I-EN 10219 S275J0H kanye ne-S275J2Hyizingxenye ezingenalutho ezakhiwe ngensimbi engaxutshwe nalutho ngokusho kwe-EN 10219.

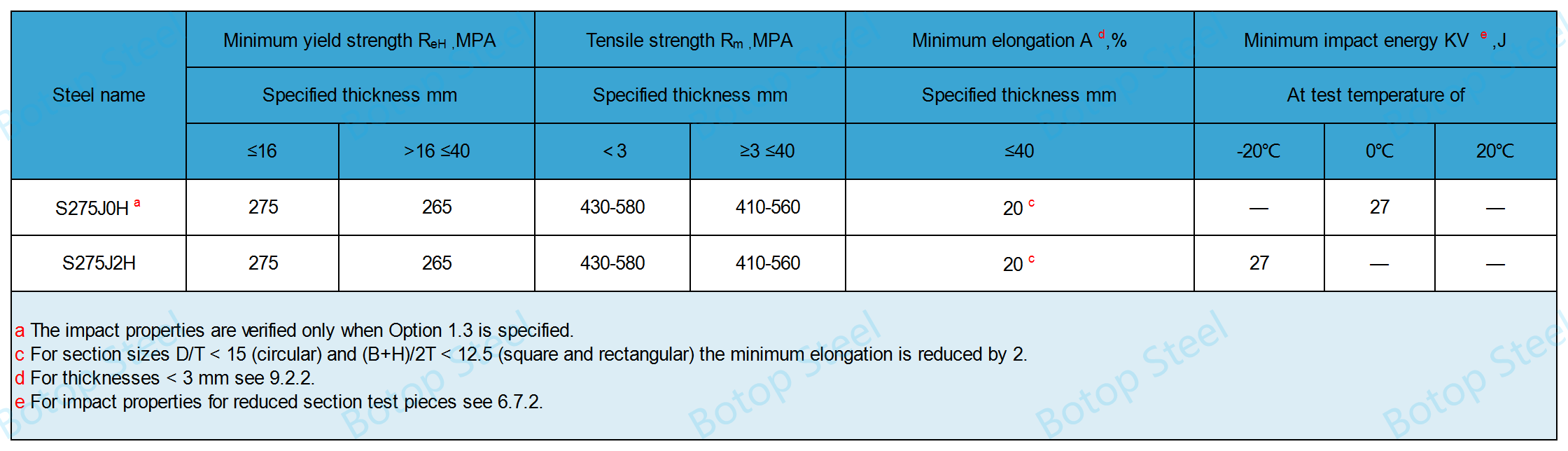

Zombili zinamandla okukhiqiza okungenani angu-275MPa (ubukhulu bodonga ≤16mm). Umehluko omkhulu usezimpahleni zomthelela: I-S275J0H inamandla omthelela amancane angu-27 J ku-0°C, kuyilapho i-S275J2H inamandla omthelela amancane angu-27 J ku--20°C.

Ifanele ukusetshenziswa ezakhiweni nasezindlini zobunjiniyela ezithwala imithwalo elula.

I-BS EN 10219 iyi-European Standard EN 10219 eyamukelwe yi-UK.

Ubukhulu bodonga ≤40mm, Ububanzi bangaphandle ≤2500mm.

I-CFCHS isifinyezo se-Cold-Formed Circular Hollow Section.

Izinga le-EN 10219 lihlanganisa izinhlobo eziningi zezimo zensimbi ezingenalutho, kufaka phakathi indilinga, isikwele, unxande, kanye ne-oval, ukuze kuhambisane nezidingo ezahlukene zokusetshenziswa.

Insimbi yeBotopigxile ekuhlinzekeni ngamapayipi ensimbi ayindilinga angenalutho anezinhlobo ezahlukene zobukhulu nezinqubo ukuze avumelane nezinhlelo zokusebenza eziningi embonini, iqinisekisa ukuthi izidingo ezithile zamakhasimende ethu zingahlangatshezwa.

Selokhu yasungulwa ngo-2014,Insimbi yeBotopisibe ngumhlinzeki ohamba phambili wamapayipi ensimbi yekhabhoni eNyakatho yeShayina, eyaziwa ngenkonzo enhle kakhulu, imikhiqizo esezingeni eliphezulu, kanye nezixazululo eziphelele.

