ASTM A106 is a standard specification for seamless carbon steel pipe for high-temperature service established by the American Society for Testing Material (ASTM).

Navigation Buttons

ASTM A106 Scope

ASTM A106 Grade

ASTM A106 Raw Materials

ASTM A106 Seamless Steel Pipe Generation Method

Hot Treatment

Chemical Composition

Mechanical Properties

Test Program

Dimensional Tolerances

Treatment of Surface Defects

Tube Marking

Alternative Materials

Application of ASTM A106

Our Related Products

ASTM A106 Scope

Pipe type: seamless steel pipe.

Nominal Pipe Size: Covers seamless steel pipe from DN6-DN1200(NPS1/8-NPS48).

Wall Thickness: Wall thickness is required to meet the specific requirements of Table 1 of ASME B36.10M.

ASTM A106 Grade

ASTM A106 has three grades of steel pipe: Grade A, Grade B, and Grade C.

The main difference between the three grades is the chemical composition and mechanical properties.

ASTM A106 Raw Materials

The steel shall be killed steel.

The steel is produced using the primary melting process, which could be either open-hearth, basic-oxygen, or electric-furnace, possibly combined with separate degassing or refining.

ASTM A106 Seamless Steel Pipe Generation Method

Seamless steel pipe is produced in two ways: cold-drawn and hot-finished.

DN ≤ 40mm seamless steel pipe can be cold-drawn or hot-finished.

DN ≥ 50mm seamless steel pipe is hot-finished.

Hot Treatment

Hot-finished ASTM A106 seamless steel pipe does not require heat treatment.

Cold-drawn ASTM A106 seamless steel tubes need to be heat-treated at temperatures ≥ 650°C.

