Ipayipi lensimbi le-JIS G 3461iyipayipi lensimbi yekhabhoni elingenamthungo (SMLS) noma elinokumelana nogesi (ERW), elisetshenziswa kakhulu kuma-boiler kanye nama-heat exchanger ukuze kusetshenziswe njengokushintshana kokushisa phakathi kwangaphakathi nangaphandle kwepayipi.

I-STB340iyizinga lepayipi lensimbi yekhabhoni ngokwezinga le-JIS G 3461. Inamandla okudonswa okungenani angu-340 MPa kanye namandla okukhiqiza okungenani angu-175 MPa.

Kuyinto ekhethwayo ezisetshenziswa ezimbonini eziningi ngenxa yamandla ayo aphezulu, ukuzinza okuhle kokushisa, ukuzivumelanisa nezimo, ukumelana nokugqwala okuhlobene, ukusebenza kahle kwezindleko, kanye nokucutshungulwa okuhle.

I-JIS G 3461inezigaba ezintathu.STB340, STB410, STB510.

I-STB340: Amandla amancane okudonseka: 340 MPa; Amandla amancane okukhiqiza: 175 MPa.

I-STB410: Amandla Okuqinela Aphansi: 410 MPa; Amandla Okukhuphula Aphansi: 255 MPa.

I-STB510:Amandla Okuqinela Aphansi: 510 MPa; Amandla Okukhuphula Aphansi: 295 MPa.

Eqinisweni, akunzima ukuthola ukuthi ibanga le-JIS G 3461 lihlukaniswe ngokwamandla amancane okunamathela kwepayipi lensimbi.

Njengoba izinga lezinto ezibonakalayo likhula, amandla azo okubamba kanye nokukhiqiza ayanda ngokufanele, okuvumela izinto ezibonakalayo ukuthi zikwazi ukumelana nemithwalo ephezulu kanye nezingcindezi ezindaweni zokusebenza ezidinga kakhulu.

