Ukushisela i-arc okucwiliswe emanzini kulungele amapayipi, imikhumbi yokucindezela kanye namathangi, ukwenziwa kwesitimela kanye nezinhlelo zokusebenza ezinkulu zokwakha, ngesimo se-monofilament esilula kakhulu, isakhiwo sezintambo ezimbili, isakhiwo sezintambo ezimbili ezihlanganisiwe kanye nesakhiwo sezintambo eziningi.

Ukushisela i-arc okucwiliswe emanzini kungabazuzisa abasebenzisi ezicelweni eziningi zokushisela. Kusukela ekukhuliseni umkhiqizo, ekuthuthukiseni indawo yokusebenza, ekuqinisekiseni ikhwalithi ehambisanayo nokuningi. Abakhiqizi bokucubungula insimbi abacabangela izinguquko enqubweni yokushisela i-arc okucwiliswe emanzini kufanele ngabe bacabanga ukuthi bangathola izinzuzo eziningi kule nqubo.

Ulwazi oluyisisekelo lokushisela i-arc ngaphansi kwamanzi

Inqubo yokushisela i-arc engaphansi komhlaba iyimfuneko efanele ukusetshenziswa kwezimboni ezisindayo njengamapayipi, imikhumbi yokucindezela kanye namathangi, ukwakhiwa kwesitimela, ukwakhiwa/ukumba okunzima. Ilungele izimboni ezidinga umkhiqizo ophezulu, ikakhulukazi uma kukhulunywa ngokushisela izinto ezijiyile kakhulu, kunezinzuzo eziningi ezingatholakala enqubweni yokushisela i-arc engaphansi komhlaba.

Izinga layo eliphezulu lokufakwa kanye nesivinini sokuhamba kungaba nomthelela omkhulu ekukhiqizeni kwabasebenzi, ukusebenza kahle kanye nezindleko zokukhiqiza, okungenye yezinzuzo ezibalulekile zenqubo yokushisela i-arc engaphansi kwamanzi.

Ezinye izinzuzo zifaka: ukwakheka kwamakhemikhali okuhle kakhulu kanye nezakhiwo zemishini ze-weld, ukubonakala okuncane kwe-arc kanye nomusi ophansi we-welding, induduzo ethuthukisiwe endaweni yokusebenza, kanye nesimo esihle se-weld kanye nomugqa wezinyawo.

Ukushisela i-arc ecmerged kuyindlela yokuphakela izintambo esebenzisa i-granular flux ukuhlukanisa i-arc emoyeni, njengoba igama lisikisela, i-arc igqitshwe ku-flux, okusho ukuthi uma amapharamitha esethiwe, i-arc ayibonakali ngokuphuma kwengqimba ye-flux. Intambo yokushisela iphakelwa njalo yithoshi elihamba nge-weld.

Ukushisa kwe-arc kuncibilikisa ingxenye yocingo, ingxenye ye-flux kanye nensimbi eyisisekelo, kwakha ichibi elincibilikisiwe, elihlangana ukuze lakhe i-weld embozwe ungqimba lwe-welding slag. Ububanzi bobukhulu bezinto zokushisela bungu-1/16"-3/4", bungaba yi-100% ye-penetration welding ngokushisela okukodwa, uma ubukhulu bodonga bungalinganiselwe, ukushisela okunama-multi-pass kungenziwa, futhi ukushisela kulungiswe futhi kukhethwe ngendlela efanele, futhi kukhethwa inhlanganisela ye-welding wire flux efanele.

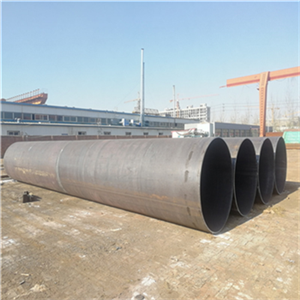

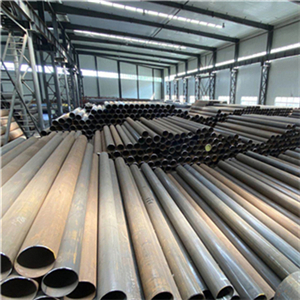

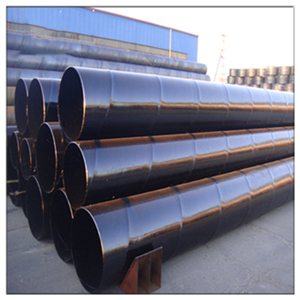

I-LSAW

I-ERW

I-SSAW

Ukukhethwa kwentambo yokushintshashintsha kanye neyokushisela

Ukukhetha i-flux efanele kanye nentambo yenqubo ethile yokushisela i-arc engaphansi kwamanzi kubalulekile ekufinyeleleni imiphumela emihle kakhulu usebenzisa inqubo. Nakuba izinqubo zokushisela i-arc engaphansi kwamanzi zodwa zisebenza kahle, ukukhiqiza kanye nokusebenza kahle kungakhuliswa ngisho nangokusebenzisa intambo yokushisela kanye ne-flux esetshenzisiwe.

