STPT 370yog qib ntawm tus qauv Nyiv Pooj JIS G 3456 rau cov kav hlau carbon, uas yog siv rau cov kav dej siab hauv cov chaw uas muaj qhov kub siab tshaj 350 ° C. Nws tuaj yeem yog cov kav dej seamless lossis welded siv cov txheej txheem hluav taws xob tsis kam vuam (ERW). Cov khoom siv kho tshuab ntawm cov khoom siv STPT 370 yog qhov tsawg kawg nkaus tensile zog ntawm 370 MPa thiab qhov tsawg kawg nkaus yield zog ntawm 215 MPa.

Yog tias koj tab tom nrhiav ib lub chaw tsim khoom thiab cov chaw muag khoom ntawm cov kav dej hlau uas ua tau raws li tus qauv JIS G 3456, ces peb yog tus khub uas koj tab tom nrhiav. Tiv tauj peb hnub no thiab peb yuav zoo siab pab koj!

Haum rau cov kab uas hla sab nraud 10.5 hli - 660.4 hli (6A - 650A) (1/8B - 26B).

A thiab B yog ob txoj hauv kev los qhia qhov nominal diameter hauv tus qauv Nyiv. Tshwj xeeb, A sib raug rau DN, thaum B sib raug rau NPS.

JIS G 3456 STPT 370 tuaj yeem tsim tau los ntawm kev siv covtsis muaj qhov tsis sib xwscov txheej txheem tsim khoom lossis qhovhluav taws xob tsis kam vuam(ERW) txheej txheem.

Cov txheej txheem tsim khoom kuj sib xws rau ntau txoj kev ua tiav kom daws tau qhov teeb meem ntawm kev siv sib txawv.

| Lub cim ntawm qib | Lub cim ntawm cov txheej txheem tsim khoom | |

| Cov txheej txheem tsim cov yeeb nkab | Txoj kev ua tiav | |

| JIS G 3456 STPT370 | Tsis Muaj Qhov Txuas: S | Kub-tiav lawm: H Txias-tiav: C |

| Hluav taws xob tsis kam welded: E Taub qab vuam: B | Kub-tiav lawm: H Txias-tiav: C Raws li hluav taws xob tsis kam welded: G | |

STPT 370 yuav tsum tau kho cua sov.

1. Cov yeeb nkab hlau tsis muaj qhov kub thiab txias: Raws li kev tsim khoom, kev ua kom sov qis lossis kev ua kom zoo li qub yuav raug siv raws li qhov xav tau;

2. Cov yeeb nkab hlau tsis muaj seamless txias: Kev ua kom sov qis lossis ua kom zoo li qub;

3. Cov yeeb nkab hlau uas ua los ntawm hluav taws xob kub thiab tsis kam: Raws li kev tsim khoom, kev ua kom sov qis lossis kev ua kom zoo li qub yuav raug siv raws li qhov xav tau;

4. Txias-ua tiav hluav taws xob tsis kam welded thiab Raws li hluav taws xob tsis kam welded steel yeeb nkab: Qis-kub annealing lossis normalizing.

| Lub cim ntawm qib | C | Si | Mn | P | S |

| JIS G 3456 STPT370 | 0.25% siab tshaj | 0.10 - 0.35% | 0.30 - 0.90% | 0.035% siab tshaj | 0.035% siab tshaj |

Yog tias tsim nyog, cov ntsiab lus ntxiv tuaj yeem ntxiv.