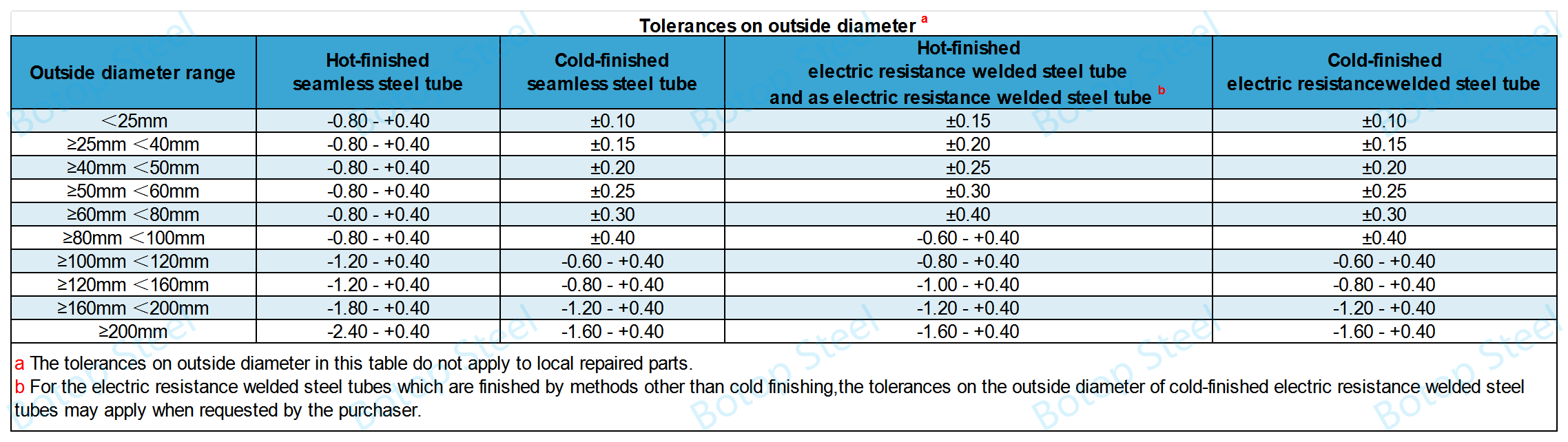

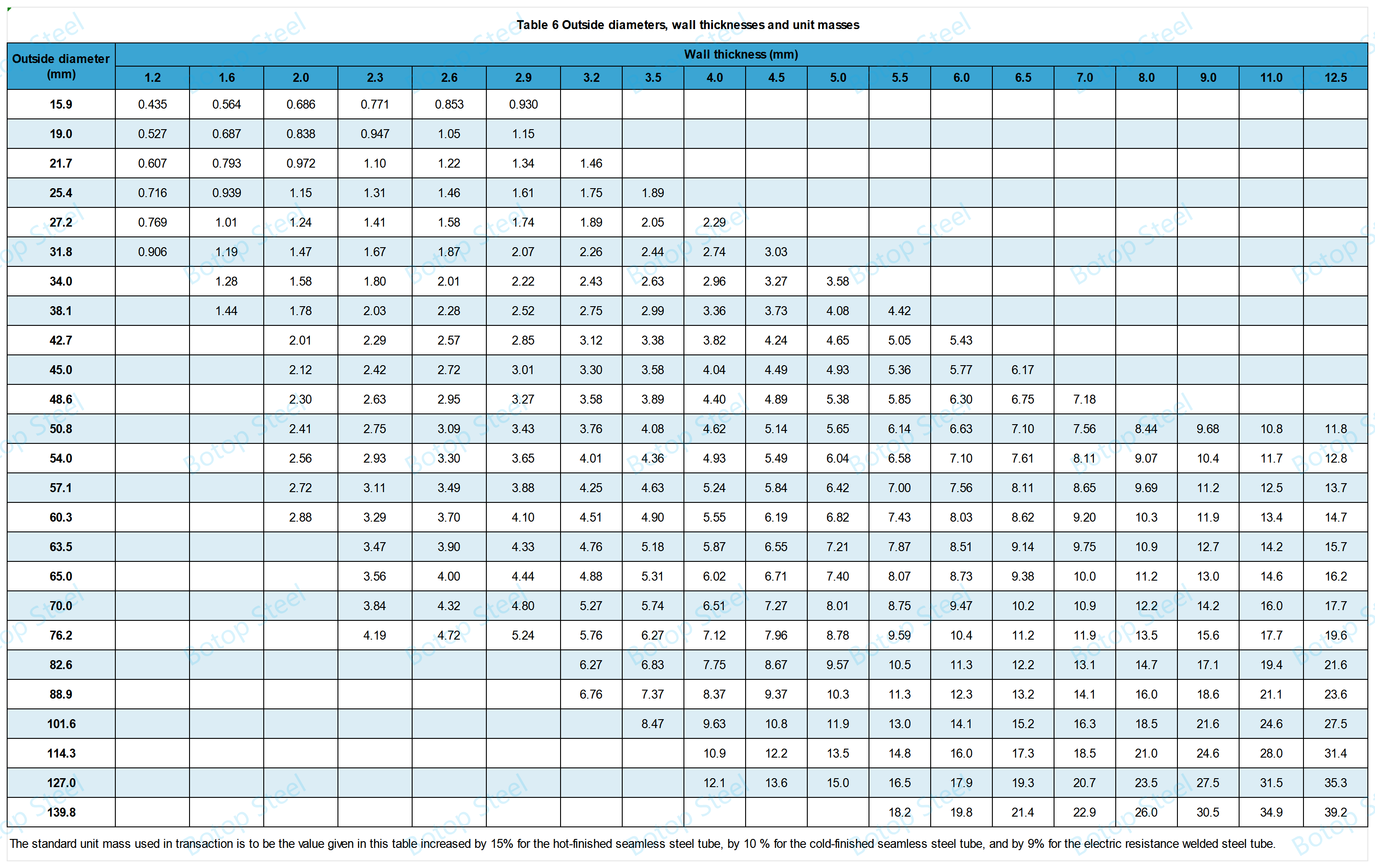

Ububanzi bangaphandle buyi-15.9-139.8mm.

Ukusetshenziswa kuma-boiler kanye nama-heat exchanger ngokuvamile akudingi ububanzi obukhulu kakhulu be-tube. Ububanzi be-tube obuncane bukhulisa ukusebenza kahle kokushisa ngoba isilinganiso sendawo ebusweni kuya kuvolumu yokudlulisa ukushisa siphezulu. Lokhu kusiza ukudlulisa amandla okushisa ngokushesha nangendlela ephumelelayo.

