Thick-walled seamless steel tubes play an important role in machinery and heavy industry due to their outstanding mechanical properties, high pressure-bearing capacity, and excellent durability.

Next, we will deeply analyze the features and advantages of thick wall seamless steel pipe from multiple angles to provide you with comprehensive product knowledge.

Manufacturing Processes

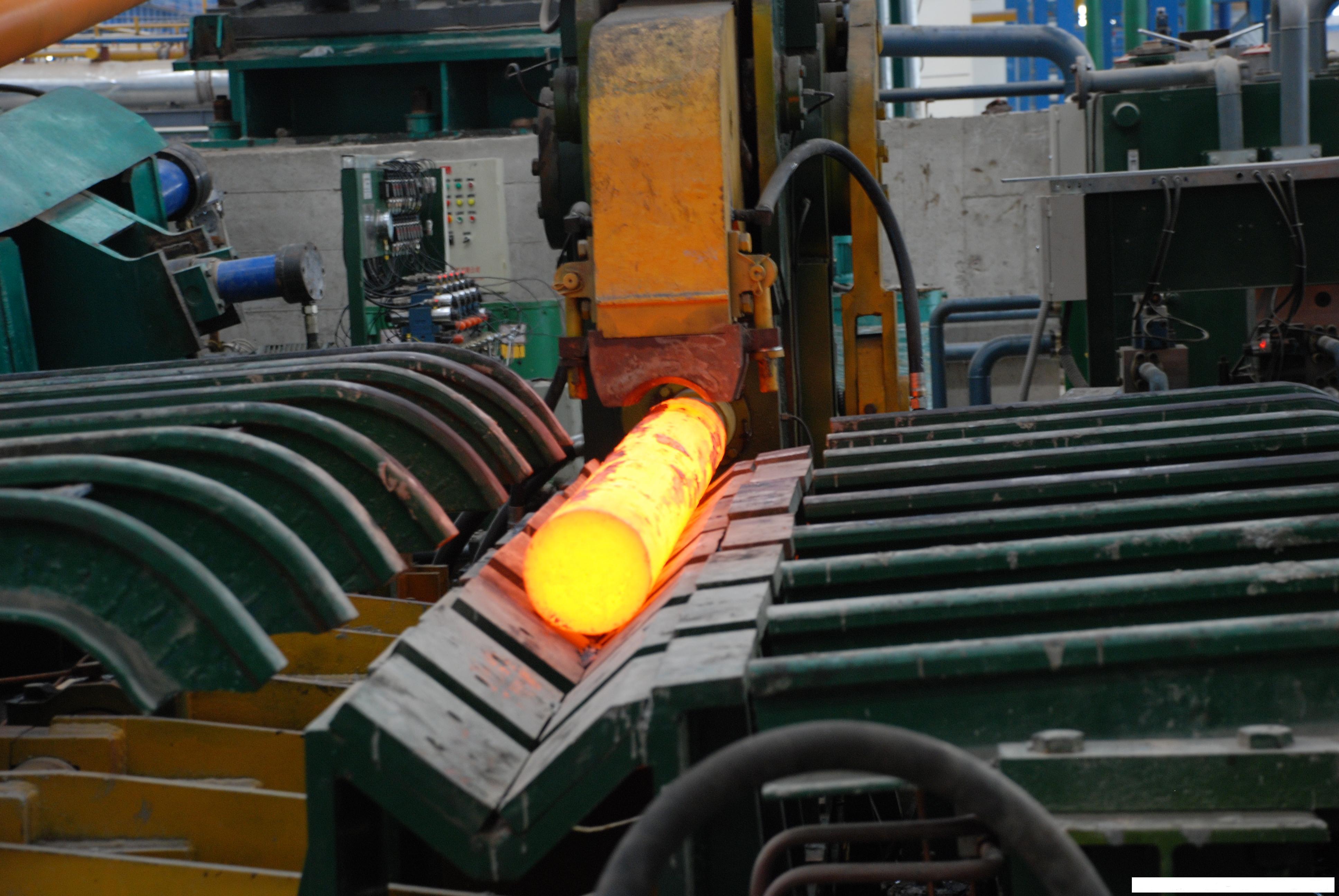

It is well known that the production process of seamless steel pipe has two kinds of hot finish and cold finish.

However, for seamless steel pipes with such wall thickness, only hot finish can be used.

The manufacturing process for the hot finish of seamless steel pipe consists mainly of :

1. Selection of billets: Select billets of suitable size and chemical composition according to the final size and requirements. The choice of billet has a significant impact on the quality of the final product.

2. Pre-treatment: Remove oxidized skin and other impurities from the surface of the billet. Ensure that these external factors do not affect the quality of the tube during heat treatment and rolling.