Le nkampani inikeza izinhlobo ezahlukene zamapayipi ensimbi yekhabhoni kanye nemikhiqizo ehlobene nawo, okuhlanganisaI-SMLS, I-ERW, I-LSAW, futhiI-SSAWipayipi lensimbi, kanye nohlu oluphelele lwezihlanganisi zamapayipi nama-flange. Imikhiqizo yayo ekhethekile ifaka phakathi ama-alloy ebanga eliphezulu kanye nezinsimbi ezingagqwali ze-austenitic, ezenzelwe ukuhlangabezana nezidingo zamaphrojekthi ahlukahlukene amapayipi.

Silangazelela ukwakha ubudlelwano bokubambisana nani kanye nokudala ikusasa elizuzisa wonke umuntu ndawonye.

Insimbi eluhlaza yokwenziwa kwezingxenye ezingenalutho ezakhiwe ngokubandayo iyasuswa oksijini futhi kumele ihlangabezane nezimo ezithile zokulethwa.

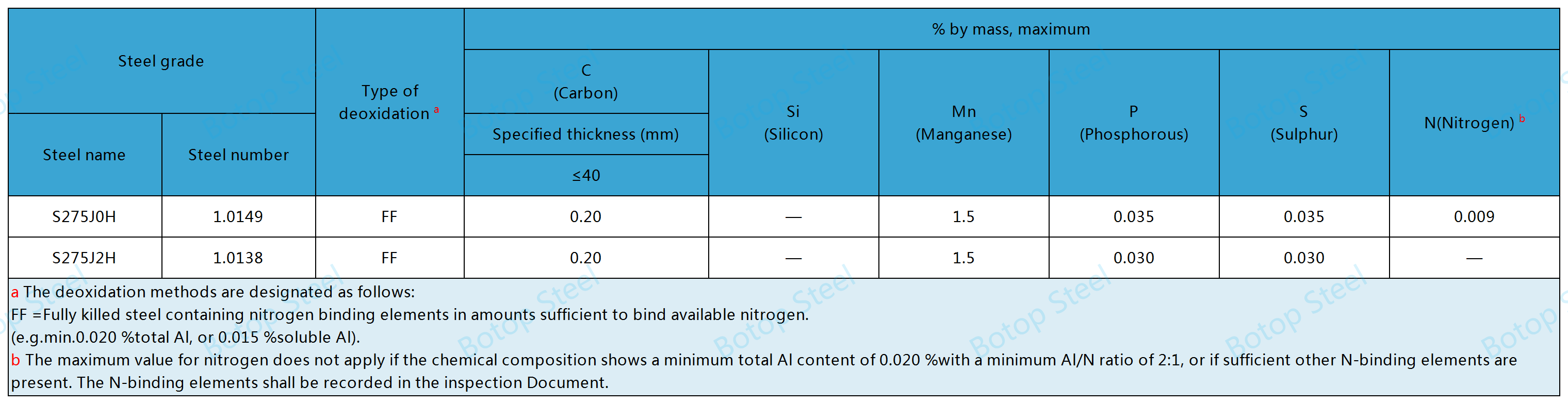

Izidingo ezifanele ze-S275J0H kanye ne-S275J2H yilezi:FF(Insimbi ebulewe ngokuphelele equkethe izakhi zokubopha i-nitrogen ngamanani anele ukubopha i-nitrogen etholakalayo (isb. okungenani i-Al iyonke engu-0,020% noma i-Al encibilikayo engu-0,015%)).

Isimo sokulethwa: I-rolled noma i-normalized/normalized rolled (N) yezinsimbi ze-JR, J0, J2, kanye ne-K2.

Amapayipi ensimbi ahambisana ne-EN 10219 angakhiqizwa yibo bobabiliI-ERW(ukushisela ukumelana nogesi) kanyeI-SAWIzinqubo zokukhiqiza (ukushisela i-arc ngaphansi kwamanzi).

Ukukhiqizwa kweAmashubhu e-ERWinenzuzo yokuba esheshayo futhi engabizi kakhulu futhi ivame ukukhethwa kumaphrojekthi adinga ukukhiqizwa okukhulu kanye nokusebenza kahle kwezindleko.

I-ERWamashubhu ngokuvamile asetshenziselwa ukukhiqiza ububanzi obuncane kanye nobukhulu bodonga obuncane, kuyilaphoI-SAWAmashubhu afaneleka kakhulu kumadayamitha amakhulu kanye nezindonga ezijiyile. Sicela ukhethe uhlobo olufanele lwepayipi lensimbi yephrojekthi yakho.

Amapayipi e-ERW akhiqizwa ngokwe-EN 10219 ngokuvamile awadingi ukunqunywa kwe-weld yangaphakathi.