Amapayipi kufanele akhiqizwe kusukela ku-insimbi ebulewe.

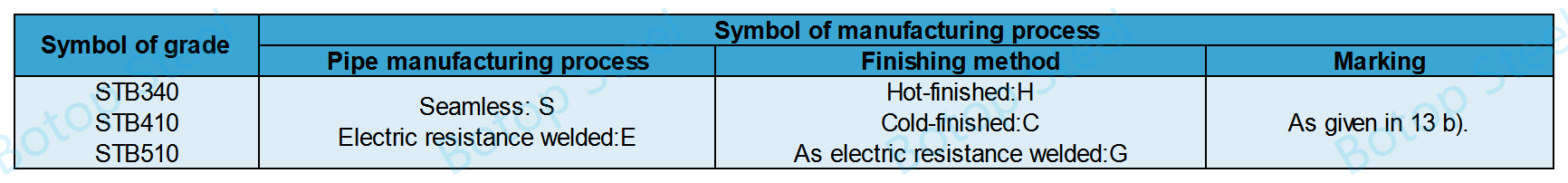

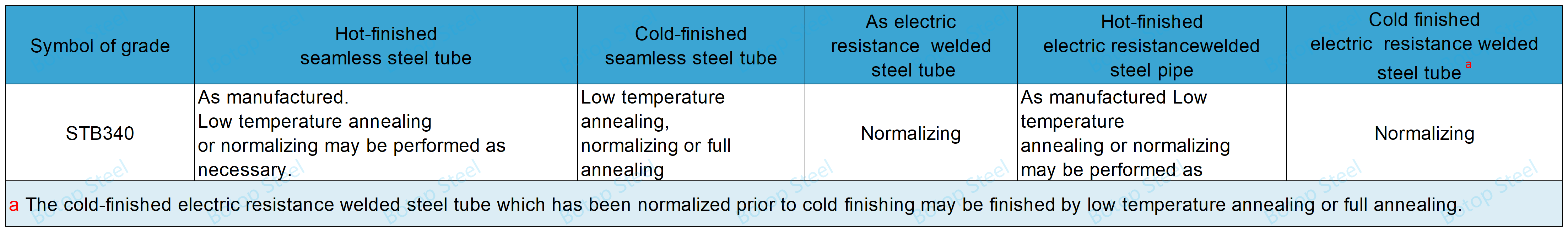

Inhlanganisela yezindlela zokukhiqiza amapayipi kanye nezindlela zokuqeda.

Ngokuningiliziwe, zingahlukaniswa kanje:

Ishubhu yensimbi engenamthungo eqediwe ngokushisa: SH

Ishubhu yensimbi engenamthungo eqediwe ngokubandayo: SC

Njengoba ukumelana kagesi okuhlanganisiwe ngepayipi lensimbi: EG

Ishubhu yensimbi ehlanganisiwe yokumelana kagesi eqediwe ngokushisa: EH

Ishubhu yensimbi ehlanganisiwe yokumelana nogesi eqediwe ngokubandayo: EC

Nansi indlela yokukhiqiza i-Hot-finished seamless.

Ngenqubo yokukhiqiza engenamthungo, ingahlukaniswa ngamapayipi ensimbi angenamthungo anobubanzi bangaphandle obungaphezu kuka-30mm kusetshenziswa ukukhiqizwa kokuqeda okushisayo, kanye no-30mm kusetshenziswa ukukhiqizwa kokuqeda okubandayo.

Izindlela zokuhlaziya ukushisa kufanele zihambisane nezindinganiso eziku-JIS G 0320.

Izinto zokuhlanganisa ngaphandle kwalezo zingangezwa ukuze kutholakale izakhiwo ezithile.

