Ipayipi lensimbi le-ASTM A556 lisetshenziswa kakhulu njengepayipi lensimbi yekhabhoni elingenamthungo elidonswa ngokubandayo lama-heater amanzi ashubhu.

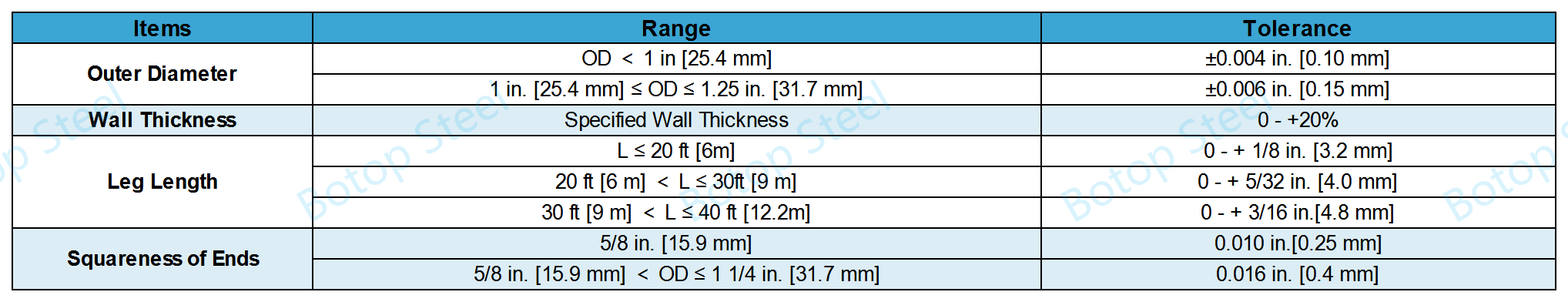

Ububanzi bokusetshenziswa kwayo yipayipi lensimbi elingenamthungo elinobukhulu obungaphandle obuphakathi kuka-15.9-31.8mm kanye nobukhulu bodonga obungaphansi kuka-1.1mm.

Lesi sihloko sigxile kumapayipi ensimbi futhi asihlanganisi ama-U-tubes okukhulunywe ngawo ku-standard.

Ububanzi bangaphandle: 5/8 - 1 1/4 in. [15.9 -31.8 mm].

Ubukhulu bodonga: ≥ 0.045 in [1.1 mm].

