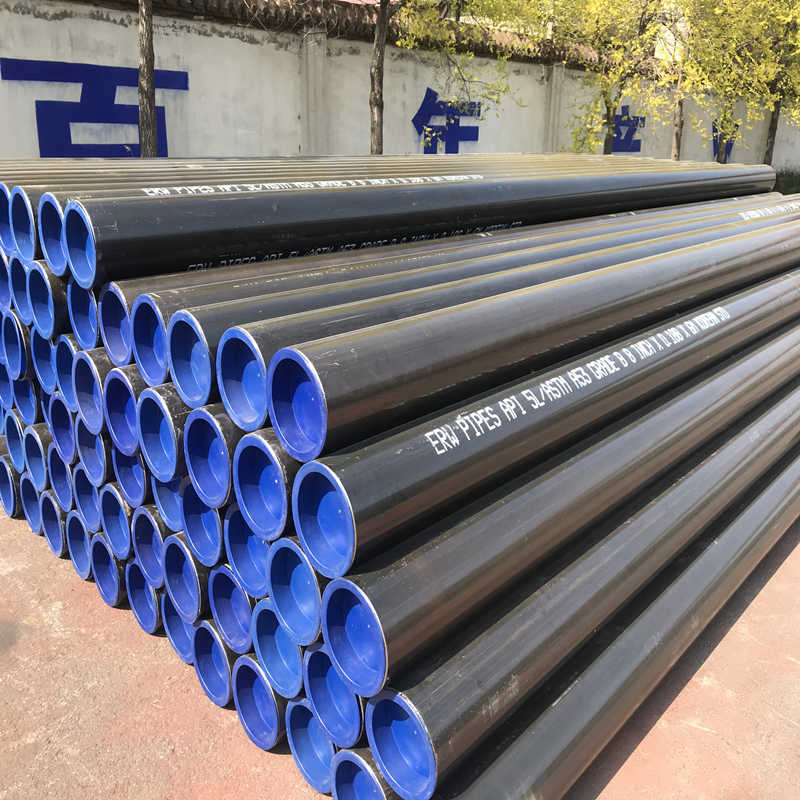

JIS G3454 carbon ERW steel pipe,

,

| Style | Technical | Material | Standard | Grade | Usage |

| Electric Resistance Welded (ERW) steel pipe | High Frequency | Carbon Steel | API 5L PSL1&PSL2 | GR.B,X42,X46,X52,X60,X65,X70,etc | Transportation of oil and gas |

| ASTM A53 | GR.A ,GR.B | For Structure (Piling) | |||

| ASTM A252 | GR.1, GR.2,GR.3 | ||||

| BS EN10210 | S275JRH,S275J0H,S355J0H,S355J2H,etc | ||||

| BS EN10219 | S275JRH,S275J0H,S355J0H,S355J2H,etc | ||||

| JIS G3452 | SGP,etc | Transportation of Low-pressure fluid | |||

| JIS G3454 | STPG370,STPG410,etc | Transportation of High-pressure fluid | |||

| JIS G3456 | STPG370,STPG410,STPG480,etc | high temperature steel pipes |

Pipe ordered under this specification is for pressure service at an approximate maximum temperature of 350℃。

Bare pipe, black coating or hot dip zinc-coated( customized);

In bundles with two cotton slings;

Both ends with end protectors;

Plain end, bevel end(When required by the purchaser and S≤22mm, the pipe end of should be bevelled, degree: 30° (+5°~0°), and the wall thickness of the root is not reduced by <2.4mm.);

Marking.

Grade and Chemical Composition (%)

|

Grade |

C≤ |

Si≤ |

Mn |

P≤ |

S≤ |

|

STPG370 |

0.25 |

0.35 |

0.30~0.90 |

0.040 |

0.040 |

|

STPG410 |

0.30 |

0.35 |

0.30~1.00 |

0.040 |

0.040 |

|

|

|

|

|

|

|

|

Mechanical Properties |

||||||

|

Grade |

Tensile strength |

Yield strength |

Elongation % |

|||

|

N/ m㎡ |

N/ m㎡ |

No.11 or No.12 test pieces |

No. 5 test pieces |

No. 4 test piece |

||

|

|

|

Longitudinal |

Transverse |

Longitudinal |

Transverse |

|

|

STPG370 |

370 min |

215 min |

30 min |

25 min |

28 min |

23 min |

|

STPG410 |

410 min |

245 min |

25 min |

20 min |

24 min |

19 min |

Tolerance of OD and W.T

|

Division |

Tolerance on O.D |

Tolerance on W.T |

||

|

Cold finished ERW Steel Pipe |

24A or under |

+/-0.3mm |

Under 3mm

3mm or over |

+/-0.3mm

+/-10% |

|

32A or over |

+/-0.8% |

|

|

|

| For pipes of nominal size 350A or over,the tolerance on O.D maybe determined by the circumferential length. In this case,the tolerance shall be +/-0.5% | ||||

