I-ASTM A501 Ibanga Biyipayipi lensimbi yekhabhoni elihlanganisiwe elenziwe ngokushisa futhi elingenamthungo elinamandla amancane okunamathela angu-448 MPa (65,000 psi) ezinhlobonhlobo zezicelo zesakhiwo.

I-ASTM A501yenzelwe ukwenziwa nokusebenza kwamapayipi ensimbi yekhabhoni ashisiwe futhi angenamthungo ukuze kusetshenziswe izakhiwo.

Lawa mashubhu ensimbi angaba mnyama (angagqokwanga) noma afakwe i-hot-dip galvanized, okwakamuva okuye kwandise ukumelana nokugqwala ngenqubo yokufaka i-galvanizing, okwenza afaneleke ezimweni eziningi zemvelo.

Lawa mapayipi ensimbi asetshenziswa kabanzi emabhulohweni, ezakhiweni, nakwezinye izinhlelo eziningi ezijwayelekile zokwakha.

I-ASTM A501 ihlukanisa ipayipi lensimbi libe amazinga amathathu,ibanga A, ibanga B, kanye nebanga C.

Ibanga B lisetshenziswa kakhulu kulawa mabanga amathathu ngoba linikeza izakhiwo ezilinganiselayo ezinhlelweni eziningi zokwakha.

Insimbi kufanele yenziwe nguinqubo yokwenza insimbi ye-oxygen eyisisekelo noma ye-arc kagesi.

Insimbi ingaphonswa ngama-ingot noma iphonswe ngentambo.

Uma izinsimbi zezinhlobo ezahlukene zihlanganiswa ngokulandelana, umkhiqizi wensimbi kufanele athole izinto eziguqukayo eziphumayo bese ezisusa esebenzisa inqubo emisiwe ehlukanisa kahle izinhlobo.

Ipayipi kufanele lenziwe ngenye yezinqubo ezilandelayo:ingenamthungo; ukushisela nge-furnace-butt (ukushisela okuqhubekayo); ukushisela ngokumelana nogesi (ERW) noma ukushisela nge-arc engaphansi komhlaba (SAW)kulandelwe ukufudumala kabusha kuyo yonke ingxenye evundlile kanye nokwakheka kokushisa ngenqubo yokunciphisa noma yokubumba, noma kokubili.

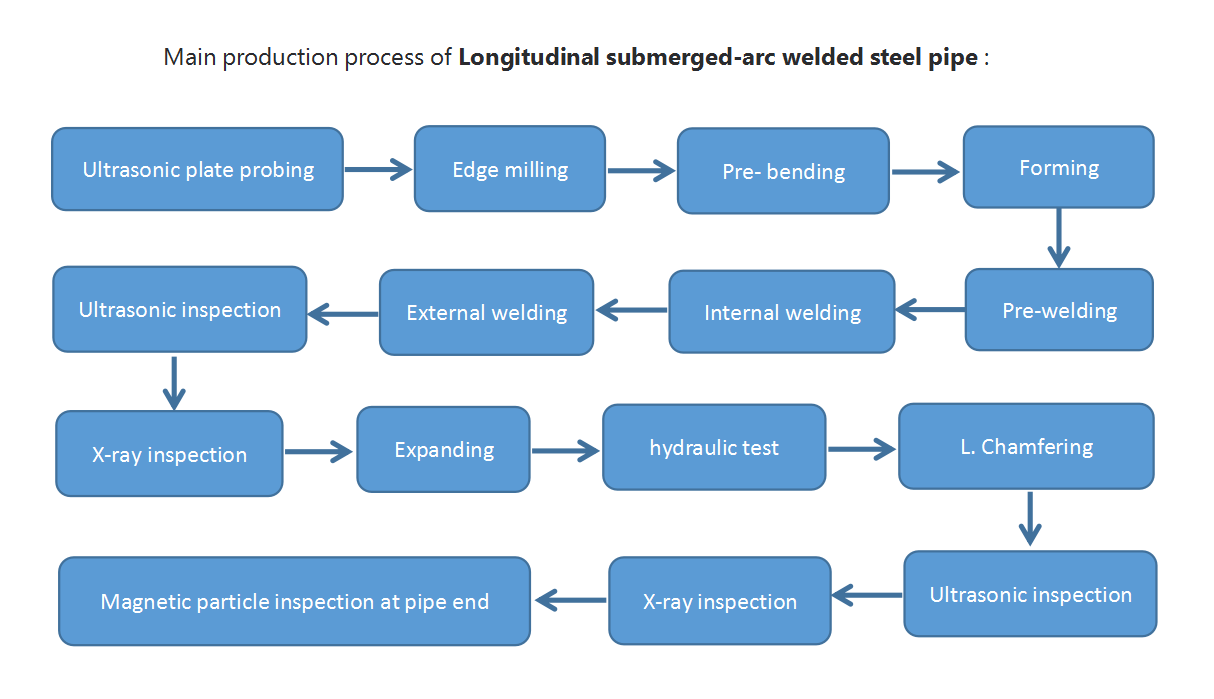

Inqubo yokushisela ye-SAW ihlukaniswe ngezigaba ezimbili:I-LSAW(SAWL) kanye ne-SSAW (I-HSAW).

