I-ASTM A500 kanye ne-ASTM A501zombili zibhekana ngqo nezidingo ezihlobene nokwakhiwa kwepayipi lesakhiwo sensimbi yekhabhoni.

Nakuba kukhona ukufana ezicini ezithile, nazo zinezici zazo ezihlukile kanye nezinhlelo zokusebenza.

Okulandelayo sizobheka umehluko oyinhloko phakathi kwe-ASTM A500 ne-ASTM A501 nokuthi isetshenziswa kanjani ezinhlelweni ezahlukene.

Izinqubo Zokukhiqiza

Izinqubo Zokukhiqiza ze-ASTM A500

Ipayipi le-ASTM A50 kumele likhiqizwe ngezinqubo ezingenamthungo noma ezihlanganisiwe.

Amapayipi ahlanganisiwe kumele enziwe ngensimbi egoqwe ngokuyisicaba ngenqubo yokushisela ngokumelana nogesi (ERW).

Izinqubo Zokukhiqiza ze-ASTM A501

Amapayipi kumele akhiwe ngenye yezinqubo ezilandelayo: ukushisela okungenamthungo, ukushisela okungapheli komlilo (ukushisela okuqhubekayo); ukushisela okuqinile noma ukushisela okungaphansi komhlaba.

Kuzophinde kufudunyezwe phezu kwengxenye yonke bese kufakwa i-thermoform ngokunciphisa noma ukwakheka kwezinqubo, noma kokubili.

Ukwakheka kokugcina kwesimo kufanele kwenziwe ngenqubo yokwakheka eshisayo.

Izinqubo Ezihlukene Zokukhiqiza

Zombili izindinganiso zivumela ukusetshenziswa kwamasu okukhiqiza amapayipi angenamthungo;

Uma inqubo yokushisela isetshenziswa ekukhiqizeni, i-ASTM A500 isebenzisa i-electric-resistance-welded (ERW), kuyilapho i-ASTM A501 ivumela izindlela ezahlukene zokushisela, okuhlanganisa i-electric-resistance-welded (ERW), i-submerged arc welding (SAW), njll.

Kodwa-ke, i-ASTM A501 idinga ukuthi ipayipi liphathwe ngokushisa, okusiza ekuthuthukiseni ukufana kanye nezakhiwo zemishini zento. Inhloso ye-thermoforming ukuthuthukisa izakhiwo zezinto ngokushisa ipayipi ngaphambi kokuba isimo salo siqedwe.

I-ASTM A500 ayinazo izidingo ezinemininingwane enjalo.