Ukugeleza akuvikeli nje kuphela ichibi lokushisela, kodwa futhi kunegalelo ekuthuthukisweni kwezakhiwo zemishini kanye nokukhiqiza kweshidi. Ukwakheka kwama-fluxes kunomthelela omkhulu kulezi zici, kuthinta amandla okuthwala amanje kanye nokukhululwa kwe-slag.

Umthamo wamanje wokuthwala usho ukuthi kungatholakala ukusebenza kahle kokufakwa kanye nephrofayili yokushisela yekhwalithi ephezulu.

Ukukhishwa kwe-slag kusuka ku-flux ethile kuthinta ukukhetha i-flux ngoba amanye ama-flux afaneleka kakhulu emiklamo ethile ye-solder kuneminye.

Izinketho zokukhetha i-flux zokufaka i-arc soldering ngaphansi kwamanzi zifaka izinhlobo ezisebenzayo nezingathathi hlangothi zama-weld. Umehluko oyisisekelo ukuthi i-active flux ishintsha i-chemistry ye-weld, kuyilapho i-neutral flux ingashintshi.

Ama-flux asebenzayo abonakala ngokufakwa kwe-silicon ne-manganese. Lezi zinto zisiza ukugcina amandla okunamathela kwe-weld ekushiseni okuphezulu, zisiza ukugcina i-weld ibushelelezi futhi ibushelelezi ngesivinini esikhulu sokuhamba futhi zinikeze ukukhululwa okuhle kwe-slag. Sekukonke, ama-flux asebenzayo angasiza ekunciphiseni ingozi yekhwalithi ye-solder ephansi, kanye nokuhlanza nokulungisa kabusha okubizayo ngemva kokushintshwa. Nokho, khumbula ukuthi ama-flux asebenzayo ngokuvamile afaneleka kakhulu ekushisweni kwe-solder okukodwa noma kabili.

Ama-flux angathathi hlangothi angcono kuma-solder amakhulu adlula i-multipass ngoba asiza ekugwemeni ukwakheka kwama-weld aqhekekayo, azwela ukuqhekeka.

Kunezinhlobo eziningi zezintambo zokushisela ezikhethwayo mayelana nokushisela i-arc engaphansi kwamanzi, ngayinye inezinzuzo kanye nokungalungi. Ezinye izintambo zenzelwe ukushisela ngokufakwa kokushisa okuphezulu, kanti ezinye zenzelwe ngokukhethekile ukuba nezinsimbi ezisiza ukugeleza ukuze kwenziwe ukuhlanza ukushisela.

Qaphela ukuthi izakhiwo zamakhemikhali kanye nokusebenzisana kokushisa kwentambo yokushisela kuthinta izakhiwo zemishini zensimbi yokushisela. Ukukhiqiza kungandiswa kakhulu ngokukhetha insimbi yokugcwalisa.

Isibonelo, ukusebenzisa ucingo oluyinhloko lwensimbi olunenqubo yokushisela i-arc engaphansi komhlaba kungandisa ukusebenza kahle kokufakwa ngo-15% kuya ku-30% uma kuqhathaniswa nokusebenzisa ucingo oluqinile, kuyilapho futhi kunikeza iphrofayili yokungena ebanzi nengajulile.

Ngenxa yesivinini sayo esikhulu sokuhamba, izintambo zensimbi eziyinhloko nazo zinciphisa ukufakwa kokushisa ukuze kuncishiswe ingozi yokuguqulwa kokushisela kanye nokusha.

Kuzo zonke izinsimbi, izinsimbi ezingagqwali ze-austenitic zinezinga eliphansi kakhulu lokukhiqiza. Ngakho-ke, ngokwezakhiwo zemishini, insimbi engagqwali ye-austenitic akuyona into engcono kakhulu yesiqu se-valve, ngoba ukuqinisekisa amandla athile, ububanzi besiqu se-valve buzokhula. Izinga lokukhiqiza alikwazi ukwanda ngokwelashwa ngokushisa, kodwa lingandiswa ngokwakhiwa okubandayo.

Sithengisa amapayipi e-carbon kanye nensimbi engenamthungo, siyakwamukela noma yimiphi imibuzo, sizokunikeza okokuqala!

Isikhathi sokuthunyelwe: Jan-30-2023