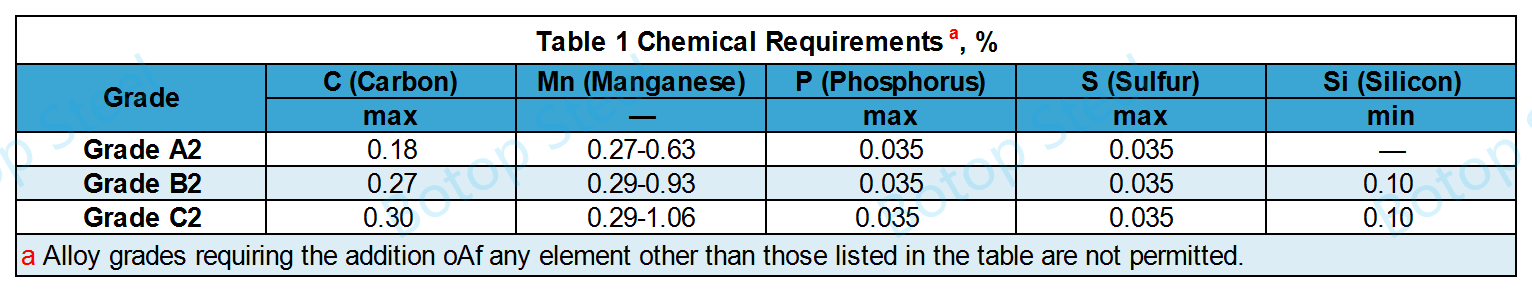

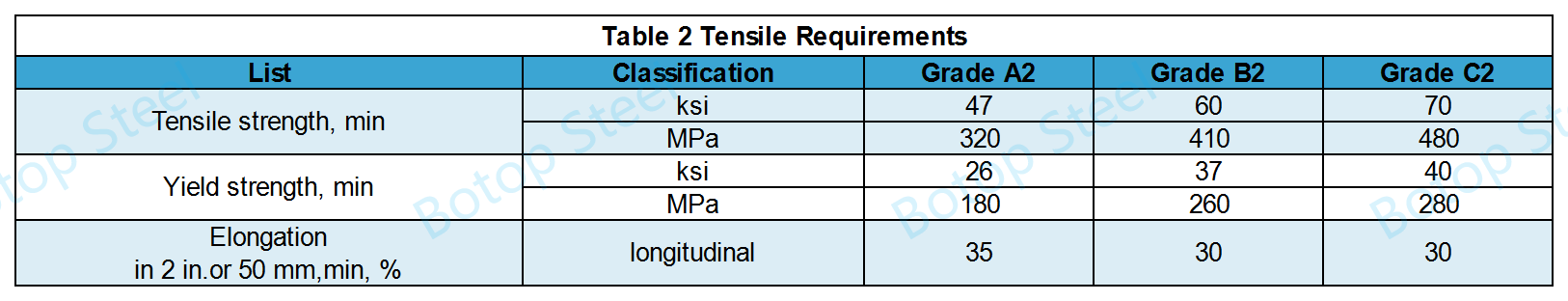

I-ASTM A556 ihlukanisa amamaki amathathu,Ibanga A2, Ibanga B2, futhiIbanga C2.

Amapayipi ensimbi kufanele akhiqizwe yi-ngaphandle komthungoinqubo futhi kufanele idonswe kubanda.

Amashubhu ensimbi angenamthungo adonswa ngokubandayo anikeza ukunemba okuphezulu kanye nokuphela okuhle kobuso ngenkathi elungisa isakhiwo esincane futhi ethuthukisa izakhiwo zawo zemishini njengokuqina nokuqina. Isakhiwo esingenamthungo senza amashubhu azinze futhi aphephe kakhulu uma ebhekene nokucindezeleka okuphezulu kanye namazinga okushisa, okwenza afaneleke ukusetshenziswa kwezimboni okudinga ukunemba okuphezulu kanye nokusebenza kahle.

Kodwa-ke, amashubhu ensimbi angenamthungo adonswa ebanda abiza kakhulu ukuwakhiqiza ngoba inqubo yawo yokukhiqiza iyinkimbinkimbi kakhulu futhi idinga imisebenzi nemishini eyinkimbinkimbi kakhulu. Ngaphezu kwalokho, ukusebenza kwawo kahle kokukhiqiza okuphansi, ikakhulukazi ekukhiqizeni ngobuningi obukhulu, akubizi kakhulu njengenqubo yokugoqa okushisayo, futhi kwezinye izimo kungase kube nokulahleka kwezinto eziningi, okunciphisa ukusetshenziswa kwawo kwezinye izinhlelo zokusebenza.

Amapayipi adonswayo abandayo kufanele aphathwe ngokushisa ngemva kokudlula kokugcina kokudonsa okubandayo ekushiseni okungu-1200°F [640°C] noma ngaphezulu ukuqinisekisa ukuthi ayakwazi ukugoqeka kumashidi epayipi futhi ahlangabezane nezakhiwo zemishini njengoba kuchaziwe.

Uma kwenziwa ukuhlaziywa komkhiqizo, bheka i-ASTM A751 ukuze uthole izindlela zokuhlola.

1. Impahla Eqinile

Indlela yokuhlola: Isigaba 7 se-ASTM A450.

Kumaqoqo amashubhu afinyelela ku-50, kufanele kukhethwe ishubhu eli-1 ukuze lihlolwe.

Kumaqoqo amashubhu angaphezu kwama-50, kuzokhethwa amashubhu ama-2 ukuze ahlolwe.

