EN 10219 S355J0Hyog ib qhotxias-ua weldedcov yeeb nkab steel hollow rauEN 10219, nrog lub zog tsawg kawg nkaus ntawm355 MPa(cov yeeb nkab phab ntsa tuab ≤ 16 hli) thiab lub zog cuam tshuam tsawg kawg27 J ntawm 0°C.

Tsim los ntawm kev siv hluav taws xob vuam lossis cov txheej txheem vuam submerged arc yam tsis tas yuav kho cua sov tom qab, lawv tsim nyog rau ntau yam kev siv hauv tsev thiab kev tsim kho vaj tse, suav nrog cov khoom tseem ceeb xws li cov ncej rau kev txhawb nqa lub hauv paus.

BS EN 10219 yog European Standard EN 10219 uas UK tau txais yuav.

Xws li cov khoom siv vuam txiasvoj voog, plaub fab, duab plaub fab thiab ellipticalcov ntu hollow ntawm cov qauv.

CFCHS = ntu hollow puag ncig uas tsim txias;

CFRHS = txias tsim square lossis rectangular hollow section;

Peb tshwj xeeb hauv kev muab cov khoom siv zoo hauv lub voj voog hollow (CHS) cov yeeb nkab hlau kom tau raws li koj cov kev xav tau ntau yam.

Phab ntsa tuab ≤40mm;

Voj Voog: Sab nraud txoj kab uas hla mus txog 2500 hli;

Cov seem hollow ntawm cov qauv yuav tsum tau tsim los ntawmkev vuam hluav taws xob los yog kev vuam submerged arc (SAW).

EN 10219 cov seem khoob yuav tsum tau xa tawm txias-tsim yam tsis muaj kev kho cua sov tom qab, tab sis welds yuav nyob rau hauv qhov xwm txheej welded lossis cua sov-kho.

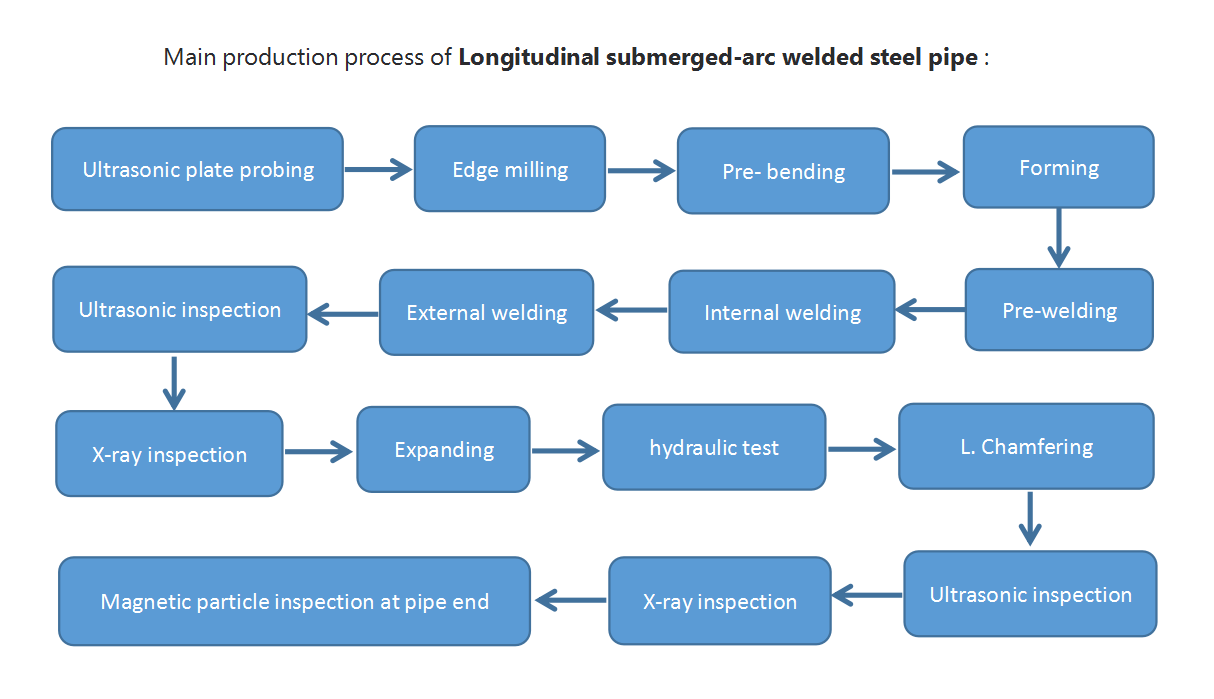

Yog tias siv cov thev naus laus zis submerged arc welding, nws tuaj yeem faib ua pawg:LSAW(SAWL) (Longitudinal Submerged Arc Vuam) thiabSSAW(HSAW)(Spiral Submerged Arc Welding) nyob ntawm seb qhov kev taw qhia ntawm cov xov hlau txuas.

