I-ASTM A53 ERWumbhobho wentsimbiUhlobo Ekwi-A53 specification, eyenziwe yinkqubo yokuwelda yokumelana, kwaye iyafumaneka kwiiklasi zeBanga A kunye neBanga B.

Ilungele ukusetyenziswa koomatshini kunye noxinzelelo kwaye ikwasetyenziswa rhoqo njengenjongo eqhelekileyo yokuhambisa umphunga, amanzi, igesi kunye nomoya.

Iingenelo zepayipi yentsimbi ye-ERW, ezifanaixabiso eliphantsikwayeimveliso ephezulu, yenza kube yinto ekhethwayo kwiintlobo ngeentlobo zezicelo zoshishino.

Intsimbi yeBotopngumvelisi kunye nomthengisi wemibhobho yentsimbi yekhabhoni edityanisiweyo ekumgangatho ophezulu evela eTshayina, kwaye ukwangumthengisi wemibhobho yentsimbi engenamthungo, ekunika uluhlu olubanzi lwezisombululo zemibhobho yentsimbi!

Uluhlu lwethu lugcwele kwaye siyakwazi ukuhlangabezana neemfuno zabathengi bethu ngokukhawuleza zobungakanani obahlukeneyo.

I-ASTM A53/A53M ibandakanya ezi ntlobo zilandelayo kunye namanqanaba:

Uhlobo E: Ifakwe i-welded engangenisi umbane, iiBanga A kunye no-B.

Uhlobo S: Ayinamthungo, Amabanga A kunye no-B.

Uhlobo F: Ifakwe isithando somlilo esinamaqhuqhuva, esidityanisiweyo ngokuqhubekayo, iiBanga A kunye no-B.

Uhlobo EkwayeUhlobo Sziintlobo ezimbini zeepayipi ezisetyenziswa kakhulu. Ngokwahlukileyo koko,Uhlobo Fidla ngokusetyenziswa kwiityhubhu ezincinci. Ngenxa yokuqhubela phambili kwetekhnoloji yokuwelda, le ndlela yokuvelisa ayisetyenziswa rhoqo.

Ububanzi obuqhelekileyo: DN 6 - 650 [NPS 1/8 - 26];

Ububanzi obungaphandle: 10.3 - 660 mm [0.405 - 26 in.];

Ubukhulu bodonga kunye neetshathi zobunzima bombhobho wentsimbi:

Iityhubhu ezithe tyaba zinokujongwa kwiTheyibhile X2.2;

Iityhubhu ezinemisonto nezidibeneyo zingabonwa kwiTheyibhile X2.3.

I-ASTM A53 ikwavumela ukubonelelwa kombhobho ngezinye izilinganiso ukuba umbhobho uhlangabezana nazo zonke ezinye iimfuno zale nkcazo.

I-ERWisetyenziswa kakhulu ukuvelisa imibhobho yentsimbi engqukuva, enesikwere, neyingxande yekhabhoni kunye nentsimbi enomluko ophantsi.

Le nkqubo ilandelayo yemveliso yokuvelisaumbhobho wentsimbi we-ERW ojikelezayo:

a) Ukulungiselela izinto: Izinto zokuqala zihlala ziyimixokelelwane yentsimbi egoqwe ngobushushu. Ezi mixokelelwane ziqala zisikwe zibe bubanzi obufunekayo.

b) Ukwenziwa: Kancinci kancinci, ngokusebenzisa uthotho lweeroli, umcu wenziwa ube yisakhiwo esijikelezayo esivulekileyo. Ngexesha lale nkqubo, imiphetho yomcu wenziwe ngokusondelana kancinci kancinci ukulungiselela ukuwelda.

c) Ukuwelda: Emva kokwenza isakhiwo setyhubhu, imiphetho yomcu wentsimbi ifudunyezwa kukuxhathisa kombane kwindawo yokuwelda. Umsinga ohamba rhoqo udlula kwizinto, kwaye ubushushu obuveliswa kukuxhathisa busetyenziselwa ukufudumeza imiphetho ukuya kwinqanaba layo lokunyibilika, kwaye emva koko idityaniswe kunye ngokucinezelwa.

d) Ukususa iimbumbuluEmva kokuwelda, ii-weld burrs (isinyithi esigqithisileyo kwi-welding) ziyasuswa ngaphakathi nangaphandle kombhobho ukuqinisekisa ukuba umphezulu uthambile ngaphakathi kombhobho.