Uma umkhiqizo uhlaziywa, amanani okuphambuka kokwakheka kwamakhemikhali epayipi kufanele ahlangabezane nezidingo zeThebula 3 le-JIS G 0321 lamapayipi ensimbi angenamthungo kanye neThebula 2 le-JIS G 0321 lamapayipi ensimbi ashiselwe ngokumelana.

| Uphawu lwebanga | C (Ikhabhoni) | I-Si (i-Silicon) | I-Mn (i-Manganese) | I-P (i-Phosphorus) | S (Isibabule) |

| ubuningi | ubuningi | ubuningi | ubuningi | ||

| I-STB340 | 0.18 | 0.35 | 0.30-0.60 | 0.35 | 0.35 |

| Umthengi angacacisa inani le-Si eliphakathi kuka-0.10% kuya ku-0.35%. | |||||

Ukwakheka kwamakhemikhali kwe-STB340 kuklanyelwe ukuqinisekisa izakhiwo ezanele zemishini kanye nokusebenza kahle kwayo ngenkathi kwenza izinto zifanelekele ukushisela kanye nokusetshenziswa ezindaweni ezishisa kakhulu.

| Uphawu lwebanga | Amandla okudonsa a | Iphuzu lokukhiqiza noma ukucindezeleka kobufakazi | Ubuncane bobude, % | ||

| Ububanzi bangaphandle | |||||

| <10mm | ≥10mm <20mm | ≥20mm | |||

| I-N/mm² (i-MPA) | I-N/mm² (i-MPA) | Ingxenye yokuhlola | |||

| Inombolo 11 | Inombolo 11 | Inombolo 11/Inombolo 12 | |||

| umzuzu | umzuzu | Isiqondiso sokuhlola ukuthambekela | |||

| Ihambisana ne-axis yeshubhu | Ihambisana ne-axis yeshubhu | Ihambisana ne-axis yeshubhu | |||

| I-STB340 | 340 | 175 | 27 | 30 | 35 |

Qaphela: kuphela amashubhu okushintshanisa ukushisa, umthengi angase, lapho kudingeka, achaze inani eliphezulu lamandla okudonsa. Kulesi simo, inani eliphezulu lamandla okudonsa kufanele libe inani elitholakala ngokungeza u-120 N/mm² enanini elikuleli thebula.

Uma kwenziwa ukuhlolwa kokuthamba engxenyeni yokuhlolwa engu-12 yepayipi elingaphansi kuka-8 mm ubukhulu bodonga.

| Uphawu lwebanga | Ingxenye yokuhlola esetshenzisiwe | Ukwelulwa ubuncane, % | ||||||

| Ubukhulu bodonga | ||||||||

| >1 ≤2 mm | >2 ≤3 mm | >3 ≤4 mm | >4 ≤5 mm | >5 ≤6 mm | >6 ≤7 mm | >7 <8 mm | ||

| I-STB340 | Inombolo 12 | 26 | 28 | 29 | 30 | 32 | 34 | 35 |

Amanani okunwebeka kuleli thebula abalwa ngokukhipha u-1.5% enanini lokunwebeka elinikezwe kuThebula 4 ngokuncipha ngakunye okungu-1 mm kobukhulu bodonga lweshubhu kusuka ku-8 mm, nangokufingqa umphumela ube yinombolo ephelele ngokusho koMthetho A we-JIS Z 8401.

Indlela yokuhlola kufanele ihambisane ne-JIS Z 2245. Ubulukhuni bengxenye yokuhlola kufanele bulinganiswe engxenyeni yayo noma ebusweni bangaphakathi ezindaweni ezintathu ngengxenye ngayinye yokuhlola.

| Uphawu lwebanga | Ubulukhuni beRockwell (inani eliphakathi lezikhundla ezintathu) I-HRBW |

| I-STB340 | 77 ubuningi. |

| I-STB410 | 79 ubuningi. |

| STB510 | 92 ubuningi. |

Lokhu kuhlolwa akufanele kwenziwe emapayipini anobukhulu bodonga obungu-2 mm noma ngaphansi. Kumapayipi ensimbi ahlanganisiwe anokumelana nogesi, ukuhlolwa kufanele kwenziwe engxenyeni engeyona eye-weld noma ezindaweni ezithintekile ekushiseni.

Akusebenzi kumapayipi ensimbi angenamthungo.

Indlela Yokuhlola Beka isampula emshinini bese uyibamba kuze kube yilapho ibanga eliphakathi kwamapulatifomu amabili lifinyelela inani elibekiwe u-H. Bese uhlola isampula ukuthi ayinamifantu yini.

Uma kuhlolwa ipayipi elihlanganisiwe elinokumelana okubucayi, umugqa ophakathi kwe-weld kanye nesikhungo sepayipi uqonde ngqo esiqondisweni sokucindezela.

