Muva nje, inkampani yethu ithole i-oda elihilela i-ASTM A335 P91amapayipi ensimbi angenamthungo, okudingeka kuqinisekiswe yi-IBR (Indian Boiler Regulations) ukuze kuhlangatshezwane nezindinganiso zokusetshenziswa eNdiya.

Ukuze ngikusize ube nereferensi lapho uhlangabezana nezidingo ezifanayo, ngihlanganise incazelo eningiliziwe elandelayo yenqubo yokuqinisekiswa kwe-IBR. Ngezansi ulwazi oluthile mayelana ne-oda kanye nezinyathelo ezihilelekile enkambisweni yokuqinisekiswa.

Ipayipi le-Alloy elingenamthungo le-ASTM A335 P91

Izinkinobho Zokuzulazula

Imininingwane ye-oda

Kuyini i-IBR

Inqubo Yesitifiketi Se-IBR Yamapayipi Angenamthungo e-ASTM A335 P91

1. Xhumana ne-Ejensi Yokuhlola ngemininingwane

2. Ukulethwa Kwemibhalo Yokuqala

3. Ukuqapha Inqubo Yokukhiqiza

4. Ukuhlolwa Nokuhlolwa Komkhiqizo Oqediwe

5. Ukuhlinzekwa Kwemibhalo Yenqubo

6. Ukubuyekezwa Kwamadokhumenti

7. Amamaki e-IBR

8. Ukukhishwa Kwesitifiketi se-IBR

Indima Yokuthola Ukugunyazwa kwe-IBR

Mayelana NATHI

Imininingwane ye-oda

Indawo yokusetshenziswa kwephrojekthi: eNdiya