e) Ubungakanani kunye nokubekwa kobudeEmva kokuba kugqityiwe ukuwelda kunye nokususa iimbumbulu, iityhubhu zidluliselwa kumatshini wokulinganisa ubungakanani ukuze kulungiswe ubukhulu ukuqinisekisa ukuba ziyahlangabezana neemfuno zobubanzi obuchanekileyo kunye nokujikeleza. Emva koko iityhubhu zinqunyulwa zibe nobude obumiselweyo.

f) Ukuhlolwa novavanyo: Umbhobho wentsimbi uza kuvavanywa ngokungqongqo kwaye uhlolwe, kubandakanya uvavanyo lwe-ultrasound, uvavanyo lwe-hydrostatic, njl.njl., ukuqinisekisa ukuba umgangatho wombhobho wentsimbi uyahlangabezana nemigangatho kunye neenkcukacha.

g) Unyango lomphezuluOkokugqibela, umbhobho wentsimbi unokwenziwa ezinye iindlela zokulungisa ezifana nokufaka i-hot dip galvanizing, ukupeyinta, okanye ezinye iindlela zokulungisa umphezulu ukuze kubonelelwe ngokhuseleko olongezelelweyo lokugqwala kunye nobuhle.

IiWelds kwi-Type E okanye kwi-Type F Grade BUmbhobho kufuneka uphathwe ngobushushu okanye uphathwe ngenye indlela emva kokuwelda ukuze ingabikho i-martensite engavuthiswanga.

Ubushushu bonyango lobushushu kufuneka bube ubuncinane1000°F [540°C].

Xa umbhobho ubanda, ukwandiswa kwawo akumele kudlule1.5%yobubanzi obuchaziweyo bangaphandle bombhobho.

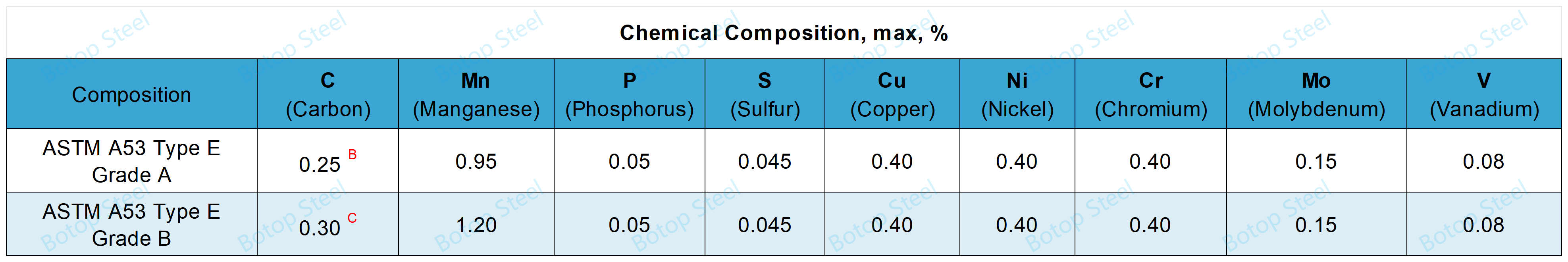

AIzinto ezintlanuCu, Ni, Cr, MokunyeVxa zidibene akufuneki zidlule kwi-1.00%.

BKwixabiso ngalinye lokunciphisa i-0.01% ngaphantsi kwe-carbon maximum echaziweyo, ukunyuka kwe-0.06% ye-manganese ngaphezu kwe-maximum echaziweyo kuya kuvunyelwa ukuya kuthi ga kwi-1.35%.

CKwixabiso ngalinye lokunciphisa i-0.01% ngaphantsi kwe-carbon maximum echaziweyo, ukunyuka kwe-0.06% ye-manganese ngaphezu kwe-maximum echaziweyo kuya kuvunyelwa ukuya kuthi ga kwi-1.65%.

Ipropati yokuThatha

| Uluhlu | Ulwahlulo | Ibanga A | Ibanga B |

| Amandla okutyhafa, umzuzu | I-MPa [psi] | 330 [48,000] | 415 [60,000] |

| Amandla okuvelisa, umzuzu | I-MPa [psi] | 205 [30,000] | 240 [35,000] |

| Ukwandiswa kwi-50 mm [2 in.] | Phawula | A,B | A,B |

Qaphela A: Ubuncinane bobude kwi-2 in[50 mm] buya kuba bobo bumiselwe yile equation ilandelayo:

e = 625,000 [1940] A0.2/U0.9

e = ubuncinci bobude kwi-2 in okanye i-50 mm kwipesenti, ijikelezwe kwipesenti ekufutshane

A = ngaphantsi kwe-0.75 kwi2[500 mm2] kunye nendawo enqamlezileyo yesampuli yovavanyo loxinzelelo, ebalwe kusetyenziswa ububanzi obuchaziweyo bangaphandle bombhobho, okanye ububanzi obuqhelekileyo bombhobho wovavanyo loxinzelelo kunye nobukhulu bodonga obuchaziweyo bombhobho, kunye nexabiso elibaliweyo elijikeleziswe kwi-0.01 in ekufutshane.2 [1 mm2].

