BS EN 10210 S275J0Hke karolo ea tšepe ea sebopeho e se nang letho e qetiloeng ka mocheso e entsoeng hoBS EN 10210ka mefuta e fapaneng ya dibopeho tse chitja, tse sekwere, tse kgutlonnetsepa, kapa tse oval.

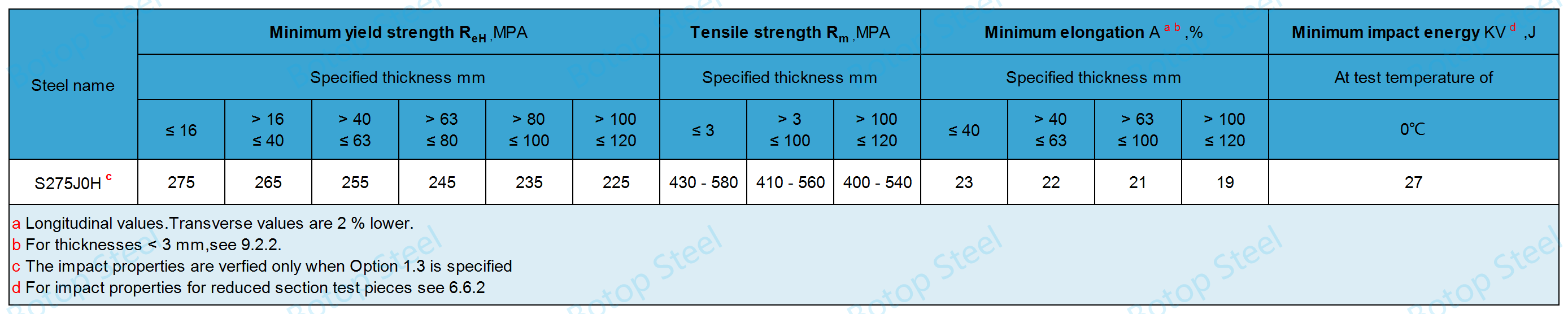

Thepa ea S275J0H e khetholloa ka matla a bonyane a tlhahiso ea 275 MPa ka botenya ba e seng ho feta 16 mm; matla a eona a bonyane a tšusumetso ke bonyane 27 J ho 0℃.

S275J0H ke ea mofuta oa tšepe ea carbon, nomoro ea tšepe1.0149, e nang le thepa e ntle ea sebopeho le ea ts'ebetso, e sebelisoang haholo-holo mehahong ea kaho, empa hape e sebelisetsoa likarolo tse sa jareng mojaro, e ka fana ka ho boloka botsitso ba sebopeho le ho tšoarella ho latela ho hlokomela melemo e theko e tlase.

Ela Hloko: Litlhoko tsohle tse ho BS EN 10210 le tsona li sebetsa ho EN 10210 'me ka hona ha li pheteloe mona.

Litlhopho tsa maemo ho BS EN 10210 li abeloa ho latela EN 10027-1 'me linomoro tsa tšepe li abeloa ho latela EN 10027-2.

| Lebitso la tšepe | Nomoro ea tšepe | Mofuta oa Tšepe | Lebitso la tšepe | Nomoro ea tšepe | Mofuta oa Tšepe |

| S235JRH | 1.0039 | tšepe ea k'habone | S275NH | 1.0493 | tšepe ea k'habone |

| S275J0H | 1.0149 | tšepe ea k'habone | S275NLH | 1.0497 | tšepe ea k'habone |

| S275J2H | 1.0138 | tšepe ea k'habone | S355NH | 1.0539 | tšepe ea k'habone |

| S355J0H | 1.0547 | tšepe ea k'habone | S355NLH | 1.0549 | tšepe ea k'habone |

| S355J2H | 1.0576 | tšepe ea k'habone | S420NH | 1.8750 | tšepe ea motsoako |

| S355K2H | 1.0512 | tšepe ea k'habone | S420NLH | 1.8751 | tšepe ea motsoako |

| S460NH | 1.8953 | tšepe ea motsoako | |||

| S460NLH | 1.8956 | tšepe ea motsoako |

Bakeng sa tlhahisoleseding e batsi ka meelelo e itseng ya ditlhaku le dinomoro dikereiting,o ka tobetsa mona.