Lokhu kungenxa yokuthi amashubhu e-EN 10219 asetshenziswa kakhulu ezindleleni zokwakha, njengokwakha kanye nobunjiniyela bemishini, lapho izidingo zokubukeka kwe-weld zivame ukuba zincane kunezemikhumbi yokucindezela noma amapayipi anomfutho ophezulu. Ngakho-ke, uma nje amandla nobuqotho be-weld buhlangabezana nezidingo zendinganiso, ama-weld angaphakathi angasetshenziswa ngaphandle kokusika okwengeziwe.

Akukho ukwelashwa kokushisa okulandelayo okwenziwayo, ngaphandle kokuthi ukushintshwa kungaba sesimweni sokushintshwa noma sokulungiswa kokushisa.

Ukuhlaziywa Kwama-Cast (Ukwakheka Kwamakhemikhali Kwezinto Ezingavuthiwe)

Zombili i-S275J0H kanye ne-S275J2H zinenani elilingana nekhabhoni eliphezulu (i-CEV) elingu-0.40%.

I-S725J0H kanye ne-S275J2H ene-CEV ephezulu engu-0.4% zibonisa ukushibilika okungcono kanye nengozi encane yokuqina nokuqhekeka ngesikhathi sokushibilika.

Kungabalwa futhi kusetshenziswa ifomula elandelayo:

CEV = C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/15.

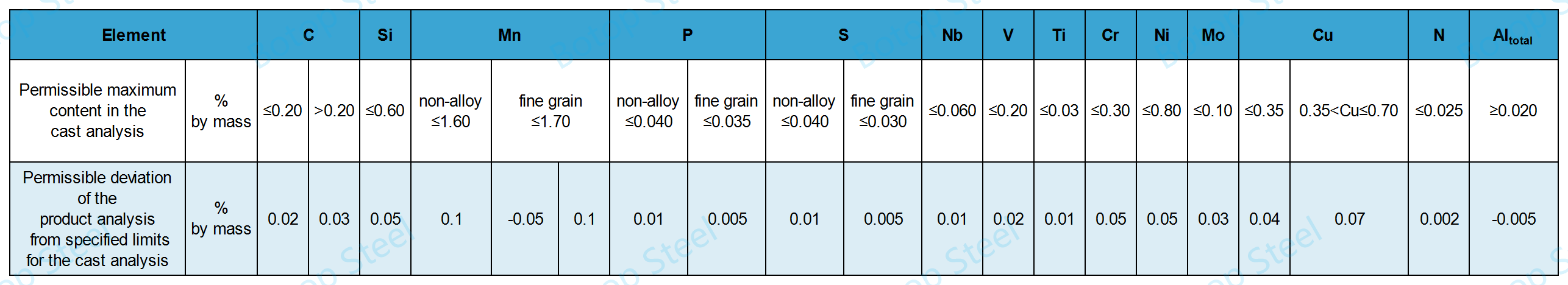

Ukuhlaziywa Komkhiqizo (Ukwakheka Kwamakhemikhali Kwemikhiqizo Eqediwe)

Ngesikhathi sokukhiqizwa kwensimbi, ukwakheka kwamakhemikhali kungashintsha ngezizathu eziningana, futhi lezi zinguquko zingathinta izakhiwo kanye nekhwalithi yensimbi.

Ukwakheka kwamakhemikhali kwepayipi lensimbi eliqediwe lokugcina kumele kuhambisane nokwakheka kwamakhemikhali kokusatshalaliswa kanye nokuphambuka kwalo okuvunyelwe.

Imingcele yezakhiwo zemishini ihlanganisa amandla okukhiqiza, amandla okudonsa, ukunwebeka, kanye namandla okushaya.

Ukunciphisa ukucindezeleka okungaphezu kuka-580 ℃ noma isikhathi esingaphezu kwehora elilodwa kungaholela ekuwohlokeni kwezakhiwo zemishini.

Amanothi:

Ukuhlolwa komthelela akudingeki uma ubukhulu obucacisiwe bungaphansi kuka-6mm.

Izakhiwo zomthelela wamashubhu ekhwalithi ye-JR ne-J0 aziqinisekiswa ngaphandle kokuthi kuchazwe.

I-EN 10219 Ama-welds kumapayipi ensimbi e-ERW angahlolwa ngokukhetha okukodwa kwalokhu okulandelayo.

I-EN 10246-3 kuya ezingeni lokwamukelwa E4, ngaphandle kokuthi inqubo ye-rotary tube/pancake coil ngeke ivunyelwe;

EN 10246-5 kuya ezingeni lokwamukelwa F5;

EN 10246-8 kuya ezingeni lokwamukelwa U5.