U= amandla okutsalwa aphantsi akhankanyiweyo, i-psi [MPa].

Inqaku B: Jonga iTheyibhile X4.1 okanye iTheyibhile X4.2, nokuba yeyiphi na efanelekileyo, ukuze ufumane amaxabiso amancinci okwandiswa afunekayo kwiindidi ezahlukeneyo zobungakanani besampuli yovavanyo lokuxinana kunye namandla amancinci okuxinana acacisiweyo.

Uvavanyo lwe-Bend

Kwipayipi i-DN ≤ 50 [NPS ≤ 2], ubude obaneleyo bombhobho buya kuba nakho ukugoba bube bandayo nge-90° ujikeleze i-mandrel esilinda, ububanzi bayo buphindwe kabini kunobubanzi obuchazwe ngaphandle bombhobho, ngaphandle kokwenza imifantu nakweyiphi na indawo kwaye ngaphandle kokuvula i-weld.

Kabini-omelele kakhulu(udidi lobunzima:XXS) umbhobho ongaphezulu kwe-DN 32 [NPS 1 1/4] akufuneki ukuba wenziwe uvavanyo lokugoba.

Uvavanyo lokuTyatya

Uvavanyo lokuthamba kufuneka lwenziwe kumbhobho odibeneyo ngaphezulu kwe-DN 50 ngobunzima obuqinileyo (XS) okanye obukhaphukhaphu.

Ifanelekile kwiityhubhu ze-Type E, Grade A kunye ne-B; kunye neetyhubhu ze-Type F, Grade B.

Iityhubhu zentsimbi ezingenamthungo akufuneki zivavanywe.

Ixesha lovavanyo

Kuzo zonke iisayizi zemibhobho yohlobo S, uhlobo E, kunye nohlobo F lweBanga B, uxinzelelo lovavanyo luza kugcinwa ubuncinane imizuzwana emi-5.

Uvavanyo lwe-hydrostatic kufuneka lusetyenziswe, ngaphandle kokuvuza ngomthungo we-weld okanye emzimbeni wombhobho.

Iingcinezelo zoVavanyo

Umbhobho ongenantokufuneka ivavanywe ngamanzi ukuze ifumane uxinzelelo olufanelekileyo olunikiweyoItheyibhile X2.2,

Umbhobho odibeneyo kunye nomgcakufuneka ivavanywe ngamanzi ukuze ifumane uxinzelelo olufanelekileyo olunikiweyoItheyibhile X2.3.

Kwimibhobho yentsimbi ene-DN ≤ 80 [NPS ≤ 80], uxinzelelo lovavanyo aluyi kudlula i-17.2MPa;

Kwimibhobho yentsimbi ene-DN >80 [NPS >80], uxinzelelo lovavanyo aluyi kudlula i-19.3MPa;

Uxinzelelo oluphezulu lovavanyo lunokukhethwa ukuba kukho iimfuno zobunjineli ezikhethekileyo, kodwa oku kufuna ingxoxo phakathi komenzi kunye nomthengi.

Ukumakisha

Ukuba umbhobho uvavanywe ngamanzi, uphawu kufuneka luboniseuxinzelelo lovavanyo.

Ezi mfuno zilandelayo ziyasebenza kwiPipe yoHlelo E kunye noHlelo F lweBanga B.

Umbhobho ongenamthungo unezinye iimfuno ezingaxoxwanga kolu xwebhu.

Iindlela zoVavanyo

Iipayipi eziveliswa ngoomatshini bokwandisa nokunciphisa umbane abangatshisi kakhulu: DN ≥ 50 [NPS ≥ 2], iukuweldakwicandelo ngalinye lombhobho kufuneka kudlule uvavanyo lombane olungonakalisiyo, kwaye indlela yovavanyo kufuneka ihambelaneE213, E273, E309 okanye E570umgangatho.

