I-JIS G 3454indinganiso yezimboni yaseJapan yamapayipi ensimbi yekhabhoni yezinhlelo zokucindezela ezinokushisa okuphezulu kokusebenza okungu-350°C. Indinganiso ifaka amamaki amabili:I-STPG 370futhiI-STPG 410Isebenza kumapayipi ahlanganisiwe anokumelana nogesi (i-ERW) noma angenamthungo anobubanzi obujwayelekile obungu-10.5 mm kuya ku-660.4 mm (okungukuthi, kusukela ku-6A kuya ku-650A, noma kusukela ku-1/8B kuya ku-26B).

I-JIS G 3454 Amapayipi ensimbi kumele akhiqizwe kusetshenziswa inhlanganisela efanele yezindlela zokukhiqiza amapayipi ensimbi kanye nezindlela zokuqeda kuthebula elingezansi.

| Uphawu lwebanga | Uphawu lwenqubo yokukhiqiza | ||

| Inqubo yokukhiqiza amapayipi | Indlela yokuqeda | Ukuhlukaniswa kwe-zinc-coating | |

| I-STPG370 I-STPG410 | Akunamthungo: S Ukumelana kukagesi okuhlanganisiwe: E | Okuqediwe ngokushisa: H Kuqediwe ngokubandayo: C Njengoba ukumelana kukagesi kuhlanganisiwe: G | Amapayipi amnyama: amapayipi angafakwanga i-zinc-coating Amapayipi amhlophe: amapayipi afakwe i-zinc-coating |

Ngokuqondile, kunezindlela ezinhlanu zokukhiqiza:

SH: Ipayipi lensimbi elingenamthungo eliqediwe ngokushisa;

I-SC: Ipayipi lensimbi elingenamthungo eliqediwe ngokubandayo;

I-EH: Ipayipi lensimbi elihlanganisiwe eliqediwe ngokumelana nogesi eliqediwe ngokushisa;

I-EC: Ipayipi lensimbi elihlanganisiwe eliqediwe ngokumelana nogesi okuqediwe ngokubandayo;

I-EG: Ipayipi lensimbi elihlanganisiwe elinokumelana nogesi ngaphandle kwaleli eliqediwe ngokushisa kanye neliqediwe ngokushisa.

Insimbi yeBotopungumkhiqizi nomhlinzeki wamapayipi ensimbi yekhabhoni ashiselwe asezingeni eliphezulu avela eShayina, kanye nomthengisi wamapayipi ensimbi angenamthungo. Uma unezidingo, sicela ukhululeke ukuxhumana nathi futhi sizokunikeza ukwesekwa kobuchwepheshe bochwepheshe kwamahhala.

| Uphawu lwebanga | C | Si | Mn | P | S |

| ubuningi | ubuningi | — | ubuningi | ubuningi | |

| I-STPG 370 | 0.25% | 0.35% | 0.30-0.90% | 0.040 % | 0.040% |

| I-STPG 410 | 0.30% | 0.35% | 0.30-1.00% | 0.040 % | 0.040% |

Ivumela ukungezwa kwezinye izinto zokuhlanganisa.

Amandla Okuqina, Ukucindezeleka Kokukhuphula Isilinganiso Noma Ubufakazi, kanye Nobude

| Uphawu yebanga | Amandla okudonsa | Iphuzu lokukhiqiza noma ukucindezeleka kobufakazi | Ukwelulwa ubuncane, % | |||

| Ingxenye yokuhlola eqine | ||||||

| Inombolo 11 noma Inombolo 12 | Inombolo 5 | Inombolo 4 | ||||

| I-N/mm² (i-MPA) | I-N/mm² (i-MPA) | Isiqondiso sokuhlola ukuthambekela | ||||

| umzuzu | umzuzu | Kuhambisana ne-axis yepayipi | Iqonde ngqo ku-axis yepayipi | Kuhambisana ne-axis yepayipi | Iqonde ngqo ku-axis yepayipi | |

| I-STPT370 | 370 | 215 | 30 | 25 | 28 | 23 |

| I-STPT410 | 410 | 245 | 25 | 20 | 24 | 19 |

Ukuhlolwa Kokuthamba

Uma ibanga eliphakathi kwamapuleti amabili lifika ebangeni elishiwo u-H, akumele kube khona iziphambeko noma imifantu ebusweni bepayipi lensimbi.