LSAWmuaj cov txiaj ntsig zoo hauv kev tsim khoomloj-txoj kab uas hlathiabcov kav hlau tuabthiab yog qhov tshwj xeeb tshaj yog rau cov xwm txheej thov uas xav tau lub zog siab, zoo, thiab qhov ntev meej.

JCOEyog ib qho txheej txheem tseem ceeb thiab sawv cev rau hauv kev tsim cov yeeb nkab hlau LSAW. Lub npe ntawm cov txheej txheem los ntawm plaub kauj ruam tseem ceeb hauv cov txheej txheem ua yeeb nkab: J-forming, C-forming, O-forming, thiab Expanding.

Peb yog cov chaw tsim khoom thiab cov chaw muag khoom ntawm cov yeeb nkab carbon steel zoo los ntawm Tuam Tshoj, thiab peb kuj yog cov chaw muag khoom ntawm cov yeeb nkab steel seamless, muab ntau yam kev daws teeb meem rau koj!

Kev Tshawb Fawb Txog Kev Ua Pov Thawj

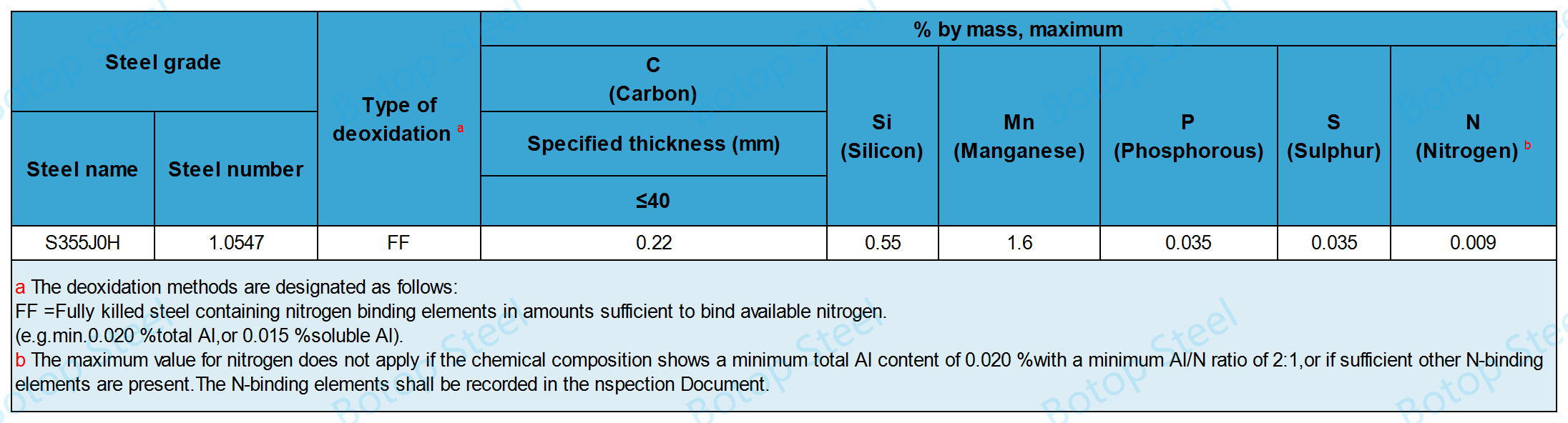

Kev tshuaj xyuas tshuaj lom neeg ntawm cov yeeb nkab hlau raw khoom

S355J0H Tus nqi siab tshaj plaws ntawm cov pa roj carbon sib npaug (CEV): 0.45%.

CEV = C + Mn/6 +(Cr + Mo + V)/5 + (Ni + Cu)/15.

