Amashubhu e-ASTM A334 amashubhu ensimbi yekhabhoni ne-alloy aklanyelwe ukusetshenziswa kwezinga lokushisa eliphansi futhi akhiqizwa kusetshenziswa izinqubo ezingenamthungo nezihlanganisiwe.

Amanye amasayizi omkhiqizo angase angatholakali ngaphansi kwale ncazelo ngoba ubukhulu bodonga obunzima bunomthelela omubi ezimpahleni zomthelela wokushisa okuphansi.

Ukuhlukaniswa KwamaBanga

I-ASTM A334 iqukethe amazinga amaningana ezimweni ezahlukene zokushisa okuphansi.

Ibanga 1, Ibanga 3, Ibanga 6, Ibanga 7, Ibanga 8, Ibanga 9, kanye neBanga 11.

Amabanga e-ipayipi lensimbi yekhabhonikukhonaIbanga 1futhiIbanga lesi-6.

Amabanga afaneleAmashubhu ensimbi e-alloy ayibanga lesi-3, ibanga lesi-7, ibanga lesi-8, ibanga lesi-9, kanye nebanga lesi-11.

Uhlobo ngalunye lwensimbi lunezakhi zalo zamakhemikhali ezithile kanye nezidingo zesakhiwo semishini, kanye nezindinganiso zokushisa zokuhlola umthelela ezincane okumele zihlangatshezwe.

Izinqubo Zokukhiqiza

Amapayipi kufanele enziwe yi-ngaphandle komthungonoma okuzenzakalelayoinqubo yokushiselangaphandle kokufakwa kwensimbi yokugcwalisa ekusebenzeni kokushisela.

Ukwelashwa Kokushisa

Ibanga 1, 3, 6, 7, kanye nele-9

Yenza kube ngokwejwayelekile ngokushisa kufike ezingeni lokushisa elifanayo okungenani elingaphansi kuka-1550 °F [845 °C] bese uphola emoyeni noma ekamelweni lokupholisa lesithando esilawulwa umoya.

Uma kudingeka ukuhlungwa, kuzodingeka kuxoxiswane ngakho.

Kuma-grade angenhla amashubhu ensimbi angenamthungo kuphela:

Fudumeza futhi ulawule ukusebenza okushisayo kanye nokushisa komsebenzi wokuqeda ukushisa kuze kufike ezingeni lokushisa lokuqeda kusukela ku-1550 - 1750 °F [845 - 955℃] bese upholisa esithandweni somoya esilawulwayo kusukela ekushiseni kokuqala okungenani okungu-1550 °F [845 °C].

Ibanga lesi-8

Khetha noma iyiphi yalezi zindlela ezilandelayo zokwelapha ukushisa.

Kucinyiwe futhi kuthotshisiwe;

Okujwayelekile kabili kanye Nokuthukuthela.

Ibanga 11

Ukuthi kufanele kufakwe yini amashubhu ebanga le-11 kungokwesivumelwano phakathi komthengi nomhlinzeki.

Uma amashubhu ebanga le-11 evalwe, kufanele abekwe ezingeni elijwayelekile kusukela ku-1400 - 1600℉[760 - 870 °C].

