ASTM A106 and ASTM A53 are widely used as common standards for the manufacture of carbon steel pipe.

Although ASTM A53 and ASTM A106 steel tubing are interchangeable in some industrial applications, their respective properties make the proper selection of standardized tubing especially important in certain specific environments and conditions.

Navigation Buttons

Pipe Type

ASTM A53 steel pipe involves both welded and seamless steel pipe.

ASTM A106 covers only seamless steel pipe.

| Standard | Scope | Types | Grade | |

| ASTM A106: Seamless Carbon Steel Pipe for High-Temperature Service | NPS 1/8 - 48 in (DN 6 -1200mm) | Seamless Carbon Steel Pipe | A, B, and C | |

| ASTM A53: Black and Hot-Dipped, Zinc-Coated, Welded and Seamless | NPS 1/8 - 26 in (DN 6 -650mm) | type S: Seamless | A and B | |

| type F: Furnace-butt-welded, continuous welded | A and B | |||

| type E: Electric-resistance-welded | A and B | |||

| Note: Both standards allow for the provision of pipe with other dimensions as long as it meets all other requirements of the code. | ||||

Heat Treatment Requirements

ASTM A106

Must be heat-treated, usually by normalizing (a process of heating above a critical temperature and then cooling to a moderate temperature).

Hot rolled pipe: does not require heat treatment. When hot rolled pipe is heat treated, it shall be heat treated at 1200 °F [650 °C] or higher.

Cold-drawn pipe: shall be heat treated at 1200 °F [650 °C] or higher after the final cold-drawing process.

ASTM A53

Type E, Grade B, and Type F, Grade B: shall be heat treated after welding to at least 1000 °F [540°C] so that no untempered martensite exists, or otherwise treated so that no untempered martensite exists.

Type S: Heat treatment is not required for seamless pipe.

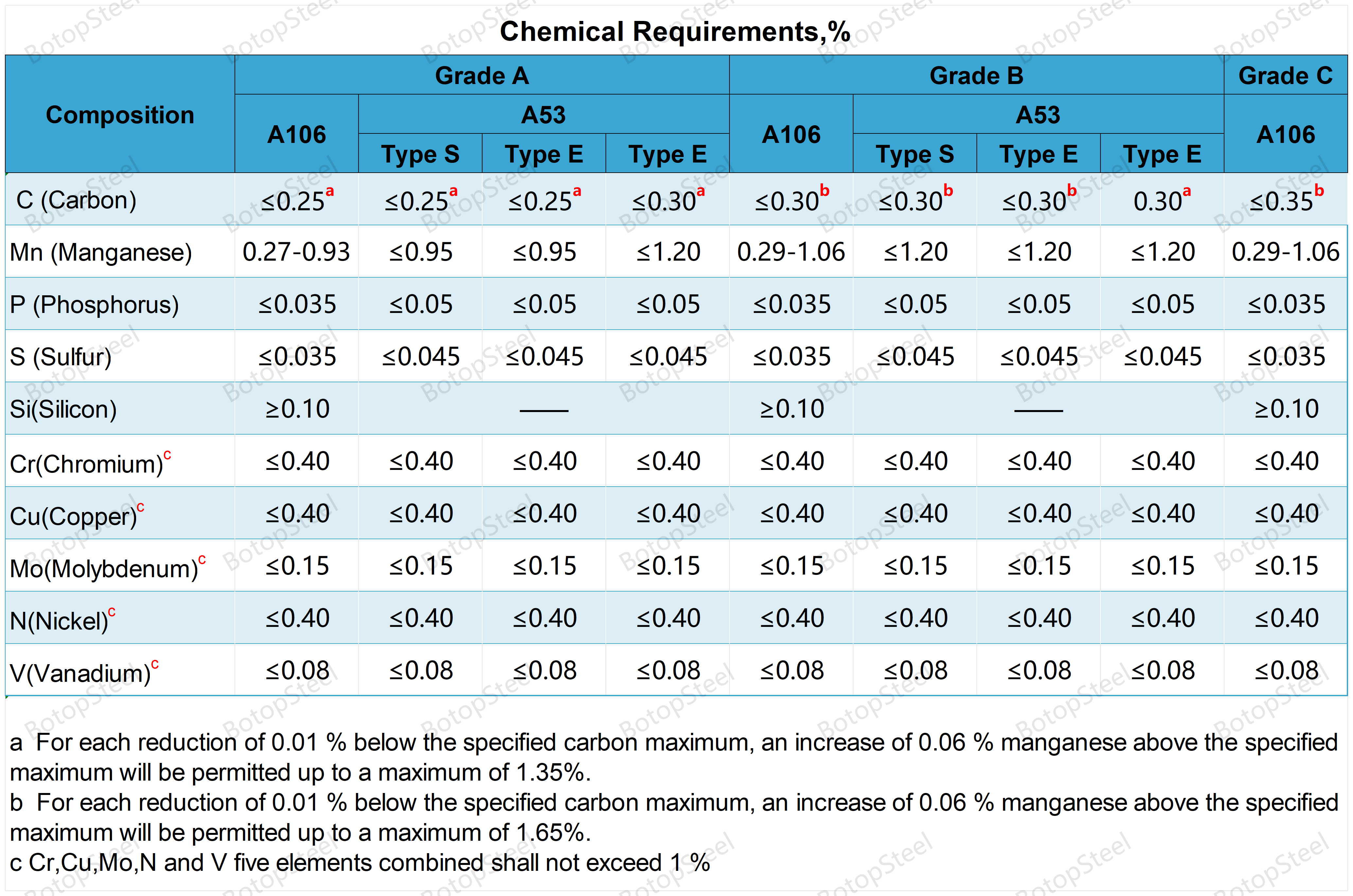

Chemical Components

When analyzing the chemical composition of ASTM A53 and ASTM A106 tubing, several key differences can be noted. ASTM A106 specifies a silicon (Si) content of not less than 0.10%, which contributes to its performance at elevated temperatures, making it particularly suitable for use in high-temperature environments such as those in the petrochemical industry and steam transmission systems.

