API 5L Grade A=L210 which means the minimum yield strength of the pipe is 210mpa.

API 5L Grade B=L245, that is, the minimum yield strength of steel pipe is 245mpa.

API 5L PSL 1 has grade A and grade B; API 5L PSL 2 has grade B only.

There are three other types of PSL 2 pipe for special applications: PSL 2 Pipe Ordered for Sour Service (S), PSL 2 Pipe Ordered for Offshore Service (O), and PSL 2 Pipe with Resistance to Ductile Fracture Propagation(G).

Acceptable Delivery Conditions

Tube grades consist of letters or a mixture of letters and numbers to identify the strength level of the tube and are related to the chemical composition of the steel.

Steel Grade A and Steel Grade B grades do not include a specified minimum yield strength.

| PSL | Delivery Condition | Pipe Grade/Steel Grade | |

| PSL1 | As-rolled,normalizing rolled,normalized,or normalizing formed | L210 | A |

| As-rolled,normalizing rolled,thermomechanical rolled,thermomechanical formed,normalizing formed,normalized,normalized and tempered;or,if agreed,quenched and tempered for SMLS pipe only |

L245 | B | |

| PSL 2 | As-rolled | L245R | BR |

| Normalizing rolled,normalizing formed,normalized,or normalized and tempered | L245N | BN | |

| Quenched and tempered | L245Q | BQ | |

| Thermomechanical rolled or thermomechanical formed | 1245M | BM | |

| Indicates that the pipe is used in acidic conditions | L245RS | BRS | |

| L245NS | BNS | ||

| L245QS | BQS | ||

| 1245MS | BMS | ||

| Indicates that the pipe is intended for use in offshore service strips | L245RO | BRO | |

| L245NO | BNO | ||

| L245QO | BQO | ||

| 1245MO | BMO | ||

In PSL2, R, N, Q, or M denotes the delivery status of the tube, and S, 0 denotes special purpose.

Chemical Composition

API 5L PSL1 Chemical Composition

PSL1: The chemical composition requirements of PSL1 are mainly to ensure that the steel pipe has good workability and adequate mechanical properties. So the chemical composition specification of PSL1 is relatively broad, with only the maximum limit of carbon content and the basic requirements of manganese, phosphorus, sulfur, and other elements.

| Mass Fraction,Based on Heat and Product Analyses a.e % |

PSL 1 | ||||

| Seamless Pipe | Welded Pipe | ||||

| Grade A | Grade B | Grade A | Grade B | ||

| C | max b | 0.22 | 0.28 | 0.22 | 0.26 |

| Mn | max b | 0.90 | 1.20 | 0.90 | 1.20 |

| P | min | — | — | — | — |

| max | 0.03 | 0.03 | 0.03 | 0.03 | |

| S | max | 0.03 | 0.03 | 0.03 | 0.03 |

| V | max | — | c,d | — | c,d |

| Nb | max | — | c,d | — | c,d |

| Ti | max | — | d | — | d |

a Cu≤0.50 %;Ni≤0.50%;Cr≤0.50 %and Mo≤0.15 %.

b For each reduction of 0.01 %below the specified maximum concentration for carbon, an increase of 0.05%above the specified maximum concentration for Mn is permissible, up to a maximum of 1.65 %for grades ≥L245 or B.

c Unless otherwise agreed, Nb+V≤0.06 %.

d Nb+V+Ti≤0.15%e Unless otherwise agreed.

e No deliberate addition of B is permitted and the residual B≤0.001 %.

