AS 1074: Steel tubes and tubulars for ordinary service

Navigation Buttons

AS 1074 Standard Overview

| Scope | Specifies requirements for threaded steel tubes and tubular, and plain-end steel tubes suitable for screwing as specified in AS 1722.1 |

| Classifications | Three wall thicknesses of the tube: designated Light, Medium, and Heavy |

| Tube | Can be welded and seamless tubes: length of uniform circular hollow section |

| Screw Threads | Threaded tubes shall comply with AS 1722.1 |

| Outside Diameter | DN 8 to DN 150 inclusive (nominal size) |

| Wall Thickness | 1.8mm-5.4mm |

| coating | Varnish coating, galvanized,3 layers PE, FBE, etc. |

| Related Standards | ISO 65;ISO 3183;ASTM A53;ASTM A106;BS EN 10255;BS 1387;DIN 2440;DIN 2448;JIS G 3452;JIS G 3454;CSA Z245.1;GOST 10704-91;SANS 62-1;API 5L;EN 10217-1;etc. |

AS 1074 Chemical Composition

| chemical composition | scope |

| CE(Carbon equivalent) | ≤0.4 |

| P (Phosphorus) | max 0.045% |

| S (Sulfur) | max 0.045% |

CE(Carbon equivalent) =C+Mn/6

Phosphorus (P) and Sulfur (S): These two elements reduce the toughness and weldability of steel. High phosphorus and sulfur levels may cause steel to become brittle, especially at low temperatures.

Carbon Equivalent (CE): This is a measure of the weldability of steel that takes into account the amount of carbon in the steel as well as other alloying elements (e.g., manganese, chromium, molybdenum, etc.) that affect its weldability. The higher the carbon equivalent, the less weldable the steel is and the more preheating and post-treatment measures are required for welding.