3. Billet heating: The billet is heated to the proper temperature to facilitate plastic deformation. The heating must be uniform to avoid temperature gradients within the material, which could lead to product defects.

4. Boring and billet extension: The heated round billet is machined into a hollow billet. The wall thickness is then reduced and the length of the billet is increased by extension.

5. Hot Rolling: The billet is rolled at high temperature through a hot rolling mill to achieve the desired outside diameter and wall thickness. Hot rolling is the main step in the formation of the tube, which determines the basic shape and size of the tube.

6. Heat treatment process: In order to improve the mechanical properties and microstructure of the tubes, the tubes are subjected to heat treatment processes such as normalizing or annealing. It can eliminate stress, fine grain and improve toughness.

7. Surface treatment and corrosion protection: This includes cleaning and coating, such as oiling or painting, to improve the corrosion resistance and appearance quality of the steel pipe.

8. Quality inspection: A series of tests and inspections, such as dimensional testing, visual and surface inspections, non-destructive testing (e.g. ultrasonic testing), mechanical property testing (e.g. tensile, impact testing), and hardness and microstructural analysis to ensure that the products comply with technical specifications and quality standards.

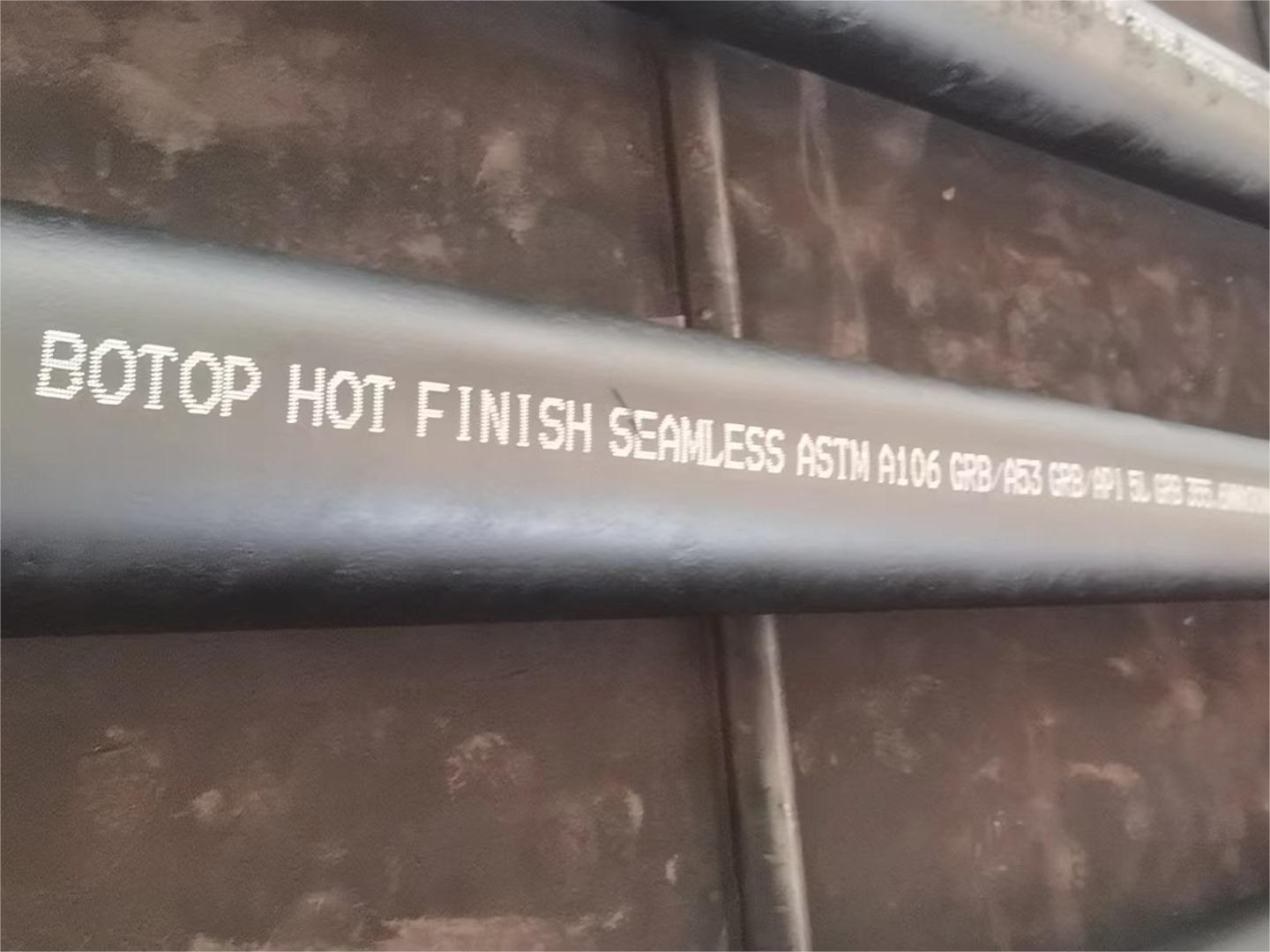

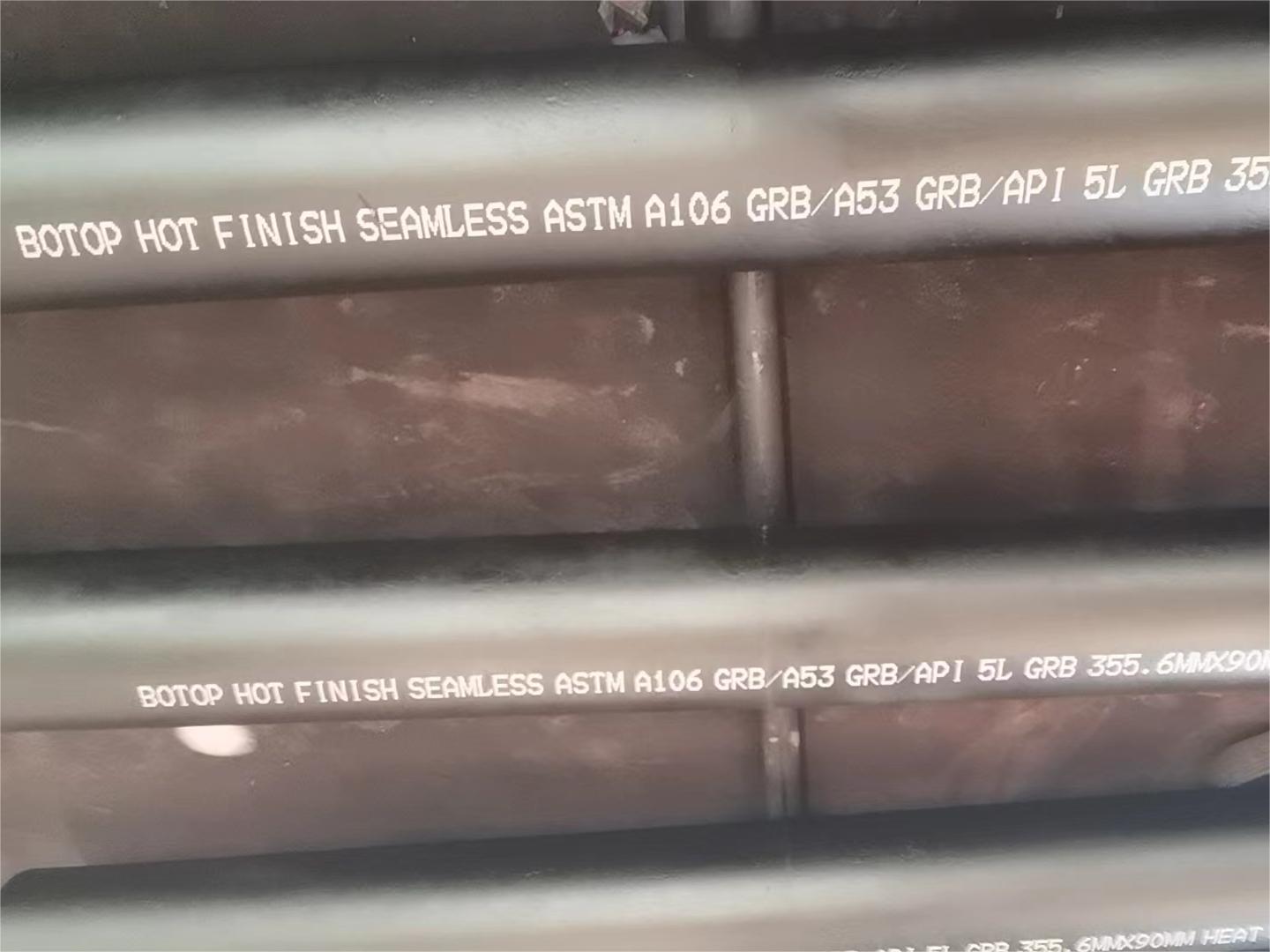

Executive Standards for Seamless Steel Tubes and Pipes

ASTM A106: Seamless carbon steel pipe for high-temperature service.

ASTM A53: Seamless and welded black and hot-dipped galvanized steel pipe for pressure and mechanical applications.

ASTM A333: Seamless and welded steel pipe for low-temperature service.

API 5L: Line pipe for pipeline transportation systems.

API 5CT: Casing and tubing for oil and gas wells.

EN 10210: Seamless and welded steel hollow sections for thermoformed structures.

