ASTM A252 :Standard Specification for Welded and Seamless Steel Pipe Piles.

Navigation Buttons

ASTM A252 Grade

ASTM A252 grades are classified as: Grade 1 Grade 2 and Grade 3

Raw Material Production Process

The steel shall be made by one or more of the following processes: open-hearth, basic-oxygen, or electric furnace.

Materials and Manufacture

Piles shall be made by the seamless, electric resistance welded, flash welded, or fusion welded process.

The seams of welded pipe piles shall be longitudinal, helical-butt, or helical-lap.

ASTM A252 Chemical Composition

Experimental method: ASTM A751.

The steel shall contain no more than 0.050 % phosphorous. This is because high phosphorus levels may cause steel to become brittle at low temperatures, reducing the toughness of the material.

ASTM A252 specification does have limited requirements for chemical composition: this is because ASTM A252 applies primarily to structural applications, especially as load-bearing elements, where physical properties (such as yield strength, tensile strength, and elongation) are more important than chemical composition. These physical properties can be achieved through proper manufacturing and heat treatment processes without strict control of chemical composition other than phosphorus.

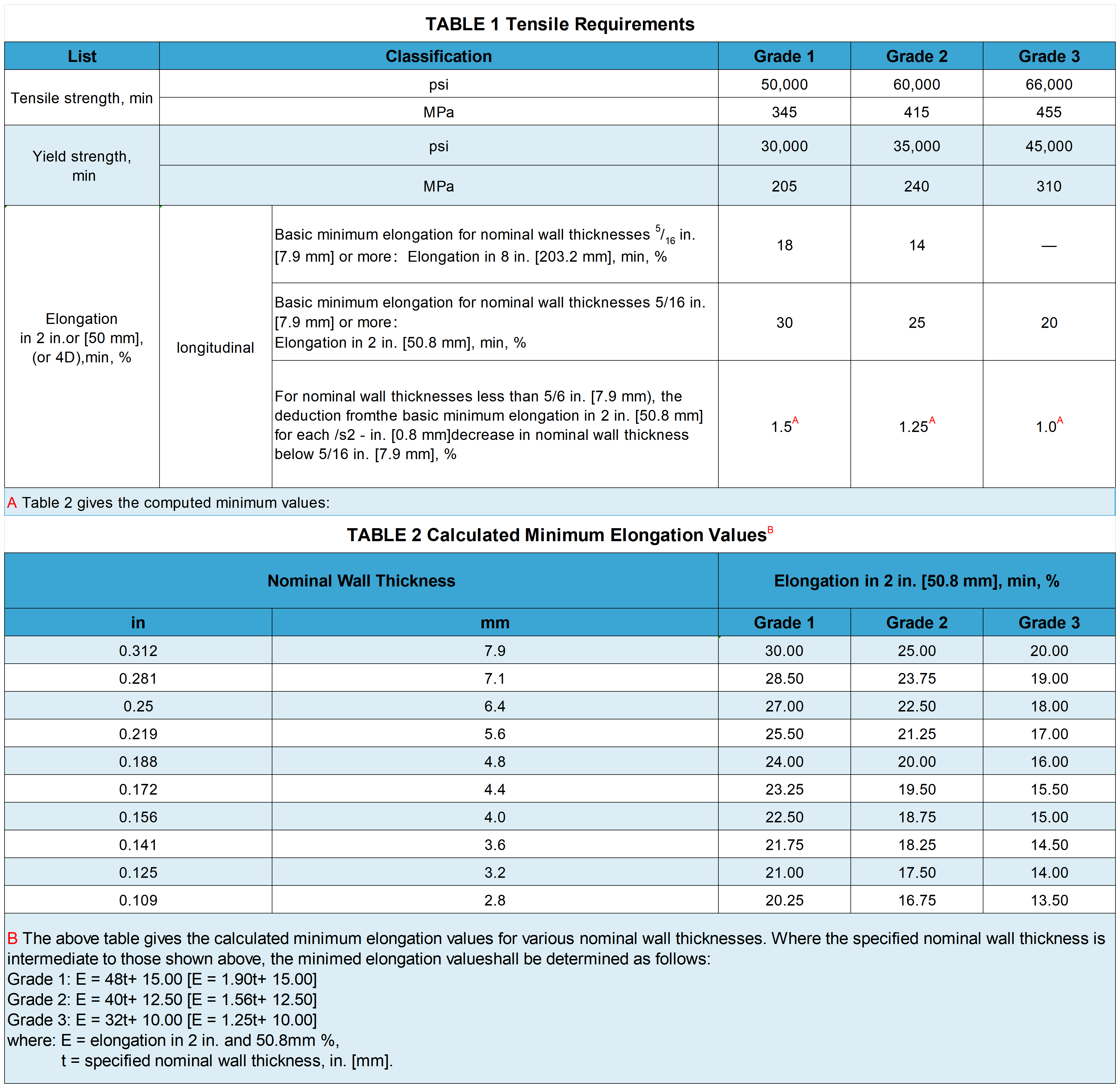

ASTM A252 Tensile Requirements

Experimental method: ASTM A370.

Hydrostatic Pressure Test

The reason that ASTM A52 does not specify hydraulic testing is primarily due to the application characteristics and design requirements of these pipes.

For steel pipe piles in the ASTM A252 specification, the primary design purpose is to withstand axial loads, not internal pressures. This is in contrast to piping for the transportation of liquids or gases, such as those under API 5L specification, which must be subjected to a direct test of internal pressure to ensure its tightness and strength.

Dimensional Tolerances

| Dimensional tolerances | ||

| List | sort | scope |

| Weight | Theoretical Weight | 95%-125% |

| Diameter | Specified Outside Diameter | ±1% |

| Thickness | specified nominal wall thickness | min 87.5% |

| Lengths | Single random lengths | 16 to 25 ft [4.88 to 7.62 m] |

| Double random lengths | over 25 ft [7.62 m] with a minimum average of 35 ft [10.67 m] | |

| Uniform lengths | length as specified with a permissible variation of ±1 in. | |

| Beveled | Pipe piles shall be furnished with plain ends: When the ends are designated as beveled |

30°- 35° |

Pipe Weight Charts

If you would like to learn more about the weight charts and schedule in the standard, please click here!

