Recently, our company received an order involving ASTM A335 P91 seamless steel pipes, which need to be certified by IBR (Indian Boiler Regulations) in order to meet the standards for use in India.

In order to help you have a reference when encountering similar requirements, I have compiled the following detailed description of the IBR certification process. Below is the specific information about the order and the steps involved in the certification process.

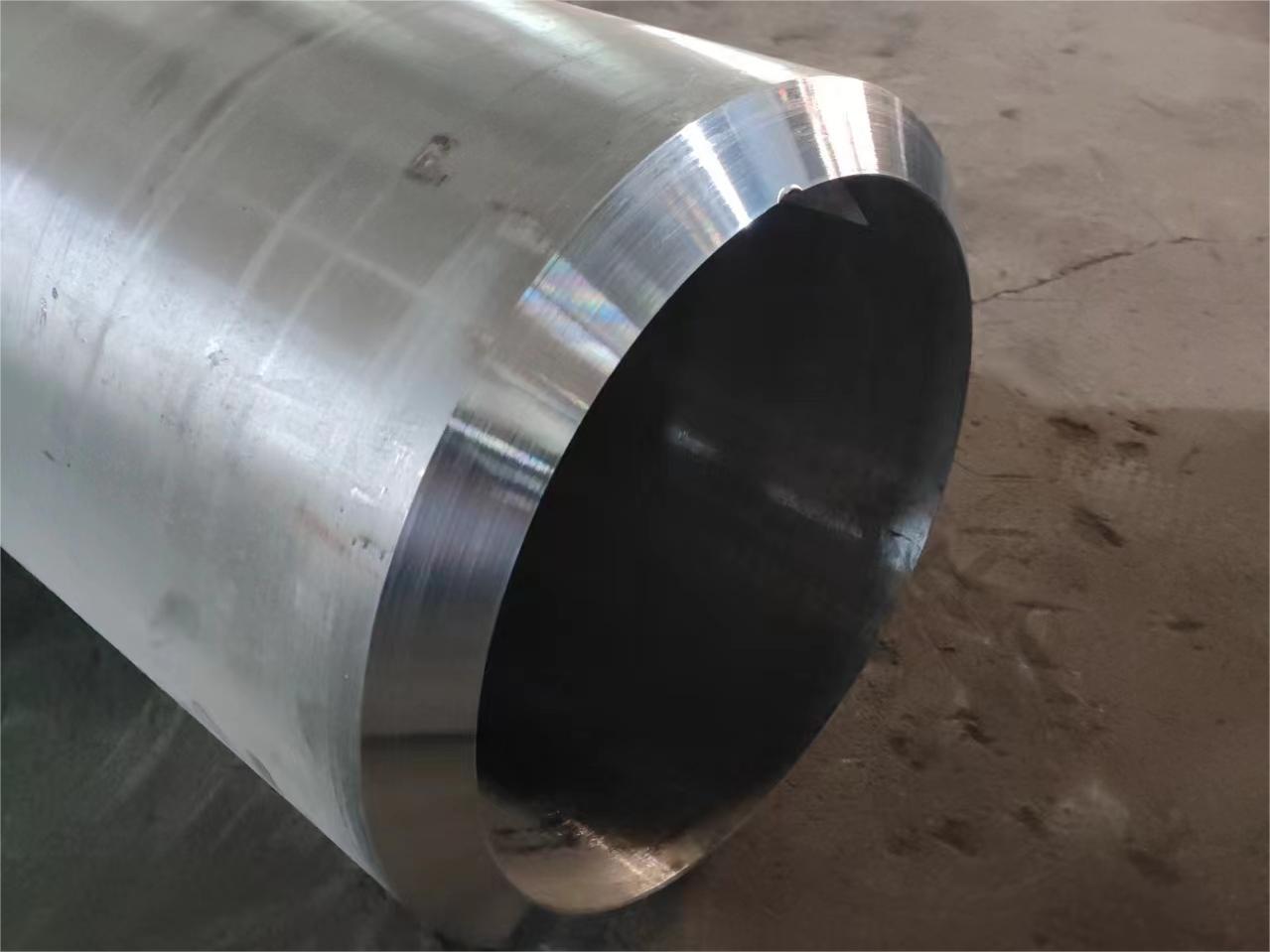

ASTM A335 P91 Seamless Alloy Pipe

Navigation Buttons

Order Details

What is IBR

IBR Certification Process for ASTM A335 P91 Seamless Pipes

1. Contact Inspection Agency with Details

2. Submission of Preliminary Documents

3. Supervision of the Manufacturing Process

4. Finished Product Inspection and Testing

5. Provision of Process Documentation

6. Review of Documents

7. IBR markers

8. IBR Certificate Issuance

Role of Obtaining IBR Accreditation

About Us

Order Details

Project use place: India

Product name: seamless alloy steel pipe

Standard material: ASTM A335 P91

Specification: 457.0×34.93mm and 114.3×11.13mm

Packing: Black paint

Requirement: Seamless alloy steel pipe should have IBR certification

What is IBR

IBR (Indian Boiler Regulations) is a set of detailed regulations for the design, manufacture, installation, and inspection of boilers and pressure vessels, which have been formulated and enforced by the Central Boiler Board of India to ensure the safety of boilers and pressure vessels used in India. All related equipment exported to India or used in India must follow these regulations.

IBR Certification Process for ASTM A335 P91 Seamless Pipes

Below are the detailed steps to obtain an IBR certificate, explaining the entire process in a clear and simple way:

1. Contact Inspection Agency with Details

Selection of Inspection Agency

After being informed of the client's specific requirements, select and contact an IBR-authorized inspection agency to ensure compliance and professionalism.

Common inspection organizations include TUV, BV, and SGS.

