I-EN 10210 S355J2Hiyinsimbi yesakhiwo esingenalutho esiqediwe ngokushisa ngokushoI-EN 10210enamandla okukhiqiza okungenani angu-355 MPa (ngobukhulu bodonga ≤ 16 mm) kanye nezakhiwo ezinhle zokuthinteka emazingeni okushisa aphansi afinyelela ku--20°C, okwenza kube kuhle ukusetshenziswa ezinhlotsheni eziningi zezakhiwo nezobunjiniyela.

Yebo, i-EN 10210 =I-BS EN 10210.

I-BS EN 10210 kanye ne-EN 10210 ziyafana ngokuqukethwe kobuchwepheshe futhi zombili zimelela amazinga aseYurophu okuklama, ukukhiqiza, kanye nezidingo zezingxenye ezingenalutho ezakhiwe ngesakhiwo esinokushisa.

I-BS EN 10210 inguqulo eyamukelwa e-UK, kanti i-EN 10210 iyindinganiso yaseYurophu yonke. Izinhlangano ezahlukene zokulinganisa zikazwelonke zingase ziqale indinganiso ngezifinyezo ezithile zikazwelonke, kodwa okuqukethwe okuyinhloko kwale ndinganiso kuhlala kungaguquguquki.

Izingxenye ezingenalutho zingahlukaniswa njengendilinga, isikwele noma unxande, noma i-elliptical.

Futhi ngoba kuyinqubo eqediwe eshisayo ngokuhambisana ne-EN 10210, isifinyezo esilandelayo singasetshenziswa.

I-HFCHS= izingxenye ezingenalutho eziqediwe ezishisayo neziyindilinga;

I-HFRHS= izingxenye ezingenalutho eziqediwe eziyisikwele noma eziyisikwele;

I-HFEHS= izingxenye ezingenalutho eziqediwe ezi-elliptical ezishisayo.

Isiyingi: Ububanzi bangaphandle obufika ku-2500 mm;

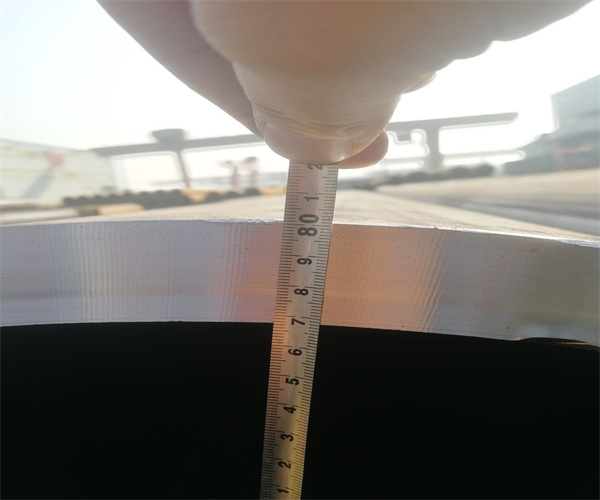

Ubukhulu bodonga bufika ku-120 mm.

Vele, ayikho indlela yokukhiqiza amashubhu alolu hlobo kanye nobukhulu bodonga uma kusetshenziswa inqubo yokushisela ye-ERW.

I-ERW ingakhiqiza amashubhu afinyelela ku-660mm anobukhulu bodonga obungu-20mm.

