Seamless steel pipe is a steel pipe made of whole round steel perforated with no welded seam on the surface.

Classification: According to the shape of the section, seamless steel pipe is divided into two kinds: round and shaped.

Wall thickness range: 0.25-200mm.

Diameter range: 4-900mm.

Production process: The production of seamless steel pipe mainly adopts the hot rolling or cold drawing method.

Advantages: better pressure capacity, more uniform structure, higher strength, and better roundness.

Disadvantages: higher cost and relatively limited size options

Uses: Mainly used as petroleum geological drilling pipe, petrochemical cracking pipe, boiler pipe, bearing pipe, as well as high-precision structural steel pipe for automobile, tractor, and aviation.

Navigation Buttons

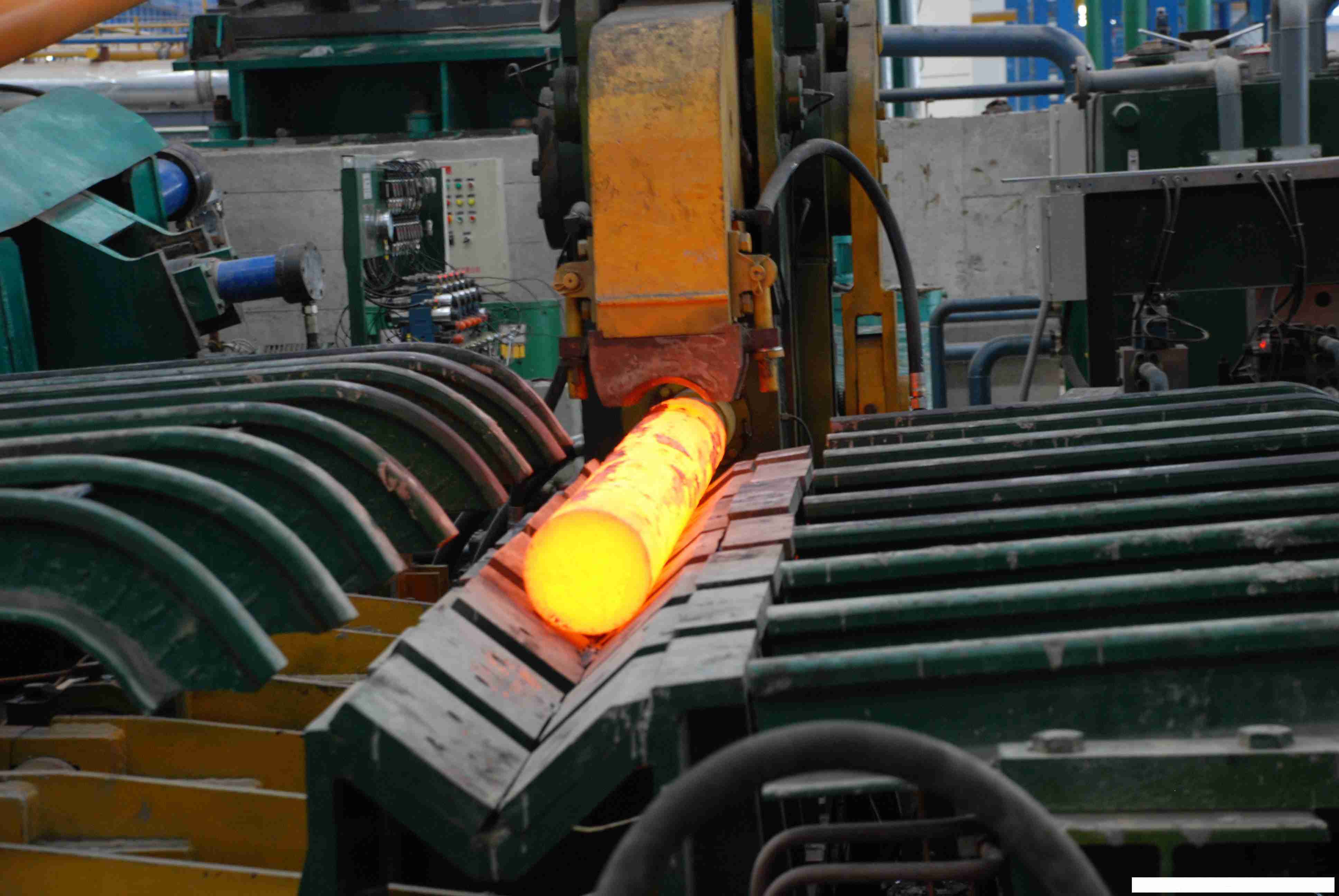

production process of hot rolling

Raw material preparation→Heating→Perforation→Rolling→Elongation→Sizing and wall reduction→Heat treatment→Straightness correction→Inspection and testing→Cutting and Finished Product Inspection→Anti-corrosion treatment

