Ipayipi lensimbi le-JIS G3454 carbon ERW,

,

| Isitayela | Ezobuchwepheshe | Izinto | Okujwayelekile | Ibanga | Ukusetshenziswa |

| Ipayipi lensimbi elihlanganisiwe elinokumelana nogesi (ERW) | Imvamisa Ephezulu | Insimbi Yekhabhoni | I-API 5L PSL1 kanye ne-PSL2 | GR.B,X42,X46,X52,X60,X65,X70,njll | Ukuthuthwa kukawoyela negesi |

| I-ASTM A53 | GR.A, GR.B | Kwesakhiwo (Ukufaka Inqwaba) | |||

| I-ASTM A252 | GR.1, GR.2,GR.3 | ||||

| I-BS EN10210 | S275JRH,S275J0H,S355J0H,S355J2H,njll | ||||

| I-BS EN10219 | S275JRH,S275J0H,S355J0H,S355J2H,njll | ||||

| I-JIS G3452 | I-SGP, njll. | Ukuthuthwa koketshezi oluphansi | |||

| I-JIS G3454 | STPG370, STPG410, njll. | Ukuthuthwa koketshezi olunomfutho ophezulu | |||

| I-JIS G3456 | STPG370, STPG410, STPG480, njll. | amapayipi ensimbi anokushisa okuphezulu |

Ipayipi eli-odiwe ngaphansi kwale ncazelo lisetshenziselwa insizakalo yokucindezela ekushiseni okuphezulu cishe okungu-350℃.

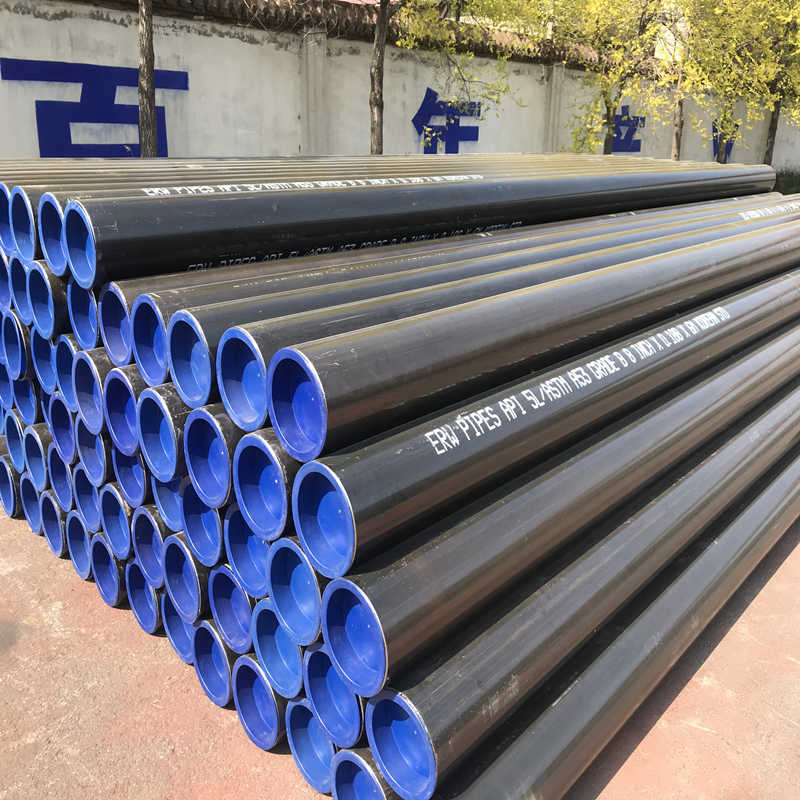

Ipayipi elingenalutho, ukugqoka okumnyama noma i-hot dip embozwe nge-zinc (eyenziwe ngokwezifiso);

Ezinqwabeni ezinezihlikihli ezimbili zikakotini;

Zombili iziphetho zinezivikelo zokuphela;

Isiphelo esilula, isiphelo se-bevel (Uma kudingeka ngumthengi kanye ne-S≤22mm, isiphelo sepayipi kufanele sibekwe eceleni, izinga: 30° (+5°~0°), futhi ubukhulu bodonga lwempande abuncishiswanga ngo-<2.4mm.);

Ukumaka.