Iipayipi ze-ERW eziveliswa ngumatshini wokunciphisa ububanzi obushushu: DN ≥ 50 [NPS ≥ 2]Icandelo ngalinyeumbhobho kufuneka uhlolwe ngokupheleleyo ngovavanyo lombane olungonakalisiyo, oluya kuhambelanaE213, E309, okanyeE570imigangatho.

Qaphela: Umatshini wokwandisa ububanzi bokunwebeka okushushu ngumatshini oqhubeka nowolula kwaye ucinezela iityhubhu zentsimbi ngamarola kubushushu obuphezulu ukuze ulungise ububanzi bazo kunye nobukhulu bodonga.

Ukumakisha

Ukuba ityhubhu iye yavavanywa ngendlela engonakalisiyo, kuyimfuneko ukubonisaI-NDEkuphawu.

Ubunzima

± 10%.

Ipayipi i-DN ≤ 100 [NPS ≤ 4], ilinganiswa njengebhetshi.

Iipayipi DN > 100 [NPS > 4], zilinganiswe zibe ziziqwenga ezilodwa.

Ububanzi

Kwipayipi i-DN ≤40 [NPS≤ 1 1/2], utshintsho lwe-OD aluyi kudlula ±0.4 mm [1/64 in.].

Kwipayipi i-DN ≥50 [NPS>2], utshintsho lwe-OD aluyi kudlula i-±1%.

Ubukhulu

Ubukhulu bodonga obuncinci abuyi kuba ngaphantsi87.5%yobukhulu bodonga obuchaziweyo.

ubunzima obukhaphukhaphu kunobunzima obugqithisileyo (XS):

a) umbhobho ongenanto: 3.66 - 4.88m [12 - 16 ft], kungabi ngaphezulu kwe-5% yenani lilonke.

b) ubude obuphindwe kabini ngokungacwangciswanga: ≥ 6.71 m [22 ft], Ubuncinane ubude obuqhelekileyo yi-10.67m [35 ft].

c) ubude obungacwangciswanga: 4.88 -6.71m [16 - 22 ft], kungabi ngaphezulu kwe-5% yenani lilonke lobude obunemisonto obufakwe kwiijointers (iziqwenga ezibini zidibene kunye).

Ubunzima obunamandla kakhulu (XS) okanye obunzima kakhulu: 3.66-6.71 m [12 - 22 ft], kungabi ngaphezulu kwe-5% iyonke yombhobho 1.83 - 3.66 m [6 - 12 ft].

Kwi-ASTM, ukugqitywa kombhobho wentsimbi we-A53 kufumaneka ngombala omnyama okanye ogqunyiweyo.

Mnyama: Iityhubhu zentsimbi ngaphandle kokulungiswa komphezulu, zihlala zithengiswa ngqo emva kwenkqubo yokwenziwa, kwezo zicelo apho kungekho mfuneko yokumelana nokugqwala okongezelelweyo.

Iipayipi ezifakwe i-galvanized mazihlangabezane neemfuno ezifanelekileyo.

Inkqubo

I-zinc mayigqunywe ngaphakathi nangaphandle ngenkqubo yokuntywila ngobushushu.

Impahla engekasilwa

I-zinc esetyenziselwa ukugquma kufuneka ibe yiyo nayiphi na inqanaba le-zinc ehambelana neemfuno zeNkcazeloI-ASTM B6.

Inkangeleko

Umbhobho we-galvanized mawungabi nazindawo zingagqunywanga, amaqamza omoya, ii-flux deposits, kunye nezinto ezifakwe kwi-slag. Amaqhuma, ii-bumps, ii-globules, okanye inani elikhulu le-zinc deposits eziphazamisana nokusetyenziswa okucwangcisiweyo kwezinto azivumelekanga.

Ubunzima bokwaleka obusegadini

Kuya kugqitywa ngovavanyo lwexolo ngokwendlela yovavanyo ye-ASTM A90.

Ubunzima bokugquma akufuneki bube ngaphantsi kwe-0.55 kg/m² [1.8 oz/ft²].

Umbhobho wentsimbi we-ASTM A53 ERWidla ngokusetyenziswa kwiindawo ezinoxinzelelo oluphantsi ukuya koluphakathi ezifana nobunjineli bukamasipala, ulwakhiwo, kunye nemibhobho yokwakha yoomatshini. Iimeko eziqhelekileyo zokusetyenziswa ziquka ukuhambisa amanzi, umphunga, umoya, kunye nezinye izinto zolwelo ezinoxinzelelo oluphantsi.

Ngenxa yokuba zikwazi ukuwelda kakuhle, zilungele ukwenza imisebenzi equka ukujijeka, ukugoba, kunye nokujika.