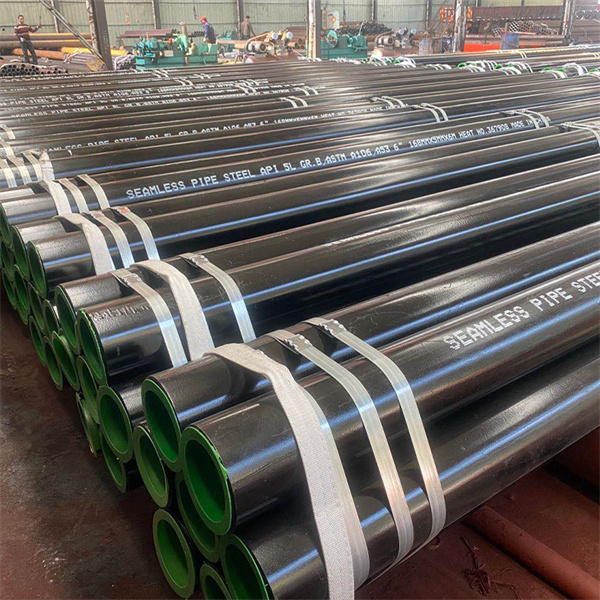

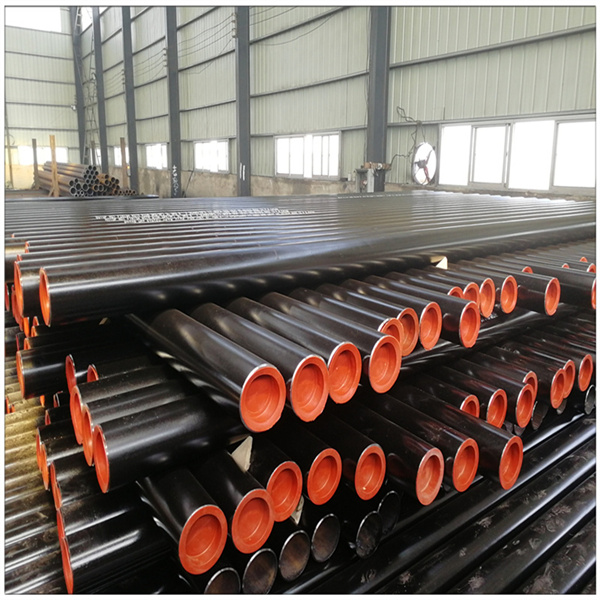

| Product Name | seamless steel pipes |

| Material/Grade | 1010,1026,X42,X46,X52,X56,X60,X70,ASTM A106,ST52,ST37,ST45,ST45. |

| Standard | API,ASTM A530,ASTM A519,ASTM A53/A106 |

| Outter Diameter (OD) | 13.7-762mm |

| Thickness | 2-80mm |

| Length | 1-12m, Fixed length, random length or as required |

| Test | Chemical Component Analysis,Mechanical Properties, Technical Properties, ExteriorSize, Nondestructive Testing |

| Advantages | Competitive price, Quality assurance, Short delivery time, Superior Service,Minimum quantity is small |

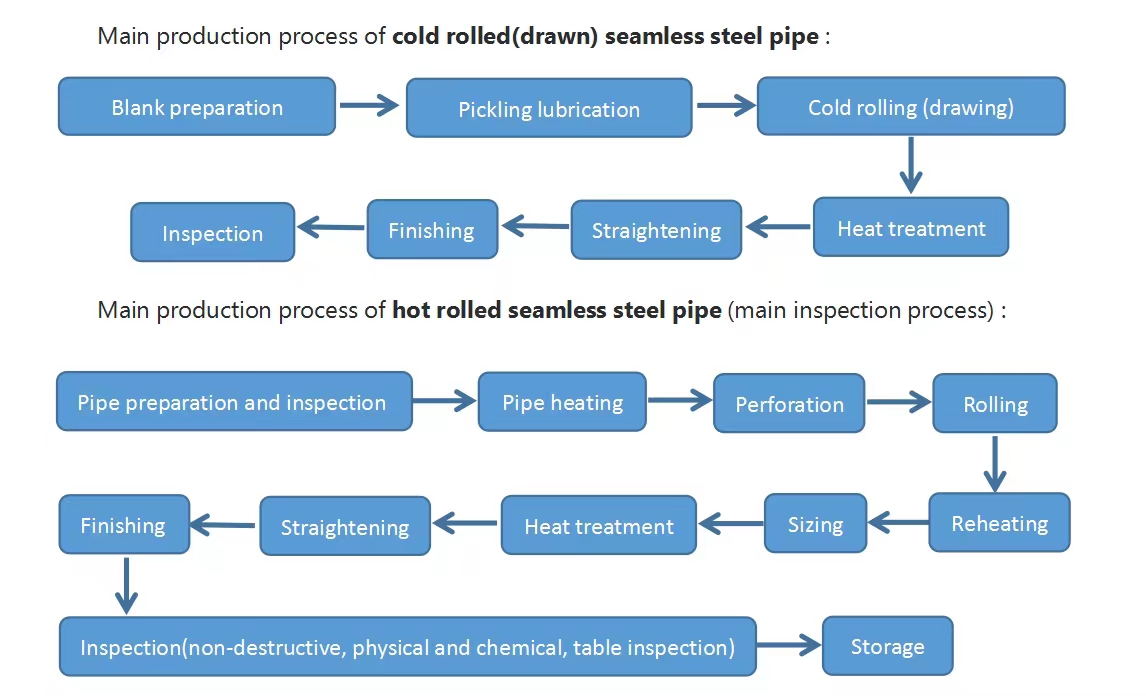

| Technique | Hold Rolled |

| Standard | ASTM AISI DIN JIS GB EN |

| Application | Construction, Industry, decoration and foodstuff etc. |

| Monthly Supply | 5000 Tons |

| Delivery Time | 7-10 Working Days after Deposit |

| Package | Plywood Case/Pallet or Other Export Package Suitable for Long Distance Shipping |

|

Grade and Chemical Composition (%) For API 5L PSL1 |

|||||

|

Standard |

Grade |

Chemical composition(%) |

|||

|

C |

Mn |

P |

S |

||

| API 5L |

B |

≤0.28 |

≤1.20 |

≤0.030 |

≤0.030 |

|

B |

≤0.26 |

≤1.20 |

≤0.030 |

≤0.030 |

|

|

Mechanical Properties of API 5L GR.B Seamless Line Pipe (PSL1) |

||||

|

Yield Strength(MPa) |

Tensile Strength(MPa) |

Elongation A% |

||

|

psi |

MPa |

psi |

MPa |

Elongation (Min ) |

|

35,000 |

241 |

60,000 |

414 |

21~27 |

|

Mechanical Properties of API 5L GR.B Seamless Line Pipe (PSL2) |

|||||

|

Yield Strength(MPa) |

Tensile Strength(MPa) |

Elongation A% |

Impact (J) |

||

|

psi |

MPa |

psi |

MPa |

Elongation (Min ) |

Min |

|

241 |

448 |

414 |

758 |

21~27 |

41(27) |

|

35,000 |

241 |

65,000 |

448 |

21~27 |

41(27) |

NDT(UT) Testing

Bend Testing

Mechanical Properties Testing