Ukuwelda kwe-arc engaphantsi komhlaba kulungele imibhobho, imikhumbi yoxinzelelo kunye neetanki, ukwenziwa kwesitimela kunye nokusetyenziswa okukhulu kolwakhiwo, kunye nohlobo olulula lwe-monofilament, ulwakhiwo lweengcingo ezimbini, ulwakhiwo lweengcingo ezimbini ezidibeneyo kunye nolwakhiwo lwe-multi-filament.

Ukuwelda kwe-arc engaphantsi komhlaba kunokubanceda abasebenzisi kwiindlela ezininzi zokuwelda. Ukususela ekwandiseni imveliso, ekuphuculeni imeko yokusebenza, ekuqinisekiseni umgangatho ohambelanayo nokunye okuninzi. Abenzi bokulungisa isinyithi abacinga ngotshintsho kwinkqubo yokuwelda kwe-arc engaphantsi komhlaba kufuneka bacinge ukuba banokufumana iingenelo ezininzi kule nkqubo.

Ulwazi olusisiseko lokuwelda i-arc engaphantsi komhlaba

Inkqubo yokuwelda i-arc engaphantsi komhlaba iyimfuneko efanelekileyo kwizicelo ezinzima zoshishino ezifana nemibhobho, iinqanawa zoxinzelelo kunye neetanki, ukwakhiwa kweelocomotive, ukwakhiwa/ukwemba okunzima. Ifanelekile kumashishini afuna imveliso ephezulu, ingakumbi xa kufikwa ekuweldaniseni izinto ezixineneyo kakhulu, kukho iingenelo ezininzi ezinokufunyanwa kwinkqubo yokuwelda i-arc engaphantsi komhlaba.

Izinga layo eliphezulu lokufaka kunye nesantya sokuhamba kunokuba nefuthe elikhulu kwimveliso yabasebenzi, ukusebenza kakuhle kunye neendleko zemveliso, enye yezona nzuzo ziphambili zenkqubo yokuwelda i-arc engaphantsi komhlaba.

Ezinye izibonelelo ziquka: ukwakheka kweekhemikhali okuhle kakhulu kunye neempawu zoomatshini ze-weld, ukubonakala okuncinci kwe-arc kunye nomsi omncinci we-welding, intuthuzelo ephuculweyo kwindawo yokusebenza, kunye nesimo esihle se-weld kunye nomgca weenyawo.

Ukuwelda kwe-arc engaphantsi komhlaba yindlela yokondla ngentambo esebenzisa i-granular flux ukwahlula i-arc emoyeni, njengoko igama lisitsho, i-arc igqunywe kwi-flux, oko kuthetha ukuba xa iiparameter zimiselwe, i-arc ayibonakali xa iphuma umaleko we-flux. Intambo yokuwelda inikwa rhoqo yitotshi ehamba ecaleni kwe-weld.

Ukufudumeza i-arc kunyibilikisa icandelo lentambo, inxalenye ye-flux kunye ne-base metal, kwenze ichibi elinyibilikisiweyo, elijika libe yi-weld egqunywe ngumaleko we-welding slag. Uluhlu lobukhulu bezinto zokuwelda yi-1/16"-3/4", lunokuba yi-100% ye-penetration welding nge-single welding, ukuba ubukhulu bodonga abukhawulelwanga, i-multi-pass welding inokwenziwa, kwaye i-weld ilungiswe kwangaphambili kwaye ikhethwe ngokufanelekileyo, kwaye kukhethwe indibaniselwano ye-welding wire flux efanelekileyo.

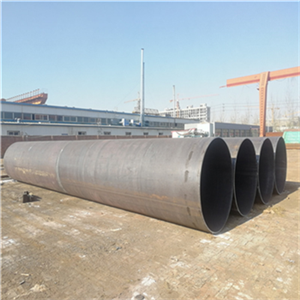

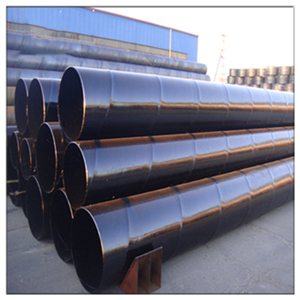

I-LSAW

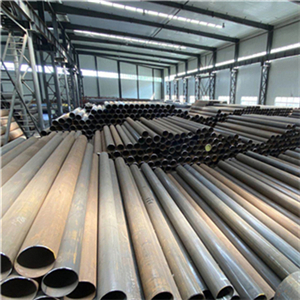

I-ERW

I-SSAW

Ukukhethwa kwentambo ye-flux kunye ne-welding

Ukukhetha i-flux kunye ne-wire efanelekileyo kwinkqubo ethile yokuwelda i-arc engaphantsi komhlaba kubalulekile ekufumaneni iziphumo ezilungileyo ngokusebenzisa le nkqubo. Nangona iinkqubo zokuwelda i-arc engaphantsi komhlaba zodwa zisebenza kakuhle, imveliso kunye nokusebenza kakuhle kunokwandiswa nokuba kuxhomekeke kwi-welding wire kunye ne-flux esetyenzisiweyo.

