STPT 370wani nau'in ma'aunin JIS G 3456 na Japan don bututun ƙarfe na carbon, wanda ake amfani da shi don bututun matsi a cikin yanayi mai zafi sama da 350°C. Yana iya zama ko dai bututun da ba su da matsala ko kuma waɗanda aka haɗa ta amfani da tsarin walda mai juriya ta lantarki (ERW). Sifofin injina na kayan STPT 370 sune mafi ƙarancin ƙarfin tauri na 370 MPa da mafi ƙarancin ƙarfin fitarwa na 215 MPa.

Idan kuna neman mai ƙera bututun ƙarfe da kuma mai samar da bututun ƙarfe waɗanda suka dace da ƙa'idar JIS G 3456, to mu ne abokin hulɗar da kuke nema. Tuntuɓe mu a yau kuma za mu yi farin cikin taimaka muku!

Ya dace da diamita na waje 10.5 mm - 660.4 mm (6A - 650A) (1/8B - 26B).

A da B hanyoyi biyu ne na bayyana diamita mara suna a cikin ma'aunin Japan. Musamman, A ya yi daidai da DN, yayin da B ya yi daidai da NPS.

Ana iya samar da JIS G 3456 STPT 370 ta amfani dababu matsalatsarin ƙera ko kumawalda juriya ta lantarkitsarin (ERW).

Tsarin kera shi ma ya yi daidai da hanyoyin kammalawa daban-daban don jure wa yanayin amfani daban-daban.

| Alamar daraja | Alamar tsarin ƙera | |

| Tsarin kera bututu | Hanyar kammalawa | |

| JIS G 3456 STPT370 | Mara sumul: S | An gama da kyau: H An gama sanyi: C |

| Juriyar wutar lantarki: E Butt ɗin da aka haɗa: B | An gama da kyau: H An gama sanyi: C Kamar yadda juriyar lantarki ta welded: G | |

Dole ne a yi wa STPT 370 magani da zafi.

1. Bututun ƙarfe mara kauri da aka gama da zafi: Kamar yadda aka ƙera, ana iya amfani da ƙaramin zafin jiki ko daidaita shi yadda ake buƙata;

2. Bututun ƙarfe mara shinge wanda aka gama da sanyi: Ƙarancin zafin jiki ko daidaita shi;

3. Bututun ƙarfe mai welded mai juriya ga lantarki mai zafi: Kamar yadda aka ƙera, ana iya amfani da ƙaramin zafin jiki ko daidaita shi yadda ake buƙata;

4. An yi amfani da bututun ƙarfe mai ƙarfi da aka gama da sanyi, kuma an yi amfani da bututun ƙarfe mai ƙarfi da ƙarfi kamar yadda aka yi amfani da shi a cikin wutar lantarki: Ƙarancin zafin jiki ko daidaita shi.

| Alamar daraja | C | Si | Mn | P | S |

| JIS G 3456 STPT370 | matsakaicin 0.25% | 0.10 - 0.35% | 0.30 - 0.90% | matsakaicin 0.035% | matsakaicin 0.035% |

Idan ya cancanta, ana iya ƙara ƙarin abubuwa.

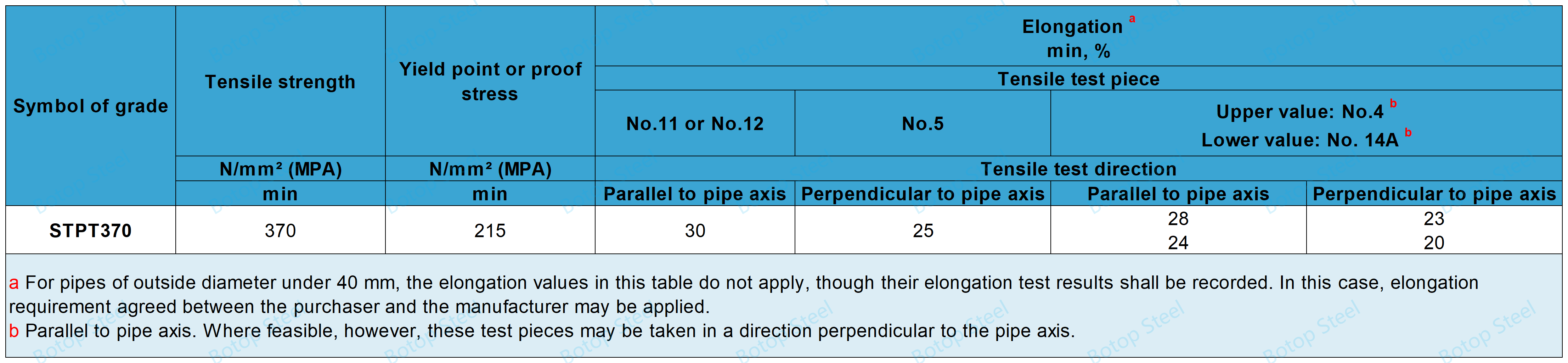

Ƙarfin Taurin Kai, Matsala ko Ƙarfin Ƙarfin Ƙarfi, da Tsawo

Kadarar Faɗaɗa

Ya dace da bututun da diamita na waje ya fi 60.5 mm.