Ukubalwa kwesisindo esicatshangelwayo samashubhu e-EN 10219 kungasuselwa ekumisweni kwamashubhu angu-7.85 kg/dm³.

M=(DT)×T×0.02466

U-M ubude besisindo ngeyunithi ngayinye;

U-D ububanzi obungaphandle obucacisiwe, amayunithi ku-mm;

U-T uwubukhulu bodonga obucacisiwe, amayunithi ngo-mm.

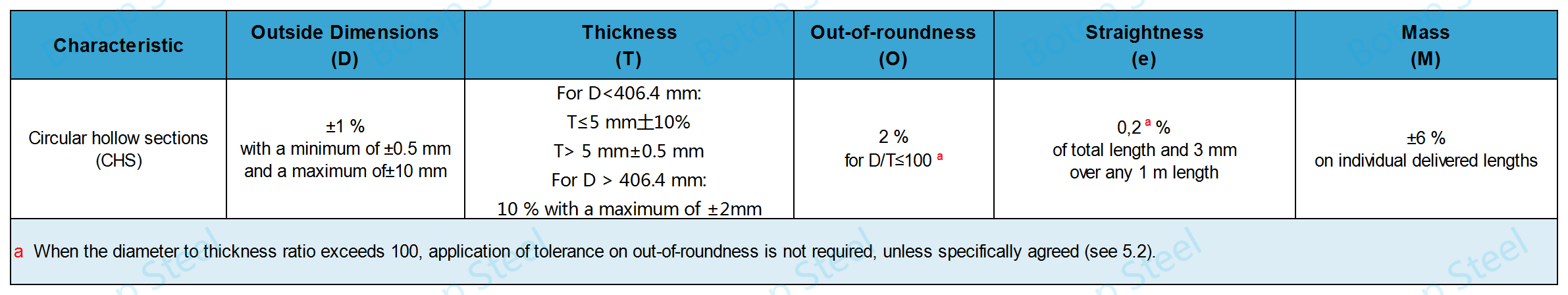

Ukubekezelelana koMumo, Ukuqonda kanye nesisindo

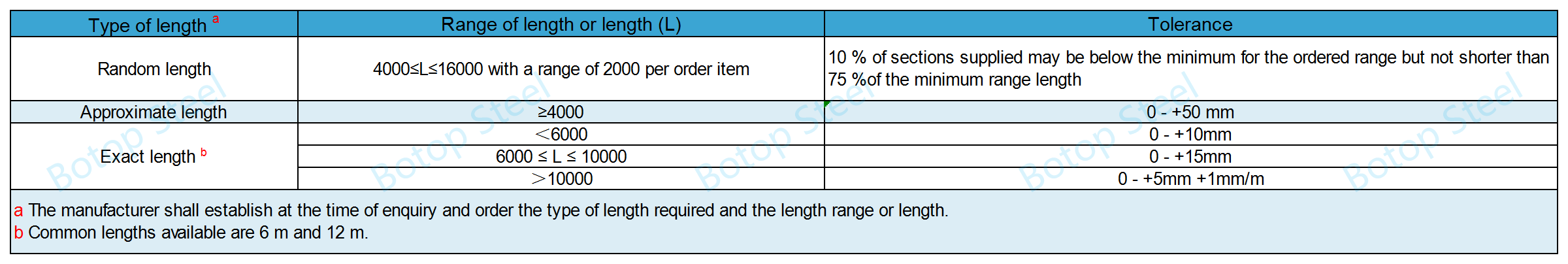

Ubude bokubekezelelana

Amashubhu ezingxenye ezingenalutho akhiqizwe ngokwe-EN 10219 ayashiselelwa.

Lapho kushiselwa, ukuqhekeka okubandayo endaweni yokushiselwa kuyingozi enkulu njengoba ukujiya, izinga lamandla, kanye ne-CEV yomkhiqizo kukhula. Ukuqhekeka okubandayo kubangelwa yinhlanganisela yezici eziningana:

amazinga aphezulu e-hydrogen esakazekayo ensimbini yokushisela;

isakhiwo esibuthakathaka endaweni ethintekile ekushiseni;

ukugxila okukhulu kokucindezeleka kokudonsa engxenyeni ehlanganisiwe.

Ubuso bepayipi lensimbi kufanele bube bushelelezi futhi bungabi namaphutha angathinta ukusebenza komkhiqizo, njengokuqhekeka, imigodi, imihuzuko, noma ukugqwala.

