I-BS EN 10210 S355J0H, inombolo yensimbi 1.0547, ingeyesigaba sensimbi esakhiwe ngesakhiwo esinomgodi esakhiwe ngokushisa futhi ingaba yipayipi lensimbi elingenamthungo noma elihlanganisiwe, elisetshenziswa kakhulu ezakhiweni ezidinga amandla aphezulu nokuqina okuhle, njengohlaka olukhulu lwezakhiwo namabhuloho.

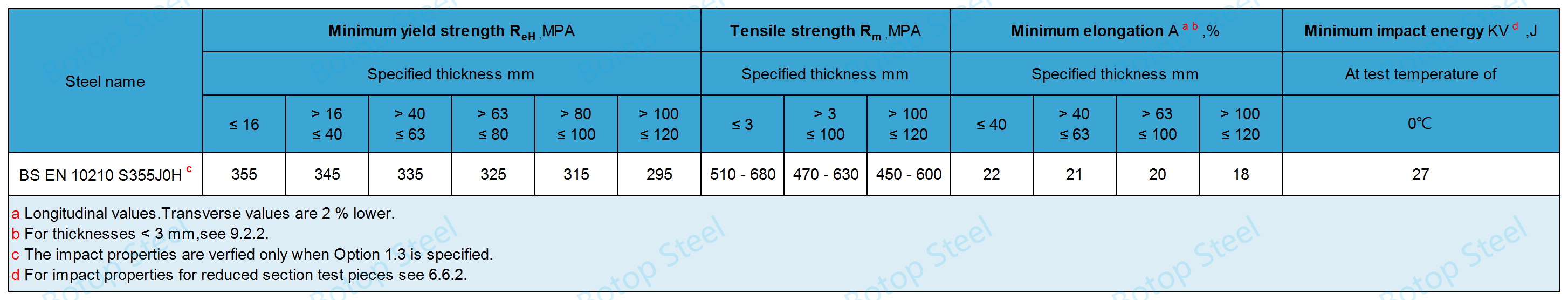

Izinto ze-S355J0H zinezakhiwo zomshini zokuthi amandla okukhiqiza amancane angama-355MPa uma ubukhulu bodonga bungadluli ku-16 mm futhi buhlangabezana namandla okushaya amancane angama-27J ku-0℃.

I-BS EN 10210 iqukethe izinhlobo ezahlukene zezimo ezinqamulelayo, njengeziyindilinga, isikwele, unxande, noma i-elliptical, i-Botop Steel igxile kumashubhu ensimbi ayindilinga ngobukhulu obuhlukahlukene, ikunikeza izinto zeshubhu yensimbi ezisezingeni eliphezulu nezihambisana nezindinganiso ngokuthengiswa ngqo kwefektri kanye nentengo yokuncintisana.

Qaphela: Zonke izidingo ezikulo mbhalo ziyasebenza naku-EN 10210.

Ubukhulu bodonga ≤120mm.

Isiyingi (HFCHS): Ububanzi bangaphandle obufika ku-2500 mm;

Isikwele (HFRHS): Ubukhulu bangaphandle bufika ku-800 mm x 800 mm;

Unxande (HFRHS): Ubukhulu bangaphandle obufika ku-750 mm x 500 mm;

I-Elliptical (HFEHS): Ubukhulu bangaphandle obufika ku-500 mm x 250 mm.

| Ibanga lensimbi | Uhlobo lwe ukususwa koketshezi emzimbenia | % ngobuningi, ubuningi | |||||||

| C | Si | Mn | P | S | Nb,c | ||||

| Igama lensimbi | Inombolo yensimbi | Ubukhulu obucacisiwe (mm) | |||||||

| ≤40 | >40 ≤120 | ||||||||

| I-BS EN 10210 S355J0H | 1.0547 | FN | 0.22 | 0.22 | 0.55 | 1.60 | 0.035 | 0.035 | 0.009 |

aI-FN = Insimbi yokubopha ayivunyelwe;

bKuvunyelwe ukudlula amanani acacisiwe uma nje ngokukhuphuka ngakunye okungu-0.001% N okuqukethwe okungu-P, okuphezulu nakho kuncishiswa ngo-0.005%. Nokho, okuqukethwe okungu-N kokuhlaziywa kwe-cast akufanele kube ngaphezu kuka-0.012%;

cInani eliphezulu le-nitrogen alisebenzi uma ukwakheka kwamakhemikhali kubonisa okuqukethwe okungenani kwe-Al okungu-0.020% kanye nesilinganiso esincane se-Al/N esingu-2:1, noma uma kukhona ezinye izakhi ze-N ezanele. Izinto ze-N-binding kufanele ziqoshwe kuDokhumenti Yokuhlola.

Izimpawu zezinto ezibonakalayo ku-BS EN 10210 zisekelwe emandleni azo amancane okukhiqiza ku-16mm ubukhulu bodonga kanye nezakhiwo zomthelela emazingeni okushisa athile. Amandla okukhiqiza, amandla okudonsa, kanye nokwelulwa kwe-BS EN 10210 S355J0H kwehla njengoba ubukhulu bodonga bukhula.

