Kutshanje, inkampani yethu ifumene iodolo ebandakanya i-ASTM A335 P91imibhobho yentsimbi engenamthungo, ekufuneka ziqinisekiswe yi-IBR (Indian Boiler Regulations) ukuze zihlangabezane nemigangatho yokusetyenziswa eIndiya.

Ukuze ndikuncede ufumane isalathiso xa uhlangabezana neemfuno ezifanayo, ndiqokelele le nkcazo ineenkcukacha zenkqubo yokuqinisekiswa kwe-IBR. Apha ngezantsi kukho ulwazi oluthile malunga ne-odolo kunye namanyathelo abandakanyekayo kwinkqubo yokuqinisekiswa.

Umbhobho we-Alloy ongenamthungo we-ASTM A335 P91

Amaqhosha okuHamba

Iinkcukacha ze-oda

Yintoni i-IBR

Inkqubo yeSatifikethi se-IBR se-ASTM A335 P91 Seamless Pipes

1. Nxibelelana ne-Arhente yoHlolo ukuze ufumane iinkcukacha

2. Ukungeniswa kwamaxwebhu okuqala

3. Ulawulo lweNkqubo yoMveliso

4. Ukuhlolwa noVavanyo lweMveliso egqityiweyo

5. Ukubonelelwa koXwebhu lweNkqubo

6. Uphononongo lwamaxwebhu

7. Iimpawu ze-IBR

8. Ukukhutshwa kweSatifikethi se-IBR

Indima yokufumana i-IBR Accreditation

Ngathi

Iinkcukacha ze-oda

Indawo yokusetyenziswa kweprojekthi: eIndiya

Igama lemveliso: umbhobho wentsimbi ye-alloy engenamthungo

Izinto ezisemgangathweni:I-ASTM A335I-P91

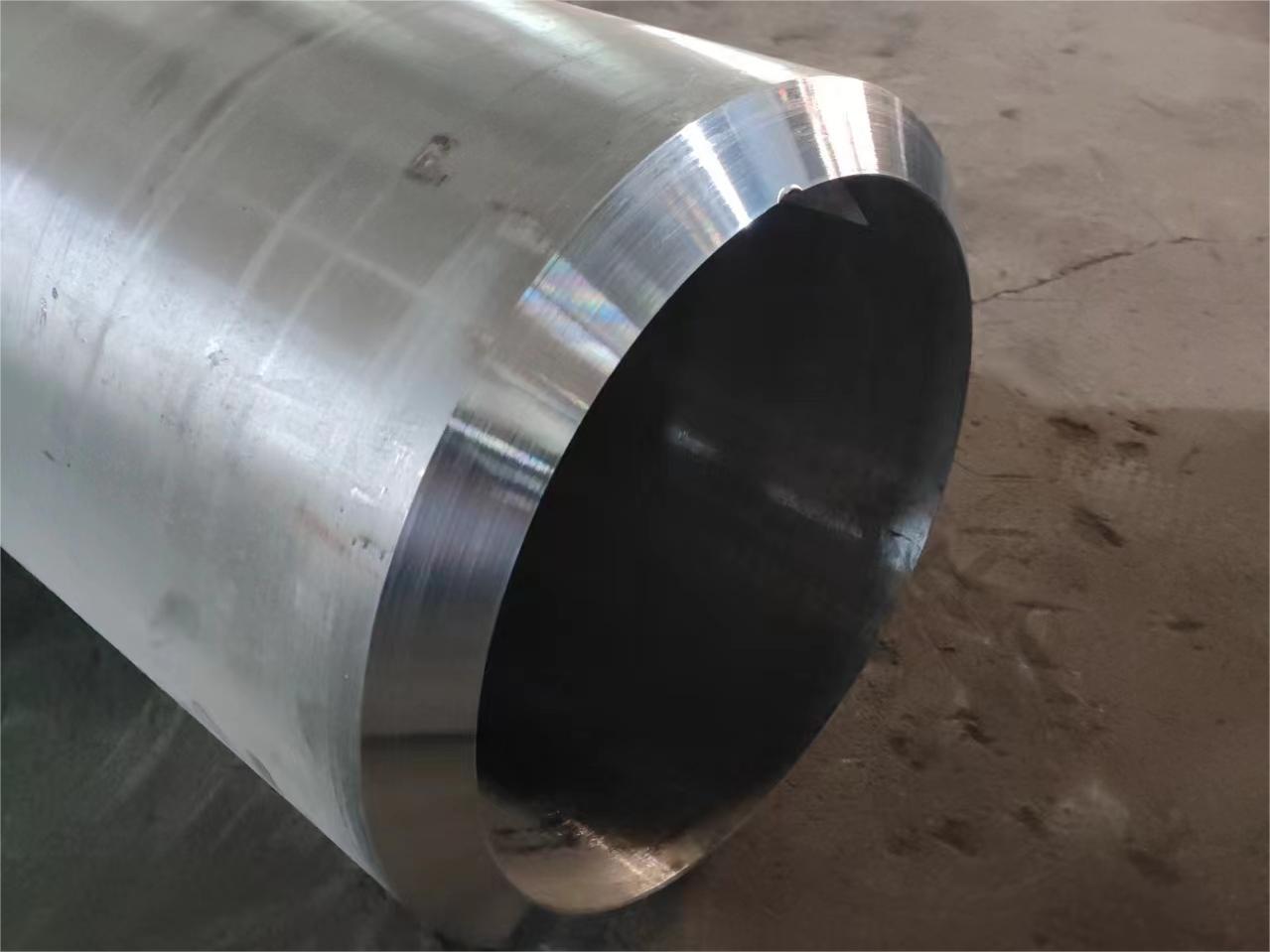

Iinkcukacha: 457.0×34.93mm kunye ne-114.3×11.13mm

Ukupakisha: Ipeyinti emnyama

Imfuneko: Umbhobho wentsimbi ye-alloy engenamthungo kufuneka ube nesatifikethi se-IBR

Yintoni i-IBR