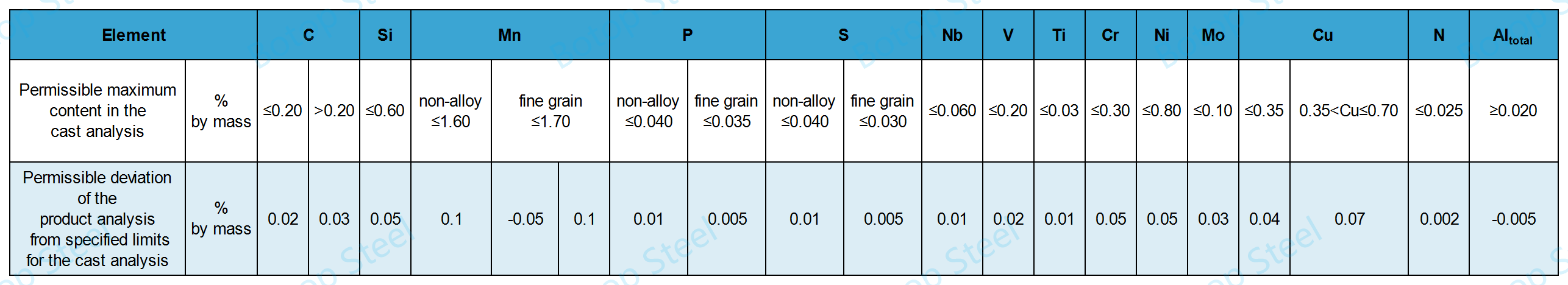

Kev Tshawb Fawb Txog Khoom

Kev tshuaj xyuas cov tshuaj lom neeg ntawm cov seem hollow tiav lawm

Kev hloov pauv ntawm kev tshuaj xyuas cov khoom los ntawm cov kev txwv uas tau teev tseg rau kev tshuaj xyuas casting yuav tsum ua raws li cov kev cai hauv qab no.

Kev txo kev ntxhov siab annealing ntawm ntau dua 580 ° C lossis ntau dua ib teev yuav ua rau puas tsuaj ntawm cov khoom siv kho tshuab.

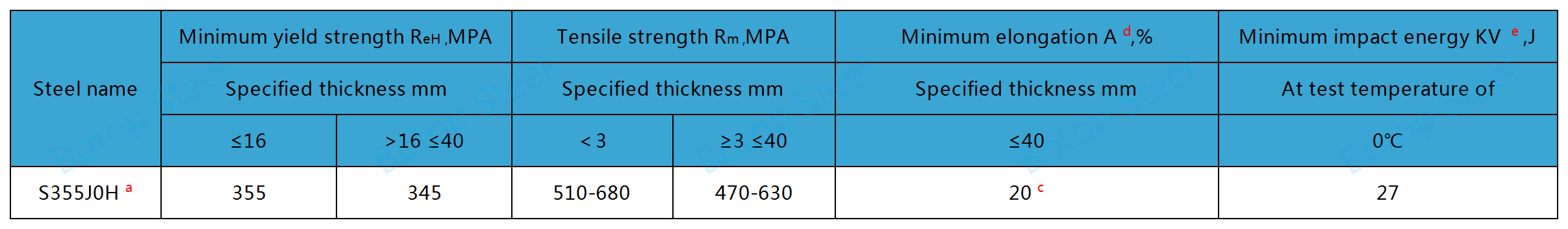

Qhov kev sim tensile yuav tsum tau ua raws li EN 10002-1.

Qhov kev ntsuam xyuas cuam tshuam yuav tsum tau ua raws li EN 10045-1.

a Cov khoom cuam tshuam tsuas yog raug txheeb xyuas thaum Xaiv 1.3 tau teev tseg.

c Rau qhov loj ntawm seem D/T < 15 (ncig) thiab (B+H)/2T < 12,5 (square thiab rectangular) qhov elongation tsawg kawg nkaus raug txo los ntawm 2.

d Rau cov tuab < 3 hli saib 9.2.2.

e Yog xav paub txog cov khoom cuam tshuam rau cov khoom sim uas muaj qhov seem tsawg, saib 6.7.2.

Cov Lus Cim: Tsis tas yuav kuaj qhov cuam tshuam thaum lub thickness teev tseg yog <6mm.

Cov vuam hauv cov seem hollow uas tau muab tso rau hauv qab dej yuav tsum tau kuaj xyuas raws li EN 10246-9 rau chav kawm lees txais U4 lossis radiographically raws li EN 10246-10 rau chav kawm zoo duab R2.

Kev Ntsuas NDT (RT)

Kev Ntsuas NDT (UT)

Kev Ntsuas Hydrostatic

Peb siv ntau yam kev sim uas tsis ua rau puas tsuaj thiab kev sim siab hydrostatic kom ntseeg tau tias txhua lub yeeb nkab muaj zog thiab ruaj khov. Peb muab rau peb cov neeg siv khoom cov yeeb nkab hlau uas ua tau raws li cov qauv siab tshaj plaws ntawm kev nyab xeeb thiab kev lees paub zoo.

Cov raj hollow section uas tsim tawm raws li EN 10219 yog weldable.

