bututun ƙarfe na ASTM A210 bututun ƙarfe ne mai matsakaicin carbon wanda ba shi da matsala wanda ake amfani da shi azaman bututun tukunya da kuma bututun zafi mai zafi don yanayin zafi mai yawa da matsin lamba, kamar a tashoshin wutar lantarki da kuma tukunyar masana'antu.

Diamita na waje: 1/2inci (12.7mm)≤ OD ≤5in (127mm)

Kauri a Bango: 0.035 inci (0.9mm)≤ WT ≤0.500 inci (12.7mm)

Ana iya samar da bututun da ke da wasu girma dabam, muddin irin waɗannan bututun sun cika duk wasu buƙatun wannan ƙa'ida.

Kayan Danye

Aikin Yin Karfe--Za a kashe ƙarfe.

Karfe da aka kashe yana nufin ƙara wasu adadin deoxidizers kamar silicon, aluminum, da manganese yayin narkewar ƙarfe.

Waɗannan ƙarin abubuwa za su iya yin aiki tare da iskar oxygen da ke cikin ƙarfe don samar da iskar oxygen mai ƙarfi, don haka rage yawan iskar oxygen da ke cikin ƙarfen da kuma hana samuwar iskar oxygen da ke cikin ƙarfen.

ASTM A210 Ajin

ASTM A210 yana samuwa a matakai biyu:A-1 da A-C.

Tsarin Samar da Tube na Karfe na ASTM A210

Za a yi bututun ƙarfe ta hanyar tsari mara matsala kuma za a yi su da kyaugamawa mai zafi or gama sanyikamar yadda aka ƙayyade.

Yawanci, bututun ƙarfe masu diamita fiye da milimita 30 ana yin su ne da zafi, kuma waɗanda diamitansu bai kai milimita 30 ba ko kuma daidai suke da shi, an yi su ne da sanyi. Wannan hanyar bambance-bambance ba ta da cikakken bayani, amma ana iya amfani da ita azaman hanya mai sauri da sauƙi don tantance hanyar sarrafa bututun ƙarfe mara matsala.

Maganin Zafi

Ba a buƙatar maganin zafi ga bututun da aka gama da zafi ba.

Za a yi wa bututun da aka gama da sanyi tiyatar cirewa ta subcritical annea, cikakken annea, ko kuma maganin zafi mai daidaita bayan kammala sanyi na ƙarshe.

Sinadaran da Aka Haɗa

| Sinadarin | Darasi na A-1 | Darasi na C |

| C (Carbon), matsakaicinA | 0.27 | 0.35 |

| Mn (Manganese) | 0.93 mafi girma | 0.29-1.06 |

| P (Fosphorus), mafi girma | 0.035 | 0.035 |

| S (Sulfur), matsakaicin | 0.035 | 0.035 |

| Si (Silikon), min | 0.1 | 0.1 |

| A. Ga kowace raguwar kashi 0.01% ƙasa da matsakaicin carbon da aka ƙayyade, za a ba da izinin ƙaruwar kashi 0.06% na manganese sama da matsakaicin da aka ƙayyade har zuwa matsakaicin kashi 1.35%. | ||

Waɗannan buƙatun sinadaran suna tabbatar da cewa bututun suna da isasshen ƙarfi da juriya ga zafin jiki.

Kayayyakin Inji

Bukatun kadarori na inji ba su shafi bututun da ya fi ƙanƙanta ba1/ 8a cikin [3.2 mm] a cikin diamita na ciki ko kuma inci 0.015 [0.4 mm] a cikin kauri.

| Jeri | Unit | Darasi na A-1 | Darasi na C | |

| Ƙarfin tauri, min | ksi | 60 | 70 | |

| MPa | 415 | 485 | ||

| Ƙarfin bayarwa, min | ksi | 37 | 40 | |

| MPa | 255 | 275 | ||

| Ƙarawa a cikin 50 mm (inci 2), minti | Don gwaje-gwajen tsiri mai tsayi, za a rage kowace raguwar kauri na 1/32-in. [0.8-mm] a cikin kauri na bango ƙasa da inci 5/16 [8 mm] daga mafi ƙarancin tsawaitawa na maki masu zuwa. | % | 1.5A | 1.5A |

| Lokacin da aka yi amfani da daidaitaccen tsawon ma'aunin zagaye mai inci 2 ko 50 mm ko ƙaramin samfurin da girmansa ya yi daidai da 4D (nisa diamita sau huɗu) | 22 | 20 | ||