I-IBR (i-Indian Boiler Regulations) yiseti yemigaqo eneenkcukacha zoyilo, ukwenziwa, ukufakwa, kunye nokuhlolwa kweebhoyila kunye neenqanawa zoxinzelelo, eziye zaqulunqwa kwaye zanyanzeliswa yiCentral Boiler Board yaseIndiya ukuqinisekisa ukhuseleko lweebhoyila kunye neenqanawa zoxinzelelo ezisetyenziswa eIndiya. Zonke izixhobo ezinxulumene noko ezithunyelwa eIndiya okanye ezisetyenziswa eIndiya kufuneka zilandele le migaqo.

Inkqubo yeSatifikethi se-IBR se-ASTM A335 P91 Seamless Pipes

Apha ngezantsi kukho amanyathelo aneenkcukacha zokufumana isatifikethi se-IBR, echaza yonke inkqubo ngendlela ecacileyo nelula:

1. Nxibelelana ne-Arhente yoHlolo ukuze ufumane iinkcukacha

Ukukhethwa kweArhente yoHlolo

Emva kokuba uxelelwe ngeemfuno ezithile zomthengi, khetha kwaye uqhagamshelane ne-arhente yokuhlola egunyazisiweyo yi-IBR ukuqinisekisa ukuthotyelwa kwemithetho kunye nobungcali.

Imibutho yokuhlolwa eqhelekileyo iquka i-TUV, i-BV, kunye ne-SGS.

Kule oda, sikhethe i-TUV njengombutho wokuhlola ukuqinisekisa ukuba umsebenzi wokuhlola weprojekthi yethu uhlangabezana nomgangatho ophezulu.

Xoxa ngeenkcukacha

Xoxa ngokweenkcukacha nombutho wokuhlola malunga nexesha lokuhlolwa, amanqaku abalulekileyo obungqina kunye namaxwebhu ekufuneka alungiselelwe, njl. ukuqinisekisa ukuba yonke inkqubo ihamba kakuhle.

2. Ukungeniswa kwamaxwebhu okuqala

Ukungeniswa kwamaxwebhu oyilo, iinkqubo zemveliso, izatifikethi zezinto eziphathekayo, kunye neenkcukacha zemveliso kwi-arhente yokuhlola, ezisisiseko sokuhlolwa okulandelayo.