| Outside Diameter | Nominal Wall Thickness | Weight per Unit Lengths | |||

| IN | MM | IN | MM | IN | MM |

| 6 | 152.4 | 0.134 | 3.40 | 8.40 | 12.50 |

| 6 | 152.4 | 0.141 | 3.58 | 8.83 | 13.10 |

| 6 | 152.4 | 0.156 | 3.96 | 9.75 | 14.50 |

| 6 | 152.4 | 0.164 | 4.17 | 10.23 | 15.20 |

| 6 | 152.4 | 0.172 | 4.37 | 10.72 | 16.00 |

| 8 | 203.2 | 0.141 | 3.58 | 11.85 | 17.60 |

| 8 | 203.2 | 0.172 | 4.37 | 14.39 | 21.40 |

| 8 5/8 | 219.1 | 0.109 | 2.77 | 9.92 | 14.80 |

| 8 5/8 | 219.1 | 0.141 | 3.58 | 12.79 | 19.00 |

| 8 5/8 | 219.1 | 0.172 | 4.37 | 15.54 | 23.10 |

| 8 5/8 | 219.1 | 0.188 | 4.78 | 16.96 | 25.30 |

| 8 5/8 | 219.1 | 0.203 | 5.16 | 18.28 | 27.20 |

| 8 5/8 | 219.1 | 0.219 | 5.56 | 19.68 | 29.30 |

| 8 5/8 | 219.1 | 0.250 | 6.35 | 22.38 | 33.30 |

| 8 5/8 | 219.1 | 0.277 | 7.04 | 24.72 | 36.80 |

| 8 5/8 | 219.1 | 0.312 | 7.92 | 27.73 | 41.20 |

| 8 5/8 | 219.1 | 0.322 | 8.18 | 28.58 | 42.50 |

| 8 5/8 | 219.1 | 0.344 | 8.74 | 30.45 | 45.30 |

| 8 5/8 | 219.1 | 0.375 | 9.53 | 33.07 | 49.30 |

| 8 5/8 | 219.1 | 0.438 | 11.13 | 38.33 | 57.10 |

| 8 5/8 | 219.1 | 0.500 | 12.70 | 43.43 | 64.60 |

| 10 | 254.0 | 0.109 | 2.77 | 11.53 | 17.20 |

| 10 | 254.0 | 0.120 | 3.05 | 12.67 | 18.90 |

| 10 | 254.0 | 0.134 | 3.40 | 14.13 | 21.00 |

| 10 | 254.0 | 0.141 | 3.58 | 14.86 | 22.10 |

| 10 | 254.0 | 0.150 | 3.81 | 15.79 | 23.50 |

| 10 | 254.0 | 0.164 | 4.17 | 17.24 | 25.70 |

| 10 | 254.0 | 0.172 | 4.37 | 18.07 | 26.90 |

| 10 | 254.0 | 0.179 | 4.55 | 18.79 | 28.00 |

| 10 | 254.0 | 0.188 | 4.78 | 19.72 | 29.40 |

| 10 | 254.0 | 0.203 | 5.16 | 21.26 | 31.70 |

| 10 | 254.0 | 0.219 | 5.56 | 22.90 | 34.10 |

| 10 | 254.0 | 0.230 | 5.84 | 24.02 | 35.70 |

| 10 | 254.0 | 0.250 | 6.35 | 26.06 | 38.80 |

| 10 3/4 | 273.1 | 0.109 | 2.77 | 12.40 | 18.50 |

| 10 3/4 | 273.1 | 0.120 | 3.05 | 13.64 | 20.30 |

| 10 3/4 | 273.1 | 0.134 | 3.40 | 15.21 | 22.60 |

| 10 3/4 | 273.1 | 0.141 | 3.58 | 15.99 | 23.80 |

| 10 3/4 | 273.1 | 0.150 | 3.81 | 17.00 | 25.30 |

| 10 3/4 | 273.1 | 0.164 | 4.17 | 18.56 | 27.70 |

| 10 3/4 | 273.1 | 0.172 | 4.37 | 19.45 | 29.00 |

| 10 3/4 | 273.1 | 0.179 | 4.55 | 20.23 | 30.10 |

| 10 3/4 | 273.1 | 0.188 | 4.78 | 21.23 | 31.60 |

| 10 3/4 | 273.1 | 0.203 | 5.16 | 22.89 | 34.10 |

| 10 3/4 | 273.1 | 0.219 | 5.56 | 24.65 | 36.70 |

| 10 3/4 | 273.1 | 0.230 | 5.84 | 25.87 | 38.50 |

| 10 3/4 | 273.1 | 0.250 | 6.35 | 28.06 | 41.80 |