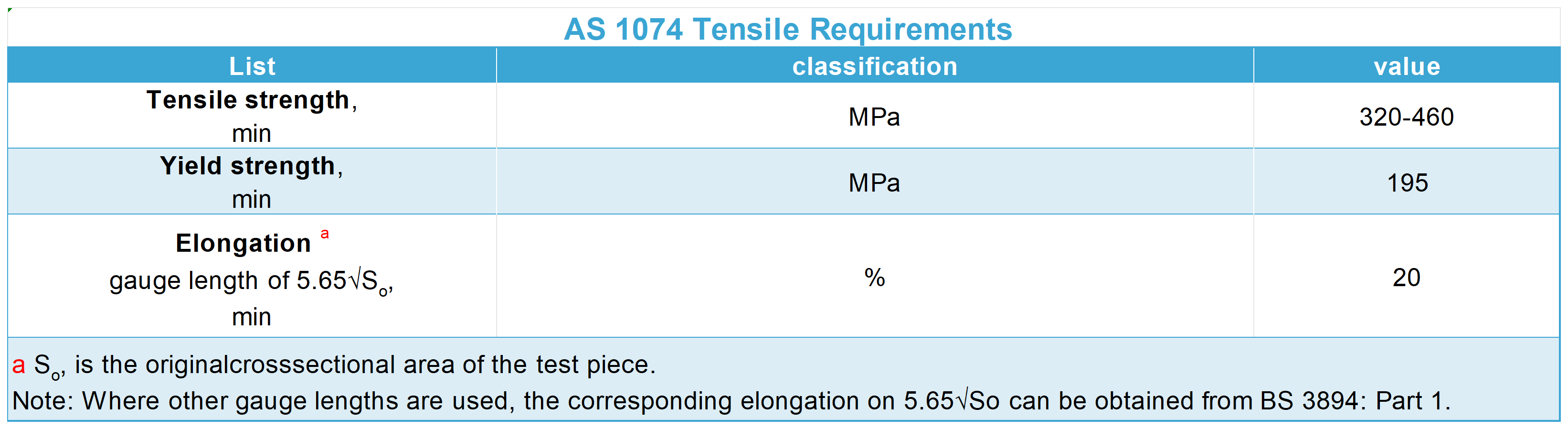

AS 1074 Tensile Requirements

AS 1074 Dimension

| TABLE 2.1 DIMENSIONS OF STEEL TUBES-LIGHT | |||||

| Nominal size | Outside Diameter mm |

Thickness mm | Mass of black tube kg/m |

||

| min | max | Plain or screwed ends |

Screwed and socketed |

||

| DN 8 | 13.2 | 13.6 | 1.8 | 0.515 | 0.519 |

| DN 10 | 16.7 | 17.1 | 1.8 | 0.67 | 0.676 |

| DN 15 | 21.0 | 21.4 | 2.0 | 0.947 | 0.956 |

| DN 20 | 26.4 | 26.9 | 2.3 | 1.38 | 1.39 |

| DN 25 | 33.2 | 33.8 | 2.6 | 1.98 | 2.00 |

| DN 32 | 41.9 | 42.5 | 2.6 | 2.54 | 2.57 |

| DN 40 | 47.8 | 48.4 | 2.9 | 3.23 | 3.27 |

| DN 50 | 59.6 | 60.2 | 2.9 | 4.08 | 4.15 |

| DN 65 | 75.2 | 76.0 | 3.2 | 5.71 | 5.83 |

| DN 80 | 87.9 | 88.7 | 3.2 | 6.72 | 6.89 |

| DN 100 | 113.0 | 113.9 | 3.6 | 9.75 | 10.0 |

| TABLE 2.2 DIMENSIONS OF STEEL TUBES-MEDIUM | |||||

| Nominal size | Outside Diameter mm |

Thickness mm | Mass of black tube kg/m |

||

| min | max | Plain or screwed ends |

Screwed and socketed | ||

| DN 8 | 13.3 | 13.9 | 2.3 | 0.641 | 0.645 |

| DN 10 | 16.8 | 17.4 | 2.3 | 0.839 | 0.845 |

| DN 15 | 21.1 | 21.7 | 2.6 | 1.21 | 1.22 |

| DN 20 | 26.6 | 27.2 | 2.6 | 1.56 | 1.57 |

| DN 25 | 33.4 | 34.2 | 3.2 | 2.41 | 2.43 |

| DN 32 | 42.1 | 42.9 | 3.2 | 3.10 | 3.13 |

| DN 40 | 48 | 48.8 | 3.2 | 3.57 | 3.61 |

| DN 50 | 59.8 | 60.8 | 3.6 | 5.03 | 5.10 |

| DN 65 | 75.4 | 76.6 | 3.6 | 6.43 | 6.55 |

| DN 80 | 88.1 | 89.5 | 4.0 | 8.37 | 8.54 |

| DN 100 | 113.3 | 114.9 | 4.5 | 12.2 | 12.5 |

| DN 125 | 138.7 | 140.6 | 5.0 | 16.6 | 17.1 |

| DN 150 | 164.1 | 166.1 | 5.0 | 19.7 | 20.3 |

| TABLE 2.3 DIMENSIONS OF STEEL TUBES-HEAVY | |||||

| Nominal size | Outside Diameter mm |

Thickness mm | Mass of black tube kg/m |

||

| min | max | Plain or screwed ends |

Screwed and socketed | ||

| DN 8 | 13.3 | 13.9 | 2.9 | 0.765 | 0.769 |

| DN 10 | 16.8 | 17.4 | 2.9 | 1.02 | 1.03 |

| DN 15 | 21.1 | 21.7 | 3.2 | 1.44 | 1.45 |

| DN 20 | 26.6 | 27.2 | 3.2 | 1.87 | 1.88 |

| DN 25 | 33.4 | 34.2 | 4.0 | 2.94 | 2.96 |

| DN 32 | 42.1 | 42.9 | 4.0 | 3.80 | 3.83 |

| DN 40 | 48.0 | 48.8 | 4.0 | 4.38 | 4.42 |

| DN 50 | 59.8 | 60.8 | 4.5 | 6.19 | 6.26 |

| DN 65 | 75.4 | 76.6 | 4.5 | 7.93 | 8.05 |

| DN 80 | 88.1 | 89.5 | 5.0 | 10.3 | 10.5 |

| DN 100 | 113.3 | 114.9 | 5.4 | 14.5 | 14.8 |

| DN 125 | 138.7 | 140.6 | 5.4 | 17.9 | 18.4 |

| DN 150 | 164.1 | 166.1 | 5.4 | 21.3 | 21.9 |

| NOTE: Dimensions and masses are in accordance with ISO 65. | |||||

If you would like to learn more about the pipe weight charts and schedule in the standard, please click here!