| ADuba Jadawali na 4 don ƙimar mafi ƙarancin da aka ƙididdige. | ||||

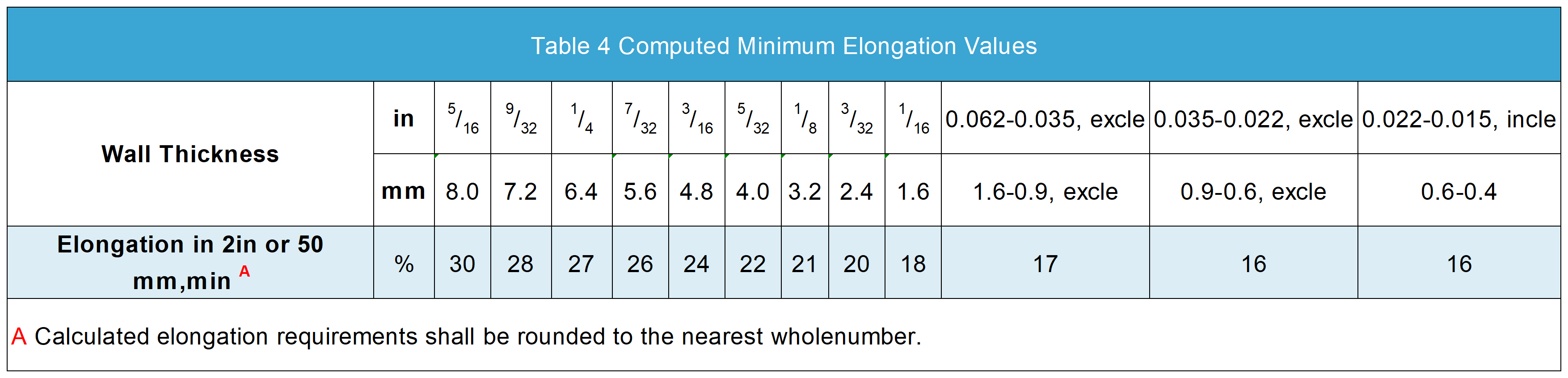

Tebur na 4 yana ba da ƙimar mafi ƙarancin tsawaitawa da aka ƙididdige ga kowane1/32raguwar kauri na bango a cikin [0.8 mm].

Inda kauri bango ya kasance tsakanin ƙimomin biyu da aka nuna a sama, za a ƙayyade mafi ƙarancin ƙimar tsawaitawa ta hanyar lissafi mai zuwa:

Rukunin Imperial(a cikin): E = 48t+15.00

Naúrar SI(mm): E = 1.87t+15.00

inda:

E = tsawaitawa a cikin inci 2 ko 50 mm, %,

t = ainihin kauri na samfurin.

Gwajin Tauri

Za a yi gwajin taurin Brinell ko Rockwell akan samfuran da aka yi daga bututu biyu daga kowane yanki.

ASTM A210 Daraja A-1:79-143 HBW

ASTM A210 Grade C: 89-179 HBW

HBW yana nufin auna ƙarfin Brinell, inda "W" ke nufin amfani da ƙwallon carbide a matsayin mai shiga.

Sauran Gwaji

Gwajin Faɗin Ƙasa

Gwajin Ƙwaƙwalwa

Gwajin Wutar Lantarki Mai Tsabtace Ruwa ko Wanda Ba Ya Halakarwa

Kammalawar Fuskar

Ana iya yayyanka shi ko a soya shi, ko kuma duka biyun, kuma wannan ɓangaren ya shafi yarjejeniya ne, kuma zaɓin ya dogara ne akan yarjejeniya tsakanin mai amfani da masana'anta.

Ana amfani da pickling ne musamman don cire yadudduka masu oxidized da sauran gurɓatattun abubuwa daga saman bututun ƙarfe.

Ana amfani da fashewar harbi don tsaftace saman da kuma ƙara ƙarfin mannewa.

Waɗannan jiyya ba wai kawai suna shafar ingancin saman bututun ba, har ma suna iya shafar halayen aikace-aikacensa na ƙarshe.

Ayyukan Ƙirƙira

Idan aka saka a cikin tukunyar, bututun za su tsaya suna faɗaɗawa da kuma ƙwallo ba tare da nuna tsagewa ko lahani ba. Idan aka yi amfani da su yadda ya kamata, bututun zafi mai zafi za su tsaya duk ayyukan ƙirƙira, walda, da lanƙwasawa da ake buƙata don amfani ba tare da haifar da lahani ba.

Alamar ASTM A210

Ya kamata a yi wa waɗannan alama a sarari:

Sunan masana'anta ko tambarinsa.

Bayyanar bututu (girman, kauri bango, da sauransu).

Matsayin bututu.

Nau'in samar da bututun ƙarfe: an gama shi da zafi ko kuma an gama shi da sanyi.

Aikace-aikacen ASTM A210

Ana amfani da shi wajen ƙera ƙananan tukunyar ruwa masu matsakaicin matsin lamba, kamar su tukunyar ruwa mai tsayawa, tukunyar ruwa mai zama, da sauran tukunyar ruwa da ake amfani da su don dumama masana'antu ko gidaje.

Na'urorin dumama na Superheaters sassan tukunyar jirgi ne da ake amfani da su don ɗaga zafin tururin sama da inda yake tafasa, kuma bututun ASTM A210 sun dace da ƙera waɗannan sassan masu zafi sosai.

Kayayyakinmu Masu Alaƙa

Mu kamfani ne mai ƙera bututun ƙarfe na carbon mai inganci kuma mai samar da kayayyaki daga China, kuma mu kamfani ne mai samar da bututun ƙarfe mara matsala, muna ba ku nau'ikan hanyoyin magance bututun ƙarfe iri-iri!

tags: astm 210, tukunyar jirgi, mara matsala, an gama da zafi, an gama da sanyi, superheater, masu kaya, masana'antun, masana'antu, masu hannun jari, kamfanoni, jumloli, siya, farashi, ƙididdigewa, yawa, don siyarwa, farashi.

Lokacin Saƙo: Afrilu-24-2024