongation shall meet the requirements of Table 5.

Flattening Resistance

The test may be omitted at the discretion of the manufacturer as long as the pipes satisfy the specified flattening resistance.

The specimen is placed between two platforms and flattened in compression until the distance H between the platforms reaches the specified value. The specimen is then checked for cracks.

H=(1+e)t/(e+t/D)

H: distance between platens (mm)

t: wall thickness of pipe (mm)

D: outside diameter of pipe (mm)

е: constant defined for each grade of pipe: 0.08 for STS370, 0.07 for STS410 and STS480.

Bendability Test

Applicable to pipes with outside diameter ≤50 mm as specified by the buyer.

The specimen shall be free of cracks when bent at an angle of 90° with an inside diameter of 6 times the outside diameter of the pipe. The bending angle shall be measured at the beginning of the bend.

Hydrostatic Test or Nondestructive Test

A hydrostatic or non-destructive test shall be performed on each pipe.

Hydrostatic Test

Hold the pipe at not less than the specified minimum hydrostatic test pressure for at least 5 seconds and check that the pipe can withstand the pressure without leakage.

When the Purchaser does not specify the test pressure, and when the pipe is subjected to the minimum hydrostatic test pressure given, the pipe shall be able to withstand it without leakage.

| Nominal wall thickness | 40 | 60 | 80 | 100 | 120 | 140 | 160 |

| Minimum hydraulic test pressure, Mpa | 6.0 | 9.0 | 12 | 15 | 18 | 20 | 20 |

When the wall thickness of the outer diameter of the steel pipe is not a standard value in the table of weight of the steel pipe, it is necessary to use the formula to calculate the pressure value.

P=2st/D

P: test pressure (MPa)

t: wall thickness of pipe (mm)

D: outside diameter of pipe (mm)

s: 60 % of the minimum value of yield point or proof stress given.

When the minimum hydrostatic test pressure of the selected plan number exceeds the test pressure P obtained by the formula, the pressure P shall be used as the minimum hydrostatic test pressure instead of selecting the minimum hydrostatic test pressure in the table above.

Nondestructive Test

The pipeline shall be inspected by ultrasonic detection or eddy current detection.

For ultrasonic detection characteristics, the signals of reference samples containing UD class reference standards specified in JIS G 0582 shall be considered as alarm level, and no signal equal to or greater than the alarm level shall exist.

For eddy current detection characteristics, the signal of the reference sample containing the reference standard of class EY as specified in JIS G 0583 shall be considered as alarm level, and no signal equal to or greater than the alarm level shall exist.