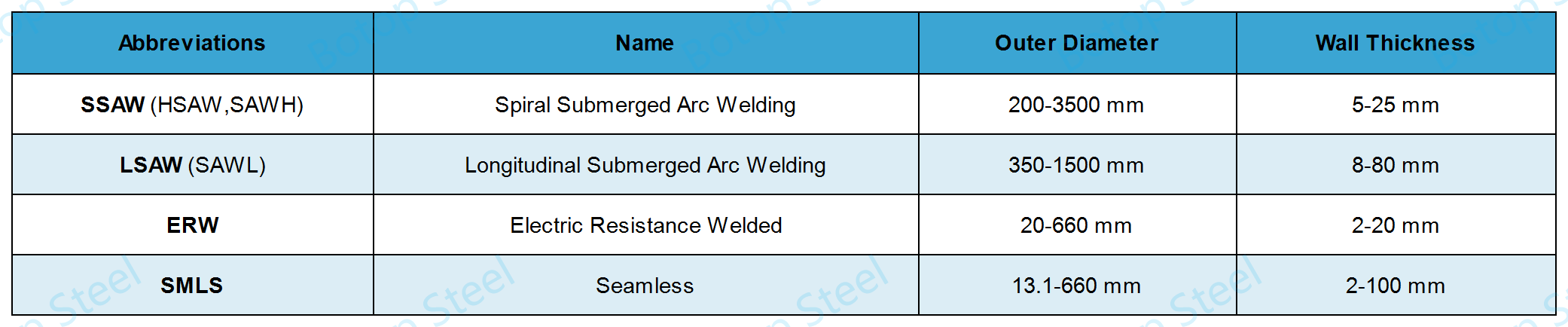

I-BS EN 10210 ivumela ukukhiqizwa kusetshenziswa izinqubo ezahlukahlukene zokukhiqiza, ngokuvamile kufaka phakathi izinqubo zokushisela ezingenamthungo, ze-LSAW, ze-SSAW, kanye ne-ERW.

Ngezansi kunohlu losayizi bezinqubo zokukhiqiza ezivamile.

Kusukela ekuqhathanisweni okungenhla, kungabonakala ukuthi ipayipi lensimbi elingenamthungo linenzuzo engokwemvelo ekukhiqizweni kwepayipi lensimbi elinodonga olujiyile, ikakhulukazi ipayipi lensimbi elinodonga olujiyile elincane, kodwa ubukhulu balo buzonqunyelwa. Uma udinga ukukhiqiza amapayipi ensimbi anobubanzi obungaphezu kuka-660mm, kuzoba nzima kakhulu.

Ipayipi Elimnyama

Lokhu kubhekisela epayipini lensimbi elingenayo indlela yokwelapha ubuso.

Isivikelo Sesikhashana Esivikelayo

Ukuze kuvinjelwe ukugqwala kwamapayipi ensimbi ngesikhathi sokugcina, ukuthuthwa, noma ukufakwa, indlela evamile iwukumboza ubuso bepayipi ngendwangu yopende noma i-varnish.

Isimbozo Sokulwa Nokugqwala

Kunezinhlobo eziningi zezingubo zokulwa nokugqwala, okuhlanganisa upende, i-FBE,3LPE, kanye ne-galvanized. Uhlobo ngalunye lwe-coating lunezici ezihlukile kanye nezindawo ezifanele. Ukugqwala nokugqwala kungavinjelwa ngempumelelo ngokusebenzisa i-coating efanele yokulwa nokugqwala ezindaweni zensimbi.

I-EN 10210 Izimbozo ezifakwe i-hot dip galvanized ebusweni bepayipi lensimbi kufanele zihambisane nezidingo ezifanele ze-EN ISO 1461.

