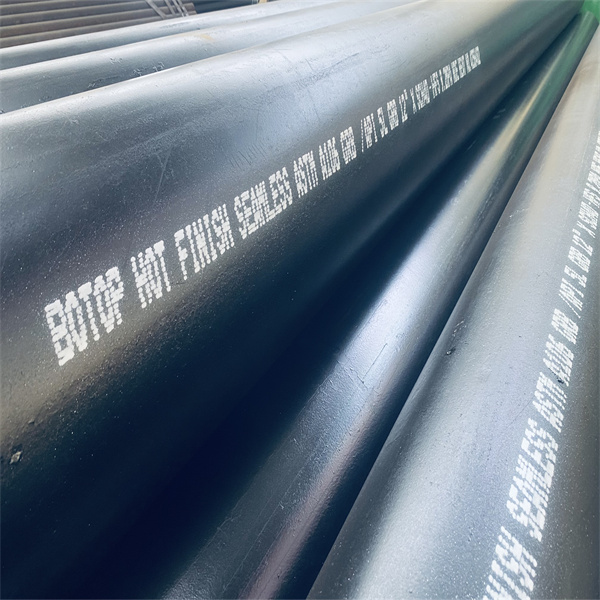

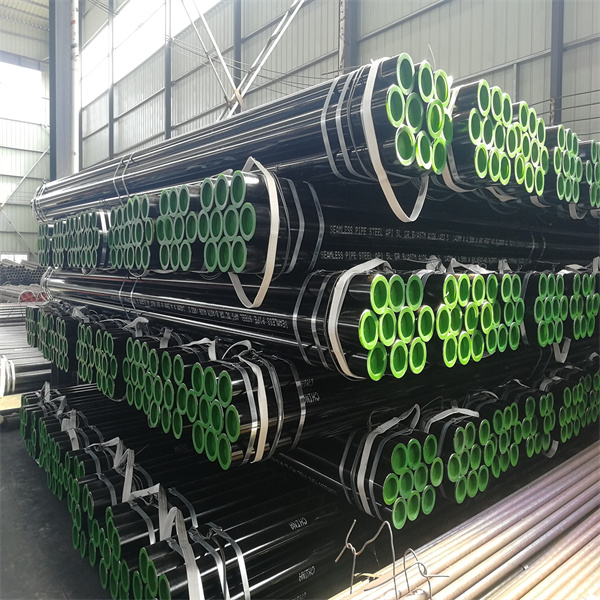

| Product Name | Carbon Steel Seamless / Ms Steel Pipe |

| Standard | ASTM A106,ASTM A53,API 5L Gr.B, DIN17175,DIN1629 |

| Outer Diameter: | 13.7mm-762mm |

| Wall Thickness | 2mm-80mm |

| Dia Tolerance | Control with in the standard, OD:+-1%,WT:+-10% |

| Materials | 10#,20#,45#,16Mn,A106(B,C),A53(A,B),API 5L (GR.B,X42/X52/X56/X65) API 5CT(H40,J55,K55,N80,P110),Q235,Q345,ST35.8,ST37,ST42,ST45,ST52 |