Raw material preparation: Billets need to be surface cleaned to remove any oxides or other impurities before manufacture.

Heating: The billet is fed into a heating furnace to be heated to the appropriate temperature, which is usually above 1200℃.

Perforation: The heated billet is fed into a perforating machine, which perforates it to form a hollow billet.

Rolling: After piercing, the billet enters the rolling mill. The billet passes through multiple pairs of rolls that continuously reduce the outside diameter and increase the length of the billet.

Elongation: The billet is further stretched by means of an elongator to achieve more precise dimensional specifications.

Sizing and wall reduction: Sizing and wall reduction of the billet in a sizing machine to achieve the final specific size and wall thickness.

Heat treatment: the pipe needs heat treatment to adjust its metal organization and improve the mechanical properties of the material, including normalizing and annealing processes.

Straightness correction: The pipe is corrected by straightening machine to ensure the straightness of the pipe.

Inspection and testing: Various inspections and tests are carried out on the completed seamless steel pipe, such as hydrotest, ultrasonic testing, eddy current testing, etc.

Cutting and Finished Product Inspection: Cut the tubes into specified lengths according to the customer's requirements and perform final visual and dimensional inspections.

Anti-corrosion treatment: If necessary, the seamless steel pipe is coated with anti-corrosion oil or other anti-corrosion treatments, such as galvanized;3LPE, FBE and so on.

Production process of cold-drawn

Billet pipe preparation→Annealing treatment→Pickling and Lubrication→Cold Drawing→Heat treatment→Straightness correction→Inspection and testing→Cutting and Finished Product Inspection→Anti-corrosion treatment

Billet pipe preparation: Selection of suitable hot rolled seamless steel pipe as raw material, i.e. initial billet pipe.

Annealing treatment: In order to eliminate the stresses generated during the hot rolling process of billet pipes, billet pipes usually need to be annealed.

Pickling and Lubrication: After annealing, the tubes need to be pickled to remove surface oxidized skin and rust. Afterward, a lubricating substance is applied to the tube surface to minimize friction and wear during the cold drawing process.

Cold Drawing: The billet pipe is placed on a cold drawing machine and stretched through a die, a process that reduces the diameter of the pipe as well as improves the surface finish and dimensional accuracy.

After that, the heat treatment and other production processes are the same as hot rolling, and will not be repeated here.

How to differentiate between hot rolled and cold drawn seamless steel pipe, you can focus on the following simple features:

| List | hot rolling | cold-drawing |

| Appearances | The surface is rougher and may have oxidized skin and more surface defects such as scratches, pockmarks, and rolling indentations | Good surface finish, usually smoother and brighter than hot rolled steel pipe |

| Outer Diameter(OD) | OD≥33.9 | OD<33.9 |

| Wall Thickness | 2.5-200mm | 0.25-12mm |

| Tolerance | Prone to uneven wall thickness and ovalization | Uniform outer diameter wall thickness with small tolerances |

| Prices | Low price for the same conditions | Higher price for the same conditions |

Seamless steel pipe implementation standards

International Standards

ISO 3183 : Steel pipes for the oil and gas industry

American Standard

ASTM A106 : Seamless carbon steel pipe for high temperature service

ASTM A53 : Seamless and Welded Black and Hot-Dipped Galvanized Steel Pipe

API 5L : Line pipe for the transportation of oil, gas and water

API 5CT : Oil well casing and tubing

ASTM A335 :Seamless alloy steel tubes and pipes for high temperature service

ASTM A312 : Seamless, Welded and Heavy Duty Cold-Finished Stainless Steel Tubes and Pipes

