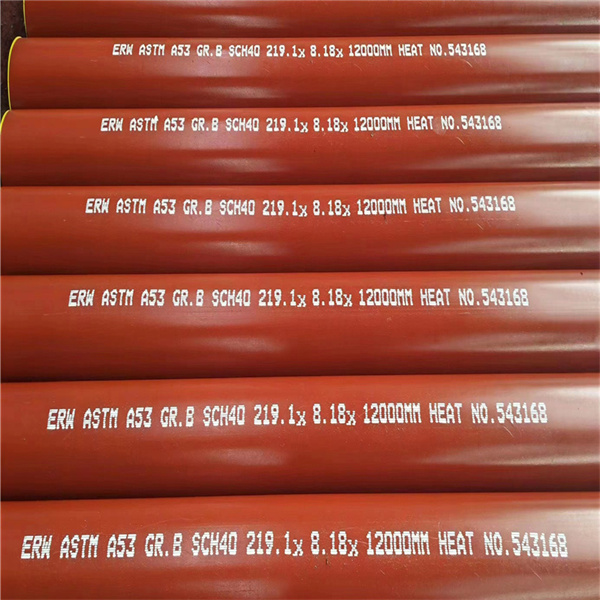

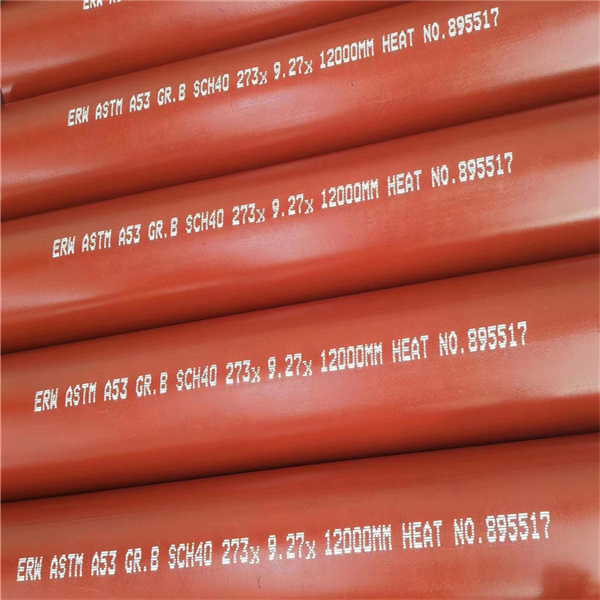

| Product name | Carbon welded Steel Pipe | |

| Technique | Longitudinal Electronic Resistance Welding(ERW) ; High Frequence Welding (HFW) | |

| Standard | API5L, BS1387,ASTM A53/A106,EN10219,EN10210,EN10255,JIS G3452,JIS G3454,etc | |

| Material Quality | Steel Grade | GR.B,S275JRH,S275JOH,X42,X52,S355J0H |

| Size | W.T | 1.5mm-16mm |

| Outer Diameter | 26.7mm-660mm | |

| Length | 1m-12m or as your requirement | |

| Surface | Galvanized, 3PE, painting, coating oil, steel stamp, etc. | |

| Ends | Plain ends, cutting, threaded with coupling, beveled, flange, etc. | |

| Inspection | With Chemical Composition and Mechanical Properties Testing; Hydrostatic Test, Dimensional and Visual Inspection, With Nondestructive Inspection | |

| Certification | BV, ISO, CE or as per customer. | |

| Application | construction pipe, structure pipe, Greenhouse pipe, Building material tube, Furniture tube, etc |

|

| Trade Terms | FOB,CFR,CIF, CNF. | |

| Payment Terms | T/T,L/C at sight 30%T/T in advance,balance 70% should be paid after receiving the copy of BL | |

| Loading Port | Tianjin Port | |

Grade and Chemical Composition (%)