For this order, we chose TUV as the inspection organization to ensure that the inspection work of our project meets a high standard of quality.

Discuss Details

Discuss in detail with the inspection organization about the timing of the inspection, key witness points and documents to be prepared, etc. to ensure that the whole process runs smoothly.

2. Submission of Preliminary Documents

Submission of design documents, production processes, material certificates, and product specifications to the inspection agency, which are the basis for subsequent inspections.

3. Supervision of the Manufacturing Process

Typically, this step involves an inspector supervising the various processes involved in production, such as material selection, welding, and heat treatment.

Since this order is for finished steel pipe, there is no manufacturing supervision involved.

4. Finished Product Inspection and Testing

Appearance and Dimensional Inspection

The appearance and dimensions of the tubes are scrutinized to ensure that there are no visible defects and that they meet the specifications.

Typical test items are appearance, diameter, wall thickness, length, and bevel angle.

Outside Diameter

Wall Thickness

Non-Destructive Testing

This time, ultrasonic testing (UT) was used to ensure that there were no defects in the steel pipe.

Non-destructive testing - UT

Non-destructive testing - UT

Mechanical Properties Testing

Tensile tests are conducted to test the tensile strength, yield strength and elongation of the pipe to ensure that its mechanical properties meet the requirements of IBR.

Tensile Properties

Tensile Properties

Chemical Composition Analysis

The chemical composition of the steel pipe is checked by spectral analysis technique and compared with ASTM A335 P91 standard to confirm its compliance with the requirements.

5. Provision of Process Documentation

Provide calibration certificates and detailed lab reports for all testing equipment to ensure that the information provided to IBR is complete and reliable.

6. Review of Documents

The IBR reviewer will thoroughly review all documentation submitted to ensure that the pipe and related information is in full compliance with IBR regulations.