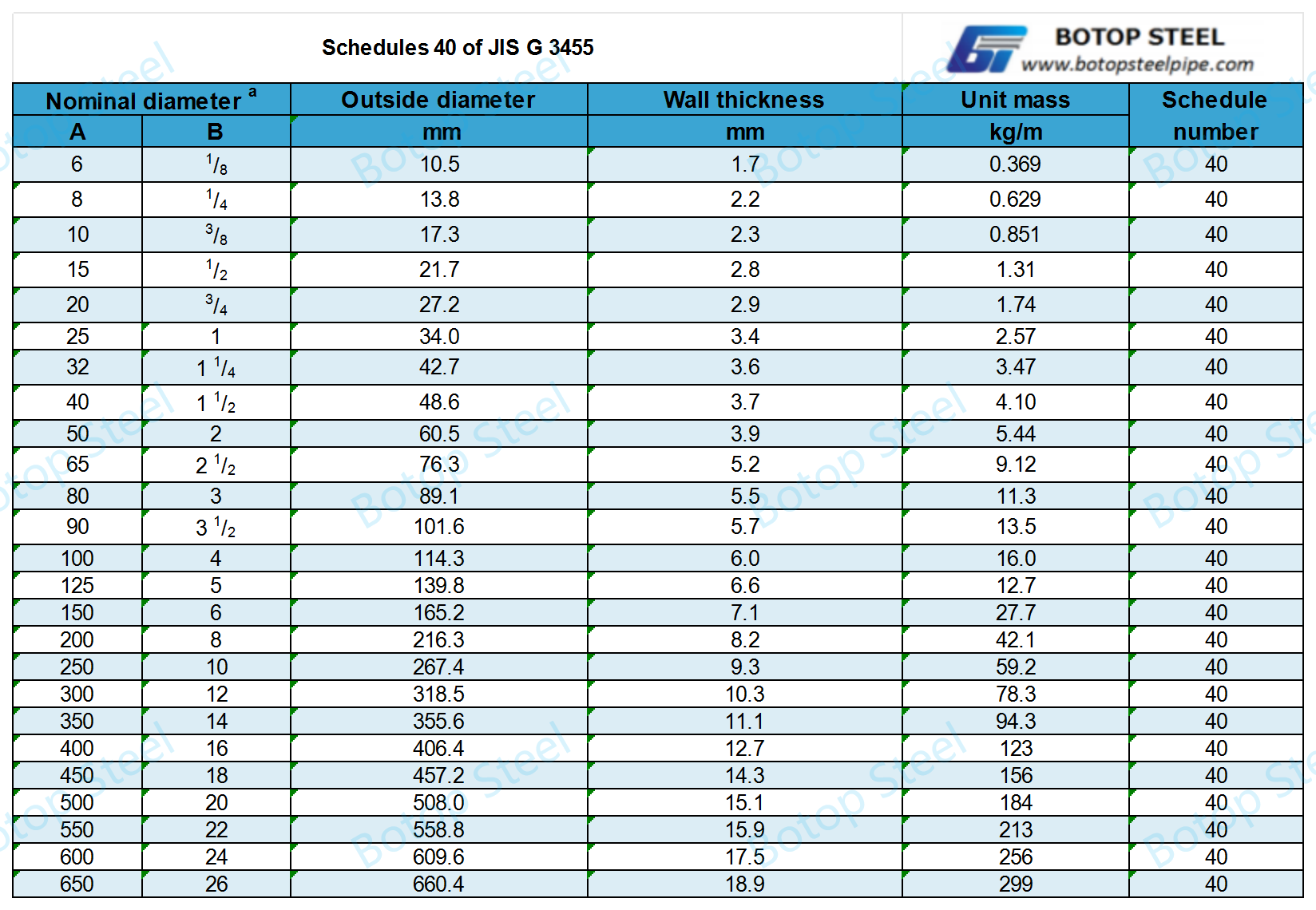

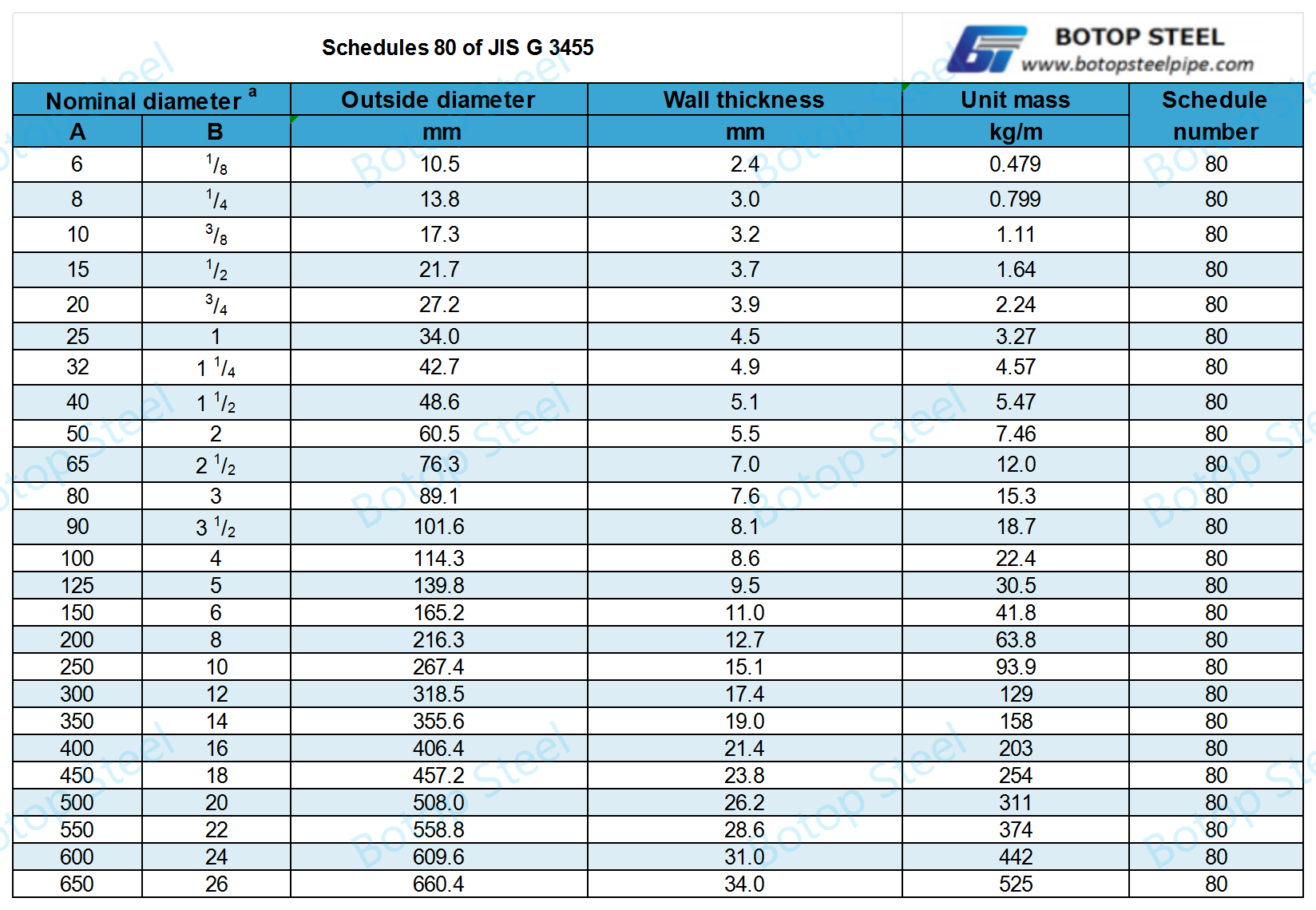

JIS G 3455 Steel Pipe Weight Chart and Pipe Schedules

Steel Pipe Weight Chart

In the case of dimensions not specified in the pipe weight tables, the formula can be used to calculate them.

W=0.02466t(D-t)

W: unit mass of pipe (kg/m)

t: wall thickness of pipe (mm)

D: outside diameter of pipe (mm)

0.02466: conversion factor for obtaining W

Assume a density of 7.85 g/cm³ for the steel tube and round the result to three significant figures.

Pipe Schedules

The standard specifies five ratings of Schedule 40, 60, 80, 100, 120, and 160.

For your convenience, here are the most commonly used schedule 40 and schedule 80.

