API 5L X70 is an API 5L material grade for line pipe with a minimum yield strength of 70,000 psi. It is primarily used for high-pressure transportation of natural gas, oil, and water.

To learn more about API 5L-46th, you can click here!

API 5L X70 Features

High yield strength: Minimum yield strength of 70,000 psi (approximately 485 MPa), suitable for high internal pressures.

Good toughness: maintains performance at low temperatures for cold regions and deep sea applications.

Excellent weldability: High strength while maintaining good weldability, with welds matching the properties of the base metal.

Corrosion resistance: can be enhanced by chemical composition control and post-treatments (e.g. coatings), suitable for offshore and corrosive environments.

Environmental suitability: Can be designed for use in standard land, offshore, and acid service environments.

Sustainability: Reduced environmental impact and improved transmission efficiency as a recyclable material.

API 5L X70 Classifications

Pipe Type: Welded and Seamless Steel Pipe

Product specification grade: API 5L X70 PSL1 and API 5L X70 PSL2

Pipe manufacturing process: SMLS, LFW, HFW, LW, SAWL, SAWH, COWL, COWH

Pipe end type: Belled end, Plain end

Raw Materials

Ingots, billets, billets, strips (coils), or plates as raw material for the manufacture of steel pipes.

The raw material for PSL2 steel pipe shall be fine-grain sedimented steel.

Furthermore, the steel strip (coil) or plate used for the manufacture of PSL2 steel pipe shall not bear any filler welds.

API 5L X70 Pipe Manufacturing Process

| Type of Pipe | SMLS | LFW | HFW | LW | SAWL c | SAWH d | COWL c | COWH d |

| API 5L X70 PSL1 | X | X | X | X | X | X | X | X |

| API 5L X70 PSL2 | X | — | X | — | X | X | X | X |

c Double-seam pipe is available if agreed, but limited to pipe with D ≥ 914 mm.

d Helical seam pipe is limited to pipe with D ≥ 114.3 mm.

Pipe End Types for API 5L X70

| Pipe End | Belled end e | Plain end |

| API 5L X70 PSL1 | X | X |

| API 5L X70 PSL2 | — | X |

e Belled-end pipe is limited to pipe with D ≤219.1 mm and t≤ 3.6 mm.

Final Delivery Status

API 5L X70 final delivery state (the final heat treatment of finished steel pipe) can be divided into: rolling, normalizing rolling, thermo-mechanical rolling, thermo-mechanical forming, normalizing forming, normalizing, normalizing and tempering or quenching and tempering.

| PSL | Delivery Condition | Pipe Grade/Steel Grade | |

| PSL1 | As-rolled, normalizing rolled, thermomechanical rolled, thermomechanical formed, normalizing formed, normalized, normalized and tempered or quenched and tempered |

X70 | L485 |

| PSL 2 | Quenched and tempered | X70Q | L485Q |

| Thermomechanical rolled or thermomechanical formed | X70M | L485M | |

These delivery states ensure that API 5L X70 tubing performs well in a variety of different applications, such as use in high-pressure, low-temperature, or corrosive environments.

Chemical Composition

API 5L X70 PSL1 Chemical Composition

The chemical composition of API 5L X70 PSL1 steel pipe includes low carbon, moderate amounts of manganese, and small amounts of phosphorus, sulfur, and silicon. In addition, alloying elements such as chromium, nickel and copper are added to enhance strength and corrosion resistance. Micro-alloying elements such as vanadium, molybdenum and titanium further optimize durability and yield properties, ensuring performance in challenging environments.

| Chemical Composition for PSL 1 Pipe with t≤25.0 mm (0.984 in.) | |||||||||

| Steel Grade (Steel Name) |

Mass Fraction, Based on Heat and Product Analyses a.g % |

||||||||

| C | Mn | P | S | V | Nb | Ti | |||

| max b | max b | min | max | max | max | max | max | ||

| Seamless Pipe | |||||||||

| L485 | X70 | 0.28 | 1.40 | — | 0.03 | 0.03 | f | f | f |

| Welded Pipe | |||||||||

| L485 | X70 | 0.26 e | 1.65 e | — | 0.03 | 0.03 | f | f | f |

| a Cu≤0.50 %;Ni≤0.50%;Cr≤0.50 %and Mo≤0.15 %. b For each reduction of 0.01 %below the specified maximum concentration for carbon, an increase of 0.05%above the specified maximum concentration for Mn is permissible, up to a maximum of 1.65 %for grades ≥L245 or B, but ≤L360 or X52; up to a maximum of 1.75 %for grades>L360 or X52, but<L485 or X70; and up to a maximum of 2.00 %for Grade L485 or X70. e Unless otherwise agreed f Unless otherwise agreed, Nb+V+Ti≤0.15 %. g No deliberate addition of B is permitted and the residual B≤0.001 %. |