Ukuhlukaniswa KwamaBanga

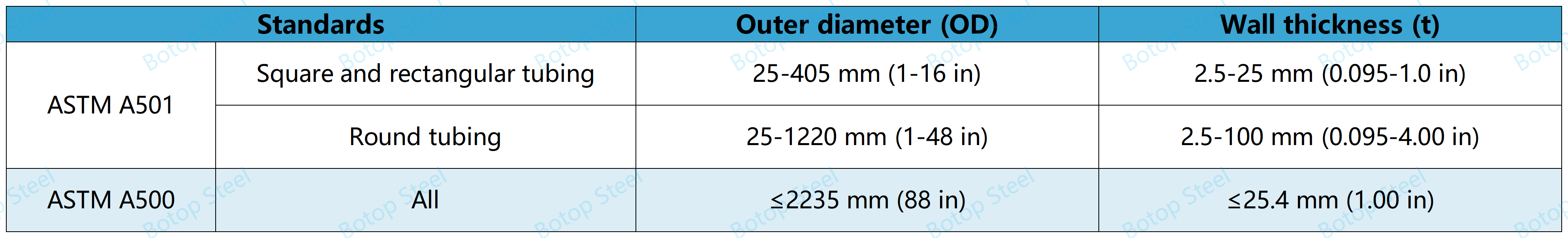

Ububanzi Bosayizi Obusebenzayo

Izingxenye Zamakhemikhali

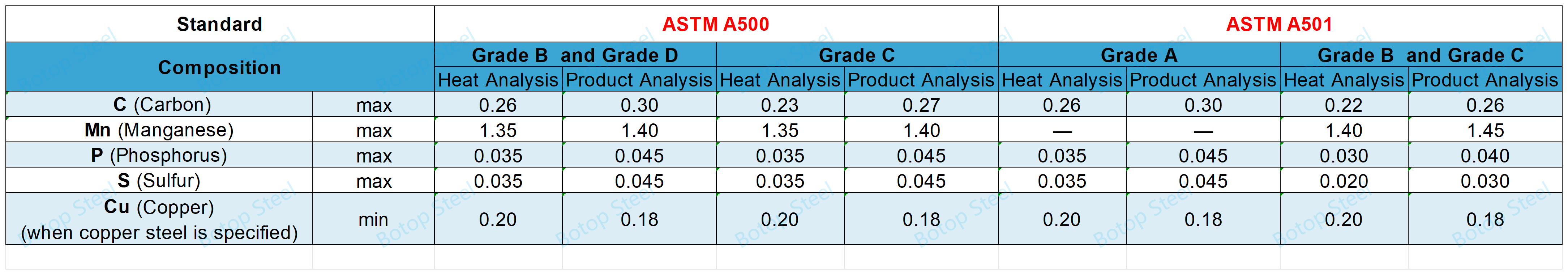

Uma kubhekwa konke, kukhona umehluko othile ekwakhiweni kwamakhemikhali kwamashubhu esakhiwo sensimbi yekhabhoni achazwe ezindinganisweni ezimbili, i-ASTM A500 kanye ne-ASTM A501.

Ku-ASTM A500, iBanga B neBanga D zinezidingo ezifanayo zokwakheka kwamakhemikhali, kuyilapho iBanga C linokuqukethwe kwekhabhoni okuncishisiwe uma kuqhathaniswa no-B no-D. Ku-ASTM A501, ukwakheka kwamakhemikhali kweBanga A kufana nokweBanga B, kuyilapho iBanga C linokuqukethwe kwekhabhoni okuncishisiwe uma kuqhathaniswa no-B.

Ku-ASTM A501, ukwakheka kwamakhemikhali eBangeni A kufana nokwamaBanga B no-D e-A500, kodwa kumaBanga B no-C okuqukethwe kwekhabhoni kuncishisiwe, okuqukethwe kwe-manganese kukhushulwa kancane, kanti okuqukethwe kwe-phosphorus ne-sulfur kuphansi kunaseBangeni A.

Okuqukethwe kwethusi kuhlala kuyisidingo esincane esiqhubekayo kuzo zonke izinhlobo.

Izidingo ezahlukene zokwakheka kwamakhemikhali zibonisa izidingo ezithile zezindinganiso ezimbili zezinqubo ezahlukene zokukhiqiza kanye nezicelo, okuqinisekisa ukuthi izinto zihlangabezana nezindinganiso zokusebenza zobubanzi bezicelo zobunjiniyela kanye nezakhiwo.