Amaqhubu, imifantu, noma imifantu emide engajulile edalwe yinqubo yokukhiqiza iyamukeleka uma nje ubukhulu bodonga obusele bungaphakathi kokubekezelelwa, iphutha lingasuswa ngokugaya, futhi ubukhulu bodonga obulungisiwe buhlangabezana nezidingo zobukhulu obuncane.

Insimbi yeBotopAkugcini nje ngokunikeza amashubhu ensimbi asezingeni eliphezulu ngokuhambisana ne-EN 10219, kodwa futhi inikeza izinketho eziningi zokufaka ungqimba olungaphezulu lwamashubhu ensimbi ukuze kuhambisane nezidingo ezithile zamakhasimende ayo kumaphrojekthi ahlukene obunjiniyela. Lezi zingqimba zenzelwe ukuthuthukisa ukumelana nokugqwala kwamashubhu nokwengeza isivikelo esengeziwe, ngaleyo ndlela kwandise impilo yawo yesevisi.

Ukushisa okushisayo

Ukugqoka kwe-3LPE (HDPE)

Isimbozo se-FBE

Isimbozo se-Varnish

Upende Wokumboza

Isimbozo Sesisindo Sesimende

Izingxenye zebhuloho: izakhiwo ezingezona eziyinhloko ezithwala imithwalo ezisetshenziswa emabhulohweni, njengezinsika zokubiyela kanye nama-parapet.

Izinsika zezakhiwo: izinsika zokusekela kanye nemishayo esetshenziswa ekwakheni nasekubunjiniyelani bezokwakha.

Izinhlelo zokufaka amapayipi: amapayipi okuthutha uketshezi namagesi, ikakhulukazi ekusetshenzisweni okudinga izinga elithile lokuguquguquka kanye nokumelana nokugqwala.

Izakhiwo zesikhashana: izisekelo zesikhashana kanye nohlaka olufanelekela izindawo zokwakha nezobunjiniyela.

Lezi zinhlelo zokusebenza zisebenzisa izakhiwo ezinhle kakhulu zemishini kanye nokushibilika kwe-S275J0H kanye ne-S275J2H ukuze kuhlangatshezwane nezidingo zezakhiwo ezilula kodwa ezizinzile.

I-ASTM A500:Imininingwane Ejwayelekile Yamapayipi Esakhiwo Sensimbi Yekhabhoni Ebunjwe Ngobumba Obuhlanganisiwe Nobungenamthungo Ngama-Rounds Nama-shapes.

I-ASTM A501: Ukucaciswa Okujwayelekile Kwepayipi Lesakhiwo Lensimbi Yekhabhoni Eyenziwe Ngokushiswa Eyakhiwe Ngokushisayo Nengenamthungo.

I-EN 10210: Izingxenye zesakhiwo eziqediwe ezishisayo nezingenalutho zensimbi ezingezona i-alloy kanye nezinsimbi ezincane.

I-EN 10219: Izingxenye ezingenalutho ezakhiwe ngokushibilika ezakhiwe ngokubandayo zezinsimbi ezingezona i-alloy kanye nezinsimbi ezincane.

I-JIS G 3466: Amashubhu ensimbi yekhabhoni ayizikwele kanye nonxande wesakhiwo esijwayelekile.

I-AS/NZS 1163: Izingxenye zensimbi ezakhiwe ngendlela ebandayo ezingenalutho.

Lezi zindinganiso zisetshenziswa kabanzi emhlabeni wonke, futhi zisiza ekuqinisekiseni ukuthi amashubhu ensimbi akhiwe ahlangabezana nezindinganiso zokusebenza ezilindelekile ezisetshenzisweni ezahlukene zobunjiniyela. Lapho ukhetha indinganiso yepayipi lensimbi, kubalulekile ukucabangela izidingo zayo ezithile zokusetshenziswa, imithetho yesifunda, kanye nezidingo zokusebenza.

Ipayipi Lensimbi Yekhabhoni le-ASTM A252 GR.3 LSAW(JCOE) Lesakhiwo

Ipayipi Lensimbi le-BS EN10210 S275J0H LSAW(JCOE)

Ipayipi Lensimbi le-ASTM A671/A671M LSAW

Ipayipi Lensimbi Yekhabhoni ye-ASTM A672 B60/B70/C60/C65/C70 LSAW LSAW

I-API 5L X65 PSL1/PSL 2 Ipayipi Lensimbi Yekhabhoni le-LSAW / Ipayipi Lensimbi Le-API 5L Lebanga le-X70 LSAW

Ipayipi Lensimbi le-EN10219 S355J0H lesakhiwo se-LSAW(JCOE)