Insimbi ye-ASTM A501iyipayipi lesakhiwo lensimbi yekhabhoni elicwiliswe ngogesi elimnyama nelishisayo elifakwe ngogesi elishisiwe nelingenamthungo lamabhuloho, izakhiwo, nezinye izinjongo ezijwayelekile zesakhiwo.

Izinkinobho Zokuzulazula

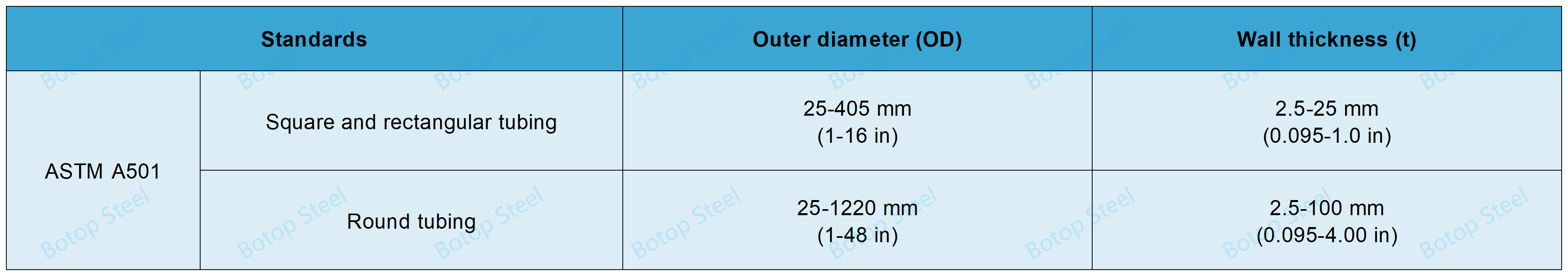

Ububanzi Bosayizi be-ASTM A501

Ukuhlukaniswa KwamaBanga

Izimo Zesigaba Esingenalutho

Ama-Raw material

Izinqubo Zokukhiqiza

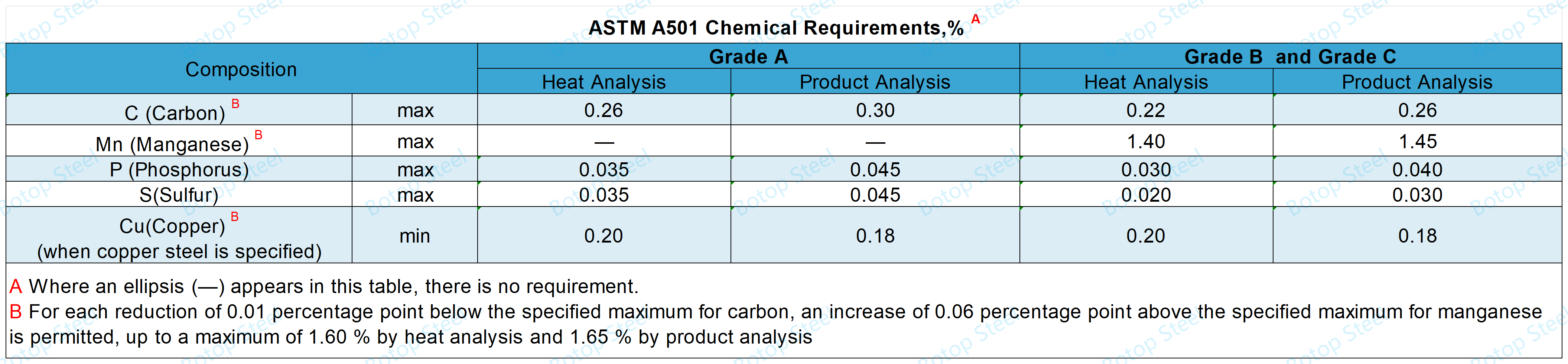

