I-ASTM A53 ERWipayipi lensimbiUhlobo Eku-A53 specification, ekhiqizwe yinqubo yokushisela ukumelana, futhi itholakala kokubili kumabanga eBanga A kanye neBanga B.

Ifaneleka kakhulu ukusetshenziswa kwemishini kanye nengcindezi futhi ivame ukusetshenziswa njengenhloso ejwayelekile yokuhambisa umusi, amanzi, igesi, nomoya.

Izinzuzo zepayipi lensimbi le-ERW, njengeintengo ephansifuthiumkhiqizo ophezulu, kwenze kube yinto ekhethwayo yezicelo eziningi zezimboni.

Insimbi yeBotopingumkhiqizi wepayipi lensimbi yekhabhoni elishiselwe ngekhwalithi ephezulu kanye nomhlinzeki ovela eShayina, futhi ingumthengisi wepayipi lensimbi elingenamthungo, ikunikeza izixazululo eziningi zamapayipi ensimbi!

Impahla yethu igcwele futhi siyakwazi ukuhlangabezana nesidingo esisheshayo samakhasimende ethu sobukhulu nobuningi obuhlukahlukene.

I-ASTM A53/A53M ifaka izinhlobo namazinga alandelayo:

Uhlobo E: Kuhlanganiswe ngokumelana nogesi, Amabanga A no-B.

Uhlobo S: Akunamthungo, Amabanga A kanye no-B.

Uhlobo F: I-Furnace-butt-welded, i-continuous welded Grades A kanye ne-B.

Uhlobo EfuthiUhlobo Skunezinhlobo ezimbili zamapayipi ezisetshenziswa kabanzi. Ngokuphambene nalokho,Uhlobo Fivame ukusetshenziselwa amashubhu amancane anobubanzi. Ngenxa yentuthuko kwezobuchwepheshe bokushisela, le ndlela yokukhiqiza ayisetshenziswa njalo.

Ububanzi obujwayelekile: DN 6 - 650 [NPS 1/8 - 26];

Ububanzi Bangaphandle: 10.3 - 660 mm [0.405 - 26 in.];

Ubukhulu bodonga kanye namashadi esisindo sepayipi lensimbi:

Amashubhu ayisicaba angabukwa kuThebula X2.2;

Amashubhu anezintambo nahlanganisiwe angabukwa kuThebula X2.3.

I-ASTM A53 ivumela futhi ukuhlinzekwa kwepayipi ngezinye izilinganiso uma nje ipayipi lihlangabezana nazo zonke ezinye izidingo zale ncazelo.

I-ERWisetshenziswa kabanzi ukukhiqiza amapayipi ensimbi e-carbon kanye ne-alloy eyindilinga, eyisikwele, neyinxande.

Umkhiqizo olandelayo inqubo yokukhiqiza yokukhiqizaipayipi lensimbi eliyindilinga le-ERW:

a) Ukulungiselela izinto ezibonakalayo: Izinto zokuqala ngokuvamile ziyizikhoyili zensimbi ezigoqwe ngokushisa. Lawa makhoyili aqale acwebezelwe futhi anqunywe ububanzi obudingekayo.

b) Ukwakheka: Kancane kancane, ngokusebenzisa uchungechunge lwemiqulu, umucu wenziwa ube yisakhiwo esiyindilinga esivulekile. Phakathi nale nqubo, imiphetho yomcu wenziwe yasondelana kancane kancane ukuze kulungiselelwe ukushiselwa.

c) Ukushisela: Ngemva kokwakha isakhiwo seshubhu, imiphetho yomcu wensimbi ishiswa ukumelana kukagesi endaweni yokushisela. Ugesi ovame kakhulu udlula ezintweni, bese ukushisa okukhiqizwa ukumelana kusetshenziselwa ukushisa imiphetho kuze kube yilapho incibilika khona, bese ihlanganiswa ndawonye ngokucindezela.

d) Ukususa ukusha: Ngemva kokushisela, ama-weld burrs (insimbi eningi evela ekushiseleni) ayasuswa ngaphakathi nangaphandle kwepayipi ukuqinisekisa ukuthi indawo ebushelelezi ngaphakathi kwepayipi.