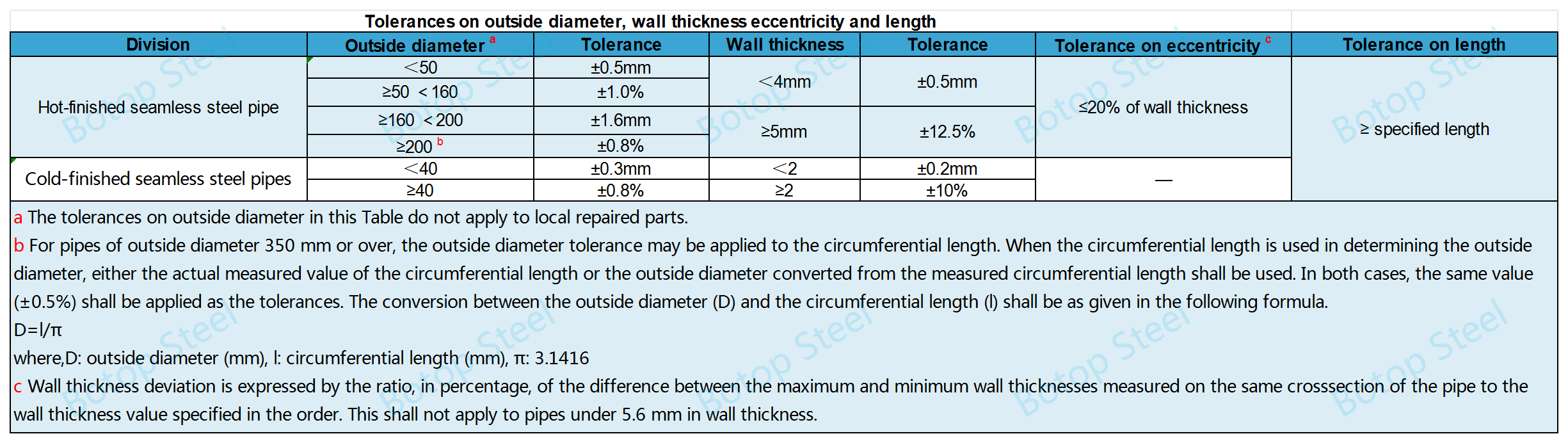

JIS G 3455 Dimensional Tolerances

Appearances

The internal and external surfaces of the pipe shall be smooth and free from defects unfavorable to use.

The ends of the steel pipe shall be at right angles to the axis of the pipe.

Marking

Each tube shall be labeled with the following information.

a) Symbol of grade;

b) Symbol of the manufacturing method;

Hot-finished seamless steel pipe: -S-H

Cold-finished seamless steel pipe: -S-C

c) Dimensions Example 50AxSch80 or 60.5x5.5;

d) Manufacturer's name or identifying brand.

When the outside diameter of each tube is small and it is difficult to mark each tube, or when the purchaser requires that each bundle of tubes is marked, each bundle may be marked by an appropriate method.

Applications of JIS G 3455 Steel Pipe

Mechanical manufacturing: Due to its high strength and high-temperature resistance, it is used in the manufacture of a variety of mechanical parts, such as parts for hydraulic systems and high-pressure fuel injection systems.

Industrial piping systems: Widely used in industrial applications that require high-pressure carrying capacity, such as piping in chemical plants, refineries, and other processing plants. They are capable of safely transporting high-pressure steam, water, oil, and other chemicals.

Power plants: Used in critical components such as boilers and superheaters that are subjected to high temperature and high-pressure operating conditions.

Building and construction: They can be used to support structures or as pressure piping, especially where extra strength and durability are required.

JIS G 3455 Equivalent Standards

ASTM A106 / ASME SA106: Standard-defining seamless carbon steel tubes for high-temperature service, often used in refineries, boilers, and heat exchangers.

DIN 17175: Covers seamless steel tubes and pipes for use in high-temperature conditions and is applicable to high-temperature pressure-resistant applications such as the boiler industry.

EN 10216-2: Covers seamless tubes and pipes of non-alloyed and alloyed steel for use in high-temperature conditions.

GB 5310: Standard for seamless steel tubes and pipes for high-pressure boilers, with technical requirements similar to those of JIS G 3455, also applicable to high-temperature and high-pressure environments.

API 5L: Mainly used for oil and gas transmission lines, its material requirements, and the use of seamless pipe under certain similar conditions.

Our Related Products

Since its establishment in 2014, Botop Steel has become a leading supplier of carbon steel pipe in Northern China, known for excellent service, high-quality products, and comprehensive solutions.

The company offers a variety of carbon steel pipes and related products, including seamless, ERW, LSAW, and SSAW steel pipe, as well as a complete lineup of pipe fittings and flanges.

Its specialty products also include high-grade alloys and austenitic stainless steels,tailored to meet the demands of various pipeline projects.

Tags: JIS G 3455, carbon steel pipe, STS, seamless.

Post time: May-14-2024