Kumapayipi ensimbi angenamthungo: H = (1+e)t/(e + t/D);

Kumapayipi ensimbi e-ERW: H = 1/3 D (ye-weld) noma H = 2/3 D (yengxenye engena-weld);

H: ibanga phakathi kwamapuleti okusicaba (mm);

е: okungaguquki okuchazwe ngazinye ngebanga ngalinye lepayipi, 0.08 ye-STPG 370, 0.07 ye-STPG 410;

t: ubukhulu bodonga lwepayipi (mm);

D: ububanzi bangaphandle bepayipi (mm);

Ukuhlolwa Kokuthamba kusebenza kumapayipi ensimbi anobubanzi obujwayelekile obungaphezu kuka-40A (48.6mm).

Ukugoba

Ukugoba kusebenza kumapayipi anobubanzi obungu-40 A (48.6) noma ngaphansi.

Ipayipi kufanele ligotshwe ngama-90° ku-radius ephindwe kasithupha ububanzi bayo bangaphandle. Udonga lwepayipi kumele lungabi namaphutha noma imifantu.

Ipayipi ngalinye lensimbi kumele lihlolwe ngengcindezi ye-hydrostatic noma lihlolwe ngendlela engonakalisi.

Ukuhlolwa Kwamanzi

Gcina ingcindezi ethile okungenani imizuzwana emi-5 ngaphandle kokuvuza.

Inani lokucindezela lihlobene nenombolo yeshejuli yepayipi lensimbi.

| Ukujiya kodonga okujwayelekile | Inombolo yeshejuli: Sch | |||||

| 10 | 20 | 30 | 40 | 60 | 80 | |

| Umfutho wokuhlola omncane we-hydraulic, i-Mpa | 2.0 | 3.5 | 5.0 | 6.0 | 9.0 | 12 |

Ukuhlolwa Okungabhubhisi

Uma kusetshenziswa ukuhlolwa kwe-ultrasonic, kufanele kusekelwe esimisweni esiqinile kunesignali yekilasi le-UD ku-JIS G 0582.

Uma kusetshenziswa ukuhlolwa kwe-eddy current, kufanele kusekelwe kuzinga eliqinile kunesignali yekilasi le-EY ku-JIS G 0583.

| Ububanzi obujwayelekile | Ububanzi bangaphandle | Ubukhulu bodonga | Isisindo seyunithi | Inombolo yeshejuli (Inombolo yeSch) | |