| 10 3/4 | 273.1 | 0.279 | 7.09 | 31.23 | 46.50 |

| 10 3/4 | 273.1 | 0.307 | 7.80 | 34.27 | 51.00 |

| 10 3/4 | 273.1 | 0.344 | 8.74 | 38.27 | 57.00 |

| 10 3/4 | 273.1 | 0.365 | 9.27 | 40.52 | 60.30 |

| 10 3/4 | 273.1 | 0.438 | 11.13 | 48.28 | 71.90 |

| 10 3/4 | 273.1 | 0.500 | 12.70 | 54.79 | 81.60 |

| 12 | 304.8 | 0.134 | 3.40 | 17.00 | 25.30 |

| 12 | 304.8 | 0.141 | 3.58 | 17.87 | 26.60 |

| 12 | 304.8 | 0.150 | 3.81 | 19.00 | 28.30 |

| 12 | 304.8 | 0.164 | 4.17 | 20.75 | 30.90 |

| 12 | 304.8 | 0.172 | 4.37 | 21.75 | 32.40 |

| 12 | 304.8 | 0.179 | 4.55 | 22.62 | 33.70 |

| 12 | 304.8 | 0.188 | 4.78 | 23.74 | 35.40 |

| 12 | 304.8 | 0.203 | 5.16 | 25.60 | 38.10 |

| 12 | 304.8 | 0.219 | 5.56 | 27.58 | 41.00 |

| 12 | 304.8 | 0.230 | 5.84 | 28.94 | 43.10 |

| 12 | 304.8 | 0.250 | 6.35 | 31.40 | 46.70 |

| 12 | 304.8 | 0.281 | 7.14 | 35.20 | 52.40 |

| 12 | 304.8 | 0.312 | 7.92 | 38.98 | 58.00 |

| 12 3/4 | 323.9 | 0.109 | 2.77 | 14.73 | 21.90 |

| 12 3/4 | 323.9 | 0.134 | 3.40 | 18.07 | 26.90 |

| 12 3/4 | 323.9 | 0.141 | 3.58 | 19.01 | 28.30 |

| 12 3/4 | 323.9 | 0.150 | 3.81 | 20.20 | 30.10 |

| 12 3/4 | 323.9 | 0.164 | 4.17 | 22.07 | 32.90 |

| 12 3/4 | 323.9 | 0.172 | 4.37 | 23.13 | 34.40 |

| 12 3/4 | 323.9 | 0.179 | 4.55 | 24.05 | 35.80 |

| 12 3/4 | 323.9 | 0.188 | 4.78 | 25.25 | 37.60 |

| 12 3/4 | 323.9 | 0.203 | 5.16 | 27.23 | 40.60 |

| 12 3/4 | 323.9 | 0.219 | 5.56 | 29.34 | 43.70 |

| 12 3/4 | 323.9 | 0.230 | 5.84 | 30.78 | 45.80 |

| 12 3/4 | 323.9 | 0.250 | 6.35 | 33.41 | 49.70 |

| 12 3/4 | 323.9 | 0.281 | 7.14 | 37.46 | 55.80 |

| 12 3/4 | 323.9 | 0.312 | 7.93 | 41.48 | 61.80 |

| 12 3/4 | 323.9 | 0.330 | 8.38 | 43.81 | 65.20 |

| 12 3/4 | 323.9 | 0.344 | 8.74 | 45.62 | 67.90 |

| 12 3/4 | 323.9 | 0.375 | 9.53 | 49.61 | 73.90 |

| 12 3/4 | 323.9 | 0.438 | 11.13 | 57.65 | 85.80 |

| 12 3/4 | 323.9 | 0.500 | 12.70 | 65.48 | 97.50 |

| 14 | 355.6 | 0.134 | 3.40 | 19.86 | 29.50 |

| 14 | 355.6 | 0.141 | 3.58 | 20.89 | 31.10 |

| 14 | 355.6 | 0.150 | 3.81 | 22.21 | 33.10 |

| 14 | 355.6 | 0.164 | 4.17 | 24.26 | 36.10 |

| 14 | 355.6 | 0.172 | 4.37 | 25.43 | 37.90 |

| 14 | 355.6 | 0.179 | 4.55 | 26.45 | 39.40 |

| 14 | 355.6 | 0.188 | 4.78 | 27.76 | 41.40 |

| 14 | 355.6 | 0.203 | 5.16 | 29.94 | 44.60 |

| 14 | 355.6 | 0.219 | 5.56 | 32.26 | 48.00 |

| 14 | 355.6 | 0.230 | 5.84 | 33.86 | 50.40 |

