ASTM A106 Grade B is a seamless carbon steel pipe based on the ASTM A106 standard and designed to withstand high temperature and pressure environments.

It is mainly used in the oil, gas, and chemical industries for constructing piping systems and related facilities.

Navigation Buttons

ASTM A106 Grade

ASTM A106 is a standard specification for seamless carbon steel pipe for high-temperature applications developed by ASTM International. The specification defines three grades of seamless carbon steel pipe, Grade A, Grade B, and Grade C. Of these, Grade B is the most commonly used.

Grade "B" represents a specific chemical composition and mechanical property level of the material for applications at certain temperatures and pressures.

If you want to know more about ASTM A106 you can click: What Does ASTM A106 Mean?

Key Features

Seamless Manufacturing

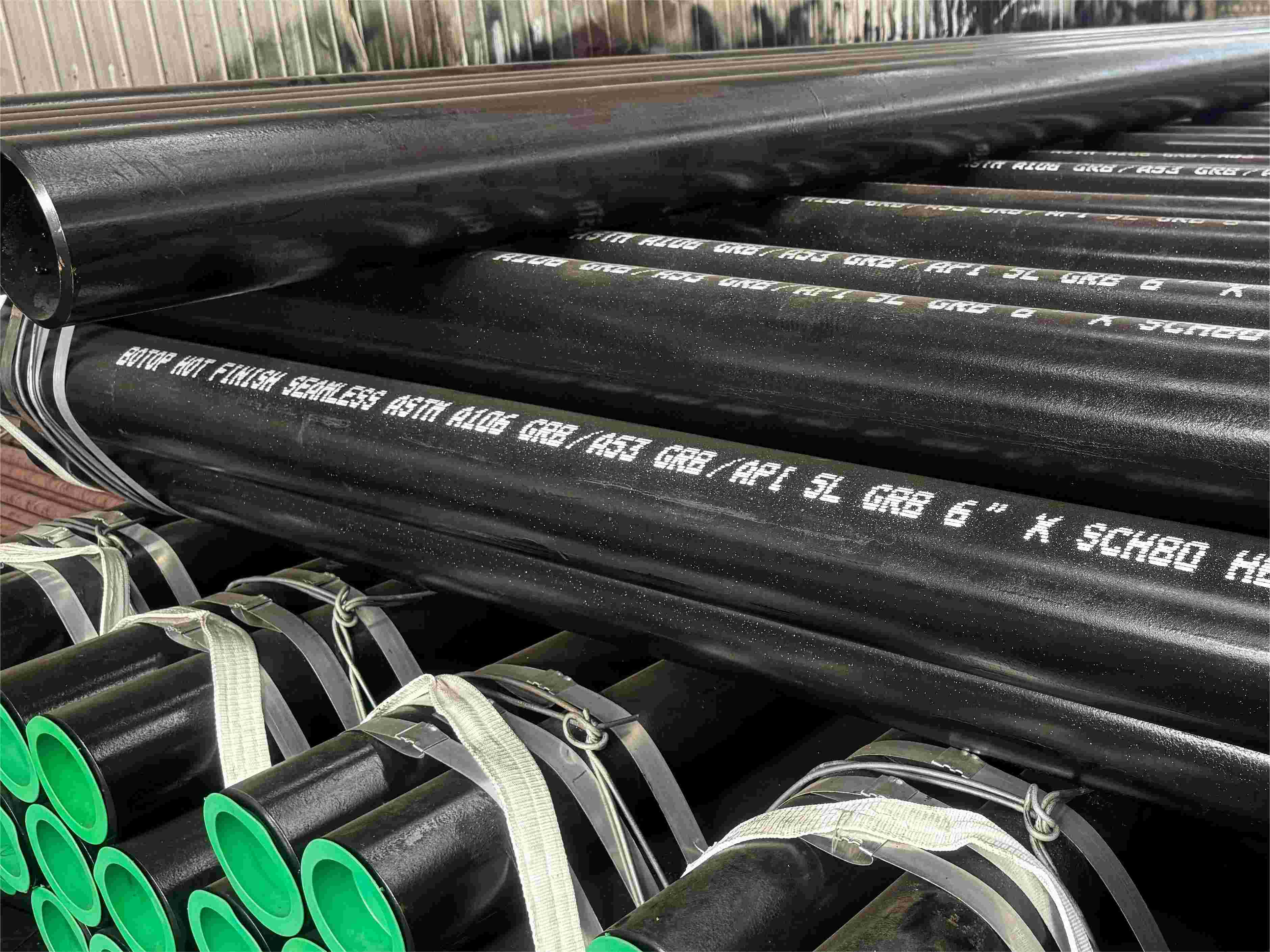

ASTM A106 Grade B tubing is produced through a seamless manufacturing process that ensures uniformity and strength for use in environments subject to high stress.

High-temperature Performance

This pipe is particularly suitable for working in high-temperature environments, such as in piping systems in power stations, refineries, and chemical plants.

Chemical Composition

The chemical composition of Grade B is designed to give it good heat resistance and processability. It typically contains a low carbon content and moderate amounts of manganese, phosphorus, sulfur, and silicon.