EN 10216: Seamless steel tubes for pressure purposes.

EN 10297: Seamless round steel tubes and pipes for general engineering purposes.

ISO 3183: Steel pipes for pipeline transportation systems for the oil and gas industry.

JIS G3454: Carbon steel pipes for pressure piping.

JIS G3455: Carbon steel pipes for high-pressure service.

JIS G3461: Carbon steel pipes for boilers and heat exchangers.

AS/NZS 1163: Hollow sections of structural steel.

AS 1074: Steel pipes and fittings.

IS 1161: Specification for steel pipe for structural purposes.

API 5L, ASTM A53, and ASTM A06 are often used in the standard, but also in a certain range of alternative use of each other.

today my company completed the inspection and is ready to ship the 355.6 × 90 thick-walled seamless steel pipe, in the implementation of these standards.

Advantages of Thick-walled Seamless Steel Pipe

1. High strength and pressure resistance: Seamless thick-walled steel pipe can withstand higher pressure without the weak points at the weld seams of welded steel pipe, which makes it suitable for high-pressure environments.

2. Corrosion resistance: Seamless steel pipe can resist corrosion in harsh environments through specific alloy composition and surface treatment.

Such as acidic service environment, and offshore service environment.

3. High-temperature resistance: Seamless steel pipe can work in high-temperature environments without loss of strength.

4. Variety of wall thickness: seamless steel pipe can be manufactured according to the needs of a variety of wall thicknesses, The wall thickness range can now reach 100mm, which is the welded steel pipe can not be reached, especially for small diameter thick-walled steel pipe.

5. Long service life: Due to its high strength and good corrosion resistance, it has a long service life and reduces the risk of post-maintenance.

Disadvantages of Thick Wall Seamless Steel Pipe

1. Price: Compared with welded steel pipe or other common wall thickness the price will be higher, this product often needs to be customized.

2. Production cycle: If you need to customize the production, the production cycle is relatively long.

3. Weight: The thicker wall thicknesses make them heavier, which can make transportation and installation more difficult.

4. Dimensional constraints: Seamless thick-walled tubes do not have the same dimensional flexibility as welded tubes in terms of very large or very small diameters.

Uses of Thick Wall Seamless Steel Tubes

Thick-walled seamless steel tubes are preferred in industrial applications requiring resistance to high pressure, high temperature, high strength, and good reliability.

1. Oil & Gas Industry: Used in the extraction and transportation of oil and natural gas, especially as oil well tubing and pipelines subjected to high-pressure underground environments.

2. Chemical industry: Used in chemical plants for the transmission of high-pressure fluids or as an integral part of heat transfer equipment such as reactors or heaters.

3. Energy industry: used as boiler piping, heat exchanger piping, and steam piping at high temperatures and pressures in cogeneration and nuclear power plants.

4. Mechanical manufacturing: Used in the manufacture of mechanical components capable of withstanding high pressures, such as hydraulic systems, bearings, and cylinders in automotive manufacturing.

5. Building and construction: for the construction of high load-bearing capacity of the building structure, such as bridges, large machinery support frames, and high-pressure environment of the pillar.

6. Marine engineering: Used in shipbuilding and in the construction of offshore platforms, especially in parts requiring high corrosion resistance and strength.

7. Aviation and aerospace industry: used in the manufacture of aircraft, rockets satellites, and other important components of aerospace vehicles, requiring materials with special high-temperature resistance and strength characteristics.

8. Environmental facilities: for piping systems in sewage treatment plants and waste treatment facilities, as well as gas collection pipes in high-pressure landfills.

9. Geothermal industry: for the extraction of geothermal energy, including the drilling of geothermal wells and piping for the transportation of geothermal fluids.

10. Military and Defense: In military engineering, for the manufacture of components for submarines, tanks, and other armored vehicles, as well as other military equipment requiring high strength and pressure resistance.

Though high in cost and weight, thick-walled seamless steel tubes are required for their high strength, pressure, and corrosion resistance in many industrial applications. These characteristics make them valuable in the oil and gas, chemical, energy, and machinery manufacturing industries, especially where consistent material properties are required and harsh environments are used.

While the upfront purchase cost may be higher, the long-term durability and low maintenance costs often make the total cost of ownership more reasonable.

Our Advantages

We are one of the leading welded carbon steel pipe and seamless steel pipe manufacturers and suppliers from China, with a wide range of high-quality steel pipe in stock, we are committed to providing you with a full range of steel pipe solutions.

For more product details, please feel free to contact us, we look forward to helping you find the best steel pipe options for your needs!

Tags: seamless, hot finish, steel pipe, suppliers, manufacturers, factories, stockists, companies, wholesale, buy, price, quotation, bulk, for sale, cost.

Post time: May-07-2024