|||||||||

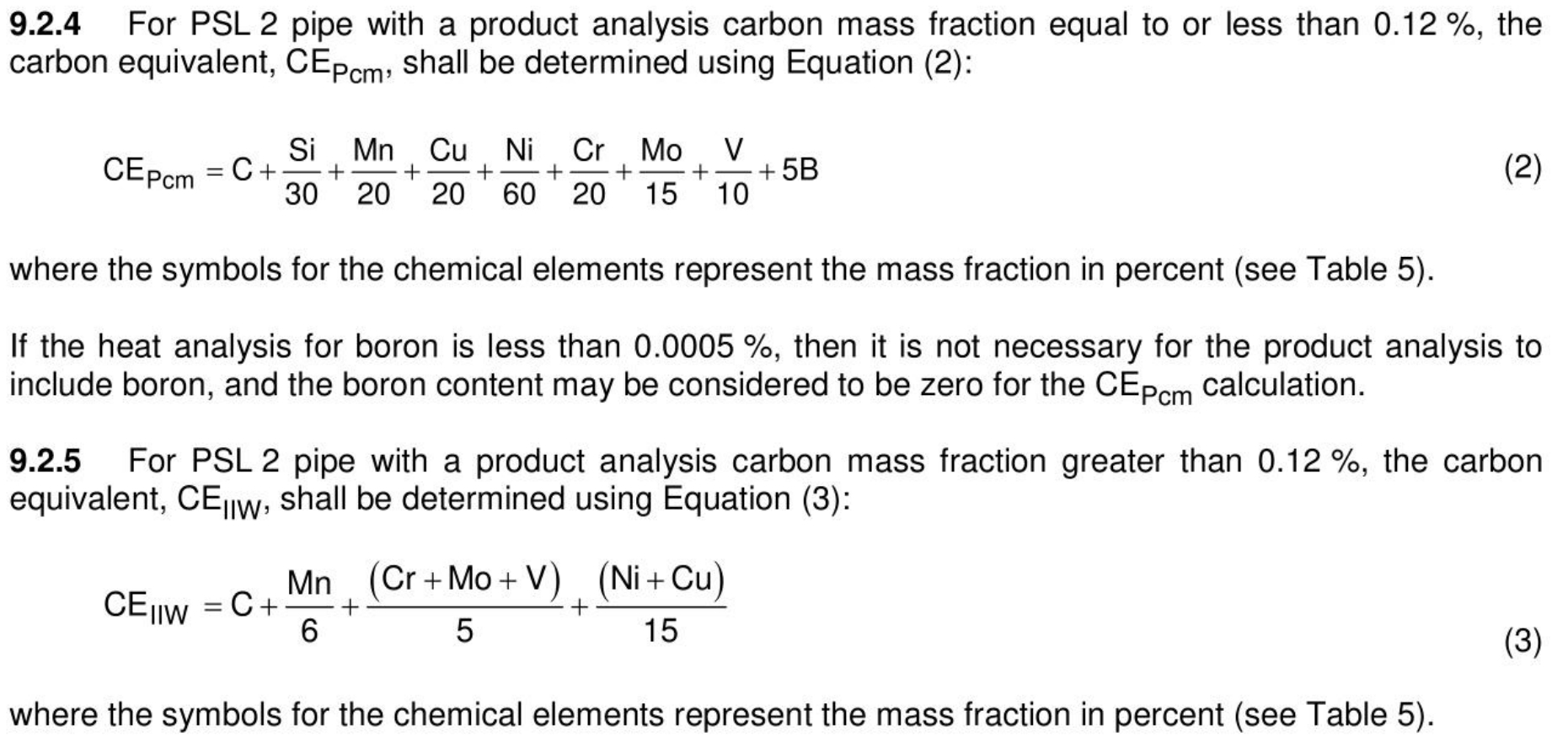

API 5L X70 PSL2 Chemical Composition

The chemical composition of API 5L X70 PSL2 includes precisely controlled carbon, manganese, sulfur, and phosphorus, as well as a judicious proportion of silicon, chromium, nickel, and copper. Strict elemental control not only enhances the yield strength and toughness of the pipe but also improves corrosion resistance under extreme conditions. In addition, trace elements such as vanadium, molybdenum, and titanium have been adapted to further enhance performance, making X70 PSL2 ideal for tackling high-risk environments.