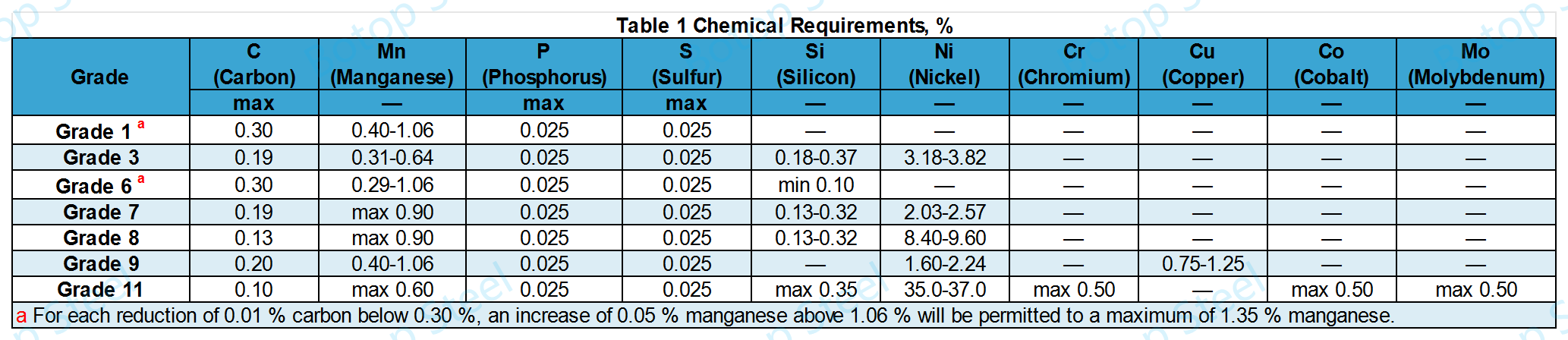

Ukwakheka Kwamakhemikhali kwe-ASTM A334

Kwezinsimbi zeBanga loku-1 noma leBanga lesi-6, akuvunyelwe ukunikeza amazinga okuhlanganisa noma yiziphi izakhi ngaphandle kwalezo ezidingekayo ngokusobala. Kodwa-ke, kuvunyelwe ukwengeza izakhi ezidingekayo ukuze kususwe i-oxidation yensimbi.

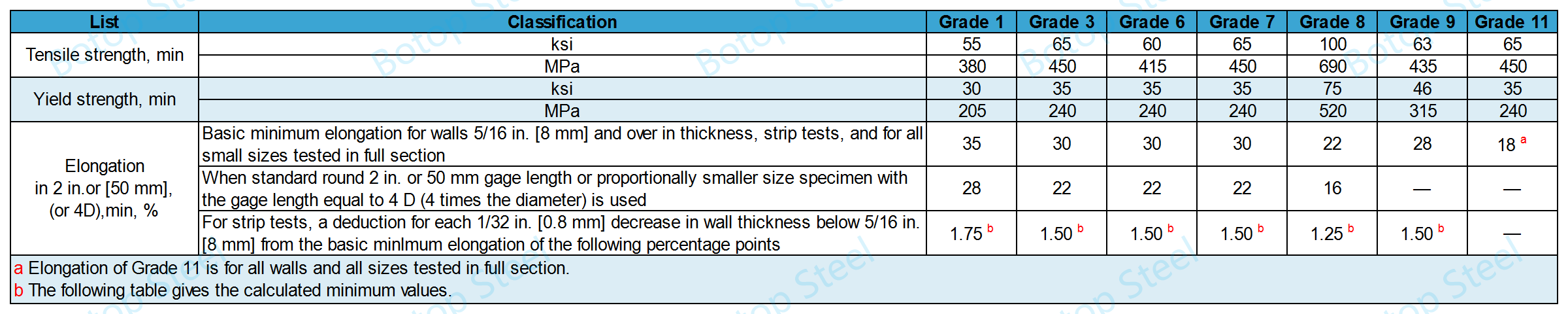

Ukuhlolwa Kwemishini kwe-ASTM A334

Izidingo zesakhiwo semishini azisebenzi kumapayipi amancane kuno-1/8 intshi [3.2 mm] ububanzi bangaphandle futhi anobukhulu bodonga obungaphansi kuka-0.015 intshi [0.4 mm].

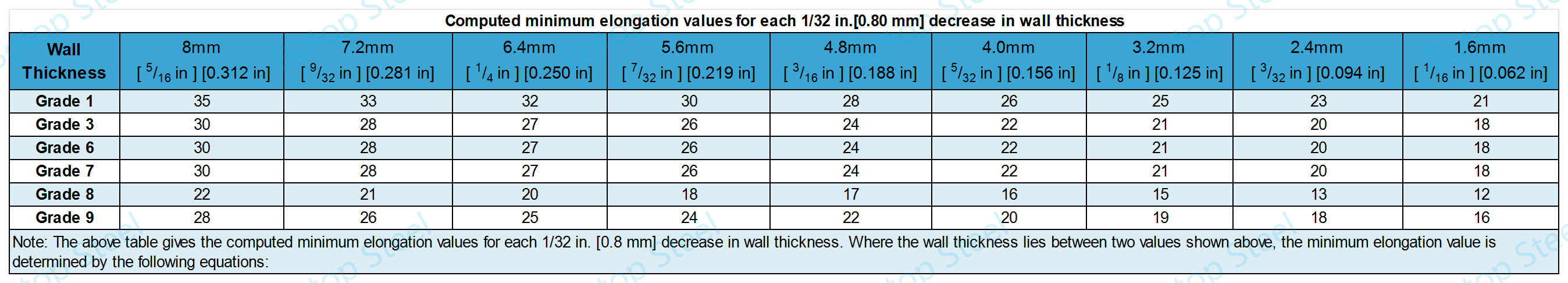

1. Impahla Eqinile

Ukwelulwa okuncane okubalwe ngokunciphisa ngakunye okungu-1/32 intshi [0.80 mm] kobukhulu bodonga:

Kumapayipi amancane kune-1/2 in. [12.7 mm] ububanzi bangaphandle, amanani okunwebeka anikezwe amasampula emicu kufanele asebenze.