Ukusebenza Kwemishini

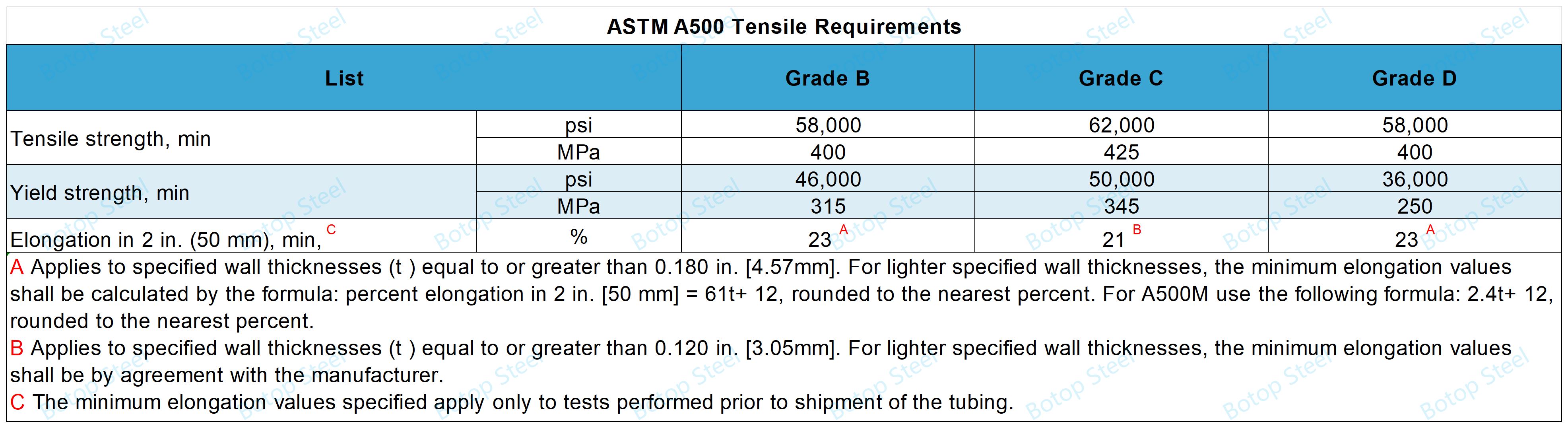

Ukusebenza Komshini we-ASTM A500

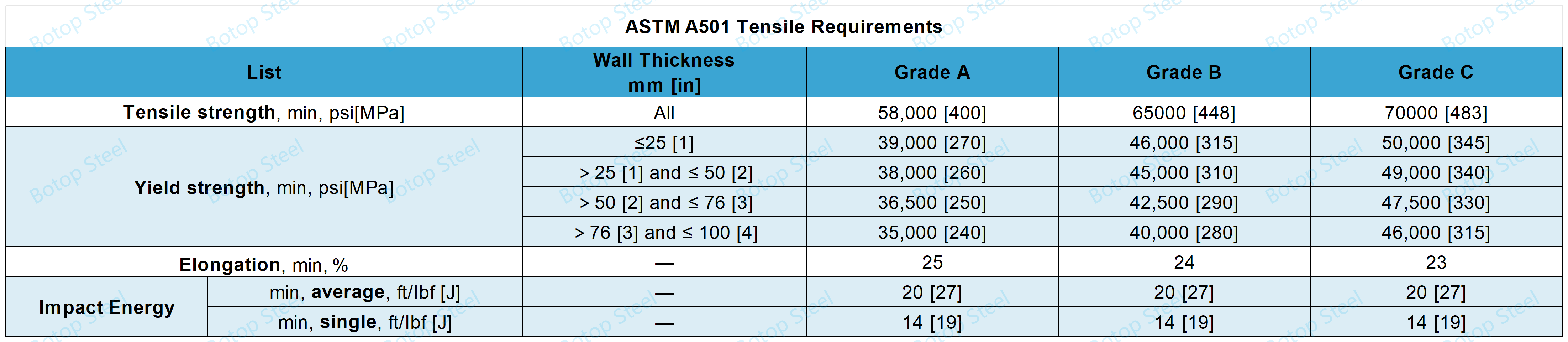

Ukusebenza Komshini kwe-ASTM A501

Izakhiwo Ezihlukene Zemishini

Izinto eziku-A501 zivame ukunikeza amazinga aphezulu amandla ngenxa yamandla akhuphukile ensimbi evela enkambisweni yokwakheka okushisayo.

Amaphrojekthi Okuhlola

Izidingo ezahlukene zezinto zokuhlola ezindinganisweni ezimbili zibonisa izinqubo zokukhiqiza kanye nokusetshenziswa okuhlosiwe kwala mashubhu amabili ahlukene.

Izinga le-ASTM A500 lidinga ukuhlaziywa kokushisa, ukuhlaziywa komkhiqizo, kanye nezakhiwo zemishini ngaphezu kokuhlolwa kwe-Flattening, ukuhlolwa kwe-Flaring, kanye ne-Wedge Crush Tes ukuqinisekisa ukuthi inqubo yokwakheka okubandayo ayithinti kabi izakhiwo zezinto ezibonakalayo.

Izinga le-ASTM A501 ligcizelela inqubo yokushisa, futhi njengoba imikhiqizo efakwe ukufudumala isivele iphathwa ngokushisa ngesikhathi senqubo yokukhiqiza, lokhu kuhlolwa kungabhekwa njengokungadingekile ngoba ukwelashwa ngokushisa sekuqinisekisile ukuqina nokuqina kwezinto.

Izindawo Zokusebenza

Nakuba zombili zidlala indima ehlelekile, ukugcizelela kuzohluka.

I-ASTM A500 tube isetshenziswa kabanzi ezakhiweni zokwakha, ekukhiqizeni imishini, ozimele bezimoto, kanye nemishini yezolimo ngenxa yezakhiwo zayo ezinhle zokugoba nokubanda kanye nokushisela.

I-ASTM A501 tube ifaneleka kakhulu ezakhiweni nasezindaweni ezidinga amandla nokuqina okuphezulu, njengokwakhiwa kwamabhuloho nezakhiwo ezinkulu zokusekela, ngenxa yokuqina nokuqina kwawo okuhle kakhulu.

Zombili lezi zindinganiso zinikeza isiqondiso sokwenza amapayipi ensimbi yekhabhoni asezingeni eliphezulu, kodwa ukukhetha okungcono kuncike ezidingweni kanye nemingcele yephrojekthi ethile.

Uma isakhiwo sidinga ukusebenza kahle endaweni enezinga lokushisa eliphansi, i-ASTM A501 ingase ikhethwe ngoba ukuqina okwandisiwe okuvela ekwakhekeni okushisayo kunikeza ukumelana okungcono nokuqhekeka okuqhekekile. Ngokuphambene nalokho, uma isakhiwo sizokwakhelwa indawo yangaphakathi, khona-ke i-ASTM A500 inganele, njengoba inganikeza amandla adingekayo kanye nokusebenza kahle, kuyilapho kungenzeka ibize kancane.

Amathegi: a500 vs a501, i-astm a500, i-astm a501, insimbi yekhabhoni, ipayipi lesakhiwo.

Isikhathi sokuthunyelwe: Meyi-06-2024