H=(1+e)t/(e+t/D)

H: ibanga phakathi kwama-platens (mm)

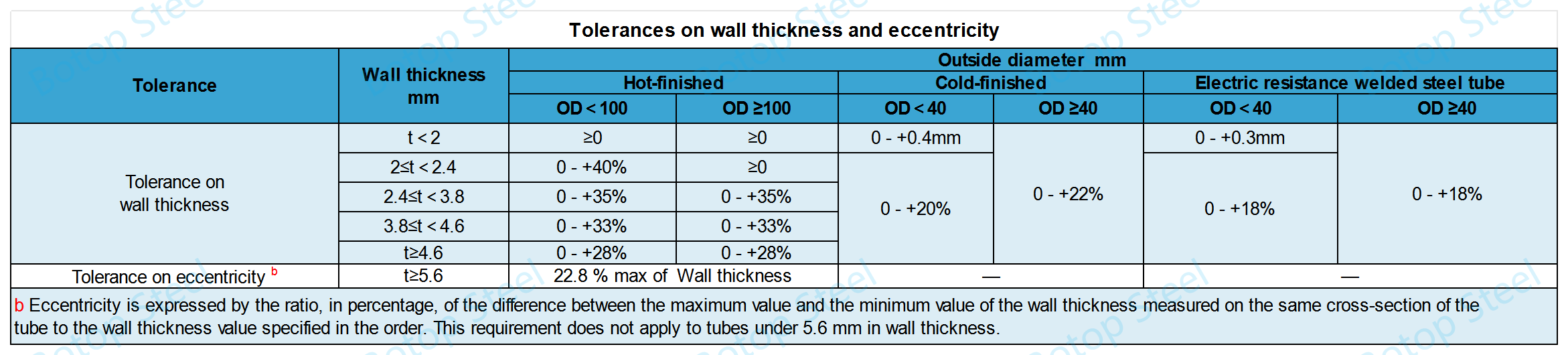

t: ukujiya kodonga lwepayipi (mm)

D: ububanzi obungaphandle kwepayipi (mm)

e:okungaguquki okuchazwe esigabeni ngasinye sethubhu. STB340: 0.09; STB410: 0.08; STB510: 0.07.

Akusebenzi kumapayipi ensimbi angenamthungo.

Ukuphela kwesampula kuvutha ekushiseni kwegumbi (5°C kuya ku-35°C) ngethuluzi eliyindilinga nge-engeli engu-60° kuze kube yilapho ububanzi bangaphandle bukhuliswa ngesilinganiso esingu-1.2 futhi kuhlolwe ukuthi akukho yini imifantu.

Le mfuneko iyasebenza nasemapayipini anobubanzi bangaphandle obungaphezu kuka-101.6 mm.

Ukuhlolwa kokuthambekela okuphambene kungase kushiywe lapho kwenziwa ukuhlolwa kokuthambekela.

Sika ingxenye yokuhlola engu-100 mm ubude komunye umkhawulo wepayipi bese usika ingxenye yokuhlola ibe yisigamu esingu-90° kusukela emugqeni wokushisela ezinhlangothini zombili zomjikelezo, uthathe ingxenye equkethe ukushisela njengengxenye yokuhlola.

Ezingeni lokushisa legumbi (5°C kuya ku-35°C) beka isampula ibe yipuleti eline-weld phezulu bese uhlola isampula ukuthi ayinayo imifantu yini ku-weld.

Wonke amapayipi ensimbi kudingeka ahlolwe ngamanzi noma angabhubhisiukuqinisekisa ikhwalithi nokuphepha kwepayipi kanye nokuhlangabezana nezindinganiso zokusetshenziswa.

Ukuhlolwa kwe-Hydraulic

Bamba ingaphakathi lepayipi ngokucindezela okungenani noma okuphezulu kwe-P (P max 10 MPa) okungenani imizuzwana emi-5, bese uhlola ukuthi ipayipi lingakwazi ukumelana nokucindezela ngaphandle kokuvuza.

P=2st/D

P: ingcindezi yokuhlola (i-MPa)

t: ubukhulu bodonga lwepayipi (mm)

D: ububanzi bangaphandle bepayipi (mm)

s: 60% yenani eliphansi elishiwo lephuzu lokukhiqiza noma ukucindezeleka kobufakazi.