e) Usayizi kanye nokuhlelwa kobude: Ngemva kokushisela nokususa amapayipi sekuqediwe, amapayipi adluliswa ngomshini wokulinganisa ukuze kulungiswe ubukhulu ukuqinisekisa ukuthi ahlangabezana nezidingo zobubanzi kanye nokuzungeza okuqondile. Amapayipi abe esenqunywa ngobude obunqunyiwe.

f) Ukuhlolwa nokuhlolwa: Ipayipi lensimbi lizohlolwa futhi lihlolwe ngokuqinile, okuhlanganisa ukuhlolwa kwe-ultrasonic, ukuhlolwa kwe-hydrostatic, njll., ukuqinisekisa ukuthi ikhwalithi yepayipi lensimbi ihlangabezana nezindinganiso kanye nezincazelo.

g) Ukwelashwa kwendawo: Okokugcina, ipayipi lensimbi lingase liphathwe ngokuqhubekayo njengokushisa i-galvanizing, ukupenda, noma okunye ukwelashwa kwendawo ukuze kuhlinzekwe ngokuvikelwa kokugqwala okwengeziwe kanye nobuhle.

Ukushintshwa kohlobo E noma uhlobo F Ibanga Bipayipi kufanele liphathwe ngokushisa noma liphathwe ngenye indlela ngemva kokushisela ukuze i-martensite engavuthiswanga ingabi khona.

Izinga lokushisa lokwelashwa kokushisa kufanele okungenani libe1000°F [540°C].

Uma ipayipi likhulisiwe libanda, ukukhuliswa akufanele kudlule1.5%ububanzi obucacisiwe bangaphandle bepayipi.

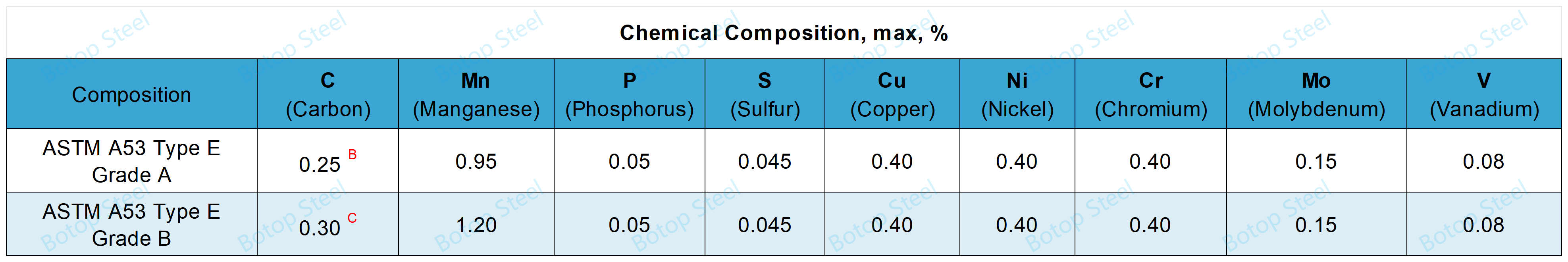

AIzinto ezinhlanuCu, Ni, Cr, Mo, futhiVndawonye akumele kudlule u-1.00%.

BNgokunciphisa ngakunye okungu-0.01% ngaphansi komkhawulo wekhabhoni ochaziwe, ukwanda okungu-0.06% we-manganese ngaphezu komkhawulo ochaziwe kuzovunyelwa kufikela kumkhawulo ophezulu ongu-1.35%.

CNgokunciphisa ngakunye okungu-0.01% ngaphansi komkhawulo wekhabhoni ochaziwe, ukwanda okungu-0.06% we-manganese ngaphezu komkhawulo ochaziwe kuzovunyelwa kufikela kumkhawulo ophezulu ongu-1.65%.

Impahla Eqinile

| Uhlu | Ukuhlukaniswa | Ibanga A | Ibanga B |

| Amandla okudonsa, ubuncane | I-MPa [psi] | 330 [48,000] | 415 [60,000] |

| Amandla okukhiqiza, ubuncane | I-MPa [psi] | 205 [30,000] | 240 [35,000] |

| Ukuphakama ngama-50 mm [2 in.] | Inothi | A,B | A,B |

Inothi A: Ukwelulwa okuncane ku-2 in[50 mm] kuzoba yilokho okunqunywa yi-equation elandelayo:

e = 625,000 [1940] A0.2/U0.9

e = ukunwebeka okuncane ku-2 in noma ku-50 mm ngephesenti, okuzungezwe kuphesenti eliseduze

A = okungaphansi kuka-0.75 ku-in2[500 mm]2] kanye nendawo enqamula ingxenye yesampula yokuhlola ukucindezeleka, ebalwe kusetshenziswa ububanzi obucacisiwe bangaphandle bepayipi, noma ububanzi obuqanjiwe besampula yokuhlola ukucindezeleka kanye nobukhulu bodonga obucacisiwe bepayipi, kanye nenani elibaliwe elizungezwe ku-0.01 in.2 [1 mm2].

