I-JIS G 3455iyi-Japanese Industrial Standard (JIS) yesevisi yokucindezela okuphezulu emazingeni okushisa angu-350 °C noma ngaphansi, ikakhulukazi ezingxenyeni zemishini.

Ipayipi lensimbi le-STS370iyipayipi lensimbi elinamandla okudonsa okungenani angu-370 MPa kanye namandla okukhiqiza okungenani angu-215 MPa, elinokuqukethwe kwekhabhoni okungadluli ku-0.25% kanye nokuqukethwe kwe-silicon okuphakathi kuka-0.10% no-0.35%, futhi lisetshenziswa kakhulu ezicelweni ezidinga amandla aphezulu kanye nokushibilika okuhle, njengezakhiwo zokwakha, amabhuloho, imikhumbi yokucindezela, kanye nezingxenye zemikhumbi.

I-JIS G 3455 inamabanga amathathu.I-STS370, STS410, STA480.

Ububanzi bangaphandle obungu-10.5-660.4mm (6-650A) (1/8-26B).

Amapayipi kufanele akhiqizwe kusukela ku-insimbi ebulewe.

Insimbi ebulewe yinsimbi esuswe ngokuphelele i-oxid ngaphambi kokuba ifakwe kuma-ingots noma kwezinye izinhlobo. Le nqubo ihlanganisa ukwengeza i-deoxidizing agent njenge-silicon, i-aluminium, noma i-manganese ensimbini ngaphambi kokuba iqine. Igama elithi "ebulewe" libonisa ukuthi akukho ukusabela komoya-mpilo okwenzekayo ensimbini ngesikhathi senqubo yokuqina.

Ngokususa umoya-mpilo, insimbi ebulewe ivimbela ukwakheka kwamabhamuza omoya ensimbini encibilikisiwe, ngaleyo ndlela igweme ukubhoboka kanye namabhamuza omoya emkhiqizweni wokugcina. Lokhu kuphumela ensimbini efanayo futhi ebanzi enezakhiwo ezinhle kakhulu zemishini kanye nobuqotho besakhiwo.

Insimbi ebulewe ifaneleka kakhulu ekusetshenzisweni okudinga ikhwalithi ephezulu nokuqina, njengemikhumbi yokucindezela, izakhiwo ezinkulu, namapayipi anezidingo zekhwalithi ephezulu.

Ngokusebenzisa insimbi ebulewe ukukhiqiza amashubhu, ungaqiniseka ngokusebenza okungcono kanye nokuphila isikhathi eside kwenkonzo, ikakhulukazi ezindaweni ezithwala imithwalo esindayo kanye nengcindezi.

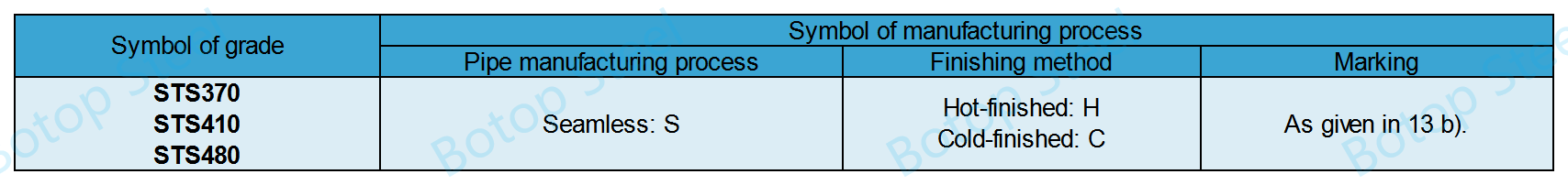

Kukhiqizwe kusetshenziswa inqubo yokukhiqiza engenamthungo ehlanganiswe nendlela yokuqeda.

Ipayipi lensimbi elingenamthungo eliqediwe ngokushisa: SH;

Ipayipi lensimbi elingenamthungo eliqediwe ngokubandayo: SC.

Ngenqubo yokukhiqiza engenamthungo, ingahlukaniswa ngamapayipi ensimbi angenamthungo anobubanzi bangaphandle obungaphezu kuka-30mm kusetshenziswa ukukhiqizwa kokuqeda okushisayo, kanye no-30mm kusetshenziswa ukukhiqizwa kokuqeda okubandayo.

Nansi indlela yokukhiqiza i-Hot-finished seamless.