3. Ulawulo lweNkqubo yoMveliso

Ngokwesiqhelo, eli nyathelo libandakanya umhloli ojongana neenkqubo ezahlukeneyo ezibandakanyekayo kwimveliso, ezinje ngokukhethwa kwezinto, ukuwelda, kunye nonyango lobushushu.

Ekubeni le oda ilungiselelwe umbhobho wentsimbi ogqityiweyo, akukho lawulo lokwenziwa kwemveliso olubandakanyekayo.

4. Ukuhlolwa noVavanyo lweMveliso egqityiweyo

Inkangeleko kunye nokuhlolwa kobukhulu

Inkangeleko kunye nobukhulu beetyhubhu buyajongwa ukuqinisekisa ukuba akukho ziphene zibonakalayo kwaye ziyahlangabezana nemigangatho.

Izinto eziqhelekileyo zovavanyo yimbonakalo, ububanzi, ubukhulu bodonga, ubude, kunye ne-bevel angle.

Ububanzi obungaphandle

Ubukhulu bodonga

Uvavanyo Olungonakalisiyo

Ngeli xesha, uvavanyo lwe-ultrasound (UT) lusetyenzisiwe ukuqinisekisa ukuba akukho ziphene kumbhobho wentsimbi.

Uvavanyo olungatshabalalisiyo - UT

Uvavanyo olungatshabalalisiyo - UT

Uvavanyo lweePropati zoMatshini

Uvavanyo lokutsalwa kwepayipi lwenziwa ukuze kuvavanywe amandla okutsalwa kwepayipi, amandla okukhupha ipayipi kunye nokwandiswa kwayo ukuqinisekisa ukuba iimpawu zayo zoomatshini ziyahlangabezana neemfuno ze-IBR.

Iipropati zokuThatha

Iipropati zokuThatha

Uhlalutyo loBume beeKhemikhali

Ukwakheka kweekhemikhali zombhobho wentsimbi kuhlolwa ngendlela yohlalutyo lwe-spectral kwaye kuthelekiswa nomgangatho we-ASTM A335 P91 ukuqinisekisa ukuthobela kwayo iimfuno.

5. Ukubonelelwa koXwebhu lweNkqubo

Nika izatifikethi zokulinganisa kunye neengxelo zelebhu ezineenkcukacha zazo zonke izixhobo zovavanyo ukuqinisekisa ukuba ulwazi olunikwe kwi-IBR luphelele kwaye luthembekile.

6. Uphononongo lwamaxwebhu

Umvavanyi we-IBR uza kuhlola ngokupheleleyo onke amaxwebhu angenisiweyo ukuqinisekisa ukuba umbhobho kunye nolwazi oluhambelana nawo luhambelana ngokupheleleyo nemigaqo ye-IBR.