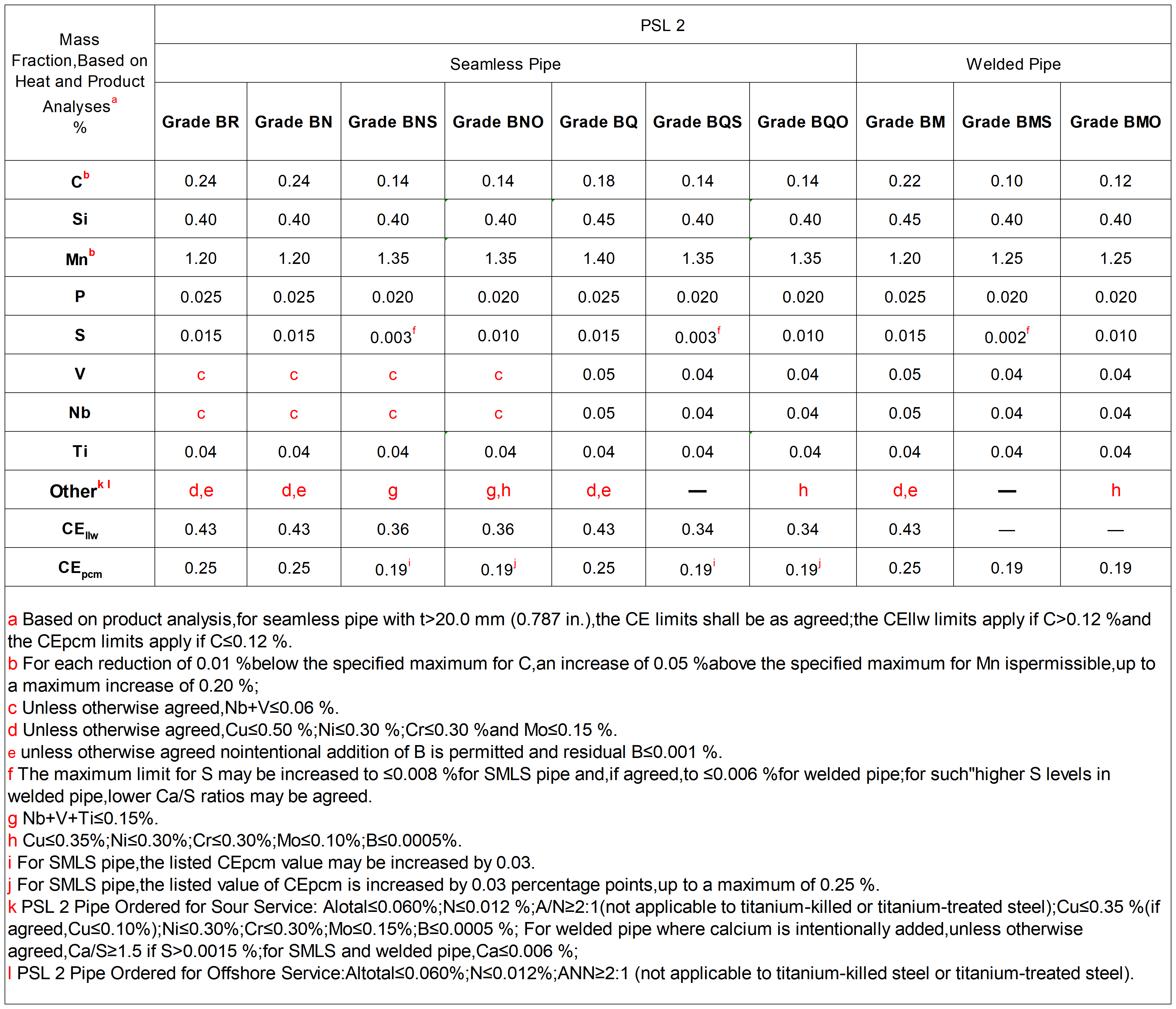

API 5L PSL2 Chemical Composition

PSL2: Compared to PSL1, PSL2 has more stringent chemical composition requirements, including lower carbon content and higher content of alloying elements (e.g. chromium, nickel, molybdenum, etc.), to improve the steel's strength, toughness, and corrosion resistance. psl2 will also typically have more specific carbon equivalent limits to optimize weldability and reduce hardening problems in the heat-affected zone.

Ductile Fracture Expansion Resistant PSL 2 Tubing There is no clear distinction between the chemical composition of "Ductile Fracture Expansion Resistant PSL 2 Tubing" and "Ordinary PSL 2 Tubing", so it will not be discussed here.

Tensile Properties

API 5L PSL1 Tensile Properties

API 5L PSL 1 has grade A and grade B.