| Chemical Composition for PSL 2 Pipe with t ≤ 25.0 mm (0.984 in.) | ||||||||||||

| Steel Grade (Steel Name) |

Mass Fraction, Based on Heat and Product Analyses

% max |

Carbon Equivalent a %max |

||||||||||

| c b | Si | Mn b | P | S | V | Nb | Ti | Other | CEllw | CEpcm | ||

| Seamless and Welded Pipe | ||||||||||||

| L485Q | X70Q | 0.18f | 0.45 f | 1.80 f | 0.025 | 0.015 | g | g | g | h, I | 0.43 | 0.25 |

| Welded Pipe | ||||||||||||

| L485M | X70M | 0.12 f | 0.45 f | 1.70 f | 0.025 | 0.015 | g | g | g | h, I | 0.43 | |

| a Based on a product analysis, for seamless pipe with t>20.0 mm (0.787 in.), the CE limits shall be as agreed; the CEllw limits apply if C>0.12 %, and the CEpcm limits apply if C≤0.12 %. b For each reduction of 0.01 %below the specified maximum for C, an increase of 0.05 %above the specified maximum for Mn impermissible, up to a maximum of 1.65 %for grades≥L245 or B, but≤L360 or X52; up to a maximum of 1.75 %for grades >L360 or X52, but<L485 or X70; up to a maximum of 2.00 %for grades≥L485 or X70, but≤L555 or X80; and up to a maximum of 2.20 %for grades >L555 or X80. c Unless otherwise agreed, Nb+V≤0.06 %. d Nb+V+Ti≤0.15%. e Unless otherwise agreed,Cu≤0.50 %;Ni≤0.30 %;Cr≤0.30 %and Mo≤0.15 %. f Unless otherwise agreed. g Unless otherwise agreed, Nb+V+Ti≤0.15 %. h Unless otherwise agreed,Cu≤0.50%;Ni≤0.50%;Cr≤0.50 %and Mo≤0.50%. i Unless otherwise agreed,Cu≤0.50 %;Ni≤1.00%;Cr≤0.50%and Mo≤0.50 %. j B≤0.004 %. k Unless otherwise agreed,Cu≤0.50 %;Ni≤1.00 %;Cr≤0.55 %and Mo≤0.80 %. l For PSL 2 pipe grades except those grades to which footnote j)already applies, the following applies: unless otherwise agreed nointentional addition of B is permitted and residual B≤0.001 %. |

||||||||||||

Chemical Composition for Sour Service Conditions API 5L X70 PSL2

Sour service conditions refer mainly to the use of pipelines in environments containing hydrogen sulfide (H₂S), which can lead to hydrogen sulfide stress corrosion cracking (HIC) and sulfide stress corrosion cracking (SSCC).

Adjustment of chemical composition: Under these conditions, the chemical composition of pipeline steels must be appropriately adjusted to improve their corrosion resistance. Usually, this includes reducing the carbon content of the material and adding alloying elements such as molybdenum (Mo) and nickel (Ni), which increase the corrosion resistance and hardness of the material.

| Table H.1—Chemical Composition for Pipe with t≤25.0 mm (0.984 in.) | |||||||||||

| Steel Grade | Mass Fraction Based on Heat and Product Analyses% max |

Carbon Equivalent a % max |

|||||||||

| C b | Si | Mn b | P | S | V | Nb | Ti | Other c,d | CEllw | CEpcm | |

| SMLS and Welded Pipe | |||||||||||

| L485QS or X70QS | 0.16 | 0.45 | 1.65 | 0.020 | 0.003e | 0.09 | 0.05 | 0.06 | g, I,k | 0.42 | 0.22 h |

| Welded Pipe | |||||||||||

| L485MS or X70MS | 0.10 | 0.45 | 1.60 | 0.020 | 0.002 e | 0.10 | 0.08 | 0.06 | g, I,j | — | 0.22 |

Detailed information can be found in API 5L Appendix H.

Chemical Composition of API 5L X70 PSL2 for Offshore Service Conditions

Offshore service conditions involve the marine environment, including exposure to salt water and extreme weather conditions. These conditions require pipes with high corrosion resistance and sufficient toughness to resist saltwater corrosion and low temperature impacts.