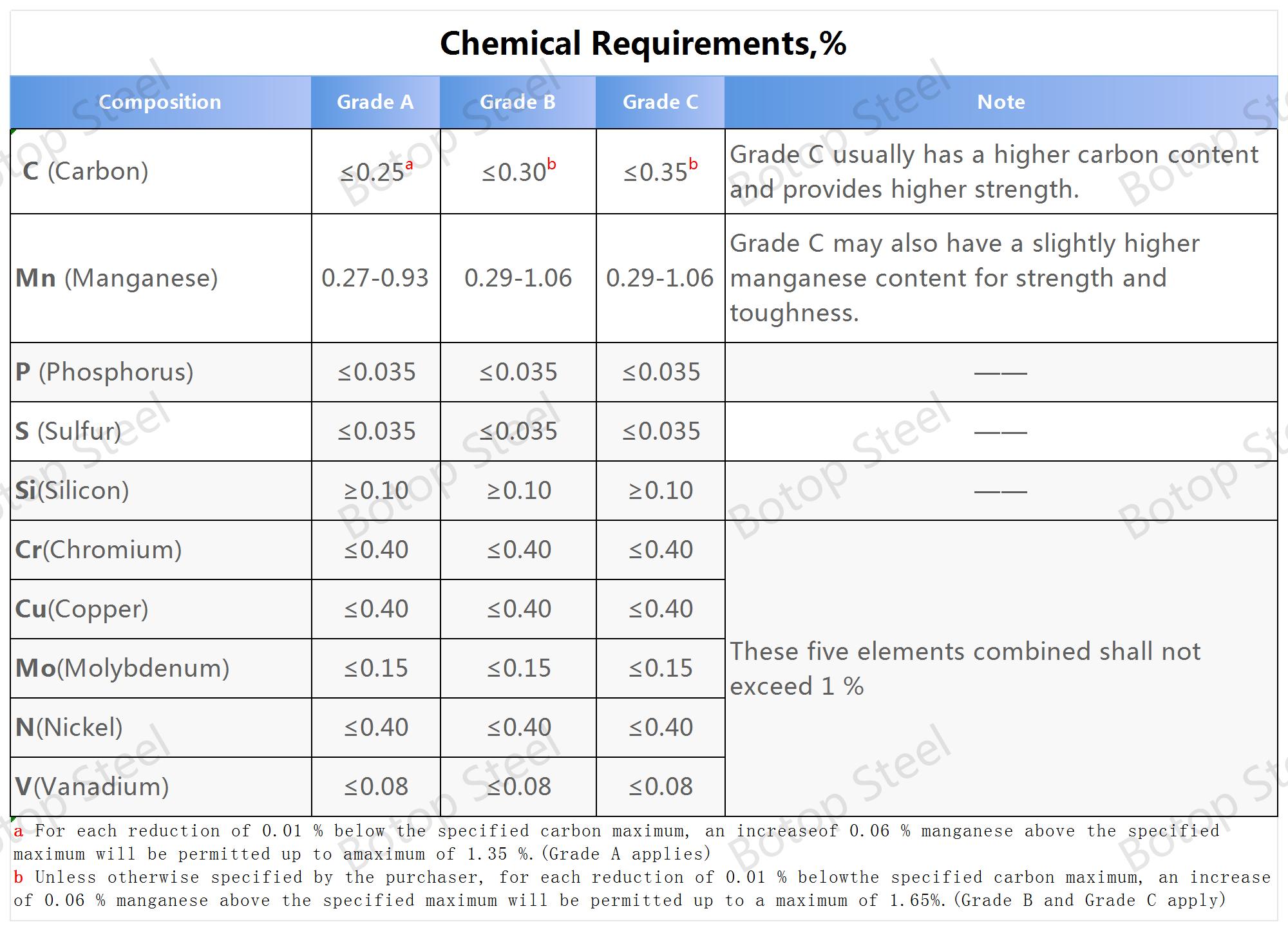

Chemical Composition

ASTM A106 Grade A, Grade B, and Grade C in the chemical composition of the biggest difference is the difference between the content of C and Mn, the content of other elements in the various grades may have a slight difference, but usually to control a relatively low range.

