ASTM A53 ERWbututun ƙarfe shineNau'in Ea cikin ƙayyadadden A53, wanda aka ƙera ta hanyar tsarin walda mai juriya, kuma yana samuwa a cikin ajin A da Ajin B.

Ya fi dacewa da aikace-aikacen injina da matsin lamba kuma galibi ana amfani da shi azaman manufa ta gabaɗaya don isar da tururi, ruwa, iska, da iska.

Fa'idodin bututun ƙarfe na ERW, kamar suƙarancin farashikumayawan aiki mai yawa, sanya shi abin da ake so ga aikace-aikacen masana'antu da yawa.

Botop Karfewani kamfani ne mai kera bututun ƙarfe na carbon mai inganci kuma mai samar da kayayyaki daga China, kuma mai sayar da bututun ƙarfe mara matsala, yana ba ku nau'ikan hanyoyin magance bututun ƙarfe iri-iri!

Kayanmu suna da wadata sosai kuma muna iya biyan buƙatun abokan cinikinmu cikin sauri na girma dabam-dabam da yawa.

ASTM A53/A53M ya haɗa da nau'ikan da maki masu zuwa:

Nau'in E: An haɗa shi da ƙarfin lantarki, maki A da B.

Nau'in S: Marasa Sulhu, Aji A da B.

Nau'in F: An haɗa murhu da bel mai ɗauri, mai ɗauri mai ci gaba da ɗauri maki A da B.

Nau'in EkumaNau'in Snau'ikan bututu guda biyu ne da ake amfani da su sosai. Sabanin haka,Nau'in Fyawanci ana amfani da shi ga ƙananan bututun diamita. Saboda ci gaban fasahar walda, wannan hanyar ƙera ba a cika amfani da ita ba.

Diamita marasa lamba: DN 6 - 650 [NPS 1/8 - 26];

Diamita na waje: 10.3 - 660 mm [0.405 - inci 26.];

Jadawalin nauyin bututun ƙarfe da kauri bango:

ASTM A53 kuma tana ba da izinin samar da bututu tare da wasu girma muddin bututun ya cika duk wasu buƙatun wannan ƙayyadaddun bayanai.

ERWana amfani da shi sosai wajen kera bututun ƙarfe masu zagaye, murabba'i, da kuma murabba'i mai siffar carbon da ƙananan ƙarfe.

Tsarin da ke gaba shine tsarin samarwa don samarwabututun ƙarfe na ERW zagaye:

a) Shirye-shiryen kayan aiki: Kayan farko yawanci na'urorin ƙarfe ne masu zafi da aka yi birgima da su. Waɗannan na'urorin da farko ana daidaita su kuma a yanka su zuwa faɗin da ake buƙata.

b) Ƙirƙira: A hankali, ta hanyar jerin naɗe-naɗe, ana samar da tsiri zuwa wani tsari mai siffar bututu mai buɗewa. A yayin wannan aikin, ana kusantar da gefun tsiri a hankali don shirya walda.

c) Walda: Bayan samar da tsarin bututun ƙarfe, gefunan ƙarfen suna dumama ta hanyar juriyar lantarki a yankin walda. Ana ratsa wutar lantarki mai yawan mita ta cikin kayan, kuma ana amfani da zafin da juriyar ke samarwa don dumama gefunan har zuwa inda suke narkewa, sannan a haɗa su da matsi.

d) Rage gudu: Bayan walda, ana cire burrs na walda (ƙarfe mai yawa daga walda) daga ciki da wajen bututun don tabbatar da santsi a cikin bututun.

e) Tsarin girma da tsayi: Bayan an kammala walda da cire kayan, ana ratsa bututun ta cikin injin girma don gyara girma don tabbatar da cewa sun cika ainihin buƙatun diamita da zagaye. Sannan ana yanke bututun zuwa tsayin da aka ƙayyade.

f) Dubawa da gwaji: Za a yi gwajin bututun ƙarfe da kuma duba shi sosai, gami da gwajin ultrasonic, gwajin hydrostatic, da sauransu, don tabbatar da ingancin bututun ƙarfe ya cika ƙa'idodi da ƙa'idodi.

g) Maganin saman jiki: A ƙarshe, ana iya ƙara yin amfani da bututun ƙarfe kamar yin amfani da galvanizing mai zafi, fenti, ko wasu hanyoyin gyaran saman don samar da ƙarin kariya daga tsatsa da kuma kyawunta.