Adjustment of chemical composition: For offshore service, the alloy of the pipe is usually increased in chromium (Cr), nickel (Ni) and molybdenum (Mo) to enhance its resistance to seawater corrosion. The amount of micro-alloying elements such as vanadium (V) and niobium (Nb) may also be adjusted to optimize toughness at low temperatures.

| Table J.1—Chemical Composition for Pipe with t≤25.0 mm (0.984 in.) | ||||||||||||

| Steel Grade | Mass Fraction Based on Heat and Product Analyses max % |

Carbon Equivalenta max % |

||||||||||

| C b | Si | Mn b | P | S | V | Nb | Ti | Other c | CEllw | CEPcm | ||

| SMLS and Welded Pipe | ||||||||||||

| L485QO | X70QO | 0.17 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.05 | 0.06 | e,h | 0.42 | 0.23 g |

| Welded Pipe | ||||||||||||

| L485MO | X70MO | 0.12 | 0.45 | 1.75 | 0.020 | 0.010 | 0.10 | 0.08 | 0.06 | e,h | — | 0.22 |

Detailed information can be found in API 5L Appendix J.

Additionally, the chemical composition of steel pipe for offshore service conditions in API 5L X70 PSL2 is the same as the requirements for pipe for applications requiring longitudinal plastic strain capacity. Interested parties can check API 5L Appendix N.

Mechanical Properties

API 5L X70 PSL1 Mechanical Properties

| Table 6—Requirements for the Results of Tensile Tests for PSL 1 Pipe | ||||

| Pipe Grade | Pipe Body of Seamless and Welded Pipe | Weld Seam of EW, LW, SAW, and COW Pipe |

||

| Yield Strength a Rto.5 MPa(psi) |

Tensile Strength a Rm MPa(psi) |

Elongation (on 50 mm or 2 in.) Af % |

Tensile Strength b Rm MPa(psi) |

|

| min | min | min | min | |

| L485 or X70 | 485(70,300) | 570 (82,700) | c | 570 (82,700) |

Specific parameters can be viewed in API 5L Table 6.

API 5L X70 PSL2 mechanical properties

PSL2 tubes for special applications are mainly adjusted for chemical composition, but the requirements for mechanical properties are the same.

| Table 7—Requirements for the Results of Tensile Tests for PSL 2 Pipe | |||||||

| Pipe Grade | Pipe Body of Seamless and Welded Pipe | Weld Seam of HFW SAW and CoW Pipe |

|||||

| Yield Strength a Rto.5 MPa(psi) |

Tensile Strength a Rm MPa (psi) |

Ratio a.c

Rt0.5/Rm |

Elongation (on 50 mm or 2 in.) Af % |

Tensile Strength d Rm MPa (psi) |

|||

| min | max | min | max | max | min | min | |

| L485Q or X70Q L485M or X70M |

485 (70.300) |

635 (92.100) |

570 (82.700) |

760 (110.200) |

0.93 | f | 570 (82.700) |

Specific parameters can be viewed in API 5L Table 7.

Experimental Methods

| Test Category | Testing Method |

| Chemical Composition | ISO 9769 or ASTM A751 |

| Mechanical Properties | ISO 6892-1 or ASTM A370 |

| Hydrostatic Test | API 5L 10.2.6 |

| Nondestructive Examination | API 5L Appendix E |

| Bending Test | ISO 8491 or ASTM A370 |

| Guided Bend Test | ISO 5173 or ASTM A370 |

| Flattening Test | ISO 8492 or ASTM A370 |

| CVN Impact Test(PLS2) | ASTM A370 |

| DWT Tests(PSL2) | API 5L3 |

Applications for API 5L X70

Oil pipelines: used for the transportation of crude oil or refined products, especially in long-distance transportation across geographical areas or underwater.

Gas pipelines: for the gathering and distribution of natural gas, including long-distance transportation and high-pressure environments.

Structural applications: API 5L X70 steel pipe is also used in special projects such as offshore platforms or high-strength support structures.

Industrial applications: Fluid transportation systems in chemical plants, refineries, etc.

Special use environments: The corrosion resistance of API 5L X70 steel pipe makes it suitable for use in a variety of special environments, especially in acidic and offshore corrosive conditions.

Our Related Products

API 5L GR.B X60 X65 X70 PSL1/PSL 2 LSAW Carbon Steel Pipe

Pipe End Processing

Pipe cutting

Anti-corrosion coatings: galvanized, painted, 3PE, FBE, etc.

We are one of the leading welded carbon steel pipe and seamless steel pipe manufacturers and suppliers from China, with a wide range of high-quality steel pipe in stock, we are committed to providing you with a full range of steel pipe solutions. For more product details, please feel free to contact us, we look forward to helping you find the best steel pipe options for your needs!

Tags: X70, API 5l x70, ai 5l, suppliers, manufacturers, factories, stockists, companies, wholesale, buy, price, quotation, bulk, for sale, cost.

Post time: Apr-14-2024