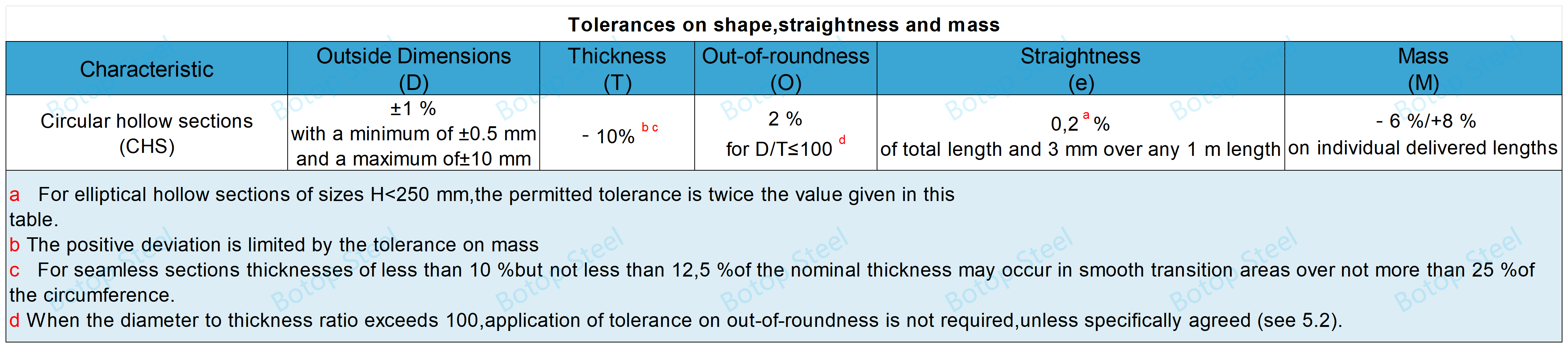

Ukubekezelelana koMumo, Ukuqonda kanye nesisindo

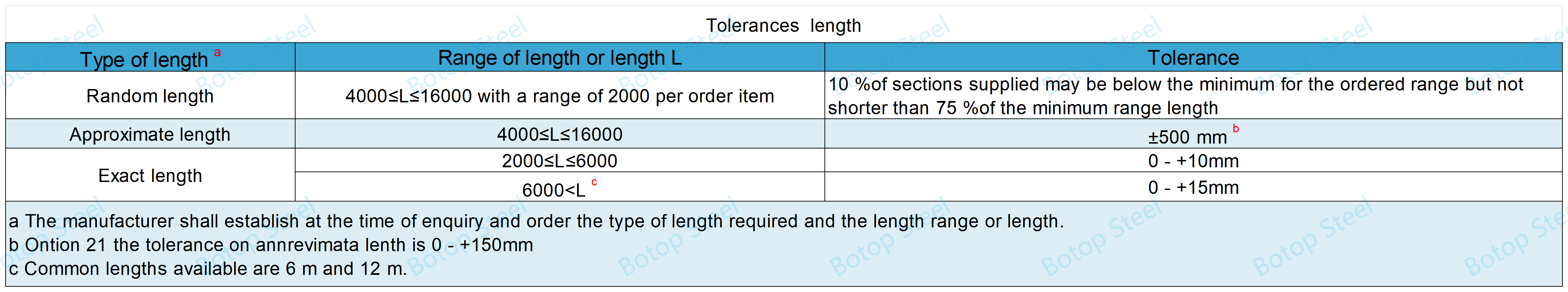

Ukubekezelelana Ngobude

Ukuphakama Komthungo Weld ye-SAW

| Ubukhulu, T | Ukuphakama okuphezulu kobuhlalu bokushisela, mm |

| ≤14,2 | 3.5 |

| >14,2 | 4.8 |

Ukuphakama komthungo wokuwelda wokumelana ngokuvamile akudluli kakhulu ngaphezu kobuso bepayipi, futhi ngesikhathi senqubo yokukhiqiza, umthungo wokuwelda uphathwa ngendlela yokuthi uhlanganiswe ngokuphelele nobuso bepayipi futhi ungabonakali.

I-BS EN 10210 S355J0H isetshenziswa kabanzi ezakhiweni zokwakha, ekukhiqizeni imishini, emapayipini okuthutha, ekwakhiweni kwengqalasizinda, emikhunjini, kanye nobunjiniyela basolwandle. Amandla ayo aphezulu kanye nokuqina okuhle kuyenza ibe yinhle kakhulu kumaphrojekthi afana namabhuloho, izakhiwo eziphakeme, izitshalo zezimboni, ama-crane, amapayipi kawoyela negesi, kanye nemibhoshongo yamandla omoya.

| I-GB/T | I-GOST | I-ASTM | I-JIS |

| GB/T 1591 Q345B | I-GOST 19281 09G2S | I-ASTM A501 Ibanga C | I-JIS G 3101 SS490 |

Kusukela yasungulwa ngo-2014, iBotop Steel isibe ngumhlinzeki ohamba phambili wamapayipi ensimbi yekhabhoni eNyakatho yeShayina, eyaziwa ngenkonzo enhle kakhulu, imikhiqizo esezingeni eliphezulu, kanye nezixazululo eziphelele.

Le nkampani inikeza amapayipi ahlukahlukene ensimbi yekhabhoni kanye nemikhiqizo ehlobene nayo, kufaka phakathi ipayipi lensimbi elingenamthungo, i-ERW, i-LSAW, kanye ne-SSAW, kanye nohlu oluphelele lwezihlanganisi zamapayipi nama-flange. Imikhiqizo yayo ekhethekile ifaka phakathi ama-alloy ebanga eliphezulu kanye nezinsimbi ezingagqwali ze-austenitic, ezenzelwe ukuhlangabezana nezidingo zamaphrojekthi ahlukahlukene amapayipi.

Eminye imikhiqizo ehlobene:

Xhumana nathi ukuze uthole ikhotheshini yamahhala kanye nokubonisana ngephrojekthi yakho.