7. Iimpawu ze-IBR

Ukumakisha

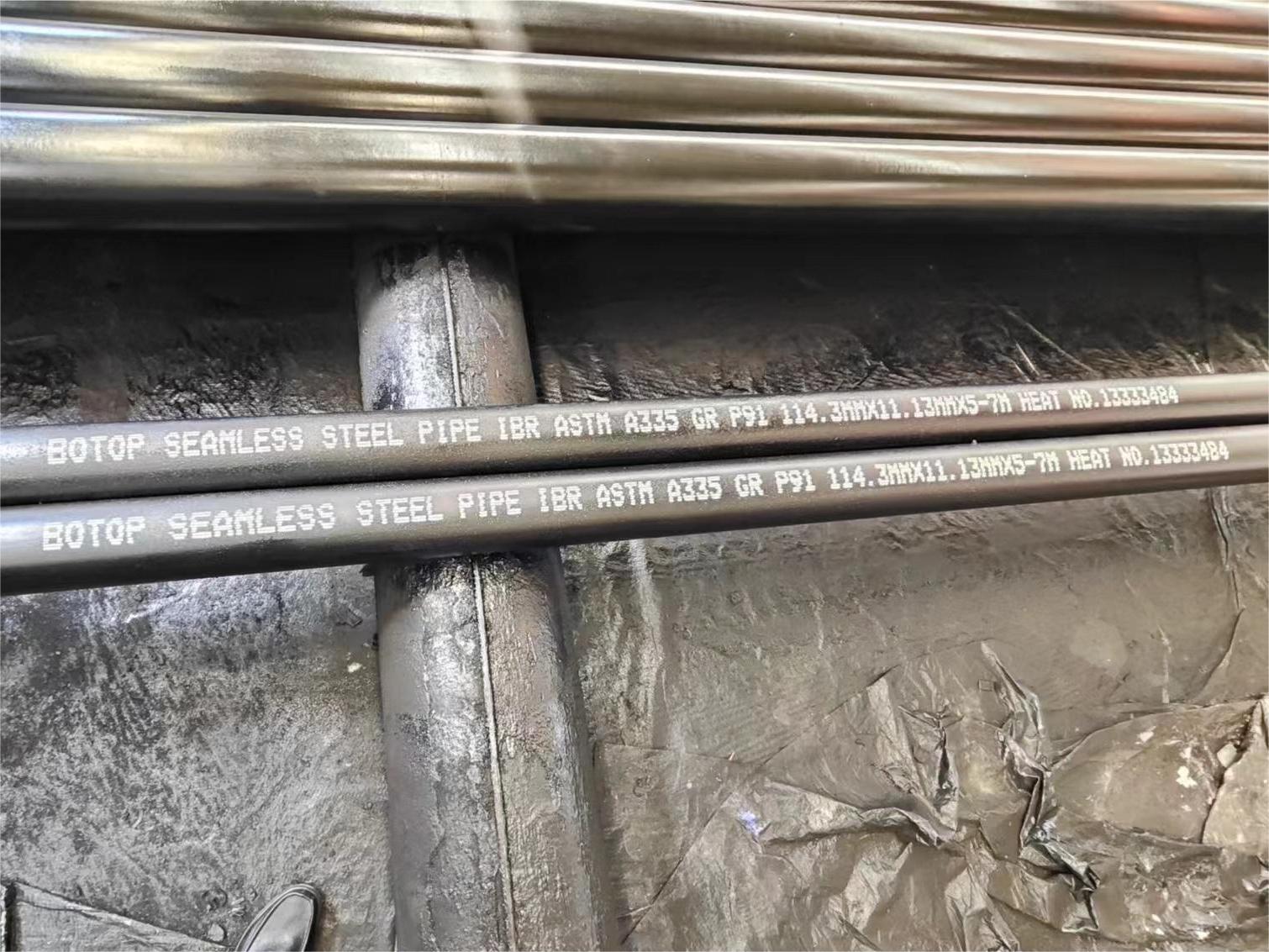

Umbhobho ohlangabezana neemfuno uza kubhalwa uphawu lwesatifikethi se-IBR, olubonisa ukuba uphumelele iimvavanyo kunye neemviwo ezifunekayo.