U= amandla amancane okudonsa acacisiwe, i-psi [MPa].

Inothi B: Bheka Ithebula X4.1 noma Ithebula X4.2, noma ngabe yikuphi okusebenzayo, ukuze uthole amanani amancane okwandiswa adingekayo ekuhlanganisweni okuhlukahlukene kosayizi wesampula yokuhlolwa kokuxineka kanye namandla amancane okudonsa acacisiwe.

Ukuhlolwa Kokugoba

Ku-DN yepayipi ≤ 50 [NPS ≤ 2], ubude obanele bepayipi buzokwazi ukugoba bube ngama-90° buzungeze i-mandrel esilinda, ububanzi bayo buphindwe kabili kunobubanzi obucacisiwe bangaphandle bepayipi, ngaphandle kokudala imifantu kunoma iyiphi ingxenye futhi ngaphandle kokuvula i-weld.

Okuphindwe kabili okunamandla kakhulu(isigaba sesisindo:XXS) ipayipi elingaphezu kwe-DN 32 [NPS 1 1/4] akudingeki ukuthi lihlolwe ukugoba.

Ukuhlolwa Kokuthamba

Ukuhlolwa kokuthamba kufanele kwenziwe ngepayipi elihlanganisiwe phezu kwe-DN 50 ngesisindo esinamandla kakhulu (XS) noma esilula.

Kufanelekela amashubhu ohlobo E, iBanga A kanye no-B; kanye nohlobo F, iBanga B.

Amashubhu ensimbi angenamthungo akudingeki ahlolwe.

Isikhathi Sokuhlolwa

Kuzo zonke izinhlobo zamapayipi e-Type S, Type E, kanye ne-Type F Grade B, ingcindezi yokuhlola kufanele igcinwe okungenani amasekhondi ama-5.

Ukuhlolwa kwe-hydrostatic kufanele kusetshenziswe, ngaphandle kokuvuza ngomthungo wokushisela noma umzimba wepayipi.

Izingcindezi Zokuhlola

Ipayipi elingenaluthokufanele ihlolwe ngamanzi ukuze ihambisane nengcindezi efanele enikezwe kuIthebula X2.2,

Ipayipi elihlanganisiwe nelinochungechungekufanele ihlolwe ngamanzi ukuze ihambisane nengcindezi efanele enikezwe kuIthebula X2.3.

Kumapayipi ensimbi ane-DN ≤ 80 [NPS ≤ 80], ingcindezi yokuhlola akufanele idlule i-17.2MPa;

Kumapayipi ensimbi ane-DN >80 [NPS >80], ingcindezi yokuhlola akufanele idlule i-19.3MPa;

Izingcindezi zokuhlola eziphakeme zingakhethwa uma kunezidingo ezikhethekile zobunjiniyela, kodwa lokhu kudinga ukuxoxisana phakathi komkhiqizi nekhasimende.

Ukumaka

Uma ipayipi lihlolwe ngamanzi, uphawu kufanele lubonise ukuthiingcindezi yokuhlola.

Lezi zimfuneko ezilandelayo ziyasebenza kuPhayiphi yohlobo E kanye nohlobo F lweBanga B.

Ipayipi elingenamthungo linezidingo ezengeziwe ezingaxoxwa ngazo kulo mbhalo.

Izindlela Zokuhlola

Amapayipi akhiqizwa imishini yokwandisa nokunciphisa ugesi engashisi kakhulu: DN ≥ 50 [NPS ≥ 2], iukushiselaesigabeni ngasinye sepayipi kudingeka baphumelele ukuhlolwa kukagesi okungonakalisi, futhi indlela yokuhlola idinga ukuhambisana ne-E213, E273, E309 noma E570ejwayelekile.