Botenya ba lebota ≤120mm.

Selikalikoe: Bophara ba kantle ho fihlela ho 2500 mm;

Sekwere: Litekanyo tsa kantle ho fihlela ho 800 mm x 800 mm;

Sekhutlonnetsepa: Litekanyo tsa kantle ho fihlela ho 750 mm x 500 mm;

E kang elliptical: Litekanyo tsa kantle ho fihlela ho 500 mm x 250 mm.

Re ikhethile ka ho fana ka litlhaloso tse fapaneng tsa Round Hollow Structural Steel Pipe, haeba u na le litlhoko life kapa life, ka kopo ikutloe u lokolohile ho ikopanya le rona, re labalabela ho sebelisana le uena!

Liphaephe tsa tšepe tse welded tsa LSAW li etsoa haholo-holo ka ho etsa lipoleiti tsa tšepe ka har'a liphaephe ho sebelisoa mokhoa oa ho bopa oa JCOE, o lateloa ke ho weld ho sebelisoa arc e kenelletseng ka mahlakoreng a mabeli (DSAW) theknoloji ea ho tjheseletsa, 'me e phethetsoe ka litlhahlobo le mekhoa e mengata ea kalafo.

U khetha mokhoa o nepahetseng oa tlhahiso joang? Phapang le melemo ea phaephe ea tšepe e se nang sekoli, LSAW, ho tjheseletsa arc e ka tlas'a metsi, le ho tjheseletsa arc e ka tlas'a metsi ke efe? Hona boholo ba ts'ebetso ka 'ngoe ke bofe? U ka tobetsa sehokelo se latelang ho se bona.

Litšobotsi JR,J0, J2 le K2 -e chesang e felile;

Litšobotsi N le NL - li tloaelehile. Li tloaelehile li kenyelletsa li phutholohile tse tloaelehileng.

| Ssehlopha sa tee | Mofuta oa ho tlosa oksideishenea | % ka boima, boholo | |||||||

| C (Khabone) | Si (Silicone) | Mn (Manganese) | P (E na le phosphorus) | S (Sebabole) | Nb,c (Naetrojene) | ||||

| Lebitso la tšepe | Nomoro ea tšepe | Botenya bo boletsoeng (mm) | |||||||

| ≤40 | >40≤120 | ||||||||

| S275J0H | 1.0149 | FN | 0.20 | 0.22 | — | 1.5 | 0.035 | 0.035 | 0.009 |

aFN = Tšepe e rapameng ha ea lumelloa;

bHoa lumelloa ho feta boleng bo boletsoeng ha feela keketseho e 'ngoe le e 'ngoe ea 0.001 % N ea P, max. content le eona e fokotsoa ka 0.005%. Leha ho le joalo, N content ea tlhahlobo ea cast ha ea lokela ho feta 0.012 %;

cBoleng bo phahameng ka ho fetisisa ba naetrojene ha bo sebetse haeba motsoako oa lik'hemik'hale o bontša bonyane kakaretso ea Al ea 0.020% ka karolelano ea bonyane ea Al/N ea 2:1, kapa haeba ho na le likarolo tse ling tse lekaneng tsa N-binding. Likarolo tsa N-binding li tla tlalehoa Tokomaneng ea Tlhahlobo.

Litšobotsi tsa mechini tsa BS EN 10210 li kenyelletsa matla a tlhahiso, matla a ho thaepa, ho lelefala le litšobotsi tsa tšusumetso.