Walda a Nau'in E ko Nau'in F Matsayi Bza a yi wa bututun magani da zafi ko kuma a yi masa magani bayan walda don kada martensite mara zafi ya kasance a wurin.

Zafin zafin maganin zafi zai zama aƙalla1000°F [540°C].

Idan bututun ya yi sanyi, faɗaɗawa ba za ta wuce gona da iri ba1.5%na diamita na waje da aka ƙayyade na bututun.

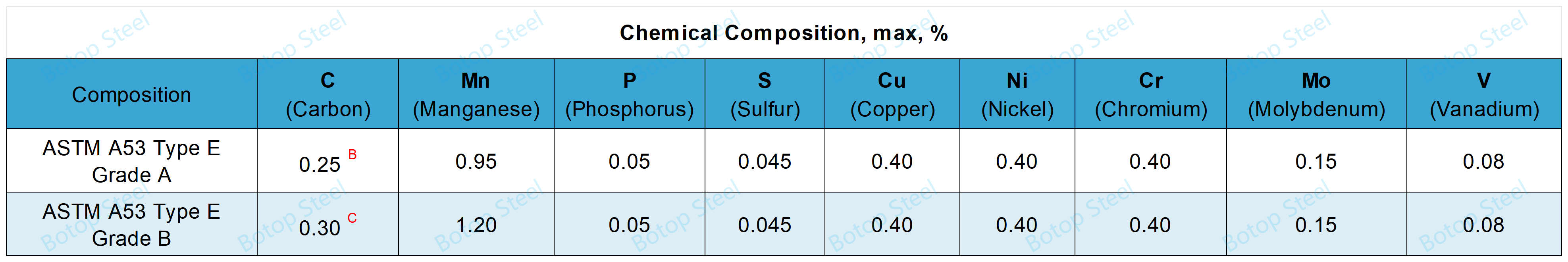

AAbubuwa biyarCu, Ni, Cr, Mo, kumaVhaɗin gwiwa bai kamata ya wuce 1.00%.

BGa kowace raguwar kashi 0.01% ƙasa da matsakaicin carbon da aka ƙayyade, za a ba da izinin ƙaruwar kashi 0.06% na manganese sama da matsakaicin da aka ƙayyade har zuwa matsakaicin kashi 1.35%.

CGa kowace raguwar kashi 0.01% ƙasa da matsakaicin carbon da aka ƙayyade, za a ba da izinin ƙaruwar kashi 0.06% na manganese sama da matsakaicin da aka ƙayyade har zuwa matsakaicin kashi 1.65%.

Kadarar Tashin Hankali

| Jeri | Rarrabawa | Darasi na A | Aji na B |

| Ƙarfin tauri, min | MPa [psi] | 330 [48,000] | 415 [60,000] |

| Ƙarfin bayarwa, min | MPa [psi] | 205 [30,000] | 240 [35,000] |

| Tsawaita a cikin mm 50 [inci 2] | Bayani | A,B | A,B |

Lura A: Mafi ƙarancin tsawaitawa a cikin inci 2[50 mm] zai zama wanda aka ƙayyade ta hanyar lissafi mai zuwa:

e = 625,000 [1940] A0.2/U0.9

e = mafi ƙarancin tsayi a cikin inci 2 ko 50 mm a cikin kashi, an zagaye shi zuwa kashi mafi kusa

A = ƙasa da 0.75 inci2[500 mm2] da kuma yankin giciye na samfurin gwajin tashin hankali, wanda aka ƙididdige ta amfani da diamita na waje da aka ƙayyade na bututun, ko faɗin samfurin gwajin tashin hankali da kauri na bango da aka ƙayyade na bututun, tare da ƙimar da aka ƙididdige ta zagaye zuwa mafi kusa da inci 0.012 [1 mm2].