Ukwakheka kokugcina kwesimo kufanele kwenziwe ngenqubo yokwakheka eshisayo.

Kuzovunyelwa ukwengeza ukwelashwa kokushisa okuvamile kwamapayipi anobukhulu bodonga obungaphezu kuka-13mm [1/2 inches].

| Izidingo Zamakhemikhali ze-ASTM A501 Grade B,% | |||

| Ukwakheka | Ibanga B | ||

| Ukuhlaziywa Kokushisa | Ukuhlaziywa Komkhiqizo | ||

| C (Ikhabhoni)B | ubuningi | 0.22 | 0.26 |

| I-Mn (i-Manganese)B | ubuningi | 1.40 | 1.45 |

| I-P (i-Phosphorus) | ubuningi | 0.030 | 0.040 |

| S(Isibabule) | ubuningi | 0.020 | 0.030 |

| I-Cu (ithusi)B (lapho insimbi yethusi icacisiwe) | umzuzu | 0.20 | 0.18 |

| BUkwehliswa ngakunye kwephuzu lamaphesenti angu-0.01 ngaphansi komkhawulo ocacisiwe wekhabhoni, ukwenyuka kwephuzu lamaphesenti angu-0.06 ngaphezu komkhawulo ocacisiwe we-manganese kuvunyelwe, kuze kufike ku-1.60% ngokuhlaziywa kokushisa kanye no-1.65% ngokuhlaziywa komkhiqizo. | |||

Ukuhlaziywa komkhiqizo kuzokwenziwa kusetshenziswa amasampula okuhlola athathwe kubude obubili bepayipi kusuka kusigaba ngasinye sobude obungama-500, noma ingxenye yaso, noma izingcezu ezimbili zesitoko esigoqekile esisicaba kusuka kusigaba ngasinye sobuningi obuhambisanayo besitoko esigoqekile esisicaba.

Amasampula athambile kufanele ahambisane nezidingo ezifanele zeZindlela Zokuhlola kanye Nezincazelo A370, Isithasiselo A2.

| Izidingo Zokunamathela ze-ASTM A501 Grade B | |||

| Uhlu | Ubukhulu Bodonga mm [ngaphakathi] | Ibanga B | |

| Amandla okudonsa, min, psi[MPa] | Konke | 65000 [448] | |

| Amandla okukhiqiza, min, psi[MPa] | ≤25 [1] | 46,000 [315] | |

| >25 [1] kanye no-≤ 50 [2] | 45,000 [310] | ||

| >50 [2] kanye no-≤ 76 [3] | 42,500 [290] | ||

| >76 [3] kanye no-≤ 100 [4] | 40,000 [280] | ||

| Ukwelulwa, ubuncane, % | — | 24 | |

| Amandla Omthelela | umzuzu,isilinganiso, ft/Ibf [J] | — | 20 [27] |

| umzuzu,ongashadile, ft/Ibf [J] | — | 14 [19] | |

Amasampula okuhlolwa kokucindezeleka kufanele abe amasampula okuhlolwa osayizi ogcwele we-longitudinal noma amasampula okuhlolwa kwe-longitudinal strip.

Kwepayipi elihlanganisiwe, noma yiziphi izivivinyo zomcu wobude obude kufanele zithathwe endaweni okungenani engama-90° ukusuka ku-weld futhi kufanele zilungiswe ngaphandle kokusikwa zibe yi-gauge ubude.

Ukuhlolwa komcu we-longitudinalamasampula kumele asuswe wonke ama-burrs.

Amasampula okuhlolwa kokucindezeleka akufanele abe namaphutha ebusweni angaphazamisa ukunqunywa okufanele kwezakhiwo zokudonsa.