| A | B | mm | mm | kg/m | |

| 6 | 1/8 | 10.5 | 1.7 | 0.369 | 40 |

| 6 | 1/8 | 10.5 | 2.2 | 0.450 | 60 |

| 6 | 1/8 | 10.5 | 2.4 | 0.479 | 80 |

| 8 | 1/4 | 13.8 | 2.2 | 0.629 | 40 |

| 8 | 1/4 | 13.8 | 2.4 | 0.675 | 60 |

| 8 | 1/4 | 13.8 | 3.0 | 0.799 | 80 |

| 10 | 3/8 | 17.3 | 2.3 | 0.851 | 40 |

| 10 | 3/8 | 17.3 | 2.8 | 1.00 | 60 |

| 10 | 3/8 | 17.3 | 3.2 | 1.11 | 80 |

| 15 | 1/2 | 21.7 | 2.8 | 1.31 | 40 |

| 15 | 1/2 | 21.7 | 3.2 | 1.46 | 60 |

| 15 | 1/2 | 21.7 | 3.7 | 1.64 | 80 |

| 20 | 3/4 | 27.2 | 2.9 | 1.74 | 40 |

| 20 | 3/4 | 27.2 | 3.4 | 2.00 | 60 |

| 20 | 3/4 | 27.2 | 3.9 | 2.24 | 80 |

| 25 | 1 | 34.0 | 3.4 | 2.57 | 40 |

| 25 | 1 | 34.0 | 3.9 | 2.89 | 60 |

| 25 | 1 | 34.0 | 4.5 | 3.27 | 80 |

| 32 | 1 1/4 | 42.7 | 3.6 | 3.47 | 40 |

| 32 | 1 1/4 | 42.7 | 4.5 | 4.24 | 60 |

| 32 | 1 1/4 | 42.7 | 4.9 | 4.57 | 80 |

| 40 | 1 1/2 | 48.6 | 3.7 | 4.10 | 40 |

| 40 | 1 1/2 | 48.6 | 4.5 | 4.89 | 60 |

| 40 | 1 1/2 | 48.6 | 5.1 | 5.47 | 80 |

| 50 | 2 | 60.5 | 3.2 | 4.52 | 20 |

| 50 | 2 | 60.5 | 3.9 | 5.44 | 40 |

| 50 | 2 | 60.5 | 4.9 | 6.72 | 60 |

| 50 | 2 | 60.5 | 5.5 | 7.46 | 80 |

| 65 | 2 1/2 | 76.3 | 4.5 | 7.97 | 20 |

| 65 | 2 1/2 | 76.3 | 5.2 | 9.12 | 40 |

| 65 | 2 1/2 | 76.3 | 6.0 | 10.4 | 60 |

| 65 | 2 1/2 | 76.3 | 7.0 | 12.0 | 80 |

| 80 | 3 | 89.1 | 4.5 | 9.39 | 20 |

| 80 | 3 | 89.1 | 5.5 | 11.3 | 40 |

| 80 | 3 | 89.1 | 6.6 | 13.4 | 60 |

| 80 | 3 | 89.1 | 7.6 | 15.3 | 80 |

| 90 | 3 1/2 | 101.6 | 4.5 | 10.8 | 20 |

| 90 | 3 1/2 | 101.6 | 5.7 | 13.5 | 40 |

| 90 | 3 1/2 | 101.6 | 7.0 | 16.3 | 60 |

| 90 | 3 1/2 | 101.6 | 8.1 | 18.7 | 80 |

| 100 | 4 | 114.3 | 4.9 | 13.2 | 20 |

| 100 | 4 | 114.3 | 6.0 | 16.0 | 40 |

| 100 | 4 | 114.3 | 7.1 | 18.8 | 60 |

| 100 | 4 | 114.3 | 8.6 | 22.4 | 80 |

| 125 | 5 | 139.8 | 5.1 | 16.9 | 20 |

| 125 | 5 | 139.8 | 6.6 | 12.7 | 40 |

| 125 | 5 | 139.8 | 8.1 | 26.3 | 60 |

| 125 | 5 | 139.8 | 9.5 | 30.5 | 80 |

| 150 | 6 | 165.2 | 5.5 | 21.7 | 20 |

| 150 | 6 | 165.2 | 7.1 | 27.7 | 40 |

| 150 | 6 | 165.2 | 9.3 | 35.8 | 60 |

| 150 | 6 | 165.2 | 11.0 | 41.8 | 80 |

| 200 | 8 | 216.3 | 6.4 | 33.1 | 20 |