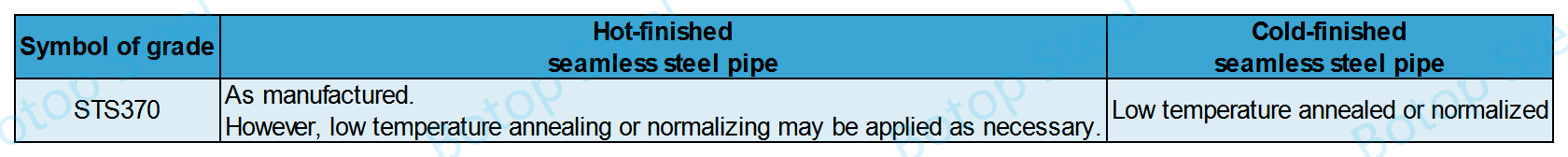

Ukufakwa kwe-annealing okushisa okuphansi kusetshenziselwa kakhulu ukuthuthukisa ukusebenza kahle kwezinto, ukunciphisa ubulukhuni, nokuthuthukisa ukuqina, futhi kufanelekile ensimbini ebanda.

Ukulungisa kusetshenziselwa ukuthuthukisa amandla nokuqina kwezinto, ukuze insimbi ifaneleke kakhulu ukumelana nokucindezeleka komshini nokukhathala, okuvame ukusetshenziselwa ukuthuthukisa ukusebenza kwensimbi ebanda.

Ngalezi zinqubo zokwelapha ukushisa, isakhiwo sangaphakathi sensimbi siyathuthukiswa futhi izakhiwo zayo ziyathuthukiswa, okwenza ifaneleke kakhulu ukusetshenziswa ezisetshenziswa ezimbonini ezidinga kakhulu.

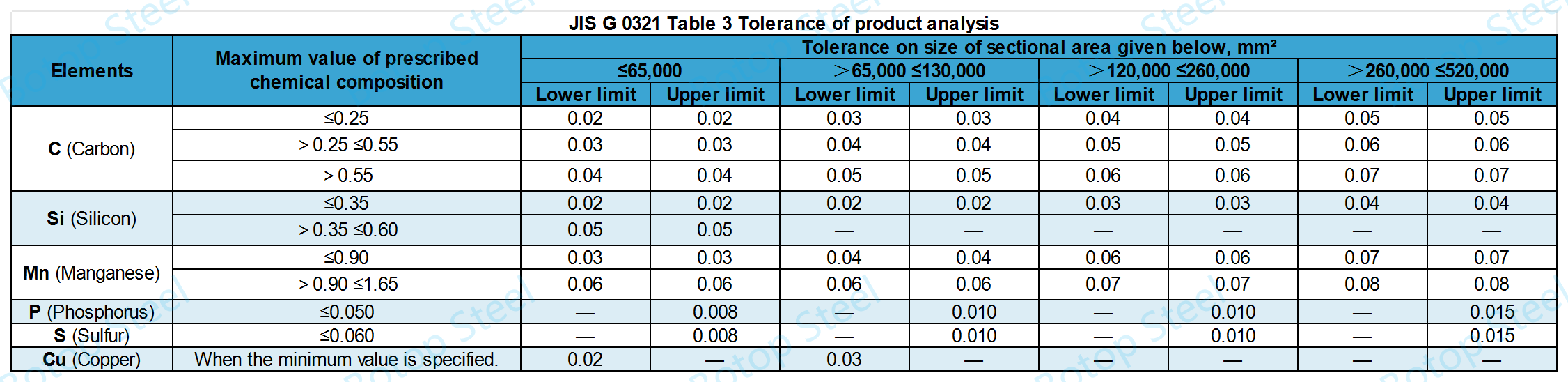

Ukuhlaziywa kokushisa kufanele kuhambisane ne-JIS G 0320. Ukuhlaziywa komkhiqizo kufanele kuhambisane ne-JIS G 0321.

| ibanga | C (Ikhabhoni) | I-Si (i-Silicon) | I-Mn (i-Manganese) | I-P (i-Phosphorus) | S (Isibabule) |

| I-STS370 | Ubuningi obungu-0.25% | 0.10-0.35% | 0.30-1.10% | Ubuningi obungu-0.35% | Ubuningi obungu-0.35% |

Ukuhlaziywa kokushisaihloselwe kakhulu ukuhlola ukwakheka kwamakhemikhali kwezinto zokusetshenziswa.