| 14 | 355.6 | 0.250 | 6.35 | 36.75 | 54.70 |

| 14 | 355.6 | 0.281 | 7.14 | 41.21 | 61.40 |

| 14 | 355.6 | 0.312 | 7.93 | 45.65 | 68.00 |

| 14 | 355.6 | 0.344 | 8.87 | 50.22 | 74.80 |

| 14 | 355.6 | 0.375 | 9.53 | 54.62 | 81.30 |

| 14 | 355.6 | 0.438 | 11.13 | 63.50 | 94.60 |

| 14 | 355.6 | 0.469 | 11.91 | 67.84 | 100.90 |

| 14 | 355.6 | 0.500 | 12.70 | 72.16 | 107.50 |

| 16 | 406.4 | 0.134 | 3.40 | 22.73 | 33.80 |

| 16 | 406.4 | 0.141 | 3.58 | 23.90 | 35.60 |

| 16 | 406.4 | 0.150 | 3.81 | 25.42 | 37.80 |

| 16 | 406.4 | 0.164 | 4.17 | 27.76 | 41.40 |

| 16 | 406.4 | 0.172 | 4.37 | 29.10 | 43.30 |

| 16 | 406.4 | 0.179 | 4.55 | 30.27 | 45.10 |

| 16 | 406.4 | 0.188 | 4.78 | 31.78 | 47.30 |

| 16 | 406.4 | 0.203 | 5.16 | 34.28 | 51.10 |

| 16 | 406.4 | 0.219 | 5.56 | 36.95 | 55.00 |

| 16 | 406.4 | 0.230 | 5.84 | 38.77 | 57.70 |

| 16 | 406.4 | 0.250 | 6.35 | 42.09 | 62.60 |

| 16 | 406.4 | 0.281 | 7.14 | 47.22 | 70.30 |

| 16 | 406.4 | 0.312 | 7.93 | 52.32 | 77.90 |

| 16 | 406.4 | 0.344 | 8.87 | 57.57 | 87.00 |

| 16 | 406.4 | 0.375 | 9.53 | 62.64 | 93.50 |

| 16 | 406.4 | 0.438 | 11.13 | 72.86 | 108.50 |

| 16 | 406.4 | 0.469 | 11.91 | 77.87 | 115.90 |

| 16 | 406.4 | 0.500 | 12.70 | 82.85 | 123.30 |

| 18 | 457.2 | 0.141 | 3.58 | 26.92 | 40.00 |

| 18 | 457.2 | 0.172 | 4.37 | 32.78 | 48.80 |

| 18 | 457.2 | 0.188 | 4.78 | 35.80 | 53.30 |

| 18 | 457.2 | 0.219 | 5.56 | 41.63 | 61.90 |

| 18 | 457.2 | 0.230 | 5.84 | 43.69 | 65.00 |

| 18 | 457.2 | 0.250 | 6.35 | 47.44 | 70.60 |

| 18 | 457.2 | 0.281 | 7.14 | 53.23 | 79.20 |

| 18 | 457.2 | 0.312 | 7.93 | 58.99 | 87.90 |

| 18 | 457.2 | 0.344 | 8.74 | 64.93 | 96.70 |

| 18 | 457.2 | 0.375 | 9.53 | 70.65 | 105.20 |

| 18 | 457.2 | 0.438 | 11.13 | 82.23 | 122.40 |

| 18 | 457.2 | 0.469 | 11.91 | 87.89 | 130.80 |

| 18 | 457.2 | 0.500 | 12.70 | 93.54 | 139.20 |

| 20 | 508.0 | 0.141 | 3.58 | 29.93 | 44.50 |

| 20 | 508.0 | 0.172 | 4.37 | 36.46 | 54.30 |

| 20 | 508.0 | 0.188 | 4.78 | 39.82 | 59.30 |

| 20 | 508.0 | 0.219 | 5.56 | 46.31 | 68.90 |

| 20 | 508.0 | 0.250 | 6.35 | 52.78 | 78.60 |

| 20 | 508.0 | 0.281 | 7.14 | 59.23 | 88.20 |

| 20 | 508.0 | 0.312 | 7.93 | 65.66 | 97.80 |

| 20 | 508.0 | 0.344 | 8.87 | 72.28 | 107.60 |

| 20 | 508.0 | 0.375 | 9.53 | 78.67 | 117.20 |

| 20 | 508.0 | 0.438 | 11.13 | 91.59 | 136.40 |

| 20 | 508.0 | 0.469 | 11.91 | 97.92 | 145.70 |