Igama lomkhiqizo: ipayipi lensimbi engenamthungo

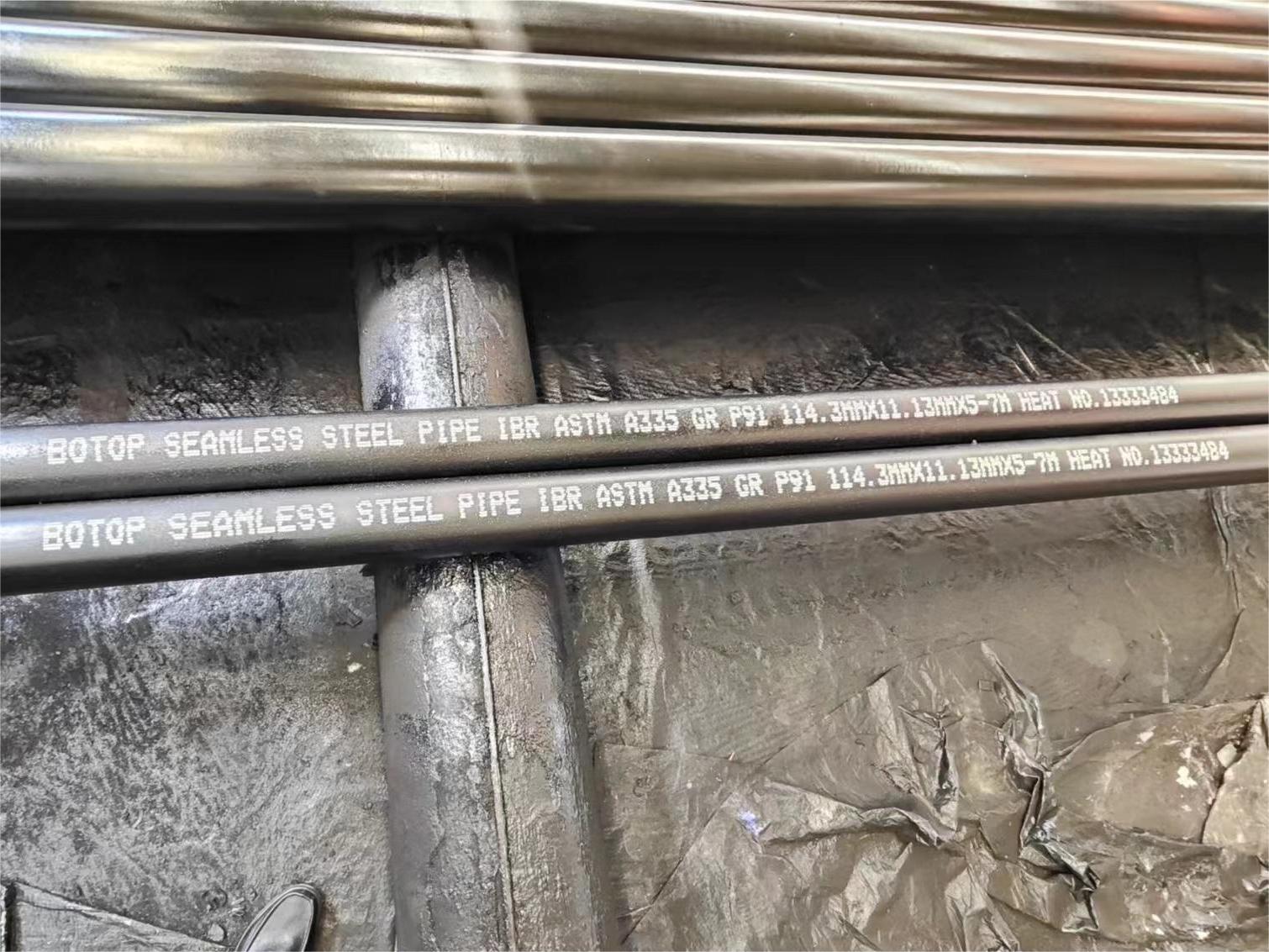

Izinto ezijwayelekile:I-ASTM A335I-P91

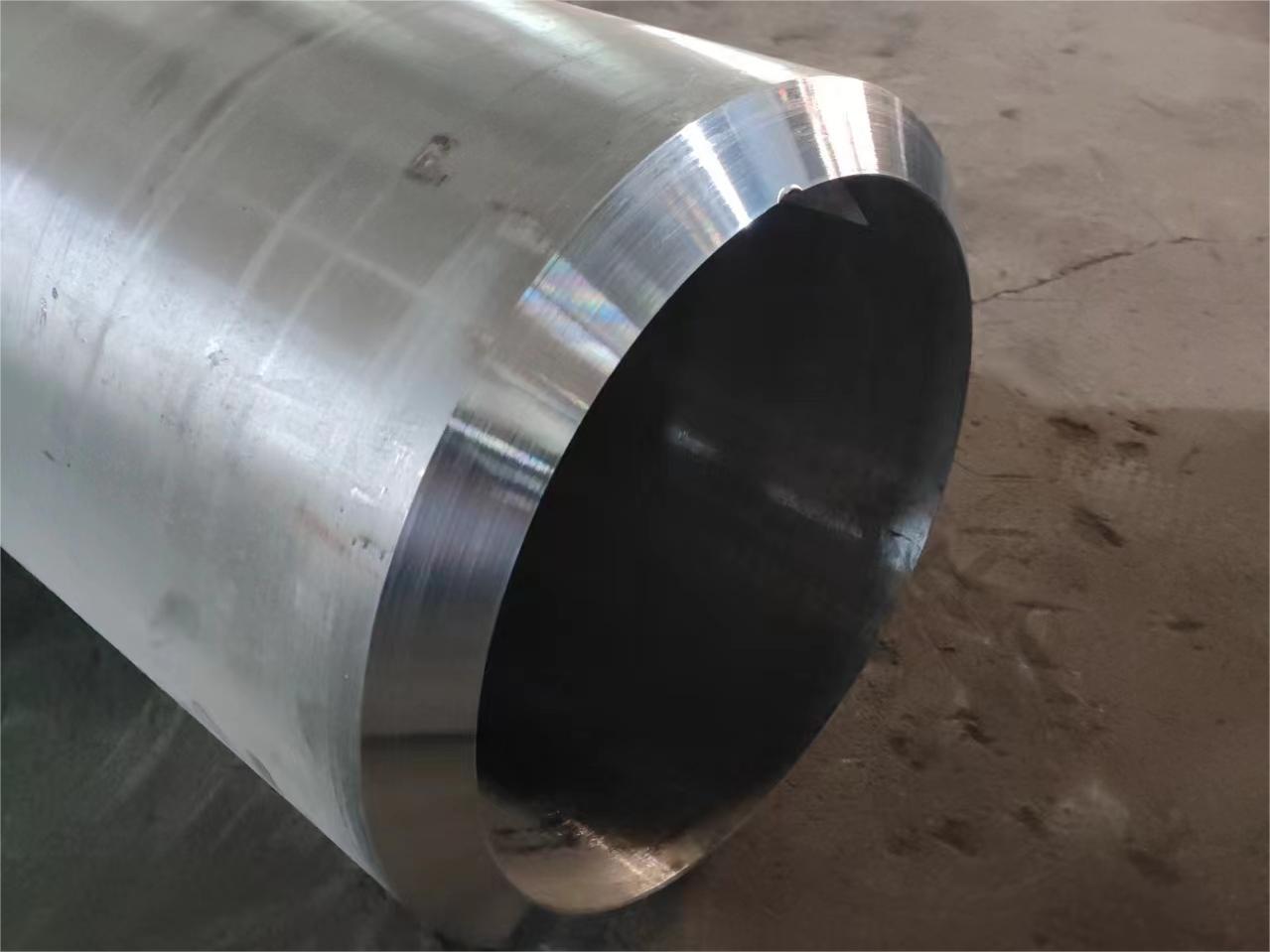

Imininingwane: 457.0×34.93mm kanye no-114.3×11.13mm

Ukupakisha: Upende omnyama

Imfuneko: Ipayipi lensimbi ye-alloy engenamthungo kufanele libe nesitifiketi se-IBR

Kuyini i-IBR

I-IBR (i-Indian Boiler Regulations) iyiqoqo lemithethonqubo eningiliziwe yokuklama, ukukhiqiza, ukufaka, kanye nokuhlola ama-boiler kanye nemikhumbi yokucindezela, eklanywe futhi yaphoqelelwa yi-Central Boiler Board of India ukuqinisekisa ukuphepha kwama-boiler kanye nemikhumbi yokucindezela esetshenziswa eNdiya. Yonke imishini ehlobene ethunyelwa eNdiya noma esetshenziswa eNdiya kumele ilandele le mithethonqubo.

Inqubo Yesitifiketi Se-IBR Yamapayipi Angenamthungo e-ASTM A335 P91

Ngezansi kunezinyathelo ezinemininingwane zokuthola isitifiketi se-IBR, ezichaza yonke inqubo ngendlela ecacile nelula:

1. Xhumana ne-Ejensi Yokuhlola ngemininingwane

Ukukhethwa kwe-Ejensi Yokuhlola