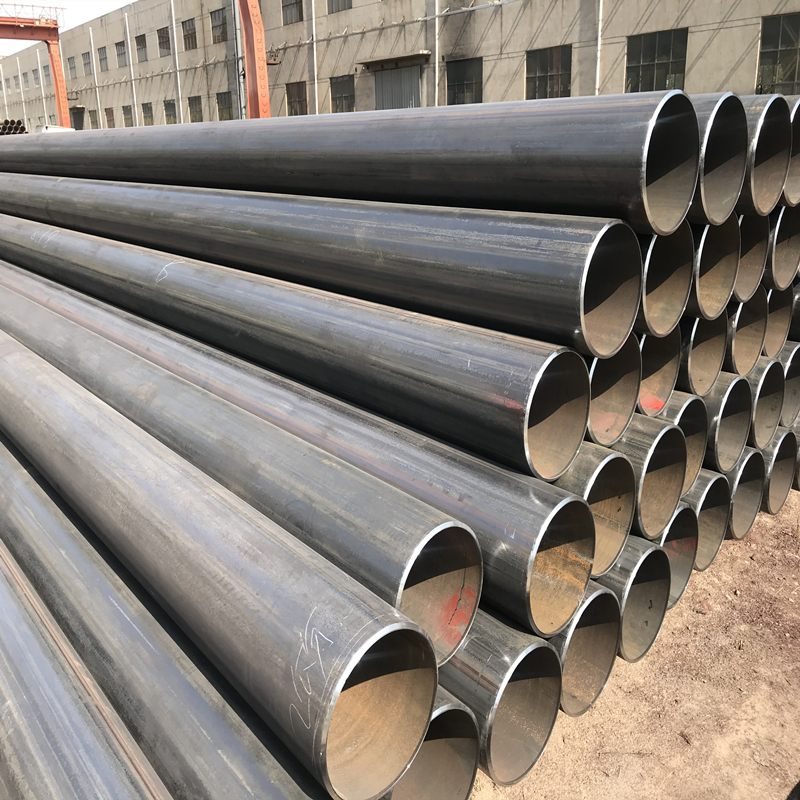

Insimbi ingakhiqizwa ngokusebenzisai-seamless noma i-weldinginqubo.

Phakathi kweizinqubo zokushisela, izindlela ezivamile zokushisela zifaka phakathiI-ERW(ukushisela ukumelana kagesi) kanyeI-SAW(ukushisela i-arc okucwiliswe emanzini).

Phakathi kwabanye,I-ERWkuyindlela yokushisela ehlanganisa izingxenye zensimbi ndawonye ngokushisa nokucindezela okumelanayo. Le ndlela isebenza ezintweni eziningi kanye nobukhulu futhi yenza inqubo yokushisela isebenze kahle.

I-SAWNgakolunye uhlangothi, kuyindlela yokushisela esebenzisa i-granular flux ukumboza i-arc, ehlinzeka ngokungena okujulile kanye nekhwalithi engcono yokushisela futhi ifaneleka kakhulu ekushiseleni amapuleti aminyene.

Okulandelayo, inqubo ye-ERW, okuyindlela yokukhiqiza esebenza kahle kakhulu esetshenziswa kabanzi ukukhiqiza amashubhu ensimbi ahlukahlukene kanye namaphrofayili.

Kufanele kuqashelwe ukuthi ezingxenyeni ezingaxutshiwe nezingenazinhlayiya ezinhle ezenziwe ngenqubo yokushisela, ukulungisa ama-weld akuvunyelwe ngaphandle kokushisela i-arc engaphansi kwamanzi.