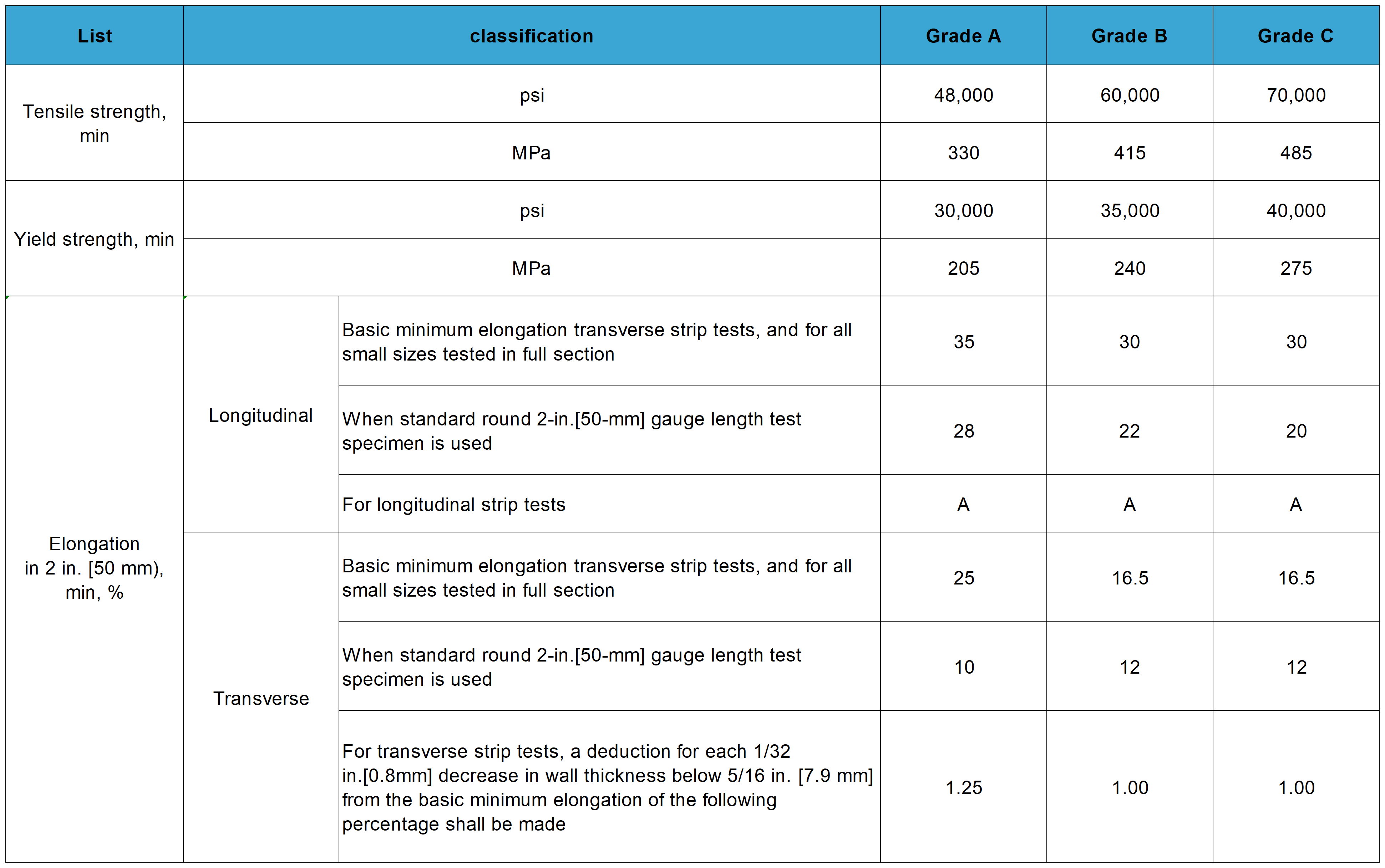

Mechanical Properties

The minimum elongation in 2 in. (50 mm) shall be determined by the following equation:

inch-pound units:

e=625,000A0.2/UO.9

Sl units:

e=1940A0.2/U0.9

e: minimum elongation in 2 in. (50 mm), %, rounded to the nearest 0.5%

A: cross-sectional area of the tension test specimen, in2 (mm2)based upon specified outside diameter or nominal specimen width and specified wall thickness, rounded to the nearest 0.01 in2 (1 mm2).

If the area thus calculated is equal to or greater than 0.75 in2 (500 mm2), then the value 0.75 in2(500 mm2) shall be used.

U: specified tensile strength, psi (MPa)

Test Program

ASTM A106 contains detailed specifications for chemical composition, thermal analysis, mechanical property requirements, bending requirements, flattening tests, hydrostatic tests, and nondestructive electrical testing.

Chemical Composition / Heat Analysis

Heat Analysis is a process used to determine the content of individual chemical elements in steel to ensure that the chemical composition of each lot of material meets the requirements of ASTM A106.

The determination of chemical composition is based on thermal analysis. The main focus is on the content of the elements carbon, manganese, phosphorus, sulfur, and silicon, the proportions of which have a direct effect on the properties of the pipe.

Tensile Requirements

Tubes must meet specific tensile strength, yield strength, and elongation requirements. This ensures the strength and toughness of the tube at elevated temperatures.

Bending Requirements

Bending tests are used to evaluate the toughness and plastic deformation of tubes when subjected to bending stresses in order to ensure the reliability of the tube during installation and use.

Flattening Tests

Flattening Tests are used to evaluate the ductility and resistance to cracking of steel tubes. This test requires the pipe to be flattened to a certain degree without cracking to prove the quality of the material and the qualification of the processing technology.

Hydrostatic Test

Hydrostatic testing is an important step in checking the pressure-bearing capacity of a steel pipe by applying pressure higher than that required by the standard to ensure its structural integrity and the absence of leaks.

Nondestructive Electric Test

Nondestructive Electric Test (e.g. ultrasonic testing or electromagnetic testing) is used to identify internal and surface defects such as cracks, inclusions, or holes in steel tubes to ensure the quality of the product.