7. IBR markers

Marking

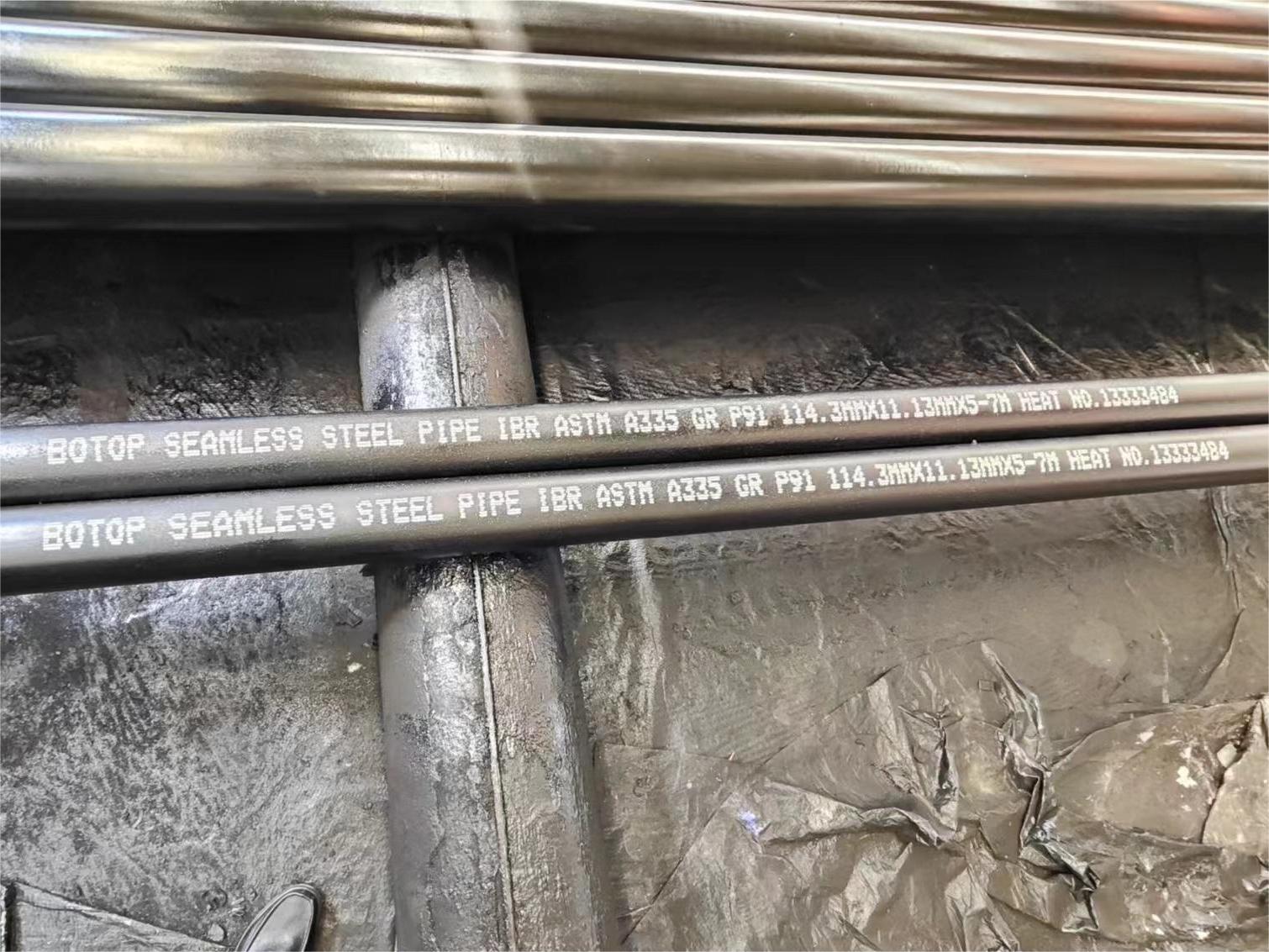

Pipe that meets the requirements will be marked with the IBR certification mark, indicating that it has passed the necessary tests and examinations.