U=ƙarfin juriya mafi ƙanƙanta, psi [MPa].

Bayani B: Duba Tebur X4.1 ko Tebur X4.2, duk wanda ya dace, don mafi ƙarancin ƙimar tsawaitawa da ake buƙata don haɗuwa daban-daban na girman samfurin gwajin tashin hankali da ƙayyadadden ƙarfin taurin kai.

Gwajin Lanƙwasa

Ga bututun DN ≤ 50 [NPS ≤ 2], tsawon bututun da ya isa ya zama mai lanƙwasa a hankali har zuwa digiri 90 a kusa da mandrel mai siffar silinda, wanda diamitansa ya ninka diamita na waje sau goma sha biyu da aka ƙayyade na bututun, ba tare da ya fashe a kowane ɓangare ba kuma ba tare da buɗe walda ba.

Ƙarfi mai ƙarfi biyu-ƙarfi(nauyi:XXS) bututun da ke kan DN 32 [NPS 1 1/4] ba sai an yi masa gwajin lanƙwasa ba.

Gwajin Faɗin Ƙasa

Za a yi gwajin lanƙwasawa a kan bututun da aka haɗa sama da DN 50 a cikin nauyi mai ƙarfi (XS) ko mai sauƙi.

Ya dace da bututun Nau'in E, Matakin A da B; da kuma bututun Nau'in F, Matakin B.

Ba sai an gwada bututun ƙarfe marasa sumul ba.

Lokacin Gwaji

Ga dukkan girman bututun nau'in S, Nau'in E, da Nau'in F Grade B, za a ci gaba da matsin lamba na gwaji na tsawon aƙalla mintuna 5.

Za a yi amfani da gwajin hydrostatic, ba tare da zubewa ta hanyar dinkin walda ko jikin bututun ba.

Matsi na Gwaji

Bututun da ba shi da tsariza a gwada shi ta hanyar hydrostatic bisa ga matsin lamba da aka bayar a cikinTebur X2.2,

Bututu mai zare da haɗin kaiza a gwada shi ta hanyar hydrostatic bisa ga matsin lamba da aka bayar a cikinTebur X2.3.

Ga bututun ƙarfe masu DN ≤ 80 [NPS ≤ 80], matsin lambar gwajin ba zai wuce 17.2MPa ba;

Ga bututun ƙarfe masu DN >80 [NPS >80], matsin lambar gwaji ba zai wuce 19.3MPa ba;

Ana iya zaɓar matsin lamba mafi girma na gwaji idan akwai buƙatun injiniya na musamman, amma wannan yana buƙatar tattaunawa tsakanin masana'anta da abokin ciniki.

Alamar

Idan an gwada bututun ta hanyar hydrostatic, alamar ya kamata ta nunamatsin lamba na gwaji.

Waɗannan buƙatu sun shafi bututun Nau'in E da Nau'in F Grade B.

Bututun da ba shi da sumul yana da ƙarin buƙatu waɗanda ba a tattauna su a cikin wannan takardar ba.

Hanyoyin Gwaji

Bututun da injunan faɗaɗawa da na'urorin rage radadi marasa zafi ke samarwa: DN ≥ 50 [NPS ≥ 2],waldaa kowane sashe na bututun yana buƙatar wucewa gwajin lantarki mara lalatawa, kuma hanyar gwajin tana buƙatar ta yi daidai daE213, E273, E309 ko E570daidaitaccen tsari.

Bututun ERW da injin mai rage girman zafi ke samarwa: DN ≥ 50 [NPS ≥ 2]Kowace sasheza a duba bututun gaba ɗaya ta hanyar gwajin lantarki mara lalatawa, wanda zai yi daidai da ƙa'idodin da aka shimfidaE213, E309, ko kumaE570ƙa'idodi.