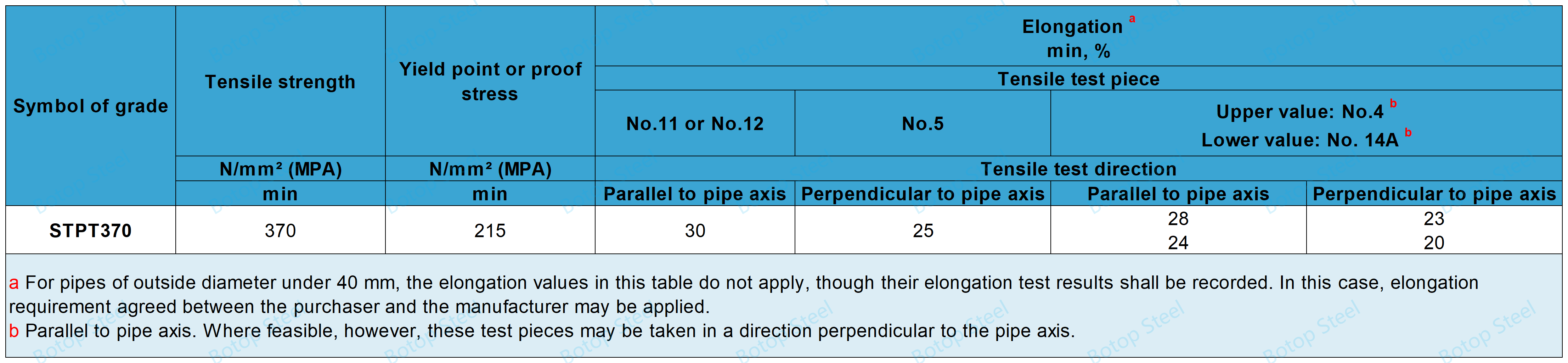

Lub Zog Tensile, Yield Point lossis Proof Stress, thiab Elongation

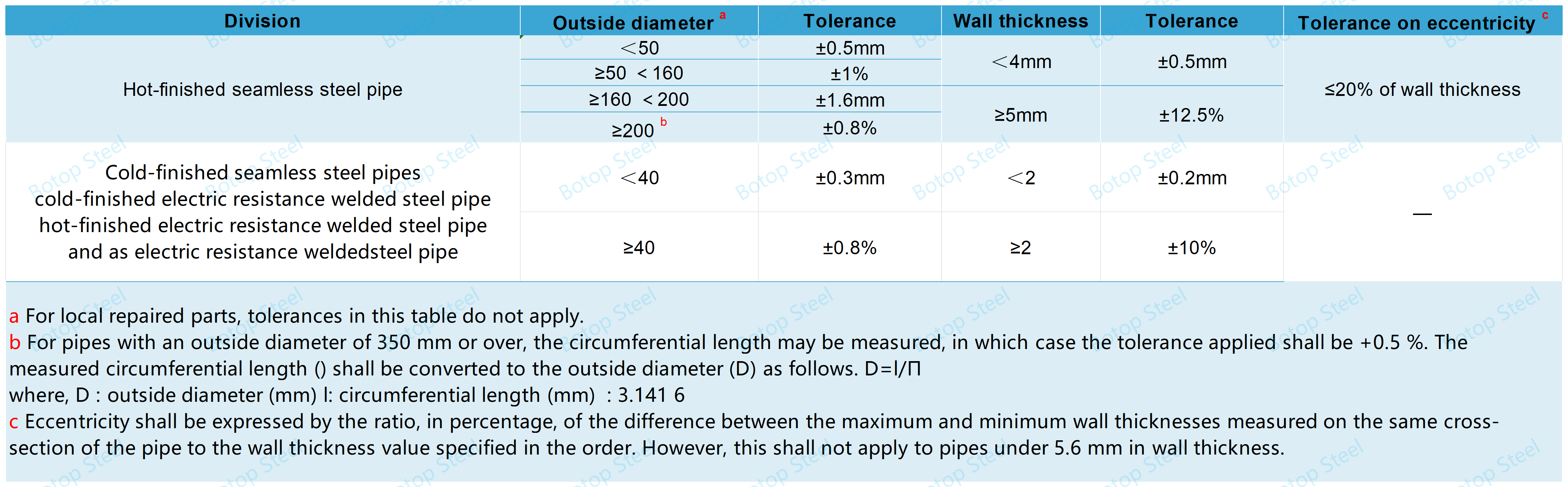

Kev Ua Kom tiaj tiaj

Haum rau cov kav dej uas muaj lub cheeb sab nraud ntau dua 60.5 hli.

Cov qauv no muab tso rau nruab nrab ntawm ob lub platform thiab ua kom tiaj tiaj. Thaum qhov deb ntawm ob lub phaj ncav cuagH, tsis muaj qhov tawg ntawm qhov chaw ntawm cov yeeb nkab hlau.