Ikhwalithi JR, JO, J2 kanye ne-K2 - iqediwe kahle,

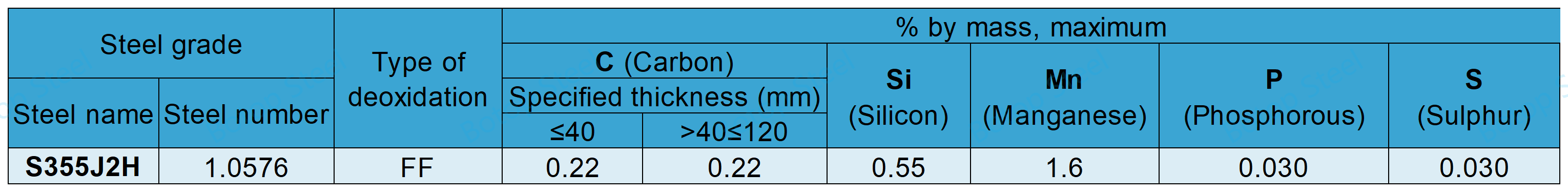

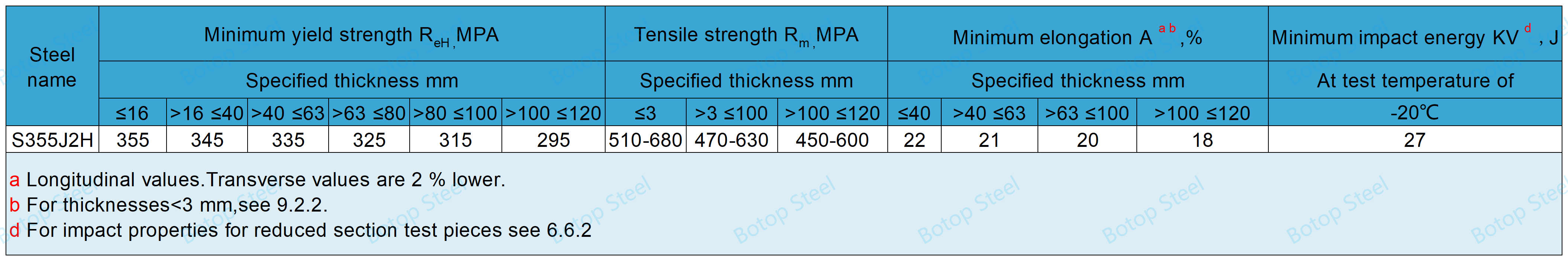

Amandla okukhiqiza amancane kakhulu epayipi lensimbi le-S355J2H awazinzile, azoshintsha ngobukhulu obuhlukile bodonga.

Ngokukhethekile, amandla okukhiqiza e-S355J2H abekwa ngokwezinga lapho ubukhulu bodonga bungaphansi noma bulingana no-16mm, kodwa lapho ubukhulu bodonga bukhula, amandla okukhiqiza azoncishiswa, ngakho-ke akuwona wonke amapayipi ensimbi e-S355J2H angafinyelela amandla okukhiqiza amancane angu-355MPa.

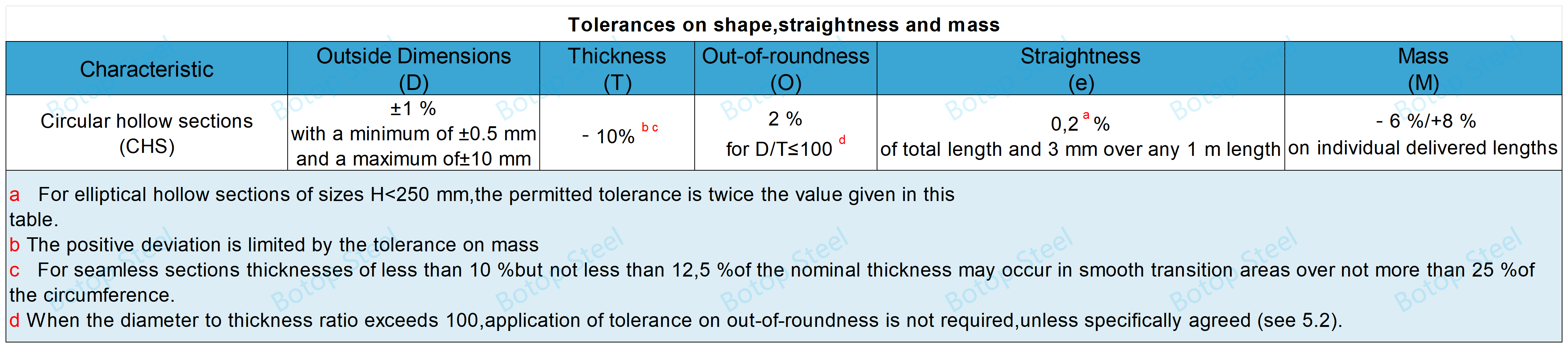

Ukubekezelela ukuma, ukuqondile kanye nobukhulu

Ubude bokubekezelelana

| Uhlobo lobudea | Ububanzi bobude noma ubude L | Ukubekezelelana |

| Ubude obungahleliwe | 4000≤L≤16000 ngebanga elingu-2000 ngento ngayinye ye-oda | Izingxenye eziyi-10% ezinikeziwe zingaba ngaphansi kobuncane bebanga eli-odiwe kodwa zingabi mfushane kune-75% yobude bebanga obuncane. |

| Ubude obulinganiselwe | 4000≤L≤16000 | ±500 mmb |

| Ubude obuqondile | 2000≤L≤6000 | 0 - +10mm |

| 6000c | 0 - +15mm | |

| aUmenzi kufanele aqinisekise ngesikhathi sophenyo futhi a-ode uhlobo lobude oludingekayo kanye nobubanzi noma ubude bobude. bI-Onion 21 ukubekezelelana kobude be-annrevimata kungu-0 - +150mm cUbude obuvamile obutholakalayo buyi-6 m kanye ne-12 m. | ||

Ipayipi lensimbi le-S355J2H liyipayipi lensimbi eliqinile kakhulu elinokusebenza kahle kokushisela kanye nokuqina komthelela ophansi, ngakho-ke linokusetshenziswa okubanzi emikhakheni eminingana yezimboni.