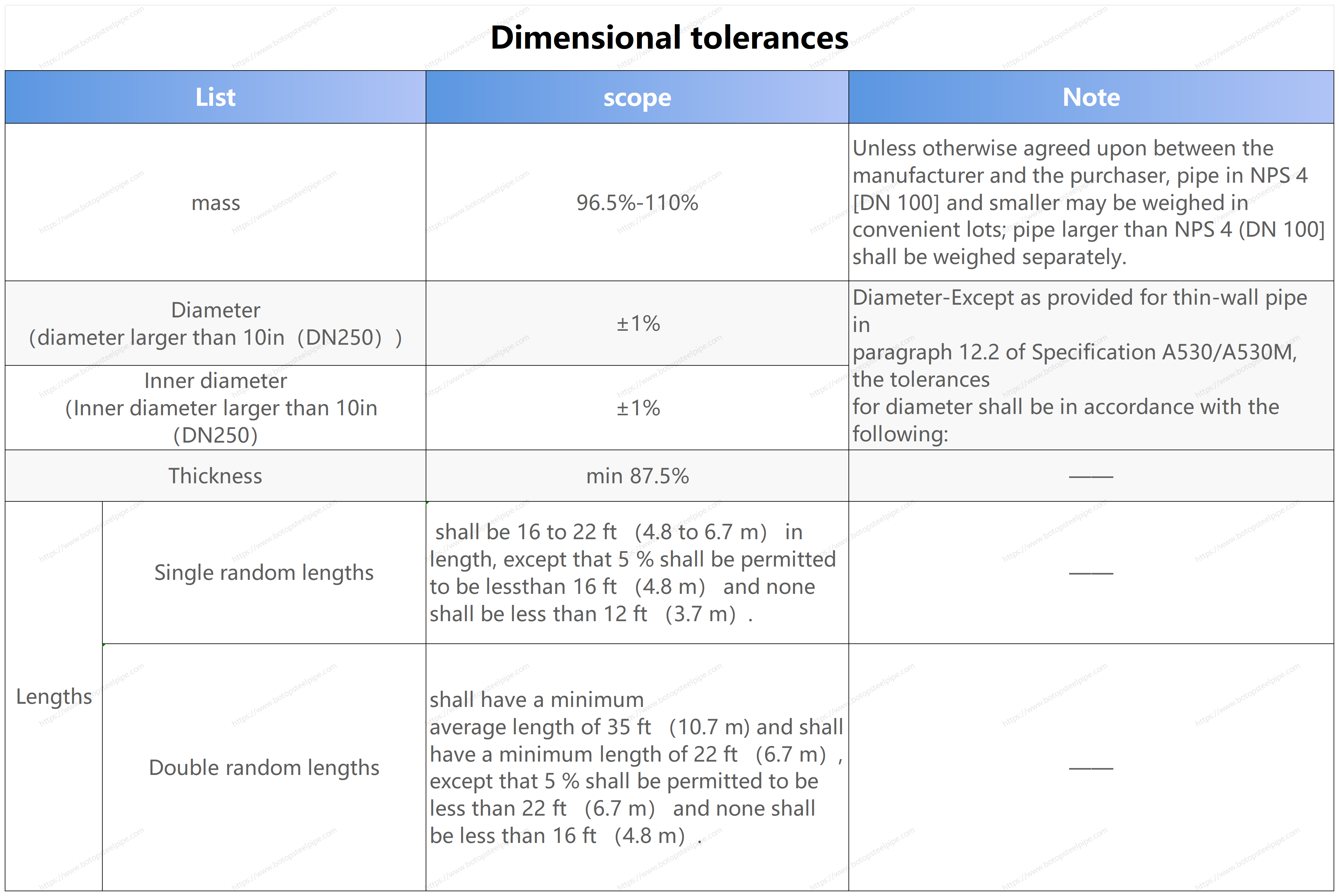

Dimensional Tolerances

Treatment of Surface Defects

Determination of Defects

When surface defects occur in tubes exceeding 12.5% of the nominal wall thickness or exceeding the minimum wall thickness, the defects must be removed by grinding as long as the remaining wall thickness is 87.5% or more of the specified thickness value.

Non-injurious Defects

To make the surface treatment in line with the process requirements, the following non-injurious defects should be removed by grinding:

1. Mechanical marks and abrasions - such as cable marks, dents, guide marks, rolling marks, ball scratches, indentations and mold marks, and pits, none of which shall exceed 1/16 in (1.6mm) in depth.

2. Visual imperfections, mostly crusts, seams, laps, tears, or slices deeper than 5 percent of the nominal wall thickness.

Defect Repair

When blemishes or defects are removed by grinding, a smooth curved surface shall be maintained and the pipe wall thickness shall not be less than 87.5% of the specified thickness value.

Repair welds are made in accordance with ASTM A530/A530M.

Tube Marking

Each ASTM A106 steel pipe shall be marked with the manufacturer's identification, specification grade, dimensions, and Schedule grade information for easy identification and traceability.

Application of ASTM A106

Oil and Gas Industry: Piping systems are used to transport oil, gas, and other fluids.

Power stations: Used as heat exchanger piping and superheater piping in boilers for the transmission of high-temperature steam and hot water.

Chemical Industry: Used in chemical plants as piping to resist high-temperature chemical reaction products.

Building and Construction: Piping for heating and steam systems in buildings.

Shipbuilding: Components of high-pressure steam systems in ships.

Machinery Manufacturing: Used in machinery and equipment requiring high temperature or high-pressure resistance.

Our Related Products

We are one of the leading welded carbon steel pipe and seamless steel pipe manufacturers and suppliers from China, with a wide range of high-quality steel pipe in stock, we are committed to providing you with a full range of steel pipe solutions. For more product details, please feel free to contact us, we look forward to helping you find the best steel pipe options for your needs!

tags:astm a106, a106, seamless, suppliers, manufacturers, factories, stockists, companies, wholesale, buy, price, quotation, bulk, for sale, cost.

Post time: Mar-02-2024