For carbon (C) content, the ASTM A53 standard specifies a lower upper limit, especially for grades A and B for Type S and Type E. This makes Type A53 tubes more suitable for welding and cold working and therefore often used in construction and fluid transportation systems, such as water and gas pipelines.

In terms of manganese (Mn) content, ASTM A106 provides a wide range for Grade B and C, which allows for increased flexibility in the manufacturing process while improving strength. A53 pipe, on the other hand, is limited to a tighter upper limit for manganese content, which facilitates stability during welding.

Mechanical Properties

| Composition | Classification | Grade A | Grade B | Grade C | ||

| A106 | A53 | A106 | A53 | A106 | ||

| Tensile strength min |

psi | 48,000 | 48,000 | 60,000 | 60,000 | 70,000 |

| MPa | 330 | 330 | 415 | 415 | 485 | |

| Yield strength min |

psi | 30,000 | 30,000 | 35,000 | 35,000 | 40,000 |

| MPa | 205 | 205 | 240 | 240 | 275 | |

ASTM A106 Grade A and Grade B have the same requirements as ASTM A53 Grade A and Grade B in terms of yield strength and tensile strength.

However, ASTM A106 Grade C does set the bar higher, meaning it offers better performance under more extreme operating conditions, such as higher pressures or temperatures.

These additional mechanical properties make Grade C more suitable for specialized industrial applications that require materials with better load-carrying capacity and durability.

Dimensional Tolerances

ASTM A106 Specific Requirements for Dimensional Tolerances

| List | Scope | Note | |

| Mass | 96.5%-110% | Unless otherwise agreed upon between the manufacturer and the purchaser, pipe in NPS 4 [DN 100] and smaller may be weighed in convenient lots; pipe larger than NPS 4 (DN 100] shall be weighed separately. | |

| Diameter (diameter larger than 10in(DN250)) |

±1% | Diameter-Except as provided for thin-wall pipe in paragraph 12.2 of Specification A530/A530M, the tolerances for diameter shall be in accordance with the following: |

|

| Inner Diameter (Inner diameter larger than 10in(DN250)) |

±1% | ||

| Thickness | min 87.5% | —— | |

| Lengths | Single random lengths | shall be 16 to 22 ft (4.8 to 6.7 m) in length, except that 5 % shall be permitted to be less than 16 ft (4.8 m) and none shall be less than 12 ft (3.7 m). | —— |

| Double random lengths | shall have a minimum the average length of 35 ft (10.7 m) and shall have a minimum length of 22 ft (6.7 m), except that 5 % shall be permitted to be less than 22 ft (6.7 m) and none shall be less than 16 ft (4.8 m). |

—— | |

ASTM A53 Specific Requirements for Dimensional Tolerances

| List | sort | scope |

| Mass | Theoretical weight = length x specified weight (in accordance with the requirements in tables 2.2 and 2.3) |

±10% |

| Diameter | DN 40mm[NPS 1/2] or smaller | ±0.4mm |

| DN 50mm[NPS 2] or larger | ±1% | |

| Thickness | minimum wall thickness shall be in accordance with Table X2.4 | min 87.5% |

| Lengths | lighter than extra-strong(XS) weight | 4.88m-6.71m (not more than 5 % of the total number of threaded lengths furnished being jointers(two pieces coupled together)) |

| lighter than extra-strong(XS) weight (plain-end pipe) |

3.66m-4.88m (Not more than 5% of the total number) |

|

| XS, XXS, or thicker wall thickness | 3.66m-6.71m ( no more than 5% total of pipe 1.83m-3.66m) |

|

| lighter than extra-strong(XS) weight (double-random lengths) |

≥6.71m (Minimum average length of 10.67m) |

Applications

The design and manufacturing requirements for ASTM A53 and ASTM A106 steel pipe reflect their respective unique application scenarios.

ASTM A53 steel pipe is commonly used in building and mechanical structures and in low-pressure environments for the transportation of liquids or gases, such as municipal water and natural gas supplies.

ASTM A106 steel tubes are mainly used in applications subjected to high-temperature environments, such as in boilers in petrochemical plants and power stations to transport high-temperature steam or thermal oil. The higher tensile and yield strengths they offer ensure performance and durability under demanding conditions, especially for A106 Grade C steel tubes, which provide a higher safety factor in high-temperature and high-pressure environments.

If you would like to know more about ASTM A106 and ASTM A53, please click here.

About Us

Botop Steel has been a professional Welded Carbon Steel Pipe manufacturer and supplier in China for 16 years, with more than 8000 tons of Seamless Steel Pipe in stock each month. We provide professional and high-quality service for you.

tags:astm a106,astm a53,a53 gr. b, suppliers, manufacturers, factories, stockists, companies, wholesale, buy, price, quotation, bulk, for sale, cost.

Post time: Mar-16-2024