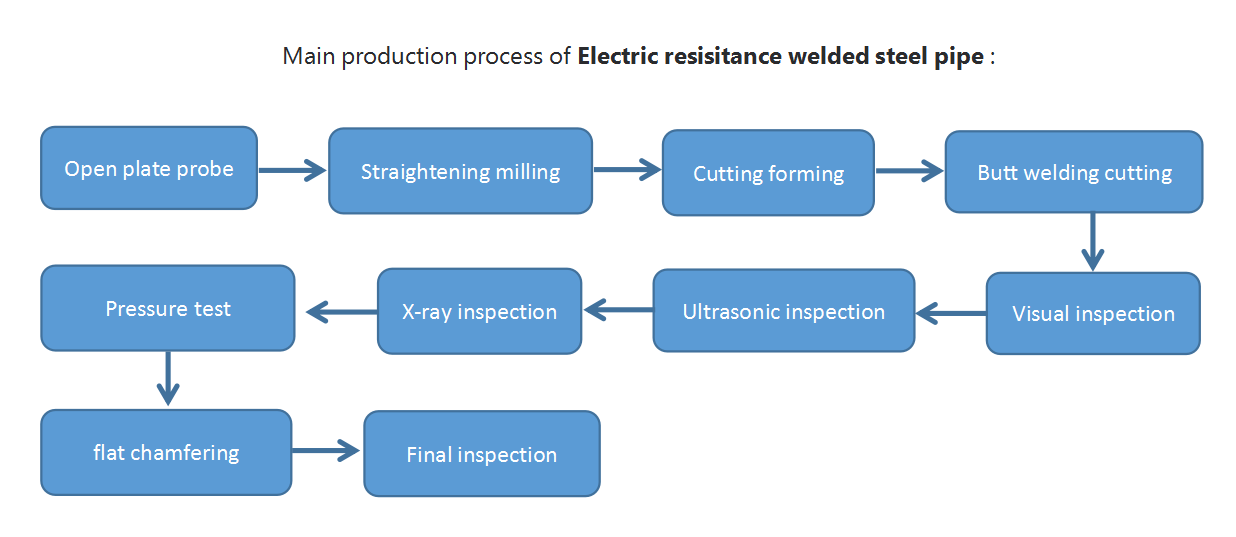

JIS G3454 ERW steel pipe stamping service is an important aspect of ERW steel pipe fabrication and production. JIS G3454 is a Japanese Industrial Standard specifying carbon steel pipes for high temperature pressure service. ERW (electric resistance welded) steel pipe is manufactured by a process in which the edges of steel sheets or strips are heated and fused together under pressure, forming a seamless and strong pipe. Stamping services involved in the production of JIS G3454 ERW Steel Pipes play a vital role in ensuring the quality and reliability of these pipes. Stamping services involve the use of high-pressure machinery to form pipes to desired dimensions and specifications. This process ensures that the pipe has smooth and precise ends, and a consistent wall thickness throughout its length. One of the key advantages of JIS G3454 ERW steel pipe press services is the ability to produce pipes with excellent dimensional accuracy and weld integrity. Stamping services allow for tighter control over the manufacturing process, ensuring that the pipe meets the required standards and specifications. Additionally, the use of high-pressure machinery during stamping services helps produce pipes with exceptional strength and durability, making them suitable for a variety of applications in industries such as oil and gas, construction, and automotive. In addition, JIS G3454 ERW steel pipe pressing services can also produce smooth and beautiful pipes. The machinery used in stamping services can polish and refine the surface of the pipe, resulting in a more visually appealing product. This is especially important for applications where piping is exposed or visible as it enhances the overall appearance and ensures a high quality finish. In conclusion, JIS G3454 ERW Steel Pipe pressing services are an integral part of the manufacturing process, ensuring the production of high quality and reliable pipes for various pressure service applications. It assures dimensional accuracy, weld integrity, and smooth surfaces, making these pipes suitable for a wide range of industries and uses.

复制