Grade and Chemical Composition (%)

|

Grade |

C≤ |

Si |

Mn |

P≤ |

S≤ |

Cr |

Mo |

|

SCM 420TK |

0.18~ 0.23 |

0.15~ 0.35 |

0.60~ 0.85 |

0.030 |

0.030 |

0.90~ 1.20 |

- |

|

SCM 415TK |

0.13~ 0.18 |

0.15~ 0.35 |

0.60~ 0.85 |

0.030 |

0.030 |

0.90~ 1.20 |

0.15~ 0.30 |

|

SCM 418TK |

0.16~ 0.21 |

0.15~ 0.35 |

0.60~ 0.85 |

0.030 |

0.030 |

0.90~ 1.20 |

0.15~ 0.30 |

|

SCM 420TK |

0.18~ 0.23 |

0.15~ 0.35 |

0.60~ 0.85 |

0.030 |

0.030 |

0.90~ 1.20 |

0.15~ 0.30 |

|

SCM 430TK |

0.28~ 0.33 |

0.15~ 0.35 |

0.60~ 0.85 |

0.030 |

0.030 |

0.90~ 1.20 |

0.15~ 0.30 |

|

SCM 435TK |

0.33~ 0.38 |

0.15~ 0.35 |

0.60~ 0.85 |

0.030 |

0.030 |

0.90~ 1.20 |

0.15~ 0.30 |

|

SCM 440TK |

0.38~ 0.43 |

0.15~ 0.35 |

0.60~ 0.85 |

0.030 |

0.030 |

0.90~ 1.20 |

0.15~ 0.30 |

| Note: 1. Ni as an impurity in various steel pipes does not exceed 0.25%, and Cu does not exceed 0.30%; 2. When the purchaser requests the analysis of the finished product, the allowable deviation is as specified in Table 3 of JIS G0321. | |||||||

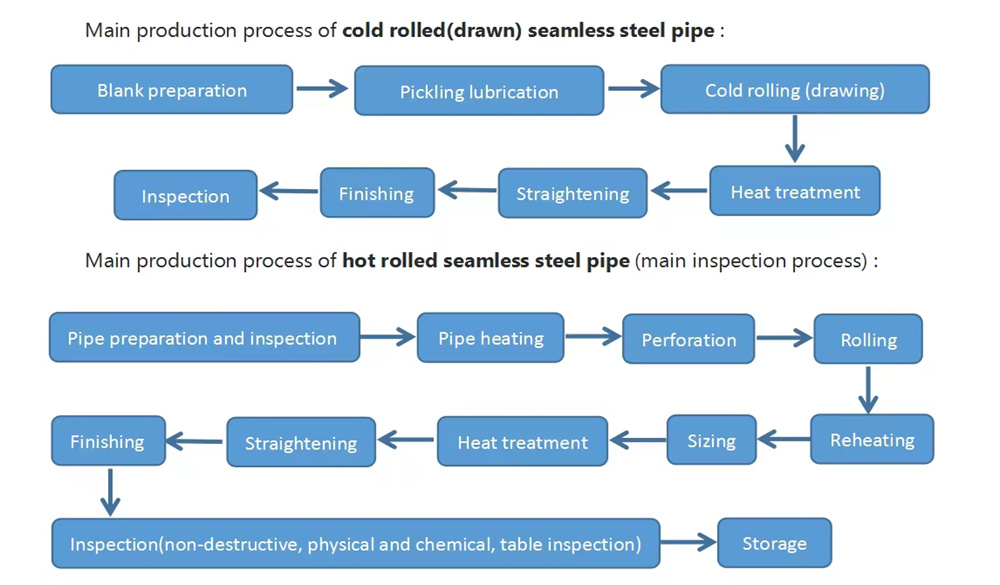

Manufacture:seamless pipe (hot finished and cold finished)

Size: O.D.: 15.0~114mm W.T.: 2~20mm

Grade: SCM 415TK,SCM 420 TK.

Length: 6M or specified length as required.

Ends: Plain End, Beveled End.

Grade

Manufacture method code(hot finished seamless steel pipe: S-H; Cold finished seamless steel pipe: S-C)

Dimensions(nominal diameter X nominal wall thickness or outside diameter X wall thickness)

Manufacturer's name or its identifying brand

-

- Tolerance of OD and W.T

Division

Tolerance on O.D

Tolerance on W.T

Class 1

D<50m

±0.5 mm

S<4mm

+0.6mm

-0.5mm

50mm≤D

±1%

S≥4mm

+1% -12.5%

Class 2

D<50m

±0.25mm

S<3mm

±0.3mm

50mm≤D

±0.5%

S≥3mm

±10%

Class 3

D<25m

±0.12 mm

S<2mm

±0.15mm

40mm>D≥25mm

±0.15 mm

50mm>D≥40mm

±0.18 mm

S≥2mm

±8%

60mm>D≥50mm

±0.20 mm

Notes: tolerance on each wall thickness shall be rounded off to one decimal place in accordance with rule a JIS Z 8401

70mm>D≥60mm

±0.23mm

80mm>D≥70mm

±0.25 mm

90mm>D≥80mm

±0.30mm

100mm>D≥90mm

±0.40 mm

D≥100mm

±0.50%

1. The OD tolerance of hot finish seamless steel pipe according to Class1 2. Quenched and tempered steel pipes according to 4 categories.

- Tolerance of OD and W.T