Lura: Injin Fadada Fadada Mai Zafi inji ne da ke miƙewa da matse bututun ƙarfe ta hanyar naɗawa a yanayin zafi mai yawa don daidaita diamita da kauri na bango.

Alamar

Idan an yi gwajin bututun ba tare da lalata shi ba, ya zama dole a nunaNDEa kan alamar.

Mass

±10%.

Bututu DN ≤ 100 [NPS ≤ 4], an auna shi a matsayin rukuni.

Bututun DN > 100 [NPS > 4], an auna su a cikin guda ɗaya.

diamita

Ga bututun DN ≤40 [NPS≤ 1 1/2], bambancin OD ba zai wuce ±0.4 mm [1/64 in.] ba.

Ga bututun DN ≥50 [NPS>2], bambancin OD ba zai wuce ±1% ba.

Kauri

Mafi ƙarancin kauri na bango ba zai zama ƙasa da haka ba87.5%na kauri na bango da aka ƙayyade.

nauyi mai sauƙi fiye da ƙarfi (XS):

a) bututu mai faɗi: mita 3.66 - 4.88 [ƙafa 12 - 16], Bai wuce kashi 5% na jimlar adadin ba.

b) tsayin da ba a saba gani ba sau biyu: ≥ 6.71 m [ƙafa 22], Matsakaicin tsawon shine mita 10.67 [ƙafa 35].

c) tsayin da ba a saba gani ba: mita 4.88 -6.71 [ƙafa 16 - 22], ba fiye da kashi 5% na jimlar tsawon zare da aka yi wa ado ba (guda biyu da aka haɗa).

Nauyin ƙarfi (XS) ko nauyi mai yawa: mita 3.66-6.71 [ƙafa 12-22], ba fiye da kashi 5% na jimlar bututun ba mita 1.83 - 3.66 [ƙafa 6 - 12].

Don kammala bututun ƙarfe na ASTM A53, ana samunsa a cikin baƙi ko galvanized.

Baƙi: Bututun ƙarfe ba tare da wani maganin saman ba, yawanci ana sayar da shi kai tsaye bayan an ƙera shi, don aikace-aikacen da ba a buƙatar ƙarin juriya ga tsatsa.

Bututun galvanized ya kamata su cika buƙatun da suka dace.

Tsarin aiki

Za a shafa sinadarin zinc a ciki da waje ta hanyar amfani da hanyar tsoma shi a cikin ruwan zafi.

Albarkatun kasa

Sinadarin zinc da ake amfani da shi don shafa shi zai kasance kowane nau'in zinc wanda ya dace da buƙatun BayaniASTM B6.

Bayyanar

Bututun galvanized zai kasance babu wuraren da ba a rufe su ba, kumfa na iska, ma'ajiyar ruwa, da kuma abubuwan da ke cikin tarkacen da ba su da kyau. Ba za a yarda da dunƙule-dunƙule, ƙuraje, globules, ko adadi mai yawa na ma'ajiyar zinc da ke kawo cikas ga amfani da kayan ba.

Nauyin Shafi na Galvanized

Za a tantance ta hanyar gwajin barewa bisa ga hanyar gwaji ta ASTM A90.

Nauyin rufin bai kamata ya zama ƙasa da 0.55 kg/m² ba [1.8 oz/ft²].

ASTM A53 ERW bututun ƙarfeAna amfani da shi galibi a aikace-aikacen ƙasa zuwa matsakaiciyar matsin lamba kamar injiniyan birni, gini, da bututun gini na injiniya. Yanayin amfani da aka saba amfani da shi sun haɗa da isar da ruwa, tururi, iska, da sauran ruwa mai ƙarancin matsin lamba.

Da yake suna da kyau wajen walda, sun dace da yin ayyukan da suka shafi naɗewa, lanƙwasawa, da kuma lanƙwasawa.