Ukuhlolwa Okungabhubhisi

Ukuhlolwa kwamashubhu ensimbi okungabhubhisi kufanele kwenziwe yi-ukuhlolwa kwe-ultrasonic noma kwe-eddy current.

Ngobai-ultrasoundizici zokuhlola, isignali evela kusampula yokubhekisela equkethe indinganiso yokubhekisela yekilasi le-UD njengoba kuchaziwe kuI-JIS G 0582kuzobhekwa njengezinga le-alamu futhi kuzoba nesignali eyisisekelo elingana noma enkulu kunezinga le-alamu.

Ukuzwela okujwayelekile kokutholwa kwe-ugesi we-eddyukuhlolwa kufanele kube yisigaba se-EU, i-EV, i-EW, noma i-EX esichazwe kuI-JIS G 0583, futhi akufanele kube khona izimpawu ezilingana noma ezinkulu kunezibonakaliso ezivela kusampula yokubhekisela equkethe indinganiso yokubhekisela yesigaba esishiwoyo.

Ukuze uthole okwengeziweAmashadi Esisindo Sepayipi kanye Namashejuli Epayipingaphakathi kwendinganiso, ungachofoza.

Sebenzisa indlela efanele yokubhala amalebula ulwazi olulandelayo.

a) Uphawu lwebanga;

b) Uphawu lwendlela yokukhiqiza;

c) Ubukhulu: ububanzi bangaphandle kanye nobukhulu bodonga;

d) Igama lomkhiqizi noma uhlobo olumchazayo.

Uma ukumaka eshubhuni ngalinye kunzima ngenxa yobubanzi balo obuncane bangaphandle noma uma umthengi ecela kanjalo, ukumaka kunganikezwa eshubhuni ngalinye ngendlela efanele.

I-STB340 ivame ukusetshenziswa ekwakhiweni kwamapayipi amanzi namapayipi omoya ophumayo kuma-boiler ahlukahlukene ezimboni, ikakhulukazi ezindaweni lapho kudingeka khona ukumelana namazinga okushisa aphezulu kanye nokucindezela.

Ngenxa yezakhiwo zayo ezinhle zokuhambisa ukushisa, ifaneleka futhi ekwakhiweni kwamapayipi okushintshanisa ukushisa, okusiza ukudlulisa ukushisa kahle phakathi kwemidiya ehlukene.

Ingasetshenziswa futhi ukuthutha uketshezi olushisa kakhulu noma olunomfutho ophezulu, njengomusi noma amanzi ashisayo, futhi isetshenziswa kabanzi ezimbonini zokukhiqiza amakhemikhali, amandla kagesi, kanye nemishini.

I-ASTM A106 Ibanga A

I-DIN 17175 St35.8

I-DIN 1629 St37.0

I-BS 3059-1 Ibanga 320

I-EN 10216-1 P235GH

I-GB 3087 20#

I-GB 5310 20G

Nakuba lezi zinto zingase zifane ngokwendlela yokwakheka kwamakhemikhali kanye nezakhiwo eziyisisekelo, izinqubo ezithile zokwelapha ukushisa kanye nomshini wokugaya kungathinta izakhiwo zomkhiqizo wokugcina.

Ngakho-ke, ukuqhathanisa okuningiliziwe kanye nokuhlolwa okufanele kufanele kwenziwe lapho kukhethwa izinto ezilinganayo zezicelo ezisebenzayo.

Kusukela yasungulwa ngo-2014, iBotop Steel isibe ngumhlinzeki ohamba phambili wamapayipi ensimbi yekhabhoni eNyakatho yeShayina, eyaziwa ngenkonzo enhle kakhulu, imikhiqizo esezingeni eliphezulu, kanye nezixazululo eziphelele. Le nkampani inikeza amapayipi ensimbi yekhabhoni ahlukahlukene kanye nemikhiqizo ehlobene nawo, kufaka phakathi ipayipi lensimbi elingenamthungo, i-ERW, i-LSAW, kanye ne-SSAW, kanye nohlu oluphelele lwezihlanganisi zamapayipi nama-flange.

Imikhiqizo yayo ekhethekile ihlanganisa nezinsimbi ezixubile zezinga eliphezulu kanye nezinsimbi ezingagqwali ezenziwe nge-austenitic, ezenzelwe ukuhlangabezana nezidingo zamaphrojekthi ahlukahlukene epayipi.