Ukwakheka Kwamakhemikhali kwe-ASTM A501

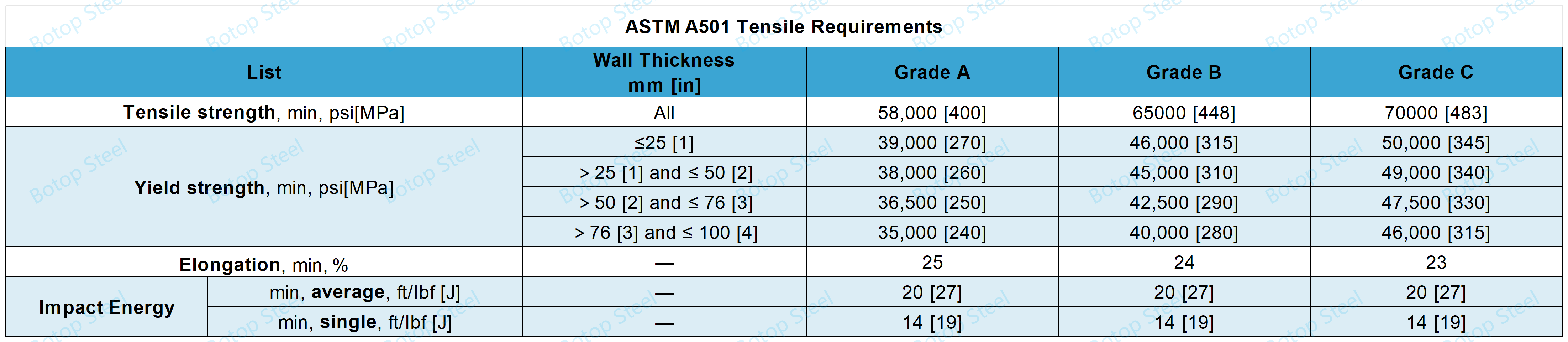

Izakhiwo Zemishini ze-ASTM A501

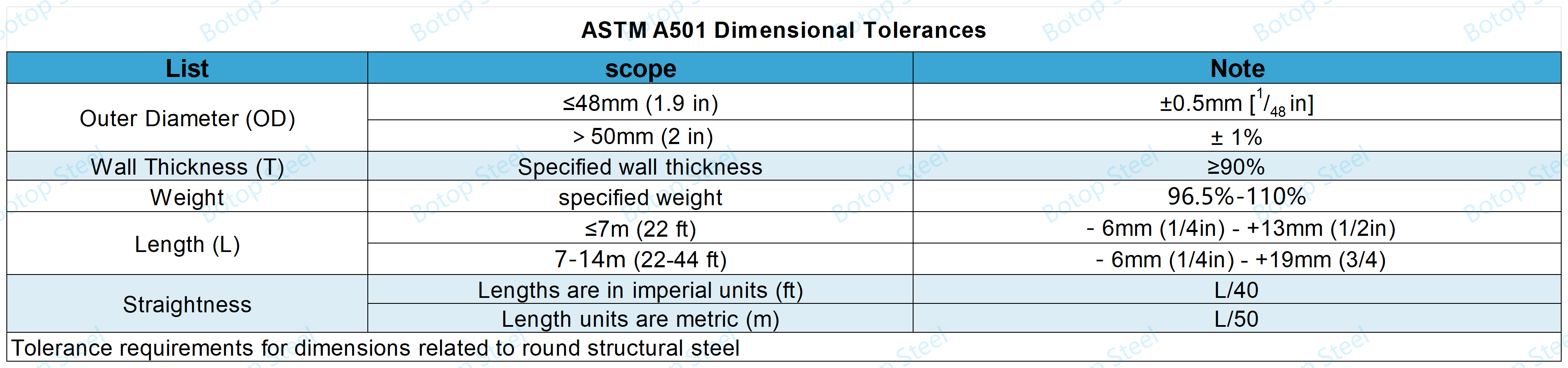

Ukubekezelelana Okulinganiselwe kwe-ASTM A501

Ukuhlanganisa nge-galvanizing

Ukubukeka

Ukumaka

Izindinganiso Ezifanele

Izicelo

Izinzuzo Zethu

Ububanzi Bosayizi be-ASTM A501

Ukuhlukaniswa KwamaBanga

I-ASTM A501 ihlukaniswe ngamagremu amathathu, iBanga A, iBanga B, kanye neBanga C.

