Kubatanidza arc mumvura kwakanakira mapaipi, midziyo yepressure nematangi, kugadzira njanji uye mashandisirwo makuru ekuvaka, nechimiro chemonofilament chiri nyore, chimiro chewaya mbiri, chimiro chewaya mbiri dzakatevedzana uye chimiro chewaya dzakawanda.

Kupinza arc mumvura kunogona kubatsira vashandisi mumabasa akawanda ekupinza. Kubva pakuwedzera kugadzirwa, kuvandudza nzvimbo yekushanda, kusvika pakuona kuti mhando yacho inogara iripo nezvimwewo. Vagadziri vesimbi vari kufunga nezvekuchinja maitiro ekupinza arc mumvura vanofanira kunge vakafunga kuti vanogona kuwana mabhenefiti akawanda kubva mukuita uku.

Ruzivo rwekutanga rwekushongedza arc pasi pemvura

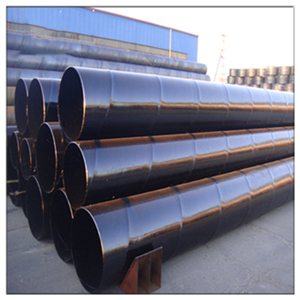

Maitiro ekuwedera arc pasi pevhu akakodzera kushandiswa mumaindasitiri makuru akadai semapaipi, midziyo yepressure nematangi, kuvaka maroketi, kuvaka/kuchera zvinorema. Yakanakira maindasitiri anoda kugadzirwa kwepamusoro, kunyanya kana zvasvika pakuwedera zvinhu zvakakora kwazvo, kune mabhenefiti akawanda anowanikwa kubva mumaitiro ekuwedera arc pasi pevhu.

Kuwanda kwayo uye kumhanya kwayo pakufamba zvinogona kukanganisa zvakanyanya kugona kwevashandi, kushanda zvakanaka uye mari yekugadzira, inova imwe yezvakanakira zvikuru zvekushandisa welding ye arc pasi pemvura.

Zvimwe zvakanakira zvinosanganisira: kuumbwa kwemakemikari kwakanaka uye hunhu hwemakanika eweld, kuonekwa kushoma kwearc uye utsi hushoma hwekuweld, kugadzikana kwenzvimbo yekushandira kuri nani, uye chimiro chakanaka chekuweld uye mutsetse wezvigunwe.

Kunyudza arc yakanyudzwa mumvura inzira yekudyisa waya inoshandisa granular flux kuparadzanisa arc kubva mumhepo, sezvinoreva zita racho, arc inovigwa muflux, zvinoreva kuti kana ma parameter akaiswa, arc haionekwe nekubuda kwe flux. Waya yekunyudza inopihwa nguva dzose ne torch inofamba ne weld.

Kupisa kweArc kunonyungudutsa chikamu chewaya, chikamu cheflux nesimbi yepasi, zvichiita dziva rakanyungudutswa, iro rinoungana kuita weld yakafukidzwa ne welding slag. Ukobvu hwewelding material i1/16"-3/4", hunogona kunge huri 100% penetration welding ne single welding, kana ukobvu hwemadziro husina muganho, multi-pass welding inogona kuitwa, uye weld inogadziriswa uye yakasarudzwa nemazvo, uye welding wire flux yakakodzera inosarudzwa.

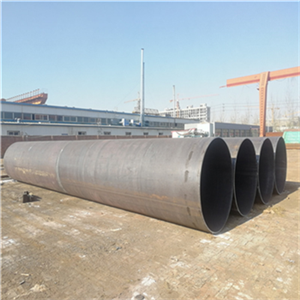

LSAW

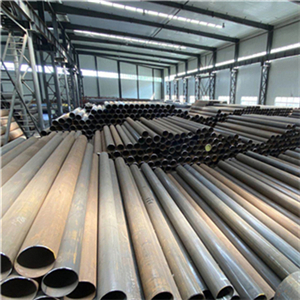

ERW

SSAW

Kusarudzwa kwewaya yekufambisa uye yekukwevera

Kusarudza nzira chaiyo yekufambisa newaya pakusanganisa arc welding nearc welding kwakakosha kuti uwane mhedzisiro yakanaka uchishandisa nzira iyi. Kunyange hazvo nzira dzekubatanidza arc welding nearc welding dzichishanda chete, kugona uye kushanda zvakanaka kunogona kuwedzerwa kunyangwe zvichibva pawaya yekufambisa nearc welding inoshandiswa.