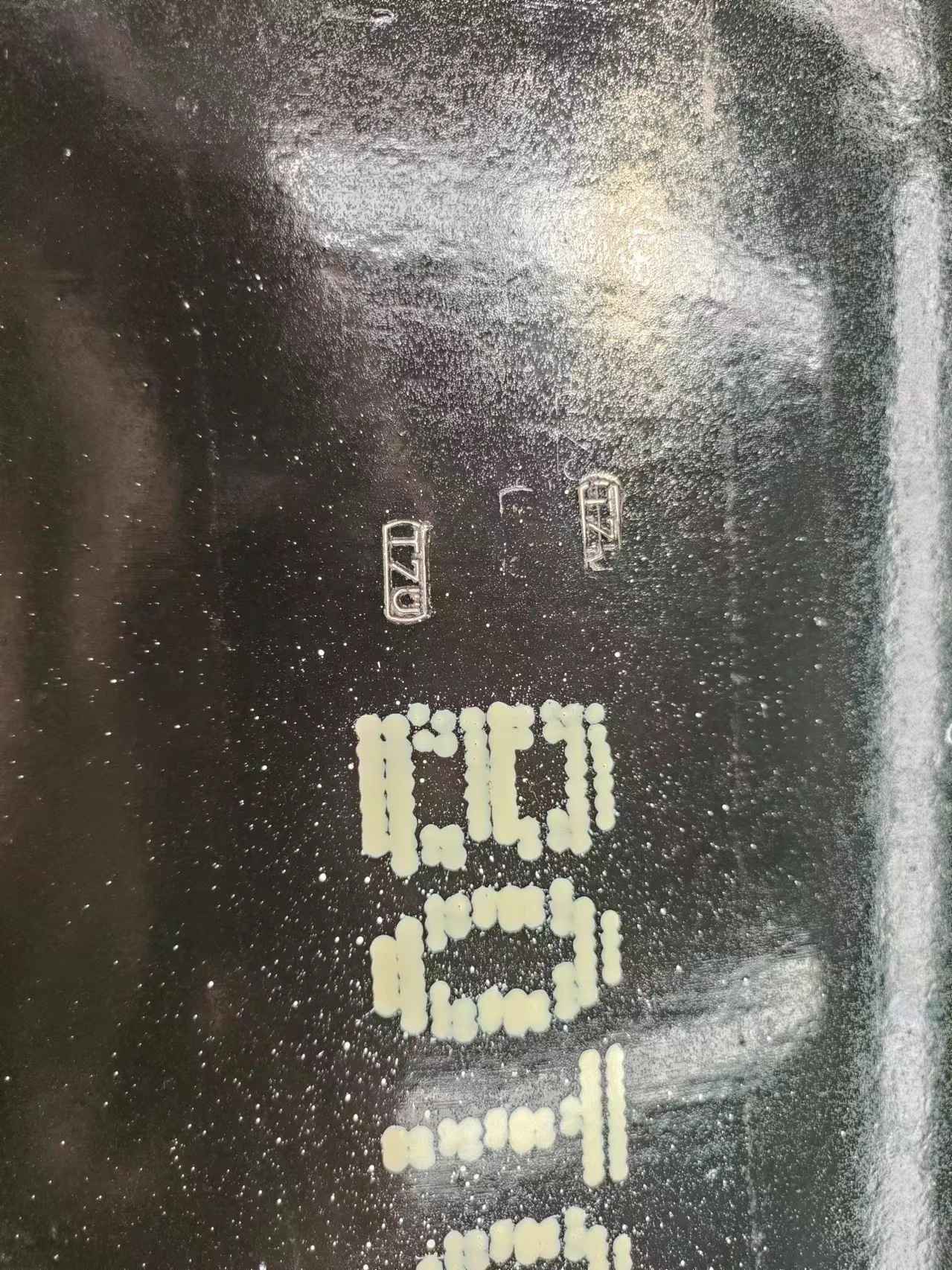

Isitampu seNsimbi

Isitampu sentsimbi yindlela yokuphawula eqinileyo, engagcini nje ngokuqinisekisa ukuqina kophawu kodwa ikwanceda ekuchongeni nasekulwamkeleni ngexesha lokuthuthwa, ukufakwa, nokusetyenziswa.

Ukuphawula imibhobho

Isitampu seNsimbi

8. Ukukhutshwa kweSatifikethi se-IBR

Emva kokuba umbhobho uphumelele zonke iimvavanyo, iarhente yokuhlola iya kukhupha isatifikethi se-IBR, esiqinisekisa ngokusesikweni ukuba umbhobho uyahambelana nemigaqo ye-IBR.

Ngokulandela inkqubo echazwe apha ngasentla, abavelisi beetyhubhu banokufumana isiqinisekiso se-IBR kwiimveliso zabo.

Indima yokufumana i-IBR Accreditation

Oku akuqinisekisi nje kuphela ukwamkelwa kweemveliso zabo kwimarike kodwa kuphucula kakhulu ukukhuphisana kwabo kwimarike yaseIndiya.

Ngathi

I-Botop Steel izimisele kakhulu kumgangatho kwaye isebenzisa ulawulo oluqinileyo kunye novavanyo ukuqinisekisa ukuthembeka kwemveliso. Iqela layo elinamava libonelela ngezisombululo ezenzelwe wena kunye nenkxaso yeengcali egxile ekwanelisekeni kwabathengi.

iithegi: IBR, ASTM A335, P91, umbhobho we-alloy, ongenamthungo.

Ixesha lokuthumela: Epreli-22-2024