| 20 | 508.0 | 0.500 | 12.70 | 104.23 | 155.10 |

| 22 | 558.8 | 0.172 | 4.37 | 40.13 | 59.80 |

| 22 | 558.8 | 0.188 | 4.78 | 43.84 | 65.30 |

| 22 | 558.8 | 0.219 | 5.56 | 50.99 | 75.90 |

| 22 | 558.8 | 0.250 | 6.35 | 58.13 | 86.50 |

| 22 | 558.8 | 0.281 | 7.14 | 65.24 | 97.10 |

| 22 | 558.8 | 0.312 | 7.93 | 72.34 | 107.70 |

| 22 | 558.8 | 0.375 | 9.53 | 86.69 | 129.10 |

| 22 | 558.8 | 0.438 | 11.13 | 100.96 | 150.30 |

| 22 | 558.8 | 0.469 | 11.91 | 107.95 | 160.60 |

| 22 | 558.8 | 0.500 | 12.70 | 114.92 | 171.00 |

| 24 | 609.6 | 0.172 | 4.37 | 43.81 | 65.20 |

| 24 | 609.6 | 0.188 | 4.78 | 47.86 | 71.30 |

| 24 | 609.6 | 0.219 | 5.56 | 55.67 | 82.80 |

| 24 | 609.6 | 0.250 | 6.35 | 63.47 | 94.50 |

| 24 | 609.6 | 0.281 | 7.14 | 71.25 | 106.10 |

| 24 | 609.6 | 0.312 | 7.93 | 79.01 | 117.70 |

| 24 | 609.6 | 0.375 | 9.53 | 94.71 | 141.00 |

| 24 | 609.6 | 0.438 | 11.13 | 110.32 | 164.30 |

| 24 | 609.6 | 0.469 | 11.91 | 117.98 | 175.60 |

| 24 | 609.6 | 0.500 | 12.70 | 125.62 | 186.90 |

Pipe Surface Defects

1. Surface imperfections having a depth not in excess of 12.5 % of the specified nominal wall thickness shall be acceptable.

It shall be permissible to establish the depth of such imperfections by grinding or filing.

2. Surface imperfections having a depth in excess of 12.5% of the specified nominal wall thickness shall be considered to be defects.

It shall be permissible for defects not deeper than 33.3 % of the specified nominal wall thickness to be repaired by welding, provided that the defect is completely removed prior to welding.

Appliance

ASTM A252 Grade 1 Applications

Lightly loaded projects in general soil conditions, such as foundations for small buildings or structures.

Foundations for temporary structures such as construction supports or temporary bridges.

Environmental remediation projects in good soil conditions where excessive stresses are not required.

ASTM A252 Grade 2 Applications:

Engineering projects with moderate loading requirements, including foundations for multi-story buildings or facilities.

Bridges, piers, and coastal projects in moderately hard soil conditions.

Use in conditions with some degree of risk of chemical corrosion or erosion.

ASTM A252 Grade 3 Applications:

Critical projects under highly loaded, complex soil conditions such as large bridges, high-rise buildings, and large industrial facilities.