H = 1.08t/(0.08+ t/H)

н: nrug ntawm platens (mm);

t: phab ntsa tuab ntawm cov yeeb nkab (hli);

D: sab nraud ntawm cov yeeb nkab (hli);

Kev khoov tau

Haum rau cov kav hlau uas muaj sab nraud ntawm 60.5 hli lossis tsawg dua.

Thaum cov qauv khoov ncig lub mandrel mus rau qhov radius sab hauv ntawm 6 npaug ntawm txoj kab uas hla sab nraud ntawm cov yeeb nkab, cov qauv raug tshuaj xyuas thiab tsis pom muaj kab nrib pleb.

| Phab ntsa tuab | Tus lej teem sijhawm: Sch | |||||||||

| 10 | 20 | 30 | 40 | 60 | 80 | 100 | 120 | 140 | 160 | |

| Yam tsawg kawg nkaus hydraulic xeem siab, Mpa | 2.0 | 3.5 | 5.0 | 6.0 | 9.0 | 12 | 15 | 18 | 20 | 20 |

Thaum lub sab nraud txoj kab uas hla thiab phab ntsa tuab ntawm cov yeeb nkab hlau tsis yog qhov loj me, cov txheej txheem hauv qab no tuaj yeem siv los txiav txim siab qib kev qhia tshwj xeeb tsim nyog:

Ua ntej, xaiv qib teem sijhawm txheem uas ze tshaj plaws rau qhov loj me tsis yog tus qauv; qhov thib ob, txiav txim siab qib kev qhia tshwj xeeb los ntawm kev xam tus nqi P.

Hauv ob txoj kev, tus nqi me dua yuav tsum raug xaiv ua qib kawg.

P = 2st/D

P: kev sim siab (MPa);

t: phab ntsa tuab ntawm cov yeeb nkab (hli);

D: sab nraud ntawm cov yeeb nkab (hli);

s: 60% ntawm tus nqi tsawg kawg nkaus uas tau teev tseg ntawm qhov taw qhia tawm lossis kev ntxhov siab pov thawj;

Cov txheej txheem sim tsis ua puas tsuaj feem ntau suav nrog kev sim ultrasonic (UT) thiab kev sim eddy tam sim no (ET).

Thaum ua qhov kev tshuaj xyuas ultrasonic, yuav tsum tau siv JIS G 0582, thiab thaum qhov tshwm sim ntawm kev tshuaj xyuas sib npaug lossis ntau dua li tus qauv siv rau chav kawm UD, nws raug suav hais tias yog qhov tsis ua tiav.

Thaum ua qhov kev tshuaj xyuas tam sim no eddy, yuav tsum tau siv JIS G 0583. Thaum qhov tshwm sim ntawm kev tshuaj xyuas sib npaug lossis ntau dua tus qauv siv rau chav kawm EY, nws raug suav hais tias tsis tsim nyog.

Cov qauv qhov ntev thiab phab ntsa tuab ntawm 10.5 hli txog 660.4 hli tau teev nyob rau hauv JIS G 3456, uas yoglub rooj hnyav ntawm cov yeeb nkab hlau thiab daim ntawv teem sijhawm sib xws No.

Teem Caij 10,Teem Caij 20,Teem Caij 30,Teem Caij 40,Teem Caij 60,Teem Caij 80,Teem Caij 100,Teem Caij 120,Teem Caij 140,Teem Caij 160.

Txij li thaum nws tau tsim tsa xyoo 2014,Botop Hlautau dhau los ua tus thawj coj ntawm cov yeeb nkab hlau carbon hauv Northern China, paub txog kev pabcuam zoo heev, cov khoom lag luam zoo, thiab cov kev daws teeb meem dav dav.

Lub tuam txhab muaj ntau yam yeeb nkab hlau carbon thiab cov khoom lag luam cuam tshuam, suav nrog cov yeeb nkab hlau seamless, ERW, LSAW, thiab SSAW, nrog rau cov khoom siv yeeb nkab thiab cov flanges tiav. Nws cov khoom tshwj xeeb kuj suav nrog cov hlau alloys zoo thiab cov hlau stainless austenitic, tsim los ua kom tau raws li qhov xav tau ntawm ntau yam haujlwm yeeb nkab.

Thov koj xav tiv tauj peb thiab peb yuav zoo siab teb koj cov lus nug.