I-flux ayikhuseli nje kuphela ichibi lokuwelda, kodwa ikwanceda ekuphuculeni iimpawu zoomatshini kunye nemveliso ye-weld. Ukwenziwa kwe-fluxes kunempembelelo enkulu kwezi zinto, kuchaphazela amandla okuthwala amandla kunye nokukhululwa kwe-slag.

Umthamo wokuthwala wangoku uthetha ukuba ukusebenza kakuhle kokubeka izinto kunye neprofayili yokuwelda esemgangathweni ophezulu kunokufunyanwa.

Ukukhululwa kwe-slag kwi-flux ethile kuchaphazela ukhetho lwe-flux kuba ezinye ii-fluxes zilungele ngakumbi uyilo oluthile lwe-solder kunezinye.

Iindlela zokukhetha i-Flux kwi-submerged arc soldering ziquka iintlobo ze-welds ezisebenzayo nezingathathi cala. Umahluko obalulekileyo kukuba i-active flux itshintsha i-chemistry ye-weld, ngelixa i-neutral flux ingatshintshi.

Iiflux ezisebenzayo zibonakaliswa kukufakwa kwesilicon kunye ne-manganese. Ezi zinto zinceda ukugcina amandla okuxinana kwe-weld ekufakweni kobushushu obuphezulu, zinceda ukugcina i-weld ithambile kwaye ithambile kwisantya esiphezulu sokuhamba kwaye zibonelela ngokukhululwa okuhle kwe-slag. Ngokubanzi, iiflux ezisebenzayo zinokunceda ukunciphisa umngcipheko womgangatho ophantsi we-solder, kunye nokucoca okubizayo emva kokuwelda kunye nokuhlaziya. Nangona kunjalo, khumbula ukuba iiflux ezisebenzayo zihlala zilungele kakhulu ukusongwa kwe-single- okanye i-double-pass.

Iiflux ezingathathi cala zilungele ii-solder ezinkulu ezisebenzisa i-multipass kuba zinceda ekuphepheni ukwakheka kwee-welds ezibuthathaka neziqhekekayo.

Kukho iintlobo ezininzi zeentambo zokuwelda ezikhethwayo malunga nokuwelda kwe-arc engaphantsi komhlaba, nganye ineengenelo kunye neengxaki. Ezinye iingcingo zenzelwe ukuwelda xa kushushu kakhulu, ngelixa ezinye zenzelwe ngokukodwa ukuba zibe nee-alloys ezinceda ukufudumeza ukwenza ukucoca ukuwelda.

Qaphela ukuba iipropati zeekhemikhali kunye nokusebenzisana kobushushu kwentambo yokuwelda kuchaphazela iipropati zoomatshini ze-weld. Imveliso nayo inokwandiswa kakhulu ngokukhetha isinyithi sokuzalisa.

Umzekelo, ukusebenzisa ucingo oluphambili lwesinyithi olunenkqubo yokuwelda ye-arc engaphantsi komhlaba kunokunyusa ukusebenza kakuhle kokufakwa kwe-deposit nge-15% ukuya kwi-30% xa kuthelekiswa nokusebenzisa ucingo oluqinileyo, ngelixa kukwabonelela ngeprofayili yokungena ebanzi nenganzulu.

Ngenxa yesantya sayo esiphezulu sokuhamba, iingcingo zentsimbi ezingundoqo zikwanciphisa ubushushu ukuze kuncitshiswe umngcipheko wokuguqulwa kwe-welding kunye nokutsha.

Kuzo zonke iintsimbi, iintsimbi ezingenasici ze-austenitic zineyona nqanaba liphantsi lesivuno. Ke ngoko, ngokweempawu zoomatshini, intsimbi engenasici ye-austenitic ayisiyonto ilungileyo kwisiqu sevalvu, kuba ukuqinisekisa amandla athile, ububanzi besiqu sevalvu buya kwanda. Inqanaba lesivuno alinakwandiswa ngonyango lobushushu, kodwa linokwandiswa ngokwenza ukubanda.

Sithengisa iipayipi zekhabhoni kunye nentsimbi engenamthungo, wamkelekile ukuba ubuze, siza kubonelela okokuqala!

Ixesha lokuposa: Jan-30-2023