When it comes to constructing pipelines, ensuring their durability and resistance against corrosion is of utmost importance. LSAW carbon steel pipes, also known as Longitudinal Submerged Arc Welding pipes, are a popular choice due to their high strength and reliability. To further enhance their corrosion resistance, these pipes can be coated with a three-layer structure polyethylene anti-corrosion known as 3PE. In this blog, we will explore the benefits of using 3PE coated LSAW carbon steel pipes and why they are an excellent choice for various industries.

The 3PE anti-corrosion coating is a reliable solution that protects the LSAW carbon steel pipes from corrosion and extends their lifespan. The 3PE structure consists of three layers, starting with an epoxy powder layer that provides excellent adhesion and bonding to the surface of the pipe. This is followed by an adhesive layer, which further strengthens the bond between the epoxy and the final layer – polyethylene anti-corrosion. The polyethylene layer acts as a barrier, preventing water, chemicals, and other corrosive substances from reaching the inner surface of the pipe. Moreover, it can withstand temperatures of up to 80°C, making it suitable for a wide range of applications.

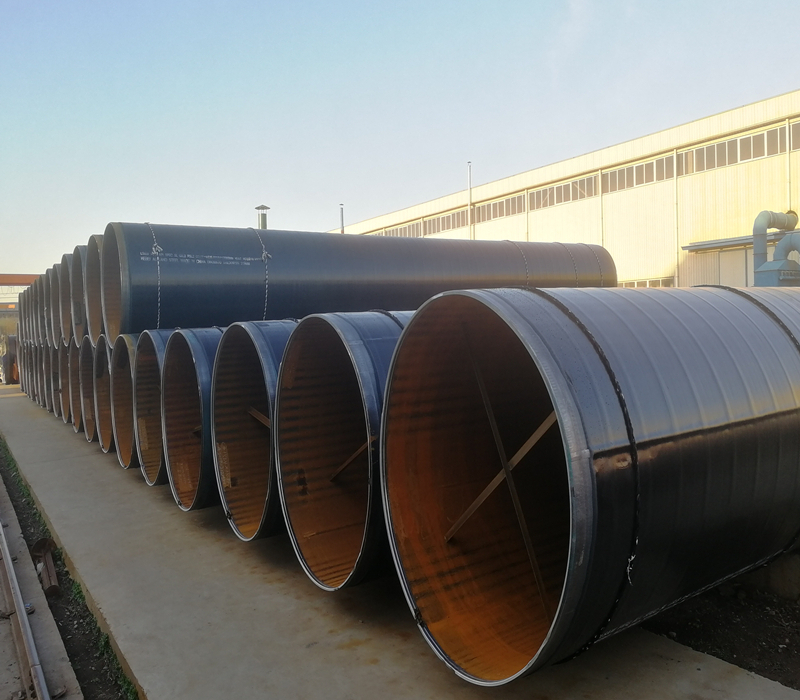

Compared to the 2PE coating, the addition of the epoxy powder layer in 3PE coated LSAW carbon steel pipes increases the overall effectiveness of the anti-corrosion properties. This additional layer enhances the durability and resistance to wear and tear, ensuring the pipes can withstand harsh environmental conditions. The common color of 3PE coated pipes is black, and they adhere to international standards such as DIN30670, CAN/CSA Z245.21, and ISO21809. These stringent standards ensure that the pipes meet the required quality and performance criteria, making them a reliable choice for various industries.

At Botop Steel, we specialize in providing high-quality LSAW carbon steel pipes with 3PE anti-corrosion coating. Our pipes are available in different sizes, grades, and specifications to cater to the specific needs of our clients. With our commitment to excellence and attention to detail, we ensure that our pipes meet the highest industry standards. Additionally, our pipes are coated with FBE anti-corrosion from the inside, further enhancing their resistance to corrosion. The internal FBE coating is non-toxic and helps prevent corrosion while improving the flow rate of gas and liquid within the pipeline. This makes our 3PE coated LSAW carbon steel pipes a reliable choice for industries such as oil and gas, water supply, and construction.

In conclusion, 3PE coated LSAW carbon steel pipes offer numerous benefits, including superior anti-corrosion properties, high durability, and resistance against wear and tear. The combination of epoxy powder layer, adhesive layer, and polyethylene anti-corrosion layer ensures that the pipes can withstand harsh conditions, making them suitable for diverse applications. At Botop Steel, we take pride in offering high-quality pipes that meet international standards and exceed customer expectations. Invest in 3PE coated LSAW carbon steel pipes for a reliable and long-lasting pipeline solution.

Post time: Nov-27-2023