Amapayipi e-ERW akhiqizwa umshini wokunciphisa ubukhulu obushisayo: DN ≥ 50 [NPS ≥ 2]Isigaba ngasinyeAmapayipi kufanele ahlolwe ngokuphelele ngokuhlolwa kukagesi okungabhubhisi, okuzohambisana nomthethoE213, E309, nomaE570amazinga.

Qaphela: Umshini Wokwandisa Ububanzi Bokwelula Okushisayo uwumshini owelula futhi ucindezela amashubhu ensimbi ngokuqhubekayo ngama-roller emazingeni okushisa aphezulu ukuze ulungise ububanzi bawo kanye nobukhulu bodonga.

Ukumaka

Uma ipayipi liye lahlolwa ngendlela engonakalisi, kubalulekile ukukhombisaI-NDEekumakisheni.

Isisindo

±10%.

Ipayipi DN ≤ 100 [NPS ≤ 4], elilinganiswe njengeqoqo.

Amapayipi DN > 100 [NPS > 4], anesisindo esisodwa.

Ububanzi

Ku-DN yepayipi ≤40 [NPS≤ 1 1/2], ukuhlukahluka kwe-OD akumele kudlule ±0.4 mm [1/64 in.].

Ku-DN yepayipi ≥50 [NPS>2], ukuhlukahluka kwe-OD akumele kudlule ±1%.

Ubukhulu

Ubukhulu bodonga obuncane akufanele bube ngaphansi kuka87.5%ubukhulu bodonga obucacisiwe.

isisindo esilula kunesisindo esinamandla kakhulu (XS):

a) ipayipi elingenalutho: 3.66 - 4.88m [12 - 16 ft], Akudluli ku-5% wenani eliphelele.

b) ubude obuphindwe kabili obungahleliwe: ≥ 6.71 m [22 ft], Ubude obulinganiselwe okungenani bungu-10.67m [35 ft].

c) Ubude obungahleliwe obungahleliwe: 4.88 -6.71m [16 - 22 ft], hhayi ngaphezu kuka-5% wenani eliphelele lobude obunezintambo obufakwe njengezihlanganisi (izingcezu ezimbili zihlanganiswe ndawonye).

Isisindo esinamandla kakhulu (XS) noma esindayo: 3.66-6.71 m [12 - 22 ft], kungabi ngaphezu kuka-5% ingqikithi yepayipi 1.83 - 3.66 m [6 - 12 ft].

Ipayipi lensimbi le-ASTM A53 liyatholakala ngombala omnyama noma ogqinsiwe.

Okumnyama: Amapayipi ensimbi ngaphandle kokwelashwa kwendawo, ngokuvamile athengiswa ngqo ngemva kwenqubo yokukhiqiza, kulezo zicelo lapho kungadingeki khona ukumelana kokugqwala okwengeziwe.

Amapayipi afakwe i-galvanized kufanele ahlangabezane nezidingo ezifanele.

Inqubo

I-zinc kumele imbozwe ngaphakathi nangaphandle ngenqubo yokucwilisa ngokushisa.

Impahla eluhlaza

I-zinc esetshenziselwa ukumboza kufanele ibe yinoma yiliphi izinga le-zinc elihambisana nezidingo ze-SpecificationI-ASTM B6.

Ukubukeka

Ipayipi elifakwe i-galvanized kumele lingabi nezindawo ezingamboziwe, amabhamuza omoya, ama-flux deposits, kanye nama-coarse slag inclusions. Amaqhubu, ama-bumps, ama-globules, noma inani elikhulu lama-zinc deposits aphazamisa ukusetshenziswa okuhlosiwe kwezinto akufanele avunyelwe.

Isisindo Sokumboza Esigaxekile

Kufanele kunqunywe ngokuhlolwa kwe-peel ngokwendlela yokuhlola i-ASTM A90.

Isisindo sokumboza akufanele sibe ngaphansi kuka-0.55 kg/m² [1.8 oz/ft²].

Ipayipi lensimbi le-ASTM A53 ERWivame ukusetshenziswa ezisetshenziswayo ezinomfutho ophansi kuya kophakathi njengobunjiniyela bomasipala, ukwakhiwa, kanye nepayipi lesakhiwo semishini. Izimo ezivame ukusetshenziswa zifaka phakathi ukuthutha amanzi, umusi, umoya, kanye nezinye izinto eziwuketshezi ezinomfutho ophansi.

Njengoba zikwazi ukushibilika kahle, zilungele ukwenza imisebenzi ehilela ukugoba, ukugoba kanye nokufulela.