API 5L PSL1, the mechanical properties are specified mainly to ensure that the pipe has sufficient strength and flexibility. Therefore, only the minimum values of tensile strength and yield strength are specified. For example, for Grade B, the minimum value for tensile strength is 415 MPa and the minimum value for yield strength is 245 MPa. These minimum values ensure the performance of the pipe under normal conveying conditions.

| Requirements for the Results of Tensile Tests for API PSL 1 Pipe | ||||

| Pipe Grade | Pipe Body of Seamless and Welded Pipe | Weld Seam of EW, LW, SAW,and COW Pipe |

||

| Yield Strengtha Rto.5 MPa(psi) |

Tensile Strengtha Rm MPa(psi) |

Elongation (on 50 mm or 2 in.) Af % |

Tensile Strengthb Rm MPa(psi) |

|

| min | min | min | min | |

| Grade A (L210) |

210 (30,500) | 335(48,600) | c | 335(48,600) |

| Grade B (L245) |

245 (35,500) | 415(60,200) | c | 415(60,200) |

If you would like a more in-depth look at API 5L, click here!

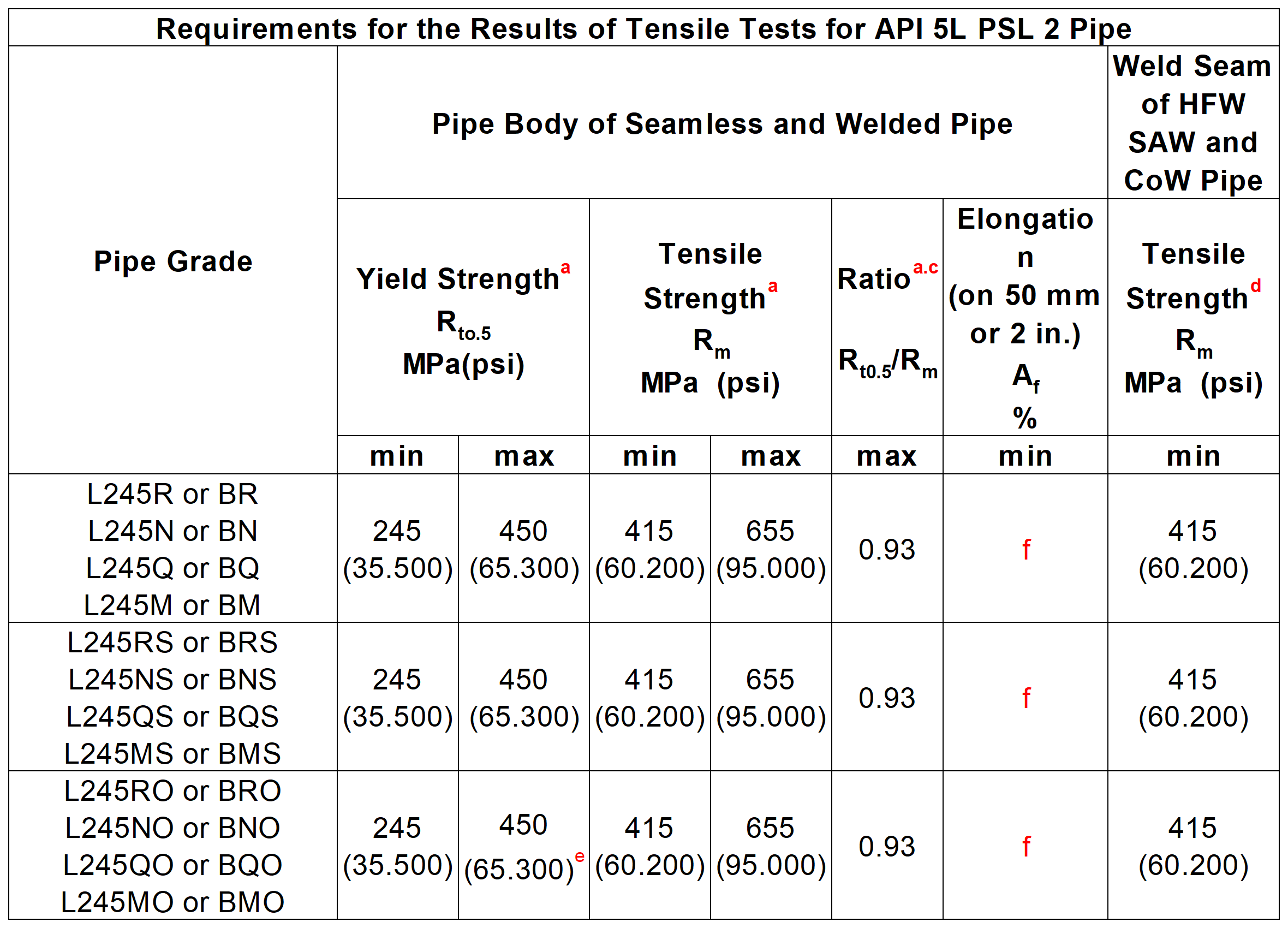

API 5L PSL2 Tensile Properties

API 5L PSL 2 has grade B only.

But there are four different delivery states: R, N, Q, and M. There are also two special service conditions for PSL2 tubes: S Sour (Service) and O (Offshore Service ).

API 5L PSL2 specifies not only minimum values for tensile and yield strength but also maximum values. This is primarily to control the uniformity and predictability of the pipe, especially during welding and fabrication. Overly dispersed material properties can be avoided, helping to ensure the reliability and safety of the pipe in extreme or changing operating environments.

Alternative Materials

API 5L Grade A Alternative Materials

ASTM A53 Grade A

ASTM A106 Grade A

ASTM A252 Grade 1

ASTM A333 Grade 6

ASTM A500 Grade B

ISO 3183 Grade L245

GB/T 9711 L245 or L290

GB/T 8163

API 5L Grade B Alternative Materials

ASTM A53 Grade B

ASTM A106 Grade B

ASTM A500 Grade B

ASTM A252 Grade 3

ISO 3183 Grade L245 or L290

GB/T 9711 L245 or L290

Application

API 5L Grade A Application