Ngokuhlaziya ukwakheka kwamakhemikhali kwezinto zokusetshenziswa, kungenzeka ukubikezela nokulungisa izinyathelo zokucubungula kanye nezimo ezingadingeka enkambisweni yokukhiqiza, njengemingcele yokwelashwa kokushisa kanye nokwengezwa kwezinto ezixubayo.

Ukuhlaziywa komkhiqizoihlaziya ukwakheka kwamakhemikhali kwemikhiqizo eqediwe ukuqinisekisa ukuhambisana kanye nekhwalithi yomkhiqizo wokugcina.

Ukuhlaziywa komkhiqizo kuqinisekisa ukuthi zonke izinguquko, izengezo noma noma yikuphi ukungcola okungenzeka kumkhiqizo ngesikhathi senqubo yokukhiqiza kuyalawulwa nokuthi umkhiqizo wokugcina uhlangabezana nezimfuneko zobuchwepheshe kanye nezidingo zokusetshenziswa.

I-JIS G 3455 amanani okuhlaziywa komkhiqizo akufanele nje ahambisane nezidingo zezinto ezisetafuleni elingenhla, kodwa futhi nobubanzi bokubekezelelana kufanele buhambisane nezidingo ze-JIS G 3021 Ithebula 3.

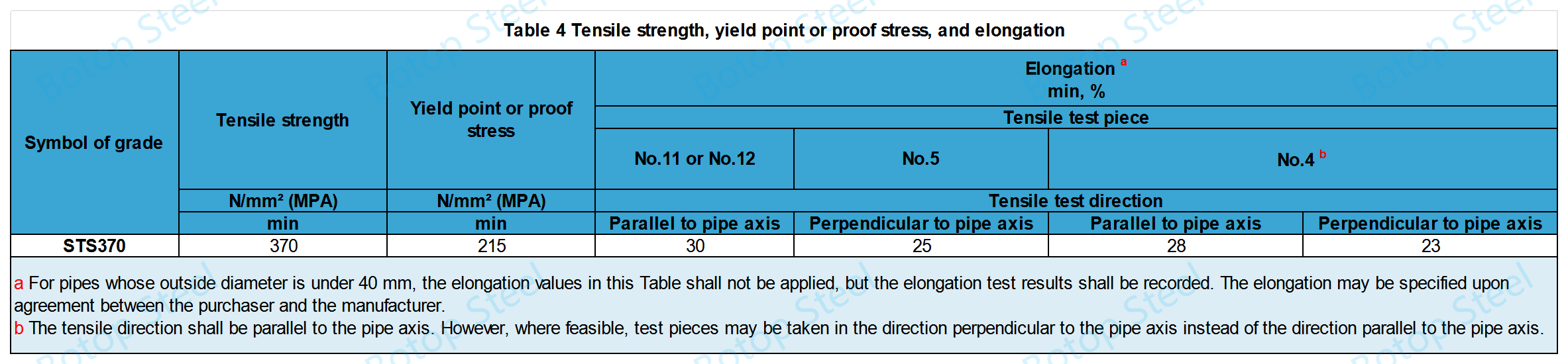

Amanani obude bengxenye yokuhlolwa enguNombolo 12 (ehambisana ne-axis yepayipi) kanye nengxenye yokuhlolwa enguNombolo 5 (eqondile ne-axis yepayipi) ethathwe kumapayipi angaphansi kuka-8 mm ubukhulu bodonga.

| Uphawu lwebanga | Ingxenye yokuhlola esetshenzisiwe | Ukwelulwa ubuncane, % | ||||||

| Ubukhulu bodonga | ||||||||

| >1 ≤2 mm | >2 ≤3 mm | >3 ≤4 mm | >4 ≤5 mm | >5 ≤6 mm | >6 ≤7 mm | >7 <8 mm | ||

| I-STS370 | Inombolo 12 | 21 | 22 | 24 | 26 | 27 | 28 | 30 |

| Inombolo 5 | 16 | 18 | 19 | 20 | 22 | 24 | 25 | |

| Amanani okunwebeka kuleli thebula atholakala ngokukhipha u-1.5% enanini lokunwebeka elinikezwe kuThebula 4 ngokuncipha ngakunye okungu-1 mm kobukhulu bodonga kusuka ku-8 mm, nangokufingqa umphumela ube yinombolo ephelele ngokusho koMthetho A we-JIS Z 8401. | ||||||||

Ukuhlolwa kokuthamba kungashiywa ngaphandle kokuthi kuchazwe ngenye indlela ngumthengi.