Izimo Zesigaba Esingenalutho

Izimo eziyisikwele, eziyindilinga, eziyisikwele, noma ezikhethekile.

Ama-Raw material

Insimbi kumele yenziwe ngenqubo yokwenza insimbi esebenzisa umoya-mpilo oyisisekelo noma kagesi.

Insimbi ingaphonswa ngama-ingot noma iphonswe ngentambo.

Izinqubo Zokukhiqiza

Ipayipi kufanele lenziwe ngenye yezinqubo ezilandelayo:ngaphandle komthungoukushisela isitofu-izinqe (ukushisela okuqhubekayo);ukushisela ukumelana kagesi (ERW)noma ukushisela i-arc engaphansi komhlaba (i-SAW) okulandelwa ukufudumala kabusha kuyo yonke ingxenye enqamulelayo kanye nokwakheka kokushisa ngenqubo yokunciphisa noma yokubumba, noma kokubili.

Ukwakheka kokugcina kwesimo kufanele kwenziwe ngenqubo yokwakheka eshisayo.

Kuzovunyelwa ukwengeza ukwelashwa kokushisa okuvamile kwamapayipi anobukhulu bodonga obungaphezu kuka-13mm [1/2 inches].

Ukwakheka Kwamakhemikhali kwe-ASTM A501

Indlela Yokuhlola: ASTM A751.

Ezingeni le-ASTM A501, kunezindlela ezimbili zokuhlaziya ukwakheka kwamakhemikhali ensimbi: ukuhlaziywa kokushisa kanye nokuhlaziywa komkhiqizo.

Ukuhlaziywa kokushisa kwenziwa ngesikhathi senqubo yokuncibilikisa insimbi. Inhloso yayo ukuqinisekisa ukuthi ukwakheka kwamakhemikhali kwensimbi kuhlangabezana nezidingo zendinganiso ethile.

Ngakolunye uhlangothi, ukuhlaziywa komkhiqizo kwenziwa ngemva kokuba insimbi isivele yenziwe umkhiqizo. Le ndlela yokuhlaziya isetshenziselwa ukuqinisekisa ukuthi ukwakheka kwamakhemikhali komkhiqizo wokugcina kuyahlangabezana nezidingo ezibekiwe.

Izakhiwo Zemishini ze-ASTM A501

Izindlela zokuhlola kanye nezincazelo ziyahambisana nezidingo ezifanele ze-ASTM A370.

Ubukhulu bodonga obungu-≤ 6.3mm [0.25in] abudingi ukuhlolwa komthelela.

Ukubekezelelana Okulinganiselwe kwe-ASTM A501

Ukuhlanganisa nge-galvanizing

Ukuze amashubhu esakhiwo afakwe i-hot-dip galvanized, lokhu kuhlanganiswa kufanele kuhlangabezane nezidingo ze-Special A53/A53M.

Linganisa inani lesembozo ebusweni bangaphandle bepayipi ukuze uthole isisindo/ukujiya kwesembozo.

Ukubukeka

Amapayipi esakhiwo kumele angabi namaphutha futhi abe nobuso obubushelelezi ngesikhathi sokukhiqiza ama-hot rolling.

Amaphutha angaphezulu kufanele ahlukaniswe kanjalo lapho ukujula kwephutha langaphezulu kudlula u-10% wobukhulu bodonga obujwayelekile.

Amaphutha adinga ukulungiswa kufanele asuswe ngokuphelele ngokusika noma ngokugaya ngaphambi kokushisela.

Ukumaka

Umaki we-ASTM A501 kufanele okungenani ube nolwazi olulandelayo:

Igama lomkhiqizi

Umkhiqizo noma uphawu lokuhweba

Usayizi

Igama lendinganiso (unyaka wokushicilelwa awudingeki)

Ibanga

Ubude ngabunye bepayipi lesakhiwo kufanele buphawulwe ngendlela efanele, njengokugoqa, ukunyathela, ukunyathela, noma ukupenda.