API 5L Grade A is a base grade in the API 5L standard, and it is primarily used in relatively low-pressure application scenarios. Due to its relatively low strength, Grade A steel pipe is typically used in the following areas:

Urban and rural water supply piping: piping systems used to transport potable water.

Irrigation systems: Irrigation piping in the agricultural sector for the transportation of water.

Gas Distribution Networks: Used in some low-pressure gas distribution systems to transport natural gas to residential and commercial customers.

Industrial Discharge: Used for the discharge of treated wastewater from industrial sites in low-pressure environments.

Auxiliary Pipelines: Pipelines used as auxiliary or maintenance pipelines at oil and gas extraction sites.

API 5L Grade B Application

API 5L Grade B steel pipe offers a higher strength rating in the API 5L standard, making it suitable for medium-pressure applications. This makes Grade B steel pipe a more versatile and widely used option, including:

Major oil and gas transmission pipelines: used to transport crude oil and natural gas from the point of production to the refinery or storage facility.

Subsea Pipelines: Used in the development of subsea oil and gas fields and for product transportation.

High-Pressure Steam Piping: Used to transport high-temperature and high-pressure steam in a number of industrial applications.

Structural Pipe: Due to its better mechanical properties, it is also used in a number of structural and architectural applications where it is required to withstand higher pressures.

Process Facility Piping: Used to transport a variety of chemicals and fluids in industrial facilities such as petroleum processing and chemical treatment.

Our Related Products

Botop Steel is a China Professional Welded Carbon Steel Pipes Manufacturer& Suppliers Over 16 Years with 8000+ Tons of Seamless Line pipe in Stock Each Month. If you have any need for steel pipe please contact us, we are glad to provide you with efficient and high-quality service!

tags: api 5l grade b, api 5l grade a, api 5l, suppliers, manufacturers, factories, stockists, companies, wholesale, buy, price, quotation, bulk, for sale, cost.

Post time: Mar-26-2024