| Inspection | ISO,BV,SGS,MTC |

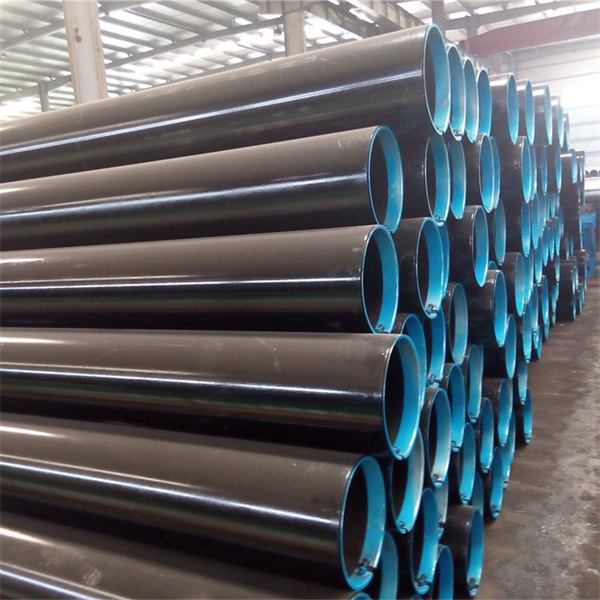

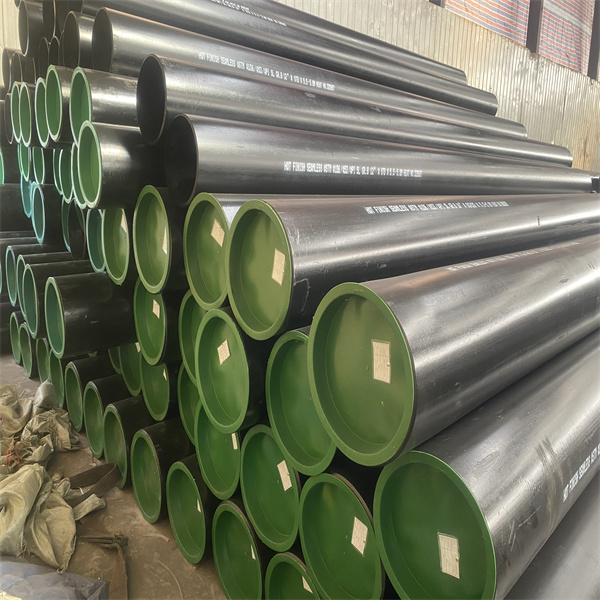

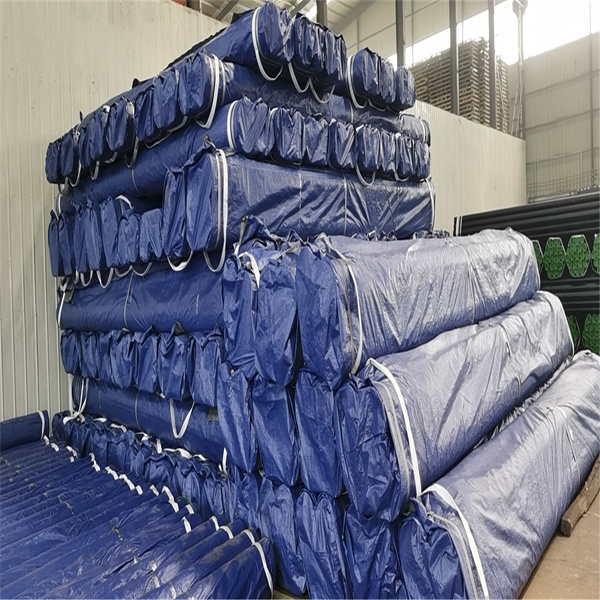

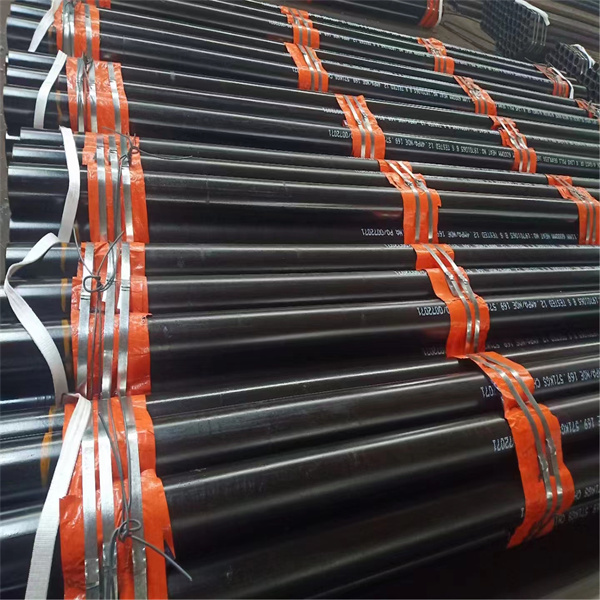

| Packing | 3LPE/3PP/FBE/BLACK painting/Varnish, and steel strip packed,Standard Export Seaworthy Package,or as required |