2. Ubulukhuni

Indlela yokuhlola: Isigaba 23 se-ASTM A450.

Amasampula avela kumashubhu amabili okuhlola avela kuhlu ngalunye kufanele ahlolwe ukuqina kukaBrinell noma kukaRockwell.

Ubulukhuni bepayipi leRockwell akumele budlule obuboniswe etafuleni.

| Ibanga | Ubulukhuni |

| Ibanga A2 | 72 HRBW |

| Ibanga B2 | 79 HRBW |

| Ibanga C2 | 89 HRBW |

3. Ukuhlolwa Kokuthamba

Indlela yokuhlola: Isigaba 19 se-ASTM A450.

Ukuhlolwa kokuthamba kufanele kwenziwe kusampula eyodwa kusukela ekugcineni ngakunye kwepayipi lensimbi eliqediwe kusukela ekukhetheni amapayipi angedluli ku-125 kusukela kuhlu ngalunye.

4. Ukuhlolwa Kokuvutha

Indlela yokuhlola: Isigaba 21 se-ASTM A450.

Ukuhlolwa kokuvutha kufanele kwenziwe kusampula eyodwa kusukela ekugcineni kwepayipi eliqediwe, kungakhethwa amapayipi angaphezu kuka-125 kuqoqo ngalinye.

Akukho ukuhlolwa kwe-hydrostatic okuphoqelekile kwamapayipi ensimbi.

Kodwa-ke, wonke amapayipi e-U kumele ahlolwe ngamanzi ngoketshezi olungaboli.

Ithubhu ngalinye kufanele lihlolwe ngethuluzi lokuhlola elingonakalisi elikwazi ukubona amaphutha kuyo yonke ingxenye yethubhu ngemva kokwelashwa kokushisa kobuso ngemuva kokudonsa kokugcina okubandayo.

Izindlela zokuhlola ezingonakalisi ze-SpecificationE213, ImininingwaneI-E309(ngezinto ze-ferromagnetic), ImininingwaneE426(ngezinto ezingezona ezikagesi), noma UkucaciswaE570kungakhethwa ukuhlolwa.

Lokhu kubekezelela okulandelayo akusebenzi engxenyeni egobile ye-U-tube.

Ipayipi eliqediwe kufanele lingabi nasikali kodwa lingase libe nefilimu ye-oxide ebusweni.

Amapayipi aqediwe kufanele aqonde kahle futhi abe neziphetho ezibushelelezi ezingenama-burrs. Amapayipi kufanele abe nokuphela okufana nokwenziwe ngumuntu futhi akufanele abe namaphutha ebusweni angenakususwa ngaphakathi kwemingcele evumelekile yodonga.

Ukususwa kweziphambeko ezingaphezulu ezifana nezimpawu zokuphatha, izimpawu zokuqondisa, izimpawu ze-mandrel ezilula kanye nezimpawu zokufa, imigodi engajulile, kanye namaphethini esikali ngeke kudingeke uma nje zingaphakathi kwemingcele evumelekile yodonga.

Ububanzi bangaphakathi nobangaphandle bepayipi eliqediwe kufanele bumbozwe ukuze kuvinjelwe ukugqwala ngesikhathi sokuthuthwa.

Izimbozo ezivamileamafutha okuvimbela ukugqwala, ama-varnishnomaupende.

Ukukhethwa kwezinto zokumboza ngokuvamile kuncike ezidingweni ezithile zokusetshenziswa kwepayipi lensimbi, indawo ehlosiwe yokusetshenziswa, kanye nesikhathi sokuvikelwa.

Ama-heater amanzi afudumele e-Tubular: Lolu olunye lwezinhlelo zokusebenza ezivame kakhulu ze-ASTM A556 steel tube.