Mechanical Properties

ASTM A106 Grade B steel pipe provides excellent tensile strength and good yield strength for applications requiring good mechanical properties.

Wide Range of Applications

Because of its heat resistance and mechanical properties, ASTM A106 Grade B tubing is used in a wide range of applications such as oil and gas, petrochemicals, boilers, and heat exchangers.

Chemical Composition

| Composition | C (Carbon ) |

Mn (Manganese) |

P (Phosphorus) |

S (Sulfur) |

Si (Silicon) |

Cr (Chromium) |

Cu (Copper) |

Mo (Molybdenum) |

Ni (Nickel) |

V (Vanadium) |

| max | — | max | max | min | max | max | max | max | max | |

| quantity contained | 0.30 % | 0.29 - 1.06 % | 0.035 % | 0.035 % | 0.10 % | 0.40 % | 0.40 % | 0.15 % | 0.40 % | 0.08 % |

Unless otherwise specified by the purchaser, for each reduction of 0.01 % below the specified carbon maximum, an increase of 0.06% of manganese above the specified maximum will be permitted up to a maximum of 1.65 %.

Cr, Cu, Mo, Ni, and V: the total of these five elements shall not exceed 1%.

Mechanical Properties

| List | Tensile strength, min | Yield strength, min | ||

| classification | psi | MPa | psi | MPa |

| ASTM A106 Grade b | 60,000 | 415 | 35,000 | 240 |

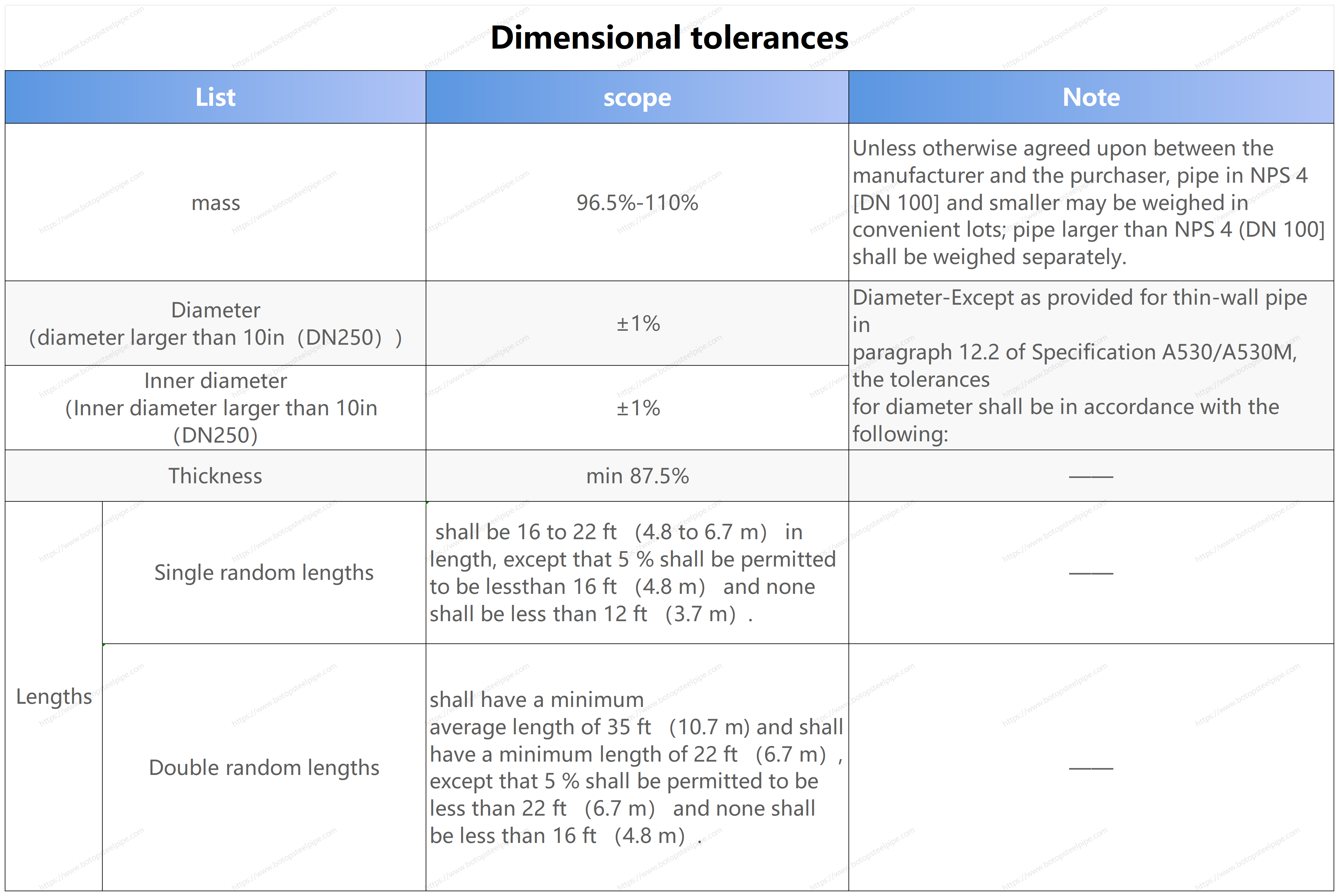

Dimensional Tolerances

Testing and Certification

Chemical Composition Analysis

Determine the chemical composition of the pipe, including carbon, manganese, phosphorus, sulfur, and silicon to ensure that the material meets the chemical composition requirements specified in the standard.