| 200 | 8 | 216.3 | 7.0 | 36.1 | 30 |

| 200 | 8 | 216.3 | 8.2 | 42.1 | 40 |

| 200 | 8 | 216.3 | 10.3 | 52.3 | 60 |

| 200 | 8 | 216.3 | 12.7 | 63.8 | 80 |

| 250 | 10 | 267.4 | 6.4 | 41.2 | 20 |

| 250 | 10 | 267.4 | 7.8 | 49.9 | 30 |

| 250 | 10 | 267.4 | 9.3 | 59.2 | 40 |

| 250 | 10 | 267.4 | 12.7 | 79.8 | 60 |

| 250 | 10 | 267.4 | 15.1 | 93.9 | 80 |

| 300 | 12 | 318.5 | 6.4 | 49.3 | 20 |

| 300 | 12 | 318.5 | 8.4 | 64.2 | 30 |

| 300 | 12 | 318.5 | 10.3 | 78.3 | 40 |

| 300 | 12 | 318.5 | 14.3 | 107 | 60 |

| 300 | 12 | 318.5 | 17.4 | 129 | 80 |

| 350 | 14 | 355.6 | 6.4 | 55.1 | 10 |

| 350 | 14 | 355.6 | 7.9 | 67.7 | 20 |

| 350 | 14 | 355.6 | 9.5 | 81.1 | 30 |

| 350 | 14 | 355.6 | 11.1 | 94.3 | 40 |

| 350 | 14 | 355.6 | 15.1 | 127 | 60 |

| 350 | 14 | 355.6 | 19.0 | 158 | 80 |

| 400 | 16 | 406.4 | 6.4 | 63.1 | 10 |

| 400 | 16 | 406.4 | 7.9 | 77.6 | 20 |

| 400 | 16 | 406.4 | 9.5 | 93.0 | 30 |

| 400 | 16 | 406.4 | 12.7 | 123 | 40 |

| 400 | 16 | 406.4 | 16.7 | 160 | 60 |

| 400 | 16 | 406.4 | 21.4 | 203 | 80 |

| 450 | 18 | 457.2 | 6.4 | 71.1 | 10 |

| 450 | 18 | 457.2 | 7.9 | 87.5 | 20 |

| 450 | 18 | 457.2 | 11.1 | 122 | 30 |

| 450 | 18 | 457.2 | 14.3 | 156 | 40 |

| 450 | 18 | 457.2 | 19.0 | 205 | 60 |

| 450 | 18 | 457.2 | 23.8 | 254 | 80 |

| 500 | 20 | 508.0 | 6.4 | 79.2 | 10 |

| 500 | 20 | 508.0 | 9.5 | 117 | 20 |

| 500 | 20 | 508.0 | 12.7 | 155 | 30 |

| 500 | 20 | 508.0 | 15.1 | 184 | 40 |

| 500 | 20 | 508.0 | 20.6 | 248 | 60 |

| 500 | 20 | 508.0 | 26.2 | 311 | 80 |

| 550 | 22 | 558.8 | 6.4 | 87.2 | 10 |

| 550 | 22 | 558.8 | 9.5 | 129 | 20 |

| 550 | 22 | 558.8 | 12.7 | 171 | 30 |

| 550 | 22 | 558.8 | 15.9 | 213 | 40 |

| 600 | 24 | 609.6 | 6.4 | 95.2 | 10 |

| 600 | 24 | 609.6 | 9.5 | 141 | 20 |

| 600 | 24 | 609.6 | 14.3 | 210 | 30 |

| 650 | 26 | 660.4 | 7.9 | 127 | 10 |

| 650 | 26 | 660.4 | 12.7 | 203 | 20 |

I-JIS G 3454 ihlanganisaishejuli 10, ishejuli 20, ishejuli 30, ishejuli 40, ishejuli 60, futhiishejuli 80.

Ungachofoza ku-schedule No. ofuna ukuyibuka; sihlele izinguqulo ze-PDF ezifanele ukuze kube lula kuwe.

