ASTM A210 steel tube is a medium carbon seamless steel tube used as boiler and superheater tubes for high temperature and high-pressure environments, such as in power stations and industrial boilers.

Navigation Buttons

Size Range of ASTM A210

Outer Diameter: 1/2 in(12.7mm)≤ OD ≤5in (127mm)

Wall Thickness: 0.035 in (0.9mm)≤ WT ≤0.500 in (12.7mm)

Tubing having other dimensions may be furnished, provided such tubes comply with all other requirements of this specification.

Raw Materials

Steelmaking Practice--The steel shall be killed.

killed steel refers to the addition of certain amounts of deoxidizers such as silicon, aluminum, and manganese during the melting process of steel.

These additives can react with the oxygen in the steel to produce solid oxides, thus reducing the oxygen content in the steel and preventing the formation of oxidizing inclusions.

ASTM A210 Grade

ASTM A210 is available in two grades: Grade A-1 and Grade C.

ASTM A210 Seamless Steel Tube Production Process

Steel pipes shall be made by the seamless process and shall be hot-finished or cold-finished as specified.

Typically, steel pipes with a diameter greater than 30 millimeters are hot-finished and those with a diameter less than or equal to 30 millimeters are cold-finished. This method of differentiation is not absolute but can be used as a quick and easy way to determine the processing method of seamless steel pipe.

Heat Treatment

Heat treatment is not required for hot-finished tubes.

Cold-finished tubes shall be given a subcritical anneal, a full anneal, or a normalizing heat treatment after the final cold-finishing process.

Chemical Components

| Element | Grade A-1 | Grade C |

| C (Carbon), max A | 0.27 | 0.35 |

| Mn (Manganese) | 0.93 max | 0.29-1.06 |

| P (Phosphorus), max | 0.035 | 0.035 |

| S (Sulfur), max | 0.035 | 0.035 |

| Si (Silicon), min | 0.1 | 0.1 |

| A For each reduction of 0.01 % below the specified carbon maximum, an increase of 0.06 % of manganese above the specified maximum will be permitted up to a maximum of 1.35 %. | ||

These chemical composition requirements ensure that the tubes have adequate strength and temperature resistance.

Mechanical Properties

Mechanical property requirements do not apply to tubing smaller than 1/ 8 in [3.2 mm] in inside diameter or 0.015 in. [0.4 mm] in thickness.

| List | Uint | Grade A-1 | Grade C | |

| Tensile strength, min | ksi | 60 | 70 | |

| MPa | 415 | 485 | ||

| Yield strength, min | ksi | 37 | 40 | |

| MPa | 255 | 275 | ||

| Elongation in50 mm (2 in ), min |

For longitudinal strip tests, a deduction shall be made for each 1/32-in. [0.8-mm] decrease in wall thickness under 5/16 in. [8 mm] from the basic minimum elongation of the following percentage points. | % | 1.5 A | 1.5 A |

| When standard round 2-in. or 50-mm gage length or smaller proportionally sized specimen with the gage length equal to 4D (four times the diameter) is used | 22 | 20 | ||

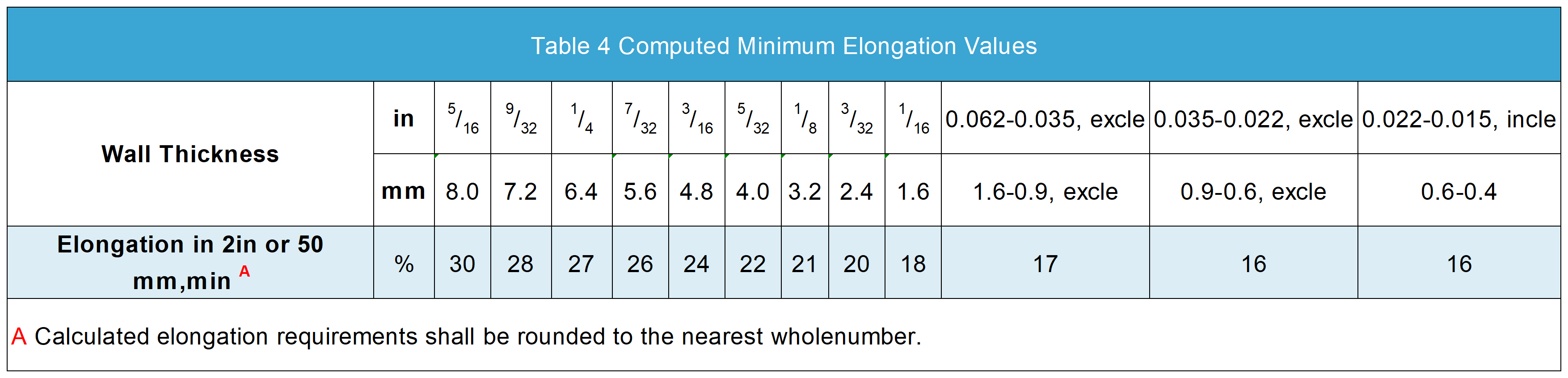

| A See Table 4 for the computed minimum values. | ||||

Table 4 gives the computed minimum elongation values for each 1/32 in. [0.8 mm] decrease in wall thickness.

Where the wall thickness lies between the two values shown above, the minimum elongation value shall be determined by the following equation:

Imperial units(in): E = 48t+15.00

SI unit(mm): E = 1.87t+15.00

where:

E = elongation in 2 in. or 50 mm, %,

t = actual thickness of specimen.

Hardness Test

Brinell or Rockwell hardness tests shall be made on specimens from two tubes from each lot.

ASTM A210 Grade A-1:79-143 HBW

ASTM A210 Grade C: 89-179 HBW

HBW refers to the measurement of Brinell Hardness, where the "W" stands for the use of a carbide ball as an indenter.

Other Experimentation

Flattening Test

Flaring Test

Hydrostatic or Nondestructive Electric Test

Surface Finishing

It can be pickled or blasted, or both, and this part is a matter of agreement, and the choice is based on the agreement between the user and the manufacturer.

Pickling is mainly used to remove oxidized layers and other contaminants from the surface of steel pipes.

Shot blasting is used to clean the surface and enhance its adhesion strength.

These treatments not only affect the surface quality of the pipe but may also affect its final application properties.

Forming Operations

When inserted in the boiler, tubes shall stand expanding and beading without showing cracks or flaws. When properly manipulated, superheater tubes shall stand all forging, welding, and bending operations necessary for application without developing defects.

ASTM A210 Marking

The following should be clearly marked:

Manufacturer's name or logo.

Pipe specification (size, wall thickness, etc.).

Pipe grade.

Type of production of the steel pipe: hot finished or cold finished.

Applications of ASTM A210

Used in the manufacture of small to medium-sized boilers of modest pressure, such as stand-up boilers, sit-down boilers, and other boilers used for industrial or residential heating.

Superheaters are parts of a boiler used to raise the temperature of steam above its boiling point, and ASTM A210 tubes are suitable for the manufacture of these high-temperature parts.

Our Related Products

We are a high-quality welded carbon steel pipe manufacturer and supplier from China, and also a seamless steel pipe stockist, offering you a wide range of steel pipe solutions!

tags: astm 210, boiler, seamless, hot-finished,cold-finished, superheater, suppliers, manufacturers, factories, stockists, companies, wholesale, buy, price, quotation, bulk, for sale, cost.

Post time: Apr-24-2024