1. Ukwakhiwa: isetshenziswa emabhulohweni, emibhoshongweni, ezakhiweni zohlaka, ezokuthutha ngesitimela, ezitimeleni ezingaphansi komhlaba, ozimele bophahla, amaphaneli odonga, nezinye izakhiwo zesakhiwo.

2. Uhlelo lwamapayipi: Isetshenziswa njengamapayipi okuthutha uketshezi, ikakhulukazi ezimweni lapho kudingeka khona amandla aphezulu kanye nokumelana nengcindezi.

3. Ubunjiniyela bezolwandle kanye nolwandle: esetshenziswa ezakhiweni zemikhumbi, amapulatifomu asogwini lolwandle, kanye nezinye izakhiwo zobunjiniyela basolwandle.

4. Imboni yamandla: esetshenziswa ezindaweni zamandla njengemibhoshongo yamandla omoya, amapulatifomu okumba uwoyela, kanye namapayipi.

5. Imithambo yokucindezela: isetshenziswa ekwakhiweni kwemithambo yokucindezela ngokuhambisana nezidingo ezithile zokushisela kanye nokwelashwa kokushisa.

6. Imboni yezimayini: esetshenziselwa izingxenye zesakhiwo sezakhiwo zokusekela imayini, izinhlelo zokuhambisa, kanye nemishini yokucubungula i-ore.

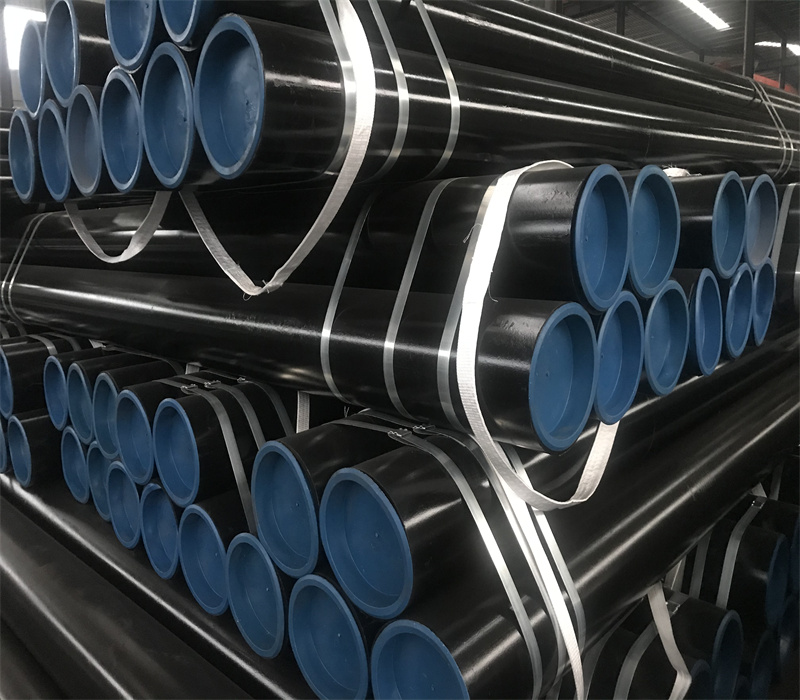

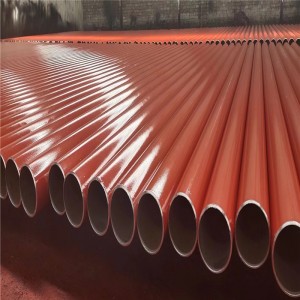

Ipayipi elingenalutho noma i-Black / Varnish coating (eyenziwe ngokwezifiso);

ngezinqwaba noma ezikhululekile;

Zombili iziphetho zinezivikelo zokuphela;

Isiphetho esilula, isiphetho se-bevel (2" nangaphezulu esinamaphethelo e-bevel, izinga: 30~35°), esinomucu kanye nesixhumi;

Ukumaka.