Thaum vuam, qhov tawg txias hauv thaj chaw vuam yog qhov kev pheej hmoo tseem ceeb vim tias qhov tuab, qib zog, thiab CEV ntawm cov khoom nce ntxiv. Qhov tawg txias yog tshwm sim los ntawm kev sib xyaw ua ke ntawm ntau yam:

cov hydrogen uas tawg tau ntau hauv cov hlau vuam;

ib qho qauv tawg yooj yim hauv thaj chaw uas raug cua sov;

qhov tseem ceeb ntawm kev ntxhov siab tensile hauv qhov sib koom ua ke welded.

Cov kav hlau EN 10219 yog tsim rau kev kub dip galvanizing. Kev xaiv tuaj yeem ua raws li qhov xav tau tiag tiag.

Yuav tsum muaj ib qho chaw du uas sib raug rau txoj kev tsim khoom siv; cov pob, cov qhov khoob, lossis cov kab ntev uas tsis tob uas tshwm sim los ntawm cov txheej txheem tsim khoom yog tso cai yog tias lawv cov tuab seem nyob hauv qhov kam rau siab.

Cov qhov tsis zoo ntawm qhov chaw yuav raug tshem tawm los ntawm kev sib tsoo, muab tias qhov tuab ntawm qhov seem hollow kho tsis tsawg dua qhov tuab tsawg kawg nkaus uas tau teev tseg hauv EN 10219-2.

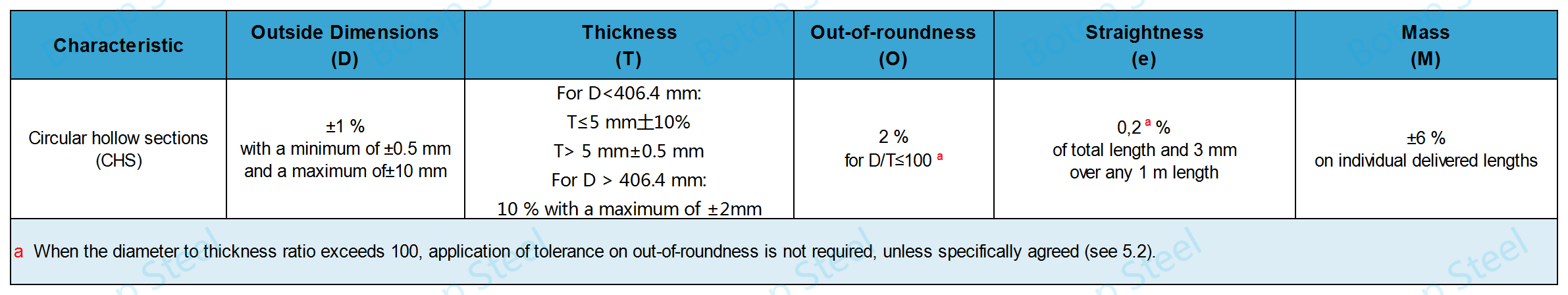

Kev kam rau siab ntawm cov duab, qhov ncaj thiab pawg

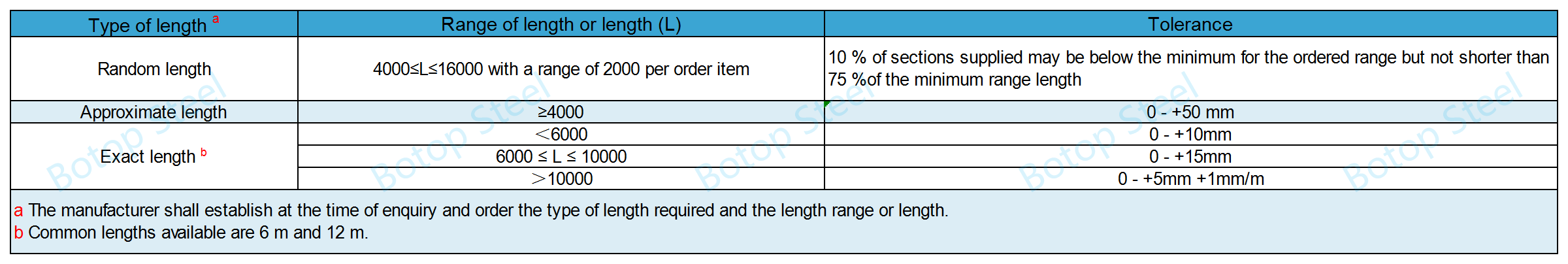

Kev kam rau siab ntev

Qhov Siab Weld

Qhov siab ntawm qhov vuam tsuas yog siv rau cov raj SAW xwb.

| Thickness, hli | Qhov siab tshaj plaws ntawm cov hlaws weld, mm |

| ≤14,2 | 3.5 |

| >14,2 | 4.8 |

EN 10219 S355J0H cov yeeb nkab steel yog cov khoom siv muaj zog thiab tiv taus corrosion uas zoo rau ntau yam kev tsim kho thiab kev tsim kho vaj tse, suav nrog cov yeeb nkab pile daim ntawv thov.