Embonini yamandla, ama-feedwater heater asetshenziselwa ukushisa amanzi okuhambisa amanzi ebhoyila, ngokuvamile ngokukhipha umusi. Ukusetshenziswa kwalolu hlobo lwamapayipi ensimbi kuvumela ukudluliselwa kwamandla okushisa okuphumelelayo, okuthuthukisa ukusebenza kahle kwamandla kanye nokusebenza kohlelo.

Izishintshi zokushisa kanye nezikhulisi zokushisa: Ngenxa yezakhiwo zayo ezinhle kakhulu zokudlulisa ukushisa kanye nokumelana nokugqwala, amashubhu ensimbi e-ASTM A556 afaneleka futhi ukusetshenziswa kwezinye izinhlobo zokushintshanisa ukushisa kanye nama-condenser, asetshenziswa ezinhlobonhlobo eziningi zamakhemikhali, i-petrochemical, kanye nezinye izinqubo zezimboni.

Izinhlelo zomusi ezicindezela kakhulu: Ukumelana nokushisa okuphezulu kanye nokucindezela okuphezulu kwepayipi le-ASTM A556 kwenza lifaneleke ukusetshenziswa ezinhlelweni zomusi ezicindezela kakhulu kanye nezinye izinhlelo zokusebenza ezidinga ukumelana nokucindezela okuphezulu kakhulu kanye nokushisa.

I-ASTM A179/A179M- Lena indinganiso yama-heat exchanger angenamthungo ensimbi yekhabhoni edonswa ebanda kanye namashubhu e-condenser ukuze kuhlinzekwe nge-cryogenic.

I-ASTM A192/A192M- Icacisa izidingo zobuchwepheshe zamashubhu ebhoyila ensimbi yekhabhoni angenamthungo kumabhoyila asetshenziswa ekuhlinzekeni ngomfutho ophezulu.

I-ASTM A210/A210M- Izinga elijwayelekile lamashubhu ebhoyila ensimbi ye-carbon ephakathi nendawo kanye ne-carbon-manganese yama-boiler nama-superheater.

I-ASTM A213/A213M- Ihlinzeka ngezindinganiso zebhoyila yensimbi ye-ferritic ne-austenitic alloy, i-superheater, kanye namashubhu okushintshanisa ukushisa angenamthungo.

I-ASTM A249/A249M- Okujwayelekile kusebenza ku-welded austenitic steel boiler, i-superheater, i-heat exchanger, kanye nama-condenser tubes.

I-ASTM A334/A334M- Izinga elijwayelekile lamapayipi e-carbon kanye nensimbi ye-alloy angenamthungo futhi ahlanganisiwe ukuze kuhlinzekwe nge-cryogenic.

Ngayinye yalezi zindinganiso ihlanganisa amashubhu ensimbi asetshenziswa kuma-heat exchanger, ama-boiler noma izinhlelo zokusebenza ezifanayo. Ukuthi iyiphi indinganiso ekhethwayo kuncike ezidingweni ezithile zesicelo, njengezinga lokushisa lokusebenza, isilinganiso sokucindezela, kanye nokumelana nokugqwala okulindelekile.

Kusukela yasungulwa ngo-2014, iBotop Steel isibe ngumhlinzeki ohamba phambili wamapayipi ensimbi yekhabhoni eNyakatho yeShayina, eyaziwa ngenkonzo enhle kakhulu, imikhiqizo esezingeni eliphezulu, kanye nezixazululo eziphelele.

Le nkampani inikeza amapayipi ahlukahlukene ensimbi yekhabhoni kanye nemikhiqizo ehlobene nayo, kufaka phakathi ipayipi lensimbi elingenamthungo, i-ERW, i-LSAW, kanye ne-SSAW, kanye nohlu oluphelele lwezihlanganisi zamapayipi nama-flange. Imikhiqizo yayo ekhethekile ifaka phakathi ama-alloy ebanga eliphezulu kanye nezinsimbi ezingagqwali ze-austenitic, ezenzelwe ukuhlangabezana nezidingo zamaphrojekthi ahlukahlukene amapayipi.