Ngemva kokwaziswa ngezidingo ezithile zeklayenti, khetha bese uxhumana ne-ejensi yokuhlola egunyazwe yi-IBR ukuqinisekisa ukuthobela imithetho kanye nobungcweti.

Izinhlangano zokuhlola ezivamile zifaka phakathi i-TUV, i-BV, kanye ne-SGS.

Ngale oda, sikhethe i-TUV njengenhlangano yokuhlola ukuqinisekisa ukuthi umsebenzi wokuhlola wephrojekthi yethu uhlangabezana nezinga eliphezulu lekhwalithi.

Xoxa Ngemininingwane

Xoxa ngokuningiliziwe nenhlangano yokuhlola mayelana nesikhathi sokuhlolwa, amaphuzu abalulekile ofakazi kanye nemibhalo okufanele ilungiselelwe, njll. ukuqinisekisa ukuthi yonke inqubo ihamba kahle.

2. Ukulethwa Kwemibhalo Yokuqala

Ukulethwa kwemibhalo yokuklama, izinqubo zokukhiqiza, izitifiketi zezinto ezibonakalayo, kanye nemininingwane yomkhiqizo enhlanganweni yokuhlola, okuyisisekelo sokuhlolwa okulandelayo.

3. Ukuqapha Inqubo Yokukhiqiza

Ngokuvamile, lesi sinyathelo sihilela umhloli oqondisa izinqubo ezahlukahlukene ezihilelekile ekukhiqizeni, njengokukhethwa kwezinto, ukushisela, kanye nokwelashwa kokushisa.