Ana sanya samfurin a tsakanin dandamali biyu kuma a daidaita shi. Lokacin da nisan da ke tsakanin faranti biyu ya kaiHbabu tsagewa a saman samfurin bututun ƙarfe.

H = 1.08t/(0.08+ t/D)

н: nisa tsakanin faranti (mm);

t: kauri na bututun bango (mm);

D: diamita na waje na bututu (mm);

Lanƙwasawa

Ya dace da bututun ƙarfe waɗanda diamita na waje ya kai mm 60.5 ko ƙasa da haka.

Idan aka lanƙwasa samfurin a kusa da mandrel zuwa radius na ciki na ninki 6 na diamita na waje na bututun, ana duba samfurin kuma ba a sami tsagewa ba.

| Kauri na bango mara iyaka | Lambar Jadawali: Sch | |||||||||

| 10 | 20 | 30 | 40 | 60 | 80 | 100 | 120 | 140 | 160 | |

| Mafi ƙarancin matsin lamba na gwajin hydraulic, Mpa | 2.0 | 3.5 | 5.0 | 6.0 | 9.0 | 12 | 15 | 18 | 20 | 20 |

Idan diamita na waje da kauri na bango na bututun ƙarfe ba su da girma dabam-dabam, ana iya amfani da waɗannan hanyoyin don tantance matakin ƙayyadaddun bayanai da ya dace:

Da farko, zaɓi ma'aunin jadawalin da ya fi kusa da girman da ba na yau da kullun ba; na biyu, ƙayyade ma'aunin ƙayyadaddun bayanai ta hanyar ƙididdige ƙimar P.

A cikin hanyoyin guda biyu, ya kamata a zaɓi ƙaramin ƙima a matsayin matakin ƙayyadaddun bayanai na ƙarshe.

P = na 2/D

P: matsin lamba na gwaji (MPa);

t: kauri na bututun bango (mm);

D: diamita na waje na bututu (mm);

s: 60% na ƙayyadadden ƙimar ƙimar yawan amfanin ƙasa ko damuwa mai tabbatarwa;

Hanyoyin gwaji marasa lalatawa da aka saba amfani da su sun haɗa da gwajin ultrasonic (UT) da gwajin halin yanzu na eddy (ET).

Lokacin yin duban ultrasonic, ya kamata a yi la'akari da JIS G 0582, kuma idan sakamakon binciken ya yi daidai da ko ya wuce ma'aunin ma'auni na aji na UD, ana ɗaukarsa a matsayin gazawa.

Lokacin da ake duba yanayin zafi, ya kamata a yi la'akari da JIS G 0583. Idan sakamakon binciken ya yi daidai da ko ya wuce ma'aunin ma'aunin zafi na ajin EY, ana ɗaukarsa a matsayin wanda bai cancanta ba.

An lissafa ma'aunin ma'auni da kauri na bango tsakanin 10.5 mm zuwa 660.4 mm a cikin JIS G 3456, wanda shineteburin nauyin bututun ƙarfe da kuma jadawalin da ya dace No.

Jadawali na 10,Jadawali na 20,Jadawali na 30,Jadawali na 40,Jadawali na 60,Jadawali na 80,Jadawali 100,Jadawali na 120,Jadawali na 140,Jadawali 160.

Tun lokacin da aka kafa ta a shekarar 2014,Botop Karfeya zama babban mai samar da bututun ƙarfe na carbon a Arewacin China, wanda aka san shi da kyakkyawan sabis, kayayyaki masu inganci, da kuma cikakkun hanyoyin magance matsaloli.

Kamfanin yana bayar da nau'ikan bututun ƙarfe na carbon da kayayyaki masu alaƙa, gami da bututun ƙarfe na ERW, LSAW, da SSAW marasa sulɓi, da kuma cikakken jerin kayan haɗin bututu da flanges. Kayayyakinsa na musamman sun haɗa da ƙarfe masu inganci da ƙarfe marasa austenitic, waɗanda aka ƙera don biyan buƙatun ayyukan bututu daban-daban.

Da fatan za ku iya tuntubar mu kuma za mu yi farin cikin amsa tambayoyinku.