High-risk environments, such as structures subject to intense erosion, chemical corrosion, or extreme weather conditions.

Large offshore projects, such as foundations for deep-water jetties, large breakwaters, and oil and gas platforms.

Related Standards

ASTM A252 grade 1

EN 10219 S235JRH - Cold-formed welded structural steel tubes.

BS EN 10219 S235JRH - Cold-formed welded and seamless steel tubes and pipes for structural purposes.

CSA G40.21 300W - Structural quality steel.

AS/NZS 1163 C250L0 - Cold-formed structural steel tubes.

GB/T 3091 Q235B - Welded steel pipe for low-pressure fluid transportation.

JIS G3444 STK400 - Carbon steel pipes for structural use.

IS 4923 YST 210 - Hollow steel pipes for structural purposes.

GOST 10704-91 - Electrically welded steel pipes.

ISO 11960 - Steel pipes for the oil and gas industry.

ASTM A36 - Structural Carbon Steel for Non-Standard Applications.

ASTM A252 Grade 2

EN 10219 S275J0H - Cold-formed welded structural steel pipe.

CSA G40.21 350W - Structural quality steel.

AS/NZS 1163 C350L0 - Cold-formed structural steel pipe.

GB/T 3091 Q345B - Welded steel pipe for low-pressure fluid transportation.

JIS G3444 STK490 - Carbon steel pipes for structural use.

IS 4923 YST 310 - Hollow Steel Pipe for Structural Purposes.

ASTM A252 Grade 3

EN 10219 S355J2H - Cold-formed welded structural steel pipes.

CSA G40.21 350W - Structural quality steel, specific configurations may meet Grade 3 requirements.

AS/NZS 1163 C450L0 - Cold-formed structural steel tubes and pipes, a high strength grade in the series.

GB/T 3091 Q460C - Welded steel pipe for low-pressure fluid transportation for applications requiring higher strength.

JIS G3444 STK540 - Carbon steel pipe for structural use, available in high-strength options.

Our Related Products

Botop Steel is a China Professional Welded Carbon Steel Pipes Manufacturer& Suppliers Over 16 Years with 8000+ Tons of Seamless Line pipe in Stock Each Month. Provide you with high-quality and low-price steel pipe products, if you need please contact us, we will provide you with a wide range of steel pipe solutions.

tags: astm a252,astm a252 grade 2,astm a252 grade 3, pipe piling, pipe pile, structural, suppliers, manufacturers, factories, stockists, companies, wholesale, buy, price, quotation, bulk, for sale, cost.

Post time: Mar-29-2024