European Standards

EN 10210 : Seamless and welded steel tubes and pipes for hot formed structures

EN 10216 : Seamless steel tubes and pipes (for pressure applications)

EN 10297 : Seamless round steel tubes and pipes for mechanical and general engineering purposes

DIN 2448 : Dimensions and quality of seamless steel tubes

DIN 17175 : Seamless heat-resistant steel tubes

DIN EN 10216-2 : Non-alloy and alloy steel tubes (pressure applications)

BS EN 10255 : Non-alloy steel tubes and pipes for welded and threaded connections

Japanese Standards

JIS G3454 : Carbon steel pipes for pressure piping

JIS G3455 : Carbon steel pipes for high pressure services

JIS G3461 : Carbon steel pipes for boilers and heat exchangers

JIS G3463 : Boiler and heat exchanger tubes of stainless steel

Russian Standard

GOST 8732-78 : Seamless hot rolled steel tubes and pipes according to Russian Standard

Australian Standards

AS/NZS 1163 : Standard for Structural Steel Tubes and Pipes covering round, square and rectangular tubes and pipe products.

AS 1074 : Steel pipes and fittings for water, gas and air pipelines.

Quality control of seamless steel pipe

1. Visual and Dimensional Inspection: To check the surface quality, including defects such as cracks, scratches, rust and corrosion, and the accuracy of dimensions, including length, diameter, and wall thickness.

2. Chemical Composition Analysis: Ensure that the chemical composition of the steel meets the standard requirements through spectral analysis and other methods.

3. Physical property testing: including tensile strength, yield strength, elongation, hardness testing, etc. to verify the mechanical properties of the material.

4. Non-destructive testing (NDT):

—Ultrasonic Testing (UT): for internal defects, such as inclusions and cracks.

—Magnetic particle testing (MT): mainly used to find defects such as cracks on and near the surface of the steel pipe.

—Radiographic testing (RT): detects internal defects by X-ray or γ-ray, suitable for detecting internal defects in welded joints and pipe bodies.

—Eddy current inspection (ET): suitable for detecting surface and sub-surface defects, mainly used for thin-walled materials.

5.Hydrostatic test: By filling the steel pipe with water and applying a specific pressure, it is checked for leakage to verify its pressure-bearing capacity.

6.Impact testing: Especially for applications with low temperatures or other special requirements, impact testing evaluates the toughness of a material when subjected to a sudden impact.

7.Metallographic analysis: Examines the microstructure of the material to ensure that the metallic organization of the seamless steel pipe meets the requirements.

Precautions for purchasing seamless steel pipe

Main Matters:

—Clarify specifications: make sure to provide accurate dimensional specifications such as outer diameter, wall thickness, length, etc.

—Select material: Select the appropriate steel grade and material according to the application environment, such as carbon steel, alloy steel, stainless steel, etc.

—Standards and certifications: Specify the standards to be followed (e.g. ASTM, API, DIN, etc.) and the required quality certifications or test reports.

—Quantity: Provide accurate quantities, taking into account possible wastage and spare requirements.

Supplementary matters:

—Surface treatment: depending on the requirements of the application, decide whether the steel pipe needs to be surface treated, such as galvanized or painted.

—End treatment: Indicate whether the pipe ends need special treatment, such as flat end, beveled, threaded, etc.

—Description of use: Provide the environment and use of the steel pipe so that the supplier can recommend suitable products.

—Packaging requirements: Specify the special requirements for packaging to ensure safety during transportation.

—Delivery time: Confirm the delivery date of the order to make sure it meets your project schedule.

—Price terms: Discuss and finalize the price terms, including shipping costs, taxes, etc.

—After-sales service: understand the supplier's after-sales service, such as how quality issues are handled.

—Technical Support: Confirm the availability of technical support, especially for special applications or installations.

About Us

Botop Steel is a professional Welded Carbon Steel Pipe manufacturer and supplier, Seamless Steel Pipe stockist in China. With more than 16 years of history, we keep more than 8,000 tons of seamless line pipe in stock each month. If you want to know more about our steel pipe products, you can contact us to provide you with high-quality products and services!

tags: seamless steel pipe; seamless steel pipe meaning; standard; Suppliers, manufacturers, factory, Stockist, companies, wholesale, buy, price, quotation, bulk, for sale, cost.

Post time: Apr-04-2024