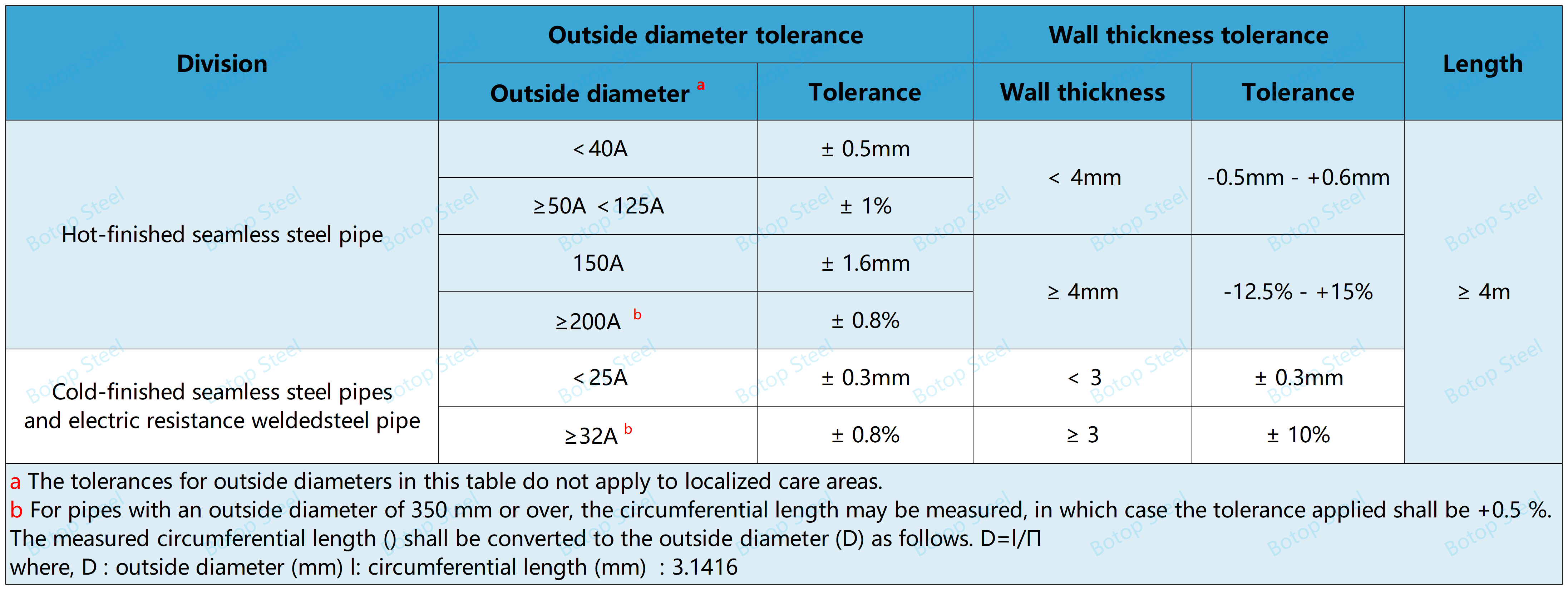

I-JIS G 3454 Ukubekezelelana kobubanzi bangaphandle, ukujiya kodonga, ukungezwani, kanye nobude kufanele kuhlangabezane nezidingo ezilandelayo.

Kusukela yasungulwa ngo-2014, iBotop Steel isibe ngumhlinzeki ohamba phambili wamapayipi ensimbi yekhabhoni eNyakatho yeShayina, eyaziwa ngenkonzo enhle kakhulu, imikhiqizo esezingeni eliphezulu, kanye nezixazululo eziphelele.

Le nkampani inikeza izinhlobo ezahlukene zamapayipi ensimbi yekhabhoni kanye nemikhiqizo ehlobene nawo, okuhlanganisa ipayipi lensimbi elingenamthungo, i-ERW, i-LSAW, kanye ne-SSAW, kanye nohlu oluphelele lwezihlanganisi zamapayipi nama-flange.

Imikhiqizo yayo ekhethekile ihlanganisa nezinsimbi ezixubile zezinga eliphezulu kanye nezinsimbi ezingagqwali ezenziwe nge-austenitic, ezenzelwe ukuhlangabezana nezidingo zamaphrojekthi ahlukahlukene epayipi.

Sicela usithinte, sizokunikeza amapayipi ensimbi asezingeni eliphezulu, ajwayelekile anesevisi yobungcweti nephumelelayo. I-Botop ilangazelela ukukukhonza.