Kumapayipi esakhiwo angaphansi kwama-50 mm [2 in] OD, kuvunyelwe ukumaka ulwazi lwensimbi kulebula enamathiselwe kuphakheji ngayinye.

Izindinganiso Ezifanele

I-ASTM A53/A53M: Imininingwane yepayipi, insimbi, emnyama neshisayo, embozwe nge-zinc, ehlanganisiwe, futhi engenamthungo.

I-ASTM A370: Izindlela Zokuhlola Nezincazelo Zokuhlolwa Kwemishini Kwemikhiqizo Yensimbi.

I-ASTM A700: Umhlahlandlela Wokupakisha, Ukumaka, kanye Nezindlela Zokulayisha Zemikhiqizo Yensimbi Yokuthunyelwa.

I-ASTM A751: Izindlela Zokuhlola Nemikhuba Yokuhlaziya Amakhemikhali Emikhiqizo Yensimbi.

I-ASTM A941: Amagama Ahlobene Nensimbi, Insimbi Engagqwali, Ama-Alloy Ahlobene, kanye nama-Ferroalloy.

Izicelo

Isetshenziswa kakhulu ekwakheni kanye nobunjiniyela bezakhiwo.

Ukwakhiwa kwebhuloho: ngenxa yezakhiwo zayo ezinhle zomshini kanye namandla, ifanelekela izingxenye ezibalulekile zezakhiwo zamabhuloho, okuhlanganisa amabhande athwala imithwalo, amadekhi amabhuloho, kanye nezakhiwo ezisekelayo.

Ukwakhiwa kwesakhiwo: ingasetshenziswa esakhiweni samathambo sezakhiwo, okuhlanganisa izinsika, imishayo, izinhlelo zozimele, kanye nezisekelo zophahla nephansi.

Izicelo Ezijwayelekile ZesakhiwoNgaphezu kwamabhuloho nezakhiwo, ifaneleka nakwamanye amaphrojekthi adinga ukwesekwa kwesakhiwo, njengokwakhiwa kwezinkundla zemidlalo, izindawo zokupaka, izikole, nezinye izikhungo zomphakathi ezinkulu.

Izicelo zezimboni: Kwezinye izikhungo zezimboni, njengezimboni kanye nezindawo zokugcina impahla, le nsimbi ingasetshenziswa futhi ukwakha izakhiwo zokusekela, ozimele bophahla, kanye nezinye izakhiwo ezithwala imithwalo.

Ingqalasizinda: Le nsimbi ingasetshenziswa futhi kwingqalasizinda njengezimpawu zomgwaqo, izibani, kanye nemibhoshongo yokuxhumana, isibonelo.

Izinzuzo Zethu

Kusukela yasungulwa ngo-2014, iBotop Steel isibe ngumhlinzeki wamapayipi ensimbi yekhabhoni ohamba phambili eNyakatho yeShayina, eyaziwa ngenkonzo yayo enhle kakhulu, imikhiqizo esezingeni eliphezulu, kanye nezixazululo eziphelele. Uhla olubanzi lwemikhiqizo yenkampani luhlanganisa amapayipi ensimbi angenamthungo, i-ERW, i-LSAW, kanye ne-SSAW, kanye nokufakwa kwamapayipi, ama-flange, kanye nezinsimbi ezikhethekile.

Ngokuzibophezela okuqinile kwikhwalithi, iBotop Steel isebenzisa izilawuli eziqinile kanye nokuhlolwa ukuqinisekisa ukuthembeka kwemikhiqizo yayo. Ithimba layo elinolwazi linikeza izixazululo ezenzelwe wena kanye nokusekelwa kochwepheshe, kugxilwe ekwanelisekeni kwamakhasimende.

Amathegi: ASTM a501, ibanga a, ibanga b, ibanga c, ishubhu lensimbi, ishubhu lensimbi yesakhiwo.

Isikhathi sokuthunyelwe: Meyi-06-2024