Likarolo tse sekoti li tla ba le bokaholimo bo boreleli bo tsamaellanang le mokhoa oa tlhahiso o sebelisitsoeng; likoti, masoba, kapa li-groove tse sa tebang tse tsoang ts'ebetsong ea tlhahiso lia lumelloa, ha feela botenya bo le ka har'a mamello.

EN 10210 Libaka tsa liphaephe tsa tšepe li loketse ho tjhesa ka galvanizing.

EN 10210 ha e hloke teko ea khatello ea hydrostatic ea liphaephe tsa tšepe.

Lebaka ke hobane lihlahisoa tse tloaelehileng tsa EN 10210 li sebelisoa haholo-holo bakeng sa merero ea sebopeho eseng bakeng sa litsamaiso tsa liphaephe tse hlokang ho hatelloa.

Haeba ho hlokahala teko ea khatello ea hydrostatic, ho ka buuoa ka litekanyetso tsa EN 10216 (li-tube tsa tšepe tse se nang seamless) kapa EN 10217 (li-tube tsa tšepe tse lahletsoeng).

Ha ho na tlhoko ea tlamo tekanyetsong ea ho etsa NDT liphaepheng tsa tšepe tse nang le sekoti.

Haeba NDT e etsoa liphaepheng tsa tšepe tse welletsoeng, litlhoko tse latelang li ka boleloa.

Likarolo tse Welded tsa Motlakase

Bakeng sa karolo e chitja e se nang letho, liphaephe tsa tšepe ke ERW.

O ka kgetha e 'ngoe ea mekhoa e latelang ea liteko bakeng sa teko.

a) EN 10246-3 ho ea boemong ba kamohelo E4, ntle le hore mokhoa oa ho potoloha tube/pancake coil o ke ke oa lumelloa;

b) EN 10246-5 ho fihlela boemong ba kamohelo F5;

c) EN 10246-8 ho fihlela boemong ba kamohelo U5.

Likarolo tse Welded tsa Arc tse qoelitsoeng ka metsing

Bakeng sa lipeipi tsa tšepe tse chitja tse se nang letho ke LSAW le SSAW.

Sekoahelo sa weld sa likarolo tse se nang letho tse koahetsoeng ka arc tse koahetsoeng ka tlas'a metsi se tla lekoa ho latela EN 10246-9 ho ea boemong ba kamohelo U4 kapa ka radiography ho latela EN 10246-10 ka sehlopha sa boleng ba setšoantšo R2.

Bakeng sa tlhahisoleseding e batsi mabapi le ditlhoko tse amanang le mamello ya dimensional,ka kopo tobetsa mona bakeng sa tlhahisoleseling e batsi.

EN 10025 - S275J0;

JIS G3106 - SM400B;

CSA G40.21 - 300W;

Ha ho kgethwa se lekanang le EN 10210 S275J0H, ho lokela ho etswa papiso e qaqileng ya sebopeho sa dikhemikhale le thepa ya mechini ho netefatsa hore thepa e kgethilweng e fihlela ditlhoko tse ikgethang tsa projeke.

Ho tloha ha e theoa ka 2014,Tšepe ea Botope se e le mofani ea ka sehloohong oa liphaephe tsa tšepe ea khabone Leboea la Chaena, ea tsebahalang ka tšebeletso e ntle haholo, lihlahisoa tsa boleng bo holimo le litharollo tse felletseng.

Khamphani e fana ka mefuta e fapaneng ya diphaephe tsa tshepe ya khabone le dihlahiswa tse amanang le yona, ho kenyeletswa le phaephe ya tshepe e se nang moedi, ERW, LSAW, le SSAW, hammoho le lethathamo le felletseng la diphaephe le di-flange. Dihlahiswa tsa yona tse ikgethang di boetse di kenyelletsa di-alloy tsa maemo a hodimo le ditshipi tse sa hlwekang tsa austenitic, tse etseditsweng ho fihlela ditlhoko tsa diporojeke tse fapaneng tsa diphaephe.