Beka isampula emshinini bese uyibamba kuze kube yilapho ibanga eliphakathi kwamapulatifomu amabili lifinyelela inani elibekiwe u-H. Bese uhlola isampula ukuthi ayinazo yini izimfa.

Uma kuhlolwa ipayipi elihlanganisiwe elinokumelana okubucayi, umugqa ophakathi kwe-weld kanye nesikhungo sepayipi uqonde ngqo esiqondisweni sokucindezela.

H=(1+e)t/(e+t/D)

H: ibanga phakathi kwama-platens (mm)

t: ukujiya kodonga lwepayipi (mm)

D: ububanzi obungaphandle kwepayipi (mm)

e:okuchazwe ngokungaguquki kwebanga ngalinye lethubhu.0.08 ye-STS370: 0.07 ye-STS410 kanye ne-STS480.

Ifanele amapayipi anobubanzi obungaphandle obungu-≤ 50 mm.

Isampula kumele ingabi nemifantu uma igobile ku-90° kanye nobubanzi bangaphakathi obuphindwe kasithupha kunobubanzi bangaphandle bepayipi.

I-engeli yokugoba kufanele ilinganiswe ekuqaleni kokugoba.

Wonke amapayipi ensimbi kudingeka ahlolwe ngamanzi noma angabhubhisiukuqinisekisa ikhwalithi nokuphepha kwepayipi kanye nokuhlangabezana nezindinganiso zokusetshenziswa.

Ukuhlolwa kwe-Hydraulic

Uma kungekho ngcindezi yokuhlola echaziwe, ingcindezi encane yokuhlola amanzi kufanele inqunywe ngokuhambisana neShejuli Yamapayipi.

| Ukujiya kodonga okujwayelekile | 40 | 60 | 80 | 100 | 120 | 140 | 160 |

| Umfutho wokuhlola omncane we-hydraulic, i-Mpa | 6.0 | 9.0 | 12 | 15 | 18 | 20 | 20 |

Uma ubukhulu bodonga lobubanzi bangaphandle bepayipi lensimbi bungeyona inani elijwayelekile etafuleni lesisindo sepayipi lensimbi, kuyadingeka ukusebenzisa ifomula ukubala inani lokucindezela.

P=2st/D

P: ingcindezi yokuhlola (i-MPa)

t: ubukhulu bodonga lwepayipi (mm)

D: ububanzi bangaphandle bepayipi (mm)

s: 60% yenani eliphansi lephuzu lokukhiqiza noma ukucindezeleka kobufakazi okunikeziwe.

Uma ingcindezi yokuhlola ye-hydrostatic encane kakhulu yenombolo yohlelo ekhethiwe idlula ingcindezi yokuhlola P etholwe yifomula, ingcindezi P kufanele isetshenziswe njengengcindezi yokuhlola ye-hydrostatic encane kakhulu esikhundleni sokukhetha ingcindezi yokuhlola ye-hydrostatic encane kakhulu kuthebula elingenhla.

Ukuhlolwa Okungabhubhisi

Ukuhlolwa kwamashubhu ensimbi okungabhubhisi kufanele kwenziwe yi-ukuhlolwa kwe-ultrasonic noma kwe-eddy current.

Ngobai-ultrasoundizici zokuhlola, isignali evela kusampula yokubhekisela equkethe indinganiso yokubhekisela yekilasi le-UD njengoba kuchaziwe kuI-JIS G 0582kuzobhekwa njengezinga le-alamu futhi kuzoba nesignali eyisisekelo elingana noma enkulu kunezinga le-alamu.

Ukuzwela okujwayelekile kokutholwa kwe-ugesi we-eddyukuhlolwa kufanele kube yisigaba se-EU, i-EV, i-EW, noma i-EX esichazwe kuI-JIS G 0583, futhi akufanele kube khona izimpawu ezilingana noma ezinkulu kunezibonakaliso ezivela kusampula yokubhekisela equkethe indinganiso yokubhekisela yesigaba esishiwoyo.

Ukuze uthole okwengeziweAmashadi Esisindo Sepayipi kanye Namashejuli Epayipingaphakathi kwendinganiso, ungachofoza.