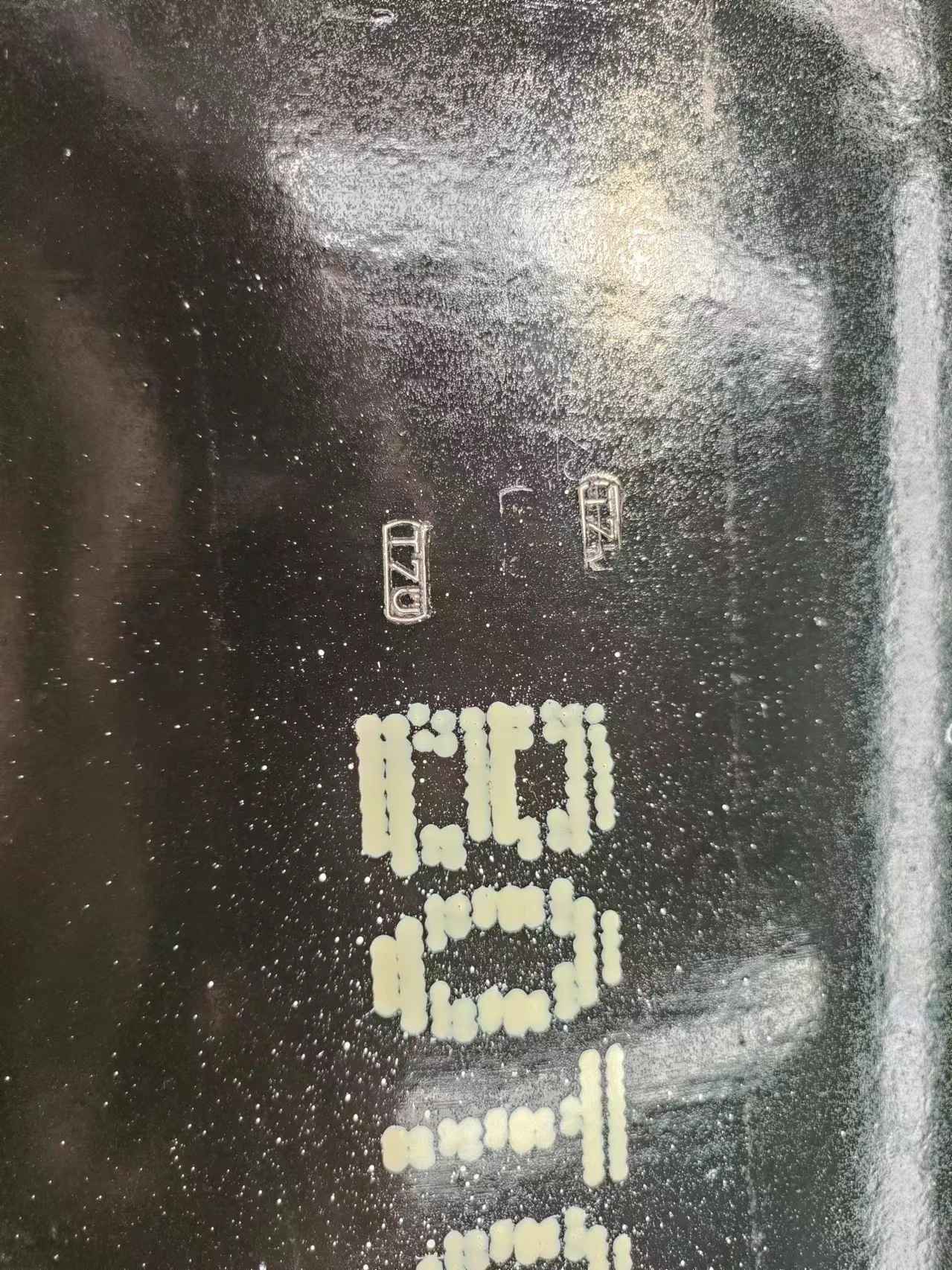

Steel Stamp

Steel stamp is a durable marking method, which not only ensures the durability of the mark but also facilitates identification and acceptance during transportation, installation, and use.

Pipe marking

Steel Stamp

8. IBR Certificate Issuance

After the pipe has passed all tests, the inspection agency will issue an IBR certificate, which officially certifies that the pipe complies with the IBR regulations.

Following the process described above, tube manufacturers can obtain IBR certification for their products.

Role of Obtaining IBR Accreditation

This not only ensures the market acceptance of their products but also greatly enhances their competitiveness in the Indian market.

About Us

Botop Steel has a strong commitment to quality and implements rigorous controls and testing to ensure product reliability. Its experienced team provides personalized solutions and expert support with a focus on customer satisfaction.

tags: IBR, astm a335, P91,alloy pipe,seamless.

Post time: Apr-22-2024