Ukwakheka Kwebanga Nokwakheka Kwamakhemikhali (%)

| Ibanga | C≤ | Si≤ | Mn | P≤ | S≤ |

| I-STPG370 | 0.25 | 0.35 | 0.30~0.90 | 0.040 | 0.040 |

| I-STPG410 | 0.30 | 0.35 | 0.30~1.00 | 0.040 | 0.040 |

|

|

|

|

|

|

|

| Izakhiwo Zemishini | ||||||

| Ibanga | Amandla okudonsa | Amandla okukhiqiza | Ukwandiswa % | |||

| N/ m㎡ | N/ m㎡ | Izingcezu zokuhlola zeNombolo 11 noma zeNombolo 12 | Izingcezu zokuhlola zenombolo 5 | Ingxenye yokuhlola yenombolo 4 | ||

|

|

| I-Longitudinal | I-Transverse | I-Longitudinal | I-Transverse | |

| I-STPG370 | imizuzu engu-370 | 215 amaminithi | imizuzu engama-30 | imizuzu engama-25 | imizuzu engama-28 | imizuzu engama-23 |

| I-STPG410 | imizuzu engu-410 | 245 amaminithi | imizuzu engama-25 | imizuzu engama-20 | imizuzu engama-24 | imizuzu eyi-19 |

Ukubekezelela i-OD kanye ne-WT

| Isigaba | Ukubekezelelana ku-OD | Ukubekezelelana ku-WT | ||

| Ipayipi Lensimbi Le-ERW Eliqediwe Elibandayo | 24A noma ngaphansi | +/-0.3mm | Ngaphansi kuka-3mm

3mm noma ngaphezulu | +/-0.3mm

+/-10% |

| 32A noma ngaphezulu | +/-0.8% |

|

| |

| Kumapayipi anosayizi ojwayelekile ongu-350A noma ngaphezulu, ukubekezelelana ku-OD kunganqunywa ubude obujikelezayo. Kulesi simo, ukubekezelelana kufanele kube ngu-+/-0.5% | ||||