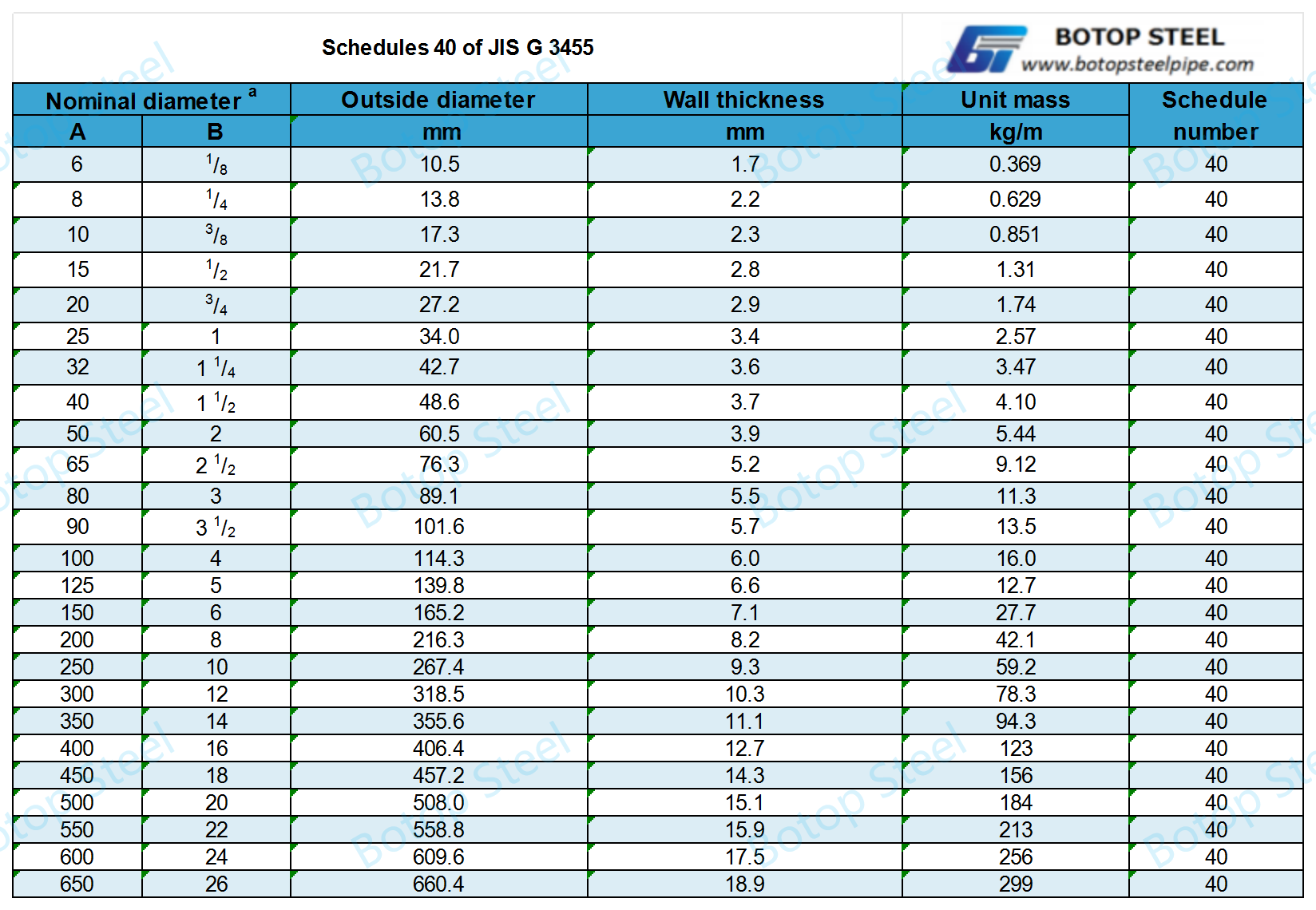

Ipayipi le-Schedule 40 lifaneleka kakhulu ekusetshenzisweni komfutho ophansi kuya kophakathi ngoba linikeza ukujiya kodonga okulingene okugwema isisindo esiningi kanye nezindleko ngenkathi kuqinisekiswa amandla anele.