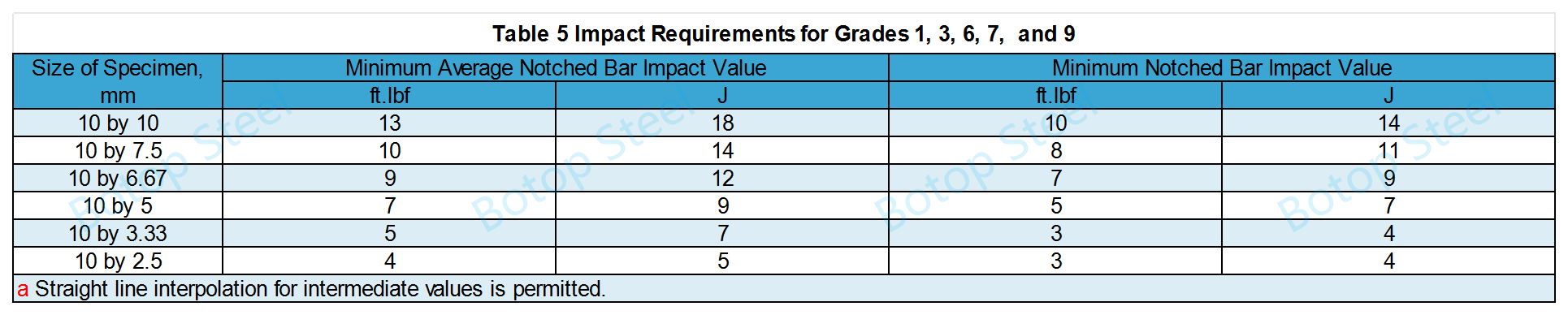

2. Ukuhlolwa Komthelela

Khetha izinga lokushisa elifanele kanye namandla omthelela ahambisanayo ngokusekelwe ebangeni kanye nobukhulu bodonga.

Amandla Omthelela

Izinga Lokushisa Elithinta Umthelela

| Ibanga | Izinga Lokushisa Lokuhlola Umthelela | |

| ℉ | ℃ | |

| Ibanga 1 | -50 | -45 |

| Ibanga lesi-3 | -150 | -100 |

| Ibanga lesi-6 | -50 | -45 |

| Ibanga lesi-7 | -100 | -75 |

| Ibanga lesi-8 | -320 | -195 |

| Ibanga lesi-9 | -100 | -75 |

3. Ukuhlolwa Kokuqina

| Ibanga | Rockwell | UBrinell |

| Ibanga 1 | B 85 | 163 |

| Ibanga lesi-3 | B 90 | 190 |

| Ibanga lesi-6 | B 90 | 190 |

| Ibanga lesi-7 | B 90 | 190 |

| Ibanga lesi-8 | — | — |

| Ibanga 11 | B 90 | 190 |

4. Ukuhlolwa Kokuthamba

Ukuhlolwa okukodwa kokuthambekela kufanele kwenziwe kumasampula avela ekugcineni ngakunye kweshubhu elilodwa eliqediwe lengxenye ngayinye kodwa hhayi elisetshenziselwa ukuhlolwa kwe-flare noma kwe-flange.

5. Ukuhlolwa Kokuvutha (Amashubhu Angenamthungo)

Ukuhlolwa okukodwa kokuqhuma kufanele kwenziwe kumasampula avela ekugcineni ngakunye kwepayipi elilodwa eliqediwe lengxenye ngayinye, kodwa hhayi elisetshenziselwa ukuhlolwa kokusicaba.

6. Ukuhlolwa kweFlange (Amashubhu Ahlanganisiwe)

Ukuhlolwa kwe-flange eyodwa kufanele kwenziwe kumasampula avela ekugcineni ngakunye kwepayipi elilodwa eliqediwe lengxenye ngayinye, kodwa hhayi elisetshenziselwa ukuhlolwa kokuthambekela.