Njengoba le oda ingeyombhobho wensimbi oqediwe, akukho ukuqondiswa kokukhiqiza okuhilelekile.

4. Ukuhlolwa Nokuhlolwa Komkhiqizo Oqediwe

Ukubukeka kanye nokuhlolwa kobukhulu

Ukubukeka nobukhulu bamapayipi kuyahlolwa ukuqinisekisa ukuthi azikho iziphambeko ezibonakalayo nokuthi ziyahlangabezana nezimfuneko.

Izinto ezijwayelekile zokuhlola ukubukeka, ububanzi, ukujiya kodonga, ubude, kanye ne-angle ye-bevel.

Ububanzi Bangaphandle

Ubukhulu Bodonga

Ukuhlolwa Okungonakalisi

Kulokhu, ukuhlolwa kwe-ultrasonic (UT) kwasetshenziswa ukuqinisekisa ukuthi akukho ziphazamiso epayipini lensimbi.

Ukuhlolwa okungabhubhisi - UT

Ukuhlolwa okungabhubhisi - UT

Ukuhlolwa Kwezakhiwo Zemishini

Ukuhlolwa kokudonsa kwenziwa ukuze kuhlolwe amandla okudonsa, amandla okukhiqiza kanye nokwandiswa kwepayipi ukuqinisekisa ukuthi izakhiwo zalo zomshini ziyahlangabezana nezidingo ze-IBR.

Izakhiwo Zokunamathela

Izakhiwo Zokunamathela

Ukuhlaziywa Kokwakheka Kwamakhemikhali

Ukwakheka kwamakhemikhali kwepayipi lensimbi kuhlolwa ngendlela yokuhlaziya i-spectral futhi kuqhathaniswa ne-ASTM A335 P91 standard ukuqinisekisa ukuhambisana kwayo nezidingo.

5. Ukuhlinzekwa Kwemibhalo Yenqubo

Nikeza izitifiketi zokulinganisa kanye nemibiko yelebhu enemininingwane yazo zonke imishini yokuhlola ukuqinisekisa ukuthi ulwazi olunikezwe ku-IBR luphelele futhi luthembekile.

6. Ukubuyekezwa Kwamadokhumenti

Umhloli we-IBR uzobuyekeza ngokucophelela yonke imibhalo ethunyelwe ukuqinisekisa ukuthi ipayipi nolwazi oluhlobene nalo luhambisana ngokugcwele nemithethonqubo ye-IBR.