Tensile Testing

Measure the tensile strength, yield strength, and elongation of the steel pipe. These tests help evaluate the material's performance and toughness under tensile stress.

Bending Test

Bending tests are performed on welded and seamless pipe to evaluate its plastic deformation capacity and the integrity of welded joints.

Flattening Test

Flattening tests are performed on tubes to evaluate their deformation and rupture characteristics under pressure.

Hardness Testing

The hardness of a material is evaluated by means of a Brinell or Rockwell hardness test. This test is important in determining the processing and application characteristics of the material.

Hydrotesting

Each pipe must be hydrostatically tested to verify that it is leak-free at the specified pressure to ensure the tightness and safety of the piping system.

Non-destructive Testing

Includes Ultrasonic Testing (UT), Magnetic Particle Testing (MT) and/or Radiographic Testing (RT) for the detection of internal and surface defects such as cracks, inclusions and porosity.

Impact Testing (upon request)

In some cases, impact testing (e.g., Charpy V-notch test) may be required to evaluate the fracture toughness of the material at low temperatures.

Main Applications of ASTM A106 Grade B

Oil and gas transportation: for high-pressure and high-temperature environments.

Chemical processing: for corrosion and high-temperature resistant piping systems.

Power stations: for steam lines and boiler outlets.

Industrial Manufacturing: for pressure piping and high-pressure equipment.

Construction and shipbuilding: for building heating and cooling systems and boiler and steam systems for ships.

Automotive industry: for the manufacture of automotive parts that are resistant to high temperatures and pressures.

Alternative to ASTM A106 GR.B

When selecting alternative materials, consideration should be given to the mechanical properties, temperature resistance, pressure resistance, and corrosion resistance of the material to ensure compliance with specific application requirements and relevant regulations and standards.

| Standard Name | Scope of application |

| ASTM A53 Grade B | Low Pressure and Mechanical Structural Applications |

| API 5L Grade B | Oil and gas pipelines |

| ASTM A333 Grade 6 | For low-temperature service |

| ASTM A335 P11 或 P22 | For high temperatures such as boilers in power stations |

| ASTM A312 TP304 或 TP316 | Applications requiring high corrosion resistance |

| ASME SA106 | High-temperature and high-pressure environments |

| AS/NZS 1163 C350L0 | Structural and mechanical purposes |

| GB 3087 | Seamless steel tubes for low and medium-pressure boilers |

| GB 5310 | Seamless steel tubes for high-pressure boilers |

| GB 9948 | Seamless steel tubes for oil cracking |

Protective Coating for ASTM A106 GR.B

Galvanized

Galvanizing is a method of providing corrosion protection by applying a zinc coating to the surface of steel.

The most common galvanizing technique is hot dip galvanizing, in which the steel pipe is dipped into molten zinc to form a dense layer of zinc on its surface.

This layer of zinc not only physically insulates the steel substrate from air and water, preventing oxidation, but also slows down the rate of steel corrosion through sacrificial anodic protection (zinc is more active than iron).

Hot-dip galvanized treated steel pipe is suitable for use outdoors or in wet environments, such as water treatment facilities and outdoor building structures.

Coating

Coating is a method of preventing corrosion by applying one or more layers of a specific anti-corrosion coating to the surface of a steel pipe.

These coatings can be epoxy, polyurethane, polyethylene, or other synthetic materials.

Epoxy coatings are widely used in industrial piping because of their excellent chemical stability and adhesion.

The main function of the coating is to block moisture and corrosive chemicals, preventing them from coming into direct contact with the steel. The coating treatment is suitable for a wide range of environments such as chemical plants, marine environments and urban pipe networks.

Lining Coating

Lining treatment is to apply a layer of anti-corrosive material, such as epoxy resin, ceramics, or rubber, inside the steel pipe to prevent corrosion of the conveying medium on the inner wall of the steel pipe.

This method is particularly suitable for conveying corrosive fluids (e.g. acids, alkalis, salt solutions, etc.).

Epoxy resin lining provides a strong anti-corrosion layer that can withstand a certain degree of chemical attack and physical abrasion.

The lining not only extends the life of the pipe but also maintains the cleanliness of the fluid and prevents contamination.

Our Related Products

We are one of the leading welded carbon steel pipe and seamless steel pipe manufacturers and suppliers from China, with a wide range of high-quality steel pipe in stock, we are committed to providing you with a full range of steel pipe solutions. For more product details, please feel free to contact us, we look forward to helping you find the best steel pipe options for your needs!

tags:a106 grade b, a106, seamless, suppliers, manufacturers, factories, stockists, companies, wholesale, buy, price, quotation, bulk, for sale, cost.

Post time: Mar-01-2024