Kuyerera uku hakungodziviriri dziva rekuwelda chete, asiwo kunobatsira mukuvandudza hunhu hwemakanika uye kubereka kweweld. Kugadzirwa kwefluxes kune simba guru pazvinhu izvi, zvichikanganisa kugona kwekutakura magetsi uye kuburitswa kweslag.

Kukwanisa kutakura zvinhu pari zvino kunoreva kuti zvinokwanisika kuisa zvinhu zvakanaka uye weld profile yepamusoro-soro zvinogona kuwanikwa.

Kuburitswa kwetsvina kubva pakuyerera kwakasiyana kunokanganisa kusarudzwa kwekuyerera nekuti mamwe maflux akakodzera mamwe magadzirirwo ekusonesa kupfuura mamwe.

Sarudzo dzekusarudza flux dzekushandisa arc soldering pasi pemvura dzinosanganisira mhando dzewelds dzinoshanda nedzisina kusimba. Musiyano mukuru ndewekuti active flux inochinja makemikari eweld, nepo neutral flux isingachinji.

Ma active fluxes anozivikanwa nekusanganiswa kwe silicon ne manganese. Zvinhu izvi zvinobatsira kuchengetedza simba rekusunga weld pakupisa kwakanyanya, zvinobatsira kuchengetedza weld yakatsetseka uye yakapfava pakufamba kwakanyanya uye zvinopa kuburitswa kwakanaka kweslag. Kazhinji, active fluxes inogona kubatsira kuderedza njodzi yemhando isina kunaka ye solder, pamwe nekuchenesa uye kugadzirisa patsva kunodhura mushure mekusunga weld. Zvisinei, yeuka kuti active fluxes inowanzo kukodzera kusanganisa single- kana double-pass.

Kuyerera kusina kusimba kwakanakira ma "solder" makuru e "multipass" nekuti anobatsira kudzivirira kugadzirwa kwe "welds" dzinopfava uye dzinonzwa kutsemuka.

Kune mhando dzakawanda dzewaya dzekuwedera dzinosarudzwa maererano nekuwedera kwearc pasi pemvura, imwe neimwe ine zvayakanakira nezvayakaipira. Dzimwe waya dzakagadzirirwa kuwedera nekupisa kwakanyanya, nepo dzimwe dzakagadzirirwa kuve ne alloys dzinobatsira flux kuita basa rekuchenesa welding.

Ziva kuti hunhu hwemakemikari uye kudyidzana kwewaya yekuwelda zvinokanganisa hunhu hwemuchina wekuwelda. Kubudirira kunogonawo kuwedzerwa zvakanyanya nekusarudza simbi yekuzadza.

Semuenzaniso, kushandisa waya yesimbi ine nzira yekuwedera arc iri pasi pemvura kunogona kuwedzera kushanda zvakanaka kwekuisa waya ne15% kusvika 30% zvichienzaniswa nekushandisa waya yakasimba, ukuwo zvichipa mukana wakakura uye usina kudzika wekupinda kwayo.

Nekuda kwekumhanya kwayo kukuru, waya dzesimbi dzinoderedzawo kupisa kuti dzideredze njodzi yekuchinjika kwesimbi uye kupera simba.

Pasimbi dzese, simbi dzisina ngura dzinoshandiswa ne austenitic dzine mwero wakaderera wekukohwa. Saka, maererano nehunyanzvi hwemakanika, simbi isina ngura inoshandiswa ne austenitic haisiyo chinhu chakanakira simbi yevharuvhu, nekuti kuti ive nechokwadi chekuti ine simba rakati, dhayamita yesimbi yevharuvhu ichawedzera. Mwero wekukohwa haugone kuwedzerwa nekupisa, asi unogona kuwedzerwa nekupisa.

Isu tinonyanya kugadzira mapaipi esimbi isina musono necarbon uye stainless, tinogamuchira chero mibvunzo, tichakupai kekutanga!

Nguva yekutumira: Ndira-30-2023