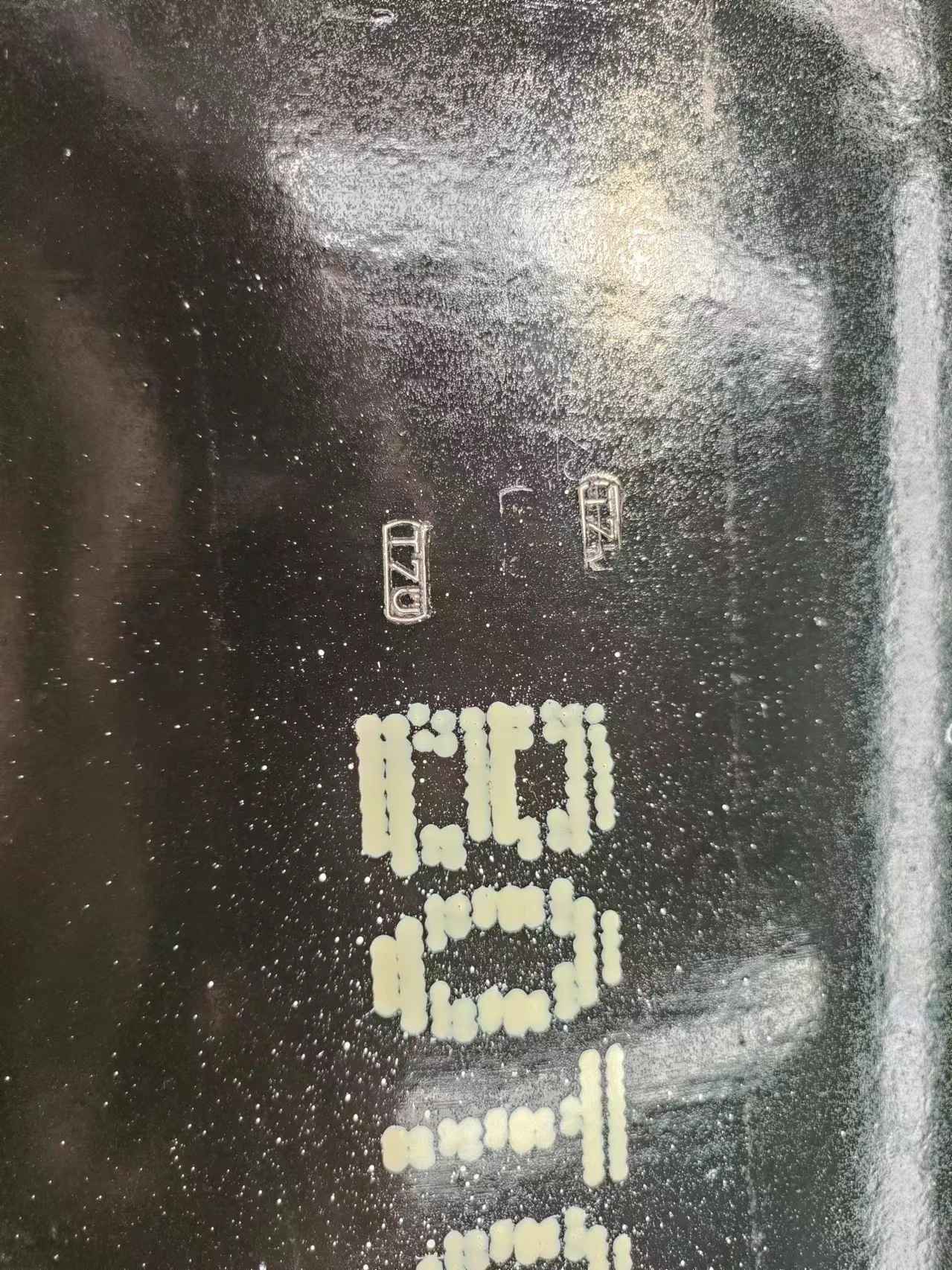

7. Amamaki e-IBR

Ukumaka

Ipayipi elihlangabezana nezidingo lizophawulwa ngophawu lwesitifiketi se-IBR, okubonisa ukuthi liphumelele izivivinyo nezivivinyo ezidingekayo.

Isitembu Sensimbi

Isitembu sensimbi siyindlela yokumaka eqinile, engagcini nje ngokuqinisekisa ukuqina kophawu kodwa futhi isisiza ukuhlonza nokwamukela ngesikhathi sokuthuthwa, ukufakwa, kanye nokusetshenziswa.

Ukumaka amapayipi

Isitembu Sensimbi

8. Ukukhishwa Kwesitifiketi se-IBR

Ngemva kokuba ipayipi seliphumelele zonke izivivinyo, i-ejensi yokuhlola izokhipha isitifiketi se-IBR, esiqinisekisa ngokusemthethweni ukuthi ipayipi liyahambisana nemithethonqubo ye-IBR.

Ngokulandela inqubo echazwe ngenhla, abakhiqizi bamashubhu bangathola isitifiketi se-IBR semikhiqizo yabo.

Indima Yokuthola Ukugunyazwa kwe-IBR

Lokhu akugcini nje ngokuqinisekisa ukwamukelwa kwemikhiqizo yabo emakethe kodwa futhi kuthuthukisa kakhulu ukuncintisana kwabo emakethe yaseNdiya.

Mayelana NATHI

I-Botop Steel izibophezele kakhulu kwikhwalithi futhi isebenzisa izilawuli eziqinile kanye nokuhlola ukuqinisekisa ukuthembeka komkhiqizo. Ithimba layo elinolwazi linikeza izixazululo ezenzelwe wena kanye nokusekelwa kochwepheshe ngokugxila ekwanelisekeni kwamakhasimende.

amathegi: IBR, ASTM A335, P91, ipayipi le-alloy, elingenamthungo.

Isikhathi sokuthunyelwe: Ephreli-22-2024