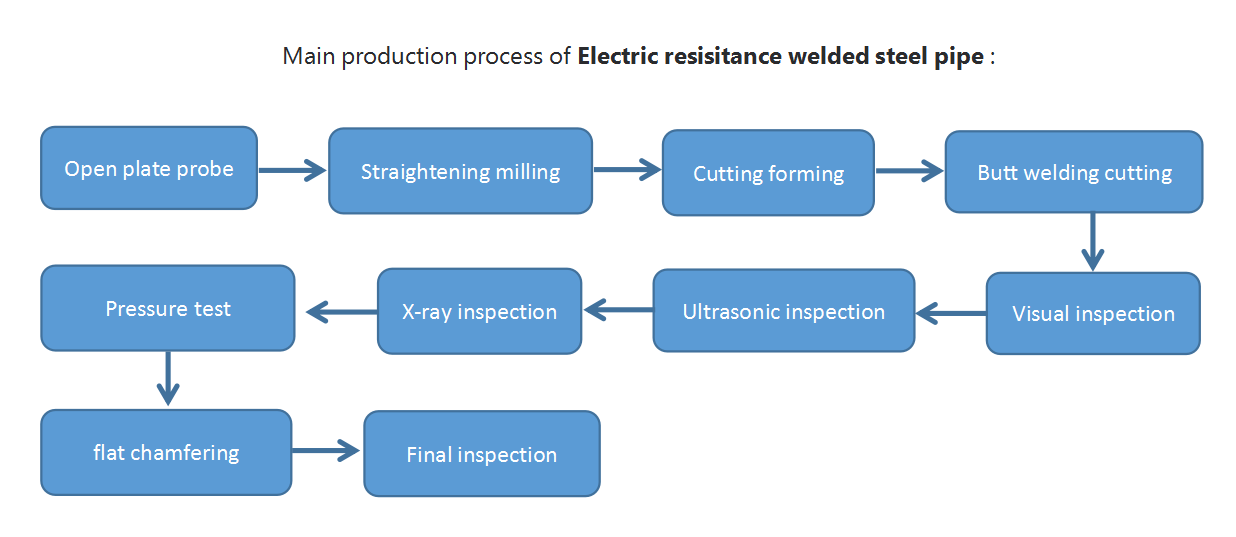

Insizakalo yokunyathela amapayipi ensimbi ye-JIS G3454 ERW iyisici esibalulekile sokwenziwa nokukhiqizwa kwamapayipi ensimbi ye-ERW. I-JIS G3454 iyi-Industrial Standard yaseJapan echaza amapayipi ensimbi yekhabhoni ukuze asetshenziswe ekucindezelweni okuphezulu. Ipayipi lensimbi le-ERW (elinokumelana nogesi elihlanganisiwe) lenziwa ngenqubo lapho imiphetho yamashidi ensimbi noma imichilo ishiswa futhi ihlanganiswe ndawonye ngaphansi kwengcindezi, yakha ipayipi elingenamthungo neliqinile. Izinsizakalo zokunyathela ezihilelekile ekukhiqizweni kwamapayipi ensimbi e-JIS G3454 ERW zidlala indima ebalulekile ekuqinisekiseni ikhwalithi nokuthembeka kwala mapayipi. Izinsizakalo zokunyathela zifaka phakathi ukusetshenziswa kwemishini yokucindezela okuphezulu ukwakha amapayipi ngobukhulu obufunwayo kanye nemininingwane. Le nqubo iqinisekisa ukuthi ipayipi lineziphetho ezibushelelezi neziqondile, kanye nobukhulu bodonga obuhambisanayo kulo lonke ubude balo. Enye yezinzuzo ezibalulekile zezinsizakalo zokunyathela amapayipi ensimbi e-JIS G3454 ERW yikhono lokukhiqiza amapayipi ngokunemba okuhle kakhulu kanye nobuqotho bokushisela. Izinsizakalo zokunyathela zivumela ukulawula okuqinile inqubo yokukhiqiza, ukuqinisekisa ukuthi ipayipi lihlangabezana nezindinganiso kanye nemininingwane edingekayo. Ngaphezu kwalokho, ukusetshenziswa kwemishini enomfutho ophezulu ngesikhathi sezinsizakalo zokunyathela kusiza ukukhiqiza amapayipi anamandla akhethekile nokuqina, okwenza afanelekele ukusetshenziswa okuhlukahlukene ezimbonini ezifana nowoyela negesi, ukwakhiwa, kanye nezimoto. Ngaphezu kwalokho, izinsizakalo zokucindezela amapayipi ensimbi ze-JIS G3454 ERW zingakhiqiza namapayipi abushelelezi futhi amahle. Imishini esetshenziswa ezinsizeni zokunyathela ingapholisha futhi icwenge ubuso bepayipi, okuholela kumkhiqizo obukeka kahle kakhulu. Lokhu kubaluleke kakhulu ezinsizeni lapho amapayipi evezwa khona noma ebonakala njengoba kuthuthukisa ukubukeka okuphelele futhi kuqinisekisa ukuqeda kwekhwalithi ephezulu. Ekuphetheni, izinsizakalo zokucindezela amapayipi ensimbi ze-JIS G3454 ERW ziyingxenye ebalulekile yenqubo yokukhiqiza, ukuqinisekisa ukukhiqizwa kwamapayipi asezingeni eliphezulu nathembekile ezicelo ezahlukahlukene zensizakalo yokucindezela. Iqinisekisa ukunemba kobukhulu, ubuqotho be-weld, kanye nezindawo ezibushelelezi, okwenza la mapayipi afaneleke ezimbonini eziningi kanye nokusetshenziswa.

复制