| Supply Ability | 1000 metric tons/month |

| MOQ | 5metric ton,sample order accepted |

| Shipment time | Within 7-10 workdays after receiving deposit or L/C |

| Payments | T/T,LC |

| Capacity | 250,000 tons/year |

Pipe ordered under this specification is used mainly for piping subjected to a temperature over 350℃。For example: transporting steam,water etc.

Bare pipe, black coating ( customized);

6" and below sizes In bundles with two cotton slings, other sizes in loose;

Both ends with end protectors;

Plain end, bevel end;

Marking.

Pipe End Beveling

Plastic Caps

Black Painting with Marking

Wrapper

Bundling and Sling

Package Appearance

Grade and Chemical Composition (%)

|

Grade |

C≤ |

Si |

Mn |

P≤ |

S≤ |

|

STPT370 |

0.25 |

0.10~0.35 |

0.30~0.90 |

0.035 |

0.035 |

|

STPT410 |

0.30 |

0.10~0.35 |

0.30~1.00 |

0.035 |

0.035 |

|

STPT480 |

0.33 |

0.10~0.35 |

0.30~1.00 |

0.035 |

0.035 |

|

Mechanical Properties |

||||||

|

Grade |

Tensile strength |

Yield strength |

Elongation % |

|||

|

N/ m㎡ |

N/ m㎡ |

No.11 or No.12 test pieces |

No. 5 test pieces |

No. 4 test piece |

||

|

Longitudinal |

Transverse |

Longitudinal |

Transverse |

|||

|

STPT370 |

370 min |

215 min |

30 min |

25 min |

28 min |

23 min |

|

STPT410 |

410 min |

245 min |

25 min |

20 min |

24 min |

19 min |

|

STPT480 |

480 min |

275 min |

25 min |

20 min |

22 min |

17 min |

| 1. The above elongation value is not applicable to tubes with outer diameter <40mm. But it must be recorded.2. The sample meets the requirements of JIS Z2201 standard;

3. For the tube with wall thickness <8mm, when the sample No. 12 or No. 5 is used, the minimum value of the elongation is reduced by 1mm according to the wall thickness, and 1.5% is subtracted from the above value. |

||||||

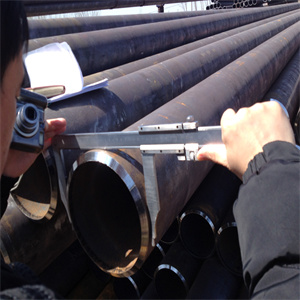

Out Diameter Inspection

Wall Thickness Inspection

End Inspection

Straightness Inspection

Seamless Pipe ship to Ecuador

UT Inspection

Appearance Inspection

-

- Tolerance of OD and W.T

Division

Tolerance on O.D

Tolerance on W.T

Hot finished Seamless Steel Pipe

D<50m

±0.5 mm

S<4mm

S≥4mm

±0.5mm

±12.5%

50mm≤D<160mm

±1%

160mm≤D<200

±1.6 mm

D≥200mm

±0.8%

Cold finished Seamless Steel Pipe

D<40m

±0.3 mm

S<2mm

±0.2mm

D≥40mm

±0.8%

S≥2mm

±10%

ERW Steel Pipe D<40m

±0.3 mm

S<2mm

±0.2mm

D≥40mm

±0.8%

S≥2mm

±10%

For pipes of nominal size 350A or over,the tolerance on O.D maybe determined by the circumferential length. In this case,the tolerance shall be +/-0.5%

- Tolerance of OD and W.T

Seamless Pipe Ship to Qatar