7. Ukuhlolwa Kokugoba Okubuyela Emuva

Kumapayipi ahlanganisiwe, ukuhlolwa okukodwa kokuthambekela okuphambene kufanele kwenziwe kusampula kusuka kumamitha angu-460 ubude bepayipi ngalinye eliqediwe.

Ukuhlolwa Kukagesi Okungashintshi Noma Okungabhubhisi

Ipayipi ngalinye kufanele lihlolwe ngogesi ngaphandle kokubhubhisa noma lihlolwe ngamanzi ngokuhambisana ne-Special A1016/A1016M.

Izicelo zepayipi lensimbi le-ASTM A334

Ngokuyinhloko isetshenziselwa ukuthutha uketshezi noma amagesi afana negesi yemvelo, uwoyela, namanye amakhemikhali emazingeni okushisa aphansi.

1. Izinhlelo zamapayipi e-Cryogenic: ivame ukusetshenziswa ekwakhiweni kwezinhlelo zamapayipi okuthutha uketshezi oluyi-cryogenic (isb. igesi yemvelo encibilikisiwe, i-nitrogen ewuketshezi). Ngenxa yezakhiwo zayo ezinhle kakhulu ze-cryogenic, iyakwazi ukugcina amandla omshini nokuqina emazingeni okushisa aphansi kakhulu.

2. Izishintshi zokushisa kanye nezikhulisi zokushisa: Ama-heat exchanger nama-condenser angasetshenziswa ngempumelelo ukupholisa noma ukushisa imidiya yokucubungula, ikakhulukazi ezimbonini zamakhemikhali kanye ne-petrochemical.

3. Imithambo yokucindezela: ingasetshenziswa futhi ukukhiqiza imikhumbi yokucindezela eyenzelwe imisebenzi ye-cryogenic. Le mikhumbi ingasetshenziswa ukugcina amakhemikhali e-cryogenic noma izinqubo ezikhethekile zezimboni.

4. Izinhlelo zefriji nemishini: Lawa mashubhu asetshenziselwa ukuthutha ama-refrigerant, ikakhulukazi lapho kudingeka khona izinto ezingamelani nokushisa okuphansi.

Izinga Elilinganayo le-ASTM A334

I-EN 10216-4: Imboza amashubhu ensimbi angaxutshwe nahlanganisiwe, anezakhiwo ezithile zokushisa okuphansi.

I-JIS G 3460: ihlobene namashubhu ensimbi e-alloy ukuze kuhlinzekwe nge-cryogenic.

I-GB/T 18984: isebenza kumashubhu ensimbi angenamthungo emikhumbi yokucindezela e-cryogenic. Icacisa ngokuningiliziwe ukwakheka kanye nokukhiqizwa kwamashubhu ensimbi afanelekela izindawo ezishisa kakhulu.

Nakuba lezi zindinganiso zingase zihluke ngemininingwane kanye nezidingo ezithile, ziyafana ngenhloso yazo iyonke kanye nokusetshenziswa kwazo, okuwukuqinisekisa ukuphepha nokusebenza kwamapayipi ensimbi ezindaweni ezi-cryogenic.

Imikhiqizo Yethu Ehlobene

Kusukela yasungulwa ngo-2014, iBotop Steel isibe ngumhlinzeki ohamba phambili wamapayipi ensimbi yekhabhoni eNyakatho yeShayina, eyaziwa ngenkonzo enhle kakhulu, imikhiqizo esezingeni eliphezulu, kanye nezixazululo eziphelele.

Le nkampani inikeza amapayipi ahlukahlukene ensimbi yekhabhoni kanye nemikhiqizo ehlobene nayo, kufaka phakathi ipayipi lensimbi elingenamthungo, i-ERW, i-LSAW, kanye ne-SSAW, kanye nohlu oluphelele lwezihlanganisi zamapayipi nama-flange. Imikhiqizo yayo ekhethekile ifaka phakathi ama-alloy ebanga eliphezulu kanye nezinsimbi ezingagqwali ze-austenitic, ezenzelwe ukuhlangabezana nezidingo zamaphrojekthi ahlukahlukene amapayipi.

Amathegi: ASTM A334, ipayipi lensimbi yekhabhoni, i-ASTM a334 gr 6, i-ASTM a334 gr 1.

Isikhathi sokuthunyelwe: Meyi-20-2024