Ubukhulu bodonga obungu-≤ 6.3mm [0.25in] abudingi ukuhlolwa komthelela.

| Ukubekezelelana Okulinganayo kwe-ASTM A501 | ||

| Uhlu | ububanzi | Inothi |

| Ububanzi Bangaphandle (OD) | ≤48mm (1.9 in) | ±0.5mm [1/48 in] |

| >50mm (2 inches) | ± 1% | |

| Ubukhulu Bodonga (T) | Ubukhulu bodonga obucacisiwe | ≥90% |

| Isisindo | isisindo esibekiwe | 96.5%-110% |

| Ubude (L) | ≤7m (22 ft) | -6mm (1/4in) - +13mm (1/2in) |

| 7-14m (22-44 ft) | -6mm (1/4in) - +19mm (3/4) | |

| Ukuqonda | Ubude bungamayunithi asebukhosini (ft) | I-L/40 |

| Amayunithi obude ayi-metric (m) | I-L/50 | |

Ipayipi lesakhiwo kumele lingabi namaphutha futhi libe nesiphetho esibushelelezi esivela enkambisweni yokukhiqiza i-hot rolling.

Uma ukujula kwamaphutha ebusweni bepayipi kudlula u-10% wobukhulu bodonga obujwayelekile, la maphutha kufanele abhekwe njengokungahambisani. Ukulungiswa ngokushisela kuzovunyelwa kuphela uma kuvunyelwene phakathi komthengi nomenzi. Ngaphambi kokulungiswa ngokushisela, amaphutha okumele alungiswe kumele asuswe ngokuphelele ngezindlela zokusika noma zokugaya.

Ukuze ipayipi lesakhiwo lifakwe i-hot-dip galvanized, lokhu kuhlanganiswa kufanele kuhambisane nezidingo ezifanele ze-SpecificationI-ASTM A53.

Ubude ngabunye bepayipi lesakhiwo kufanele buphawulwe ngendlela efanele, njengokugoqa, ukunyathela, ukunyathela, noma ukupenda.

Umaki we-ASTM A501 kufanele okungenani ube nolwazi olulandelayo:

Igama lomkhiqizi

Umkhiqizo noma uphawu lokuhweba

Usayizi

Igama lendinganiso (unyaka wokushicilelwa awudingeki)

Ibanga

Kumapayipi esakhiwo angaphansi kwama-50 mm [2 in] OD, kuvunyelwe ukumaka ulwazi lwensimbi kulebula enamathiselwe kuphakheji ngayinye.

Insimbi ye-ASTM A501 Grade B ihlanganisa amandla kanye nokuguquguquka nenqubo yokukhiqiza eshisa kakhulu, okwenza ifaneleke ezinhlotsheni ezahlukene zezakhiwo.

Ukwakha nokwakha: Ngokuvamile isetshenziswa ezakhiweni nasezakhiweni lapho kudingeka khona amandla aphezulu nokuqina kwezinto eziqinile. Lokhu kufaka phakathi izakhiwo, izinkundla zemidlalo, amabhuloho, nezinye izakhiwo.

Izakhiwo ZezimboniNgenxa yamandla ayo aphezulu, ifaneleka ukusetshenziswa ezindaweni zezimboni ezifana nezimboni kanye nezindawo zokugcina impahla lapho ubuqotho besakhiwo bubaluleke kakhulu.

Ingqalasizinda yezokuthutha: leli banga lisetshenziswa ekwakhiweni kwengqalasizinda yezokuthutha, okuhlanganisa iziteshi zesitimela, izikhumulo zezindiza, kanye nezindawo zokudlula emigwaqweni emikhulu.

Izingxenye Zesakhiwo: Isetshenziswa kakhulu nasekukhiqizweni kwezingxenye zesakhiwo ezifana namakholomu, imishayo, kanye nama-trusses, akha uhlaka lwezakhiwo ezahlukahlukene.

Ukukhiqizwa kwemishini: Ekukhiqizweni kwemishini esindayo nemishini, ingasetshenziswa ezingxenyeni ezidinga izingxenye zesakhiwo ezinamandla aphezulu.

Umenzi kufanele anikeze umthengi isitifiketi sokuthobela imithetho esisho ukuthi umkhiqizo uthathwe amasampula, wahlolwa, futhi wahlolwa ngokuhambisana nale ncazelo kanye nanoma yiziphi ezinye izidingo ezichazwe ku-oda lokuthenga noma inkontileka nokuthi zonke izidingo ezinjalo zihlangatsheziwe. Isitifiketi sokuthobela imithetho kufanele sihlanganise inombolo ethile kanye nonyaka wokukhishwa.

I-Botop Steel ingumkhiqizi kanye nomhlinzeki wepayipi lensimbi elihlanganisiwe elisezingeni eliphezulu elivela eShayina, futhi ungumthengisi wamapayipi ensimbi angenamthungo.

I-Botop Steel izibophezele kakhulu kwikhwalithi futhi isebenzisa izilawuli eziqinile kanye nokuhlola ukuzeqinisekisa ukuthembeka komkhiqizo. Ithimba layo elinolwazi linikeza izixazululo ezenzelwe wena kanye nokusekelwa kochwepheshe, kugxilwe ekwanelisekeni kwamakhasimende. Silangazelela ukusebenza nawe.