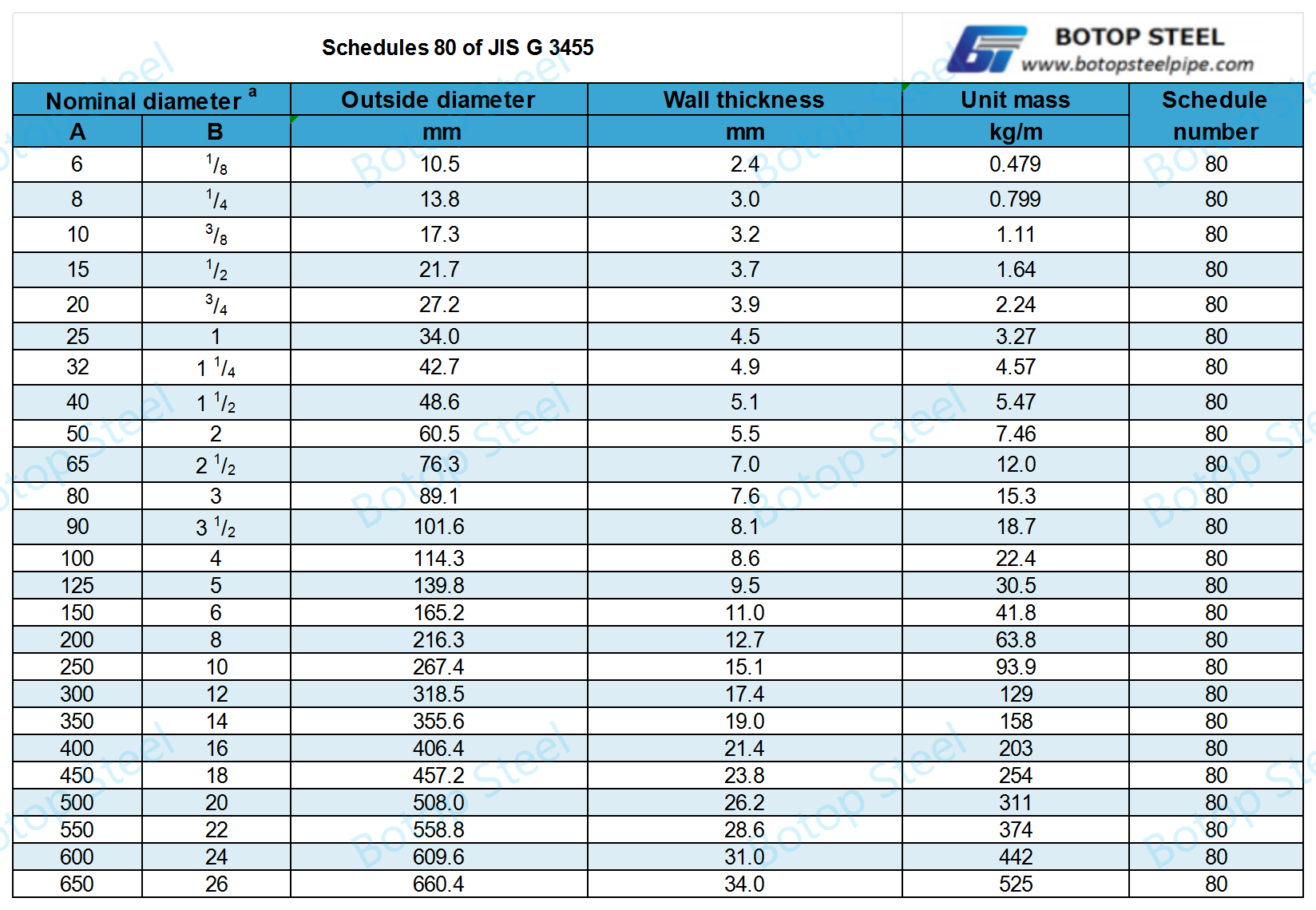

Amapayipi e-Schedule 80 asetshenziswa kabanzi ezindaweni zezimboni ezidinga ukuphathwa ngokucindezela okuphezulu, njengezinhlelo zokucubungula amakhemikhali kanye namapayipi okudlulisa uwoyela negesi, ngenxa yekhono lawo lokubekezelela ukucindezela okuphezulu kanye nemiphumela enamandla yemishini ngenxa yobukhulu bawo bodonga obukhulu, okunikeza ukuphepha okwengeziwe, ukuphepha, kanye nokuqina.

Ithubhu ngalinye kufanele libhalwe ulwazi olulandelayo.

a)Uphawu lwebanga;

b)Uphawu lwendlela yokukhiqiza;

c)UbukhuluIsibonelo 50AxSch80 noma 60.5x5.5;

d)Igama lomkhiqizi noma uhlobo olumkhombayo.