Dimensional Tolerances

| Dimensional tolerances | ||

| List | Type | scop |

| Thickness(T) | Light welded tubes | min 92% |

| Medium and heavy welded tubes | min 90% | |

| Medium and heavy Seamless tubes | min 87.5% | |

| Outside Diameter(OD) | Light welded tubes | Table 2.1 |

| Medium tubes | Table 2.2 | |

| Heavy tubes | Table 2.3 | |

| Mass | total length≥150 m | ±4% |

| One steel pipe | 92%~110% | |

| Lengths | Standard lengths | 6.50±0.08 m |

| Exact lengths Where exact lengths are specified, either for threaded tubes or for plain end tubes |

0 ~ +8 mm | |

Galvanized

| List | Element | |

| Standard | Tubes ordered galvanized shall comply with AS 1650. | |

| Appearances | The surface of the galvanized pipe shall be continuous, as smooth and evenly distributed as possible, and free from defects that would affect the performance or function of the pipe in use. | |

| Inside Diameter |

Tubes of DN 8 to DN 25 inclusive shall, after galvanizing, be capable of having a rod 230 mm long, of the appropriate diameter as given in Note A, passed through them to ensure a free internal diameter. | |

| Note | Tubes | Tubes that are to be threaded shall be galvanized before threading. |

| Sockets | Sockets that are to be threaded shall be galvanized before threading. | |

| Tubular | Tubulars that are to be threaded shall be galvanized before threading. | |

| Note A: Pipe Diameter: DN 8 Diameter of rod: 4.4mm Pipe Diameter: DN 10 Diameter of rod: 7.1mm Pipe Diameter: DN 15 Diameter of rod: 9.5mm Pipe Diameter: DN 20 Diameter of rod: 14.3mm Pipe Diameter: DN 25 Diameter of rod: 20.6mm |

||

Marking

Tubes shall be distinguished by color at one end as follows:

| Tube | Color |

| Light tube | Brown |

| Medium tube | Blue |

| Heavy tube | Red |

Markings shall be applied before the tubes leave the manufacturer's work.

Protection

The threads of all tubes shall be effectively protected against corrosion. Each tube larger than DN 80 shall have a protecting ring affixed to the screwed end.

AS 1074 Related Standards

ISO 65: Carbon steel tubes suitable for screwing in accordance with ISO 7-1

ISO 3183: Petroleum and natural gas industries — Steel pipe for pipeline transportation systems

ASTM A53: Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless

ASTM A106: Standard Specification for Seamless Carbon Steel Pipe for High-Temperature Service

BS EN 10255: Non-alloy steel tubes suitable for welding and threading

BS 1387: Steel tubes for use for water, gas, air, and steam

DIN 2440: Steel tubes medium weight suitable for screwing

DIN 2448: Seamless steel pipes and tubes dimensions, conventional masses per unit length

JIS G 3452: Carbon steel pipes for ordinary piping

JIS G 3454: Carbon steel pipes for pressure service

CSA Z245.1: Steel Pipe

GOST 10704-91: Electrically Welded Steel Line-End Tubes

SANS 62-1: Steel Pipes for Water and Waste Water

API 5L: Specification for Line Pipe

EN 10217-1: Welded steel tubes for pressure purposes - Non-alloy steel tubes with specified room temperature properties

Scope of Application

Construction: Used in building structures as an integral part of plumbing, gas piping, and heating systems.

Industry and manufacturing: as piping systems for the transportation of raw materials, waste, and finished products.

Oil and gas industry: as pipes for the transportation of oil and gas, especially in gathering and distribution systems.

Agriculture: for water transportation in irrigation systems.

Mining industry: conveying minerals and other materials, as well as drainage systems.

Municipal engineering: piping in urban water supply and drainage systems, as well as in fire-fighting systems.

Machinery and vehicles: for the transportation of liquids and gases as part of mechanical components and vehicles.

Our Products

About Us

BotopSteel is a China Professional Welded Carbon Steel Pipes Manufacturer& Suppliers Over 16 Years with 8000+ Tons of Seamless Line pipe in Stock Each Month. Provide you with high-quality and low-price steel pipe products, if you need please contact us, we will provide you with a wide range of steel pipe solutions.

tags: as 1074, Steel tubes, welded tubes, seamless tubes, suppliers, manufacturers, factories, stockists, companies, wholesale, buy, price, quotation, bulk, for sale, cost.

Post time: Mar-29-2024