|

Grade |

C |

Mn |

P≤ |

S≤ |

Cu |

Ni |

Cr |

Mo |

V |

|

Type S (Seamless pipe) |

|||||||||

|

Grade A |

0.25 |

0.95 |

0.05 |

0.045 |

0.40 |

0.40 |

0.40 |

0.15 |

0.08 |

|

Grade B |

0.3 |

1.2 |

0.05 |

0.045 |

0.40 |

0.40 |

0.40 |

0.15 |

0.08 |

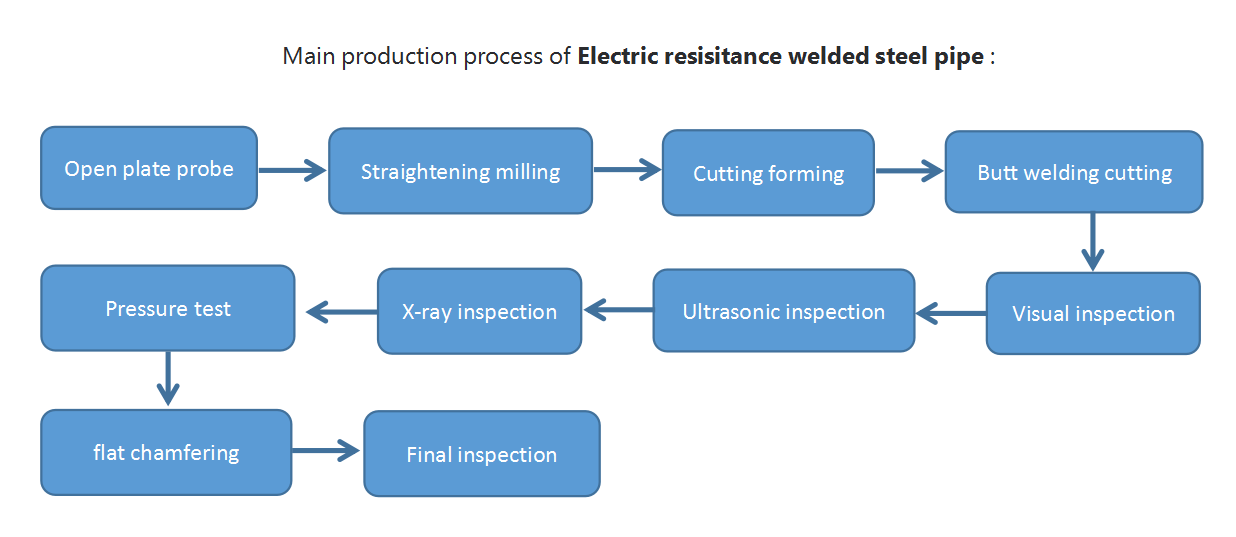

Tensile testing of the pipe body—The tensile test should be carried out in accordance with ISO6892 or ASTM A370. Longitudinal samples should be used. Twice per test unit of pipe with the same cold-expansion ratio a.b.d.

Flattening Test—One flattening test shall be made on specimens from each end of two tubes selected from each lot.

Bending Test— a sufficient length of pipe shall stand being bent cold through 90° around a cylindrical mandrel.

Nondestructive electric test-as an alternative to the hydro-static test, the full body of each pipe shall be tested with a nondestructive electric test. Where nondestructive electric test is performed, the lengths shall be marked with the letters"NDE"

Hydro-static Test—Each tube shall be subjected to the hydro-static pressure test.

100% X-ray test for the weld seam.

The ultrasonic testing.

The eddy current examination.

ERW steel pipe in this standard is For mechanical and pressure applications and is also acceptable for ordinary uses in steam, water,gas, and air lines. It is suitable for welding,and suitable for forming operations involving coiling,bending,and flanging.

Tensile Requirements:

|

|

Grade A |

Grade B |

|

Tensile strength, min,psi (MPa) |

48000 (330) |

60000 (415) |

|

Yield strength, min,psi (MPa) |

30000 (205) |

35000 (240) |

Bare pipe, Black / Varnish coating, zinc coated and epoxy coated, etc ( customized);

6" and below in bundles with two cotton slings;

Both ends with end protectors;

Plain end, bevel end(2"and above with bevel ends, degree: 30~35°), threaded and coupling;

Marking.

EN10219 S275J0H S275J2H / S275JRH STRUCTURAL ERW Steel Piles Pipe

ERW Steel Pipes

JIS G3454 Carbon ERW Steel Pipe Pressure Service

EN10210 S355J2H STRUCTURAL ERW STEEL PIPE

JIS G3452 Carbon ERW Steel Pipes For Ordinary Piping