Uma ububanzi bangaphandle bepayipi ngalinye buncane futhi kunzima ukumaka ipayipi ngalinye, noma lapho umthengi efuna ukuthi iphakethe ngalinye lamapayipi limakwe, iphakethe ngalinye lingaphawulwa ngendlela efanele.

I-STS370 ifaneleka ezinhlelweni zokudlulisa uketshezi olunomfutho ophansi kodwa olushisa kakhulu.

Izinhlelo zokushisa: Ezinhlelweni zokushisa zedolobha noma zesakhiwo esikhulu, i-STS370 ingasetshenziswa ukuthutha amanzi ashisayo noma umusi ngoba ingamelana nokucindezeleka kanye nokushintsha kwezinga lokushisa ohlelweni.

Izitshalo zikagesi: Ekukhiqizweni kukagesi, kudingeka inani elikhulu lamapayipi anomfutho ophezulu, kanti i-STS370 iyinto efanelekile yokukhiqiza la mapayipi ngoba ingamelana nezimo zokusebenza ezishisa kakhulu nezinomfutho ophezulu.

Izinhlelo zomoya ezicindezelwe: Emigqeni yokukhiqiza kanye neyokukhiqiza ezenzakalelayo, umoya ocindezelwe uwumthombo obalulekile wamandla, kanti ipayipi lensimbi le-STS370 lisetshenziselwa ukwakha amapayipi alezi zinhlelo ukuqinisekisa ukulethwa komoya okuphephile nokuphumelelayo.

Ukusetshenziswa kwesakhiwo kanye nemishini ejwayelekileNgenxa yezakhiwo zayo ezinhle zemishini, i-STS370 ingasetshenziswa futhi ekwakhiweni kwezingxenye ezahlukahlukene zesakhiwo nezemishini, ikakhulukazi ekusetshenzisweni lapho kudingeka khona amandla athile okucindezela.

I-JIS G 3455 STS370 iyinto yensimbi yekhabhoni esetshenziswa ekuhlinzekeni ngomfutho ophezulu. Izinto ezilandelayo zingabhekwa njengezilingana noma cishe ezilingana:

1. I-ASTM A53 Ibanga B: Ifanele ukusetshenziswa kwesakhiwo kanye nokwemishini kanye nokuthuthwa koketshezi.

2. I-API 5L Ibanga B: Amapayipi okuthutha uwoyela negesi anomfutho ophezulu.

3. I-DIN 1629 St37.0: Kobunjiniyela bemishini obujwayelekile kanye nokwakhiwa kwemikhumbi.

4. I-EN 10216-1 P235TR1: Ipayipi lensimbi elingenamthungo lendawo yokushisa ephezulu kanye nengcindezi ephezulu.

5. I-ASTM A106 Ibanga B: Ipayipi lensimbi yekhabhoni elingenamthungo lenkonzo yokushisa okuphezulu.

6.I-ASTM A179: Amapayipi ensimbi athambile adonswa ngokubandayo angenamthungo kanye namapayipi esevisi yokushisa okuphansi.

7. I-DIN 17175 St35.8: Izinto zamapayipi ezingenamthungo zama-boilers kanye nemikhumbi yokucindezela.

8. I-EN 10216-2 P235GH: Amashubhu namapayipi angenamthungo ensimbi engeyona i-alloy ne-alloy yezindawo ezishisa kakhulu nezinomfutho ophezulu.

Kusukela yasungulwa ngo-2014, iBotop Steel isibe ngumhlinzeki ohamba phambili wamapayipi ensimbi yekhabhoni eNyakatho yeShayina, eyaziwa ngenkonzo enhle kakhulu, imikhiqizo esezingeni eliphezulu, kanye nezixazululo eziphelele. Le nkampani inikeza amapayipi ensimbi yekhabhoni ahlukahlukene kanye nemikhiqizo ehlobene nawo, kufaka phakathi ipayipi lensimbi elingenamthungo, i-ERW, i-LSAW, kanye ne-SSAW, kanye nohlu oluphelele lwezihlanganisi zamapayipi nama-flange.

Imikhiqizo yayo ekhethekile ihlanganisa nezinsimbi ezixubile zezinga eliphezulu kanye nezinsimbi ezingagqwali ezenziwe nge-austenitic, ezenzelwe ukuhlangabezana nezidingo zamaphrojekthi ahlukahlukene epayipi.