1. Cov Yeeb Nkab: Cov yeeb nkab hlau S355J0H yog qhov tsim nyog rau kev siv ua cov ncej hauv paus vim nws lub zog thiab kev tiv thaiv corrosion thiab yog siv dav hauv kev tsim cov chaw nres nkoj, choj, lub hauv paus tsim kho, thiab lwm yam haujlwm uas xav tau lub hauv paus tob.

2. Cov qauv tsev: Feem ntau siv rau cov khoom xws li cov qauv pob txha, cov kem txhawb nqa, thiab cov ntoo ntawm cov tsev.

3. Kev thauj mus los ntawm cov kav dejNws kuj tseem zoo rau kev siv ua cov kav dej rau kev thauj roj thiab roj av mus deb. Txawm li cas los xij, nws feem ntau yog coated kom ntev lub neej kev pabcuam, piv txwv li 3LPE, FBE, galvanized, thiab lwm yam.

4. Cov tshuab siv hauv kev tsim kho: Nws siv tau los tsim cov brackets thiab qhov chaw ntawm ntau yam kev siv tshuab.

5. Cov chaw pej xeem: xws li cov chaw ua si hauv chaw ua si thiab lwm yam kev txhawb nqa rau cov chaw pej xeem loj.

EN 10210 S355J0H: Qhov seem hollow rau cov qauv thermoforming welded. Txawm hais tias nws feem ntau yog siv rau thermoforming, nws cov tshuaj lom neeg muaj pes tsawg leeg thiab cov khoom siv kho tshuab zoo ib yam li cov ntawm S355J0H thiab nws tuaj yeem siv ua cov khoom siv zoo sib xws.

ASTM A500 Qib CSiv rau hauv kev tsim cov raj welded lossis seamless txias-formed puag ncig, square, thiab rectangular rau cov ntawv thov kev tsim kho. ASTM A500 Qib C muab cov txiaj ntsig zoo sib xws thiab lub zog tensile rau cov qauv vaj tse thiab cov khoom siv kho tshuab.

CSA G40.21 350WQhov no yog cov lus qhia ntawm Canadian Standards Association uas suav nrog ntau hom hlau qauv. 350W qib hlau muaj cov zis thiab lub zog tensile zoo ib yam li S355J0H.

JIS G3466 STKR490Qhov no yog cov khoom siv raj plaub fab thiab plaub fab rau kev siv ua qauv raws li tau teev tseg hauv Japanese Industrial Standard (JIS). Nws yog qhov tsim nyog rau kev tsim kho vaj tse thiab cov hom phiaj kho tshuab.

Txij li thaum nws tau tsim tsa xyoo 2014,Botop Hlautau dhau los ua tus thawj coj ntawm cov yeeb nkab hlau carbon hauv Northern China, paub txog kev pabcuam zoo heev, cov khoom lag luam zoo, thiab cov kev daws teeb meem dav dav.

Lub tuam txhab muaj ntau yam yeeb nkab hlau carbon thiab cov khoom lag luam cuam tshuam, suav nrog cov yeeb nkab hlau seamless, ERW, LSAW, thiab SSAW, nrog rau cov khoom siv yeeb nkab thiab cov flanges tiav. Nws cov khoom tshwj xeeb kuj suav nrog cov hlau alloys zoo thiab cov hlau stainless austenitic, tsim los ua kom tau raws li qhov xav tau ntawm ntau yam haujlwm yeeb nkab.

ASTM A252 GR.3 Cov Qauv LSAW (JCOE) Cov Yeeb Nkab Hlau Carbon

BS EN10210 S275J0H LSAW (JCOE) Cov Yeeb Nkab Hlau

ASTM A671/A671M LSAW Cov Yeeb Nkab Hlau

ASTM A672 B60/B70/C60/C65/C70 LSAW Cov Yeeb Nkab Hlau Carbon

API 5L X65 PSL1/PSL 2 LSAW Cov Yeeb Nkab Hlau Carbon / API 5L Qib X70 LSAW Cov Yeeb Nkab Hlau

EN10219 S355